Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Exodraft BP

- Page 1 Heat Recovery | Read and save these instructions! Your energy. Optimized.

-

Page 3: Table Of Contents

Your energy. Optimized. Heat Recovery | Basic Plate Content Product information Scope of supply Accessories and spare parts Warranty Technical specifications Mechanical installation Orientation Placement Drain connection Mounting Mounting points Connection Installation without water connection Electrical installation Placement of Safety Thermostat Operating conditions Primary-/Flue Gas Side Secondary-/Liquid Side... - Page 4 How to use this manual This manual has been prepared based on the specific product and contains relevant technical information and installations guides. Accessories and spare parts are not covered by this manual. Please refer to the individual manuals of these components. This installation manual does not contain any system design documentation.

- Page 5 Symbols The following symbols may be used in the manual to draw attention to danger or risk of personal injury or damage to the product. General prohibition Failure to observe instructions marked with the prohibited symbol may result in extreme danger or serious personal injury. General attention Marks a dangerous situation that, in the worst-case scenario, can cause serious personal injury or significant damage to the product.

- Page 6 • Please always read the manual and only use the product in accordance with the manufacturer’s instructions. If in doubt, contact one of the Exodraft specialized dealers. • All installations must be carried out by properly qualifi ed personnel in accordance with national legislation and regulations.

-

Page 7: Product Information

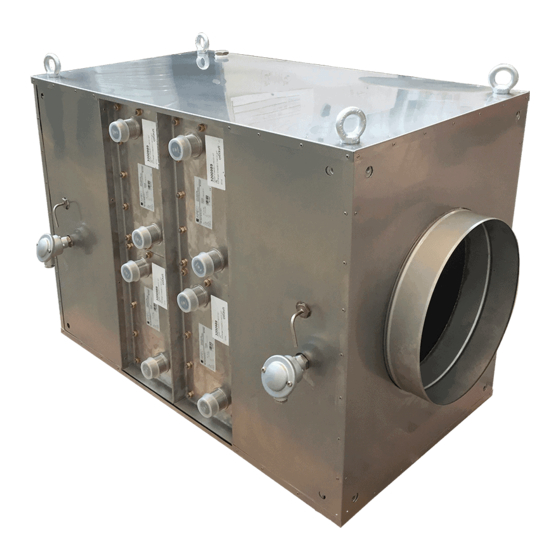

3112025_BP_UK Product information An Exodraft Basic Plate is a compact heat recovery unit for use in Exodraft system solutions. The heat exchanger is a compact module that utilizes the passing heat (air to water). Basic Plate is used primarily in industrial and commercial plants with long operating hours and high exit temperatures (max 600°C) in flue pipes and chimneys. -

Page 8: Accessories And Spare Parts

3200988 Exchanger Cross30-C-120-G1.25 (Copper brazed) 3200989 Exchanger Cross30-C-140-G1.25 (Copper brazed) *This manual does not describe the specific use of spare parts. We refer to the separate manuals for such components. For more details contact your Exodraft dealer. 8 | UK... -

Page 9: Warranty

3112025_BP_UK Warranty All Exodraft products are covered by a 2-year guarantee as per European consumer rights legislation. For some countries an extended period of guarantee may apply depending on either national legislation or other clearly stipulated conditions. Customer complaints must be handled by a specialised dealer or wholesaler (preferably where the Exodraft product has been bought originally). -

Page 10: Technical Specifications

Your energy. Optimized. Technical specifications Basic types Approximate Natural gas Exodraft Type Description connection Nominal flow item number (Basic Plate) power 250°C λ 1.2 Basic housing AIREC exchanger (Plate), Copper brazed 8002300 BP250 Standard pipe connection dimensions 250 kW 600 m3 Max. - Page 11 (there is a total of three mounting points in each corner of Basic Plate, each with M12 thread) Lifting eye Cover Nameplate Danger/Caution sign Optional components PT 1000 temperature transmitter BP Model PT 1000 Type Length BP250 2400278 300 mm BP500 2400278 300 mm...

- Page 12 Your energy. Optimized. Technical data Dimensions [mm] Model BP250/-2 251.20 250.50 BP500/-2 1092 351.20 350.50 BP750/-2 1013 1092 401.20 400.50 BP1000/-2 1013 1092 501.20 500.50 BP2000/-2 1376 1014 1795 701.20 700.50 *Specifies inside sleeve dimensions **Specifies outside adapter dimensions 12 | UK...

- Page 13 3112025_BP_UK Weight Number of Model heat exchangers Incl. heat Excl. heat exchanger [kg] exchanger [kg] BP250 BP250-2 BP500 BP500-2 BP750 BP750-2 BP1000 BP1000-2 BP2000 BP2000-2 UK | 13...

-

Page 14: Mechanical Installation

CAUTION! If the Exodraft Basic Plate heat recovery unit is not installed, maintained, and/or operated in compliance with the manufacturer’s instructions, conditions may arise which could lead to personal injury or material damage. -

Page 15: Placement

3112025_BP_UK Placement Placement of the Basic Plate heat recovery unit must be considered carefully. We recommend placing the Basic Plate as close to the heat source as possible. Furthermore, you must allow for hot surfaces on the Basic Plate. DANGER! Observe national regulations regarding distance from flammable materials. If Basic Plate is placed where it is easily accessible, it must be shielded to avoid inadvertent touch and any risk of collision. -

Page 16: Drain Connection

Your energy. Optimized. Drain connection Placement of drain holes in Basic Plate Model A [mm] B [mm] BP250 66.50 BP500 66.50 BP750 66.50 BP1000 66.50 BP2000 66.50 16 | UK... -

Page 17: Mounting

Mounting points are only intended to support the weight of the product itself. Basic Plate is not built to support the weight of any chimney. DANGER! Max. load on mounting corner 100kg 3 x M12 tread DETAIL A Exodraft item Weight incl. heat Number of heat Weight each heat Type (Basic Plate) -

Page 18: Mounting Points

Your energy. Optimized. Mounting points Basic Plate must be fitted in at least four different corners of the product. In addition, for safety reasons, it must be ensured that the weight of the product is evenly distributed over all four assembly points. The following examples of this and next page show different solutions to approved and unauthorized mounting methods. - Page 19 3112025_BP_UK Unapproved mounting methods UK | 19...

-

Page 20: Connection

Your energy. Optimized. Connection • Connection on heat exchangers is 1 1/4” outside thread • Connection to drain is 1” inside thread • Connection to measuring points is ½” inside thread CAUTION! Basic Plate comes with heat exchangers temporarily mounted for shipping. When installing, the included gaskets, nuts, and washers must be fitted. - Page 21 3112025_BP_UK Water connection for BP250 Water connection for BP250-2 Water connection for BP500 Water connection for BP500-2 Project: Title: Error: No reference Draw. No.: Material: Format: A3 Date: 31-05-2017 Rev. No.: Ref.: Weight: 0,000 kg Error: No reference Rev.: Approved: Sheet: 1 of 2 Error: No refer ence...

- Page 22 Your energy. Optimized. Water connection for BP750/1000 Water connection for BP750/1000-2 Water connection for BP2000 Water connection for BP2000-2 Project: Title: Error: No reference Draw. No.: Material: Format: A3 Date: 31-05-2017 Rev. No.: Ref.: Weight: 0,000 kg Error: No reference Rev.: Approved: Sheet:...

-

Page 23: Installation Without Water Connection

3112025_BP_UK Installation without water connection If Basic Plate is installed without water connection, the exchanger must be pulled out and a cover plate installed (if needed see section about Optional Components). Tightening of the exchanger cover plate is done as shown in the illustration. Nuts are tightened crosswise to 20 Nm. -

Page 24: Electrical Installation Placement Of Safety Thermostat

Your energy. Optimized. Electrical installation Placement of Safety Thermostat CAUTION! If using safety thermostat ST110, it must be placed away from the heat source, so the ambient temperature of the sensor is as low as possible. If this is not complied with, the boiler may be disabled inadvertently. Heat Kedel source... -

Page 25: Operating Conditions

3112025_BP_UK Operating conditions Primary-/Flue Gas Side • Max. flue gas temperature: 600°C • Max. working pressure: 5000 Pa • Min. working pressure: -5000 Pa • Max. temperature on surface of heat exchanger: 190° (calculated in Opticalc) • Flue gas quality: check that the flue gas is not corrosive for exchanger (option of other types of exchangers upon request) •... -

Page 26: Startup And Configuration

Your energy. Optimized. Startup and configuration The purpose of this Exodraft Basic Plate heat recovery unit is to recover surplus energy from flue gasses and process air. The unit is environmentally friendly, economical, and compact. System startup CAUTION! Basic Plate should not be put into operation before being properly installed. -

Page 27: Maintenance And Troubleshooting

Follow directions from the point about Secondary-/Liquid Side as far as restarting the system CAUTION! Use gloves and protective glasses when cleaning the exchanger. Note: The exchangers are heavy – see weight table below. Exodraft Exchanger Number of Weight per... -

Page 28: Troubleshooting

Your energy. Optimized. Troubleshooting Observation Problem Solution There is air in the water system The system needs to be bled The circulation pump is not operating Check the operation of the circulation correctly pump The water flow is too fast Check the operation of the circulation pump and mixing loop The supply water temperature is low... -

Page 29: System Pressure

3112025_BP_UK System pressure System pressure is tested according to these standards: 2014/68/EU Fluid Group: 1 & 2 201, 2006/42/EF and 2014/35/EU System pressure BP250 - 1. step Minimum system pressure [bar Exhaust temperature [°C] Exhaust temperature [°C] Δt Δt Water Water sample sample... - Page 30 Your energy. Optimized. System pressure BP500 - 1. step Minimum system pressure [bar Exhaust temperature [°C] Exhaust temperature [°C] Δt Δt Water Water sample sample 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 temperature temperature 1.50 1.50 1.50 1.50 1.50 1.50...

- Page 31 3112025_BP_UK System pressure BP750 - 1. step Minimum system pressure [bar Exhaust temperature [°C] Exhaust temperature [°C] Δt Δt Water Water sample sample 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 temperature temperature 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50...

- Page 32 Your energy. Optimized. System pressure BP1000 - 1. step Minimum system pressure [bar Exhaust temperature [°C] Exhaust temperature [°C] Δt Δt Water Water sample sample 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 temperature temperature 1.50 1.50 1.50 1.50 1.50 1.50...

- Page 33 3112025_BP_UK System pressure BP2000 - 1. step Minimum system pressure [bar Exhaust temperature [°C] Exhaust temperature [°C] Δt Δt Water Water sample sample 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50 temperature temperature 1.50 1.50 1.50 1.50 1.50 1.50 1.50 1.50...

-

Page 34: Uk Conformity Assessed

UK Conformity Assessed UK Conformity Assessed Exodraft a/s Industrivej 10 DK-5550 Langeskov Hereby declares that the following products: BP250, BP250-2, BP500, BP500-2, BP750, BP750-2, BP1000, BP1000-2, BP2000, BP2000-2 Were manufactured in conformity with the provisions of the following regulations: The Supply of Machinery (Safety) Regulations 2008... -

Page 35: Declaration Of Conformity

EU-Vaatimustenmukaisuusvakuutus Déclaration de conformité de l’Union Européenne ESS-Samræmisstaðfesting EU-Samsvarserklæring Dichiarazione di Conformità Unione Europea EU Deklaracja zgodności Exodraft a/s Industrivej 10 DK-5550 Langeskov Erklærer på eget ansvar, at følgende produkter: Veklaart dat onderstaande producten: Hereby declares that the following products: Deklarerar på... - Page 36 DK: Exodraft a/s Industrivej 10 DK-5550 Langeskov Tel: +45 7010 2234 Fax: +45 7010 2235 info@exodraft.dk www.exodraft.dk SE: Exodraft a/s Kalendevägen 2 SE-302 39 Halmstad Tel: +46 (0)8-5000 1520 info@exodraft.se www.exodraft.se NO: Exodraft a/s Storgaten 88 NO-3060 Svelvik Tel: +47 3329 7062 info@exodraft.no...

Need help?

Do you have a question about the BP and is the answer not in the manual?

Questions and answers