Cleco DGD mPro400GC Quick Setup Manual

Global controller

Hide thumbs

Also See for DGD mPro400GC:

- Programming manual (68 pages) ,

- Hardware description (16 pages) ,

- Installation manual (20 pages)

Summary of Contents for Cleco DGD mPro400GC

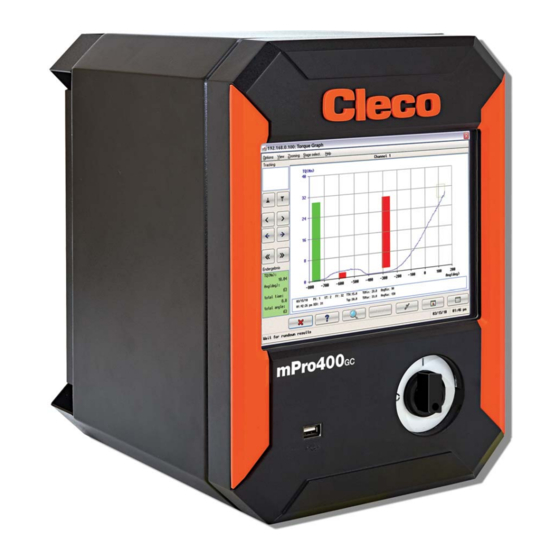

- Page 1 Quick Set-Up Guide PL12EN-1004 2011-01 mPro400GC Global Controller For additional product information visit our website at http://www.apextoolgroup.com...

- Page 2 About this Quick Set-Up Guide This quick set-up guide is the -- original Quick Set-Up Guide -- and is intended for all persons who configure settings on the mPro400GC controller. The quick set-up guide does the following: • describes a quick and facile way to start-up and configure the mPro400GC controller. •...

- Page 3 Workplace safety symbols Warning notes are identified by a signal word and a pictogram: • The signal word describes the severity and the probability of the impending danger. • The pictogram describes the type of danger. Observe these notes and proceed with special care in the situations described. Pass all safety instructions on to other operators.

-

Page 4: Controller Description

Set-Up Guide Set-Up Guide Controller description The mPro400GC product line consists of three controllers; Master, Primary and Secondary. • Primary - Controls up to sixteen (16) tools. This unit includes a servo. One (1) standard corded hand- held or fixtured tool could directly connect. For further corded tools / fixtured spindles are Secondary controllers required. -

Page 5: General Information

Set-Up Guide General Information It is mandatory that national, state and local safety and wiring standards be followed during installation. These standards take precedence over any information presented in this section. CAUTION! To avoid the hazard of electrical shock or burn, the following instructions must be adhered to. Failure to fol- low these instructions may also cause damage to your unit and void existing warranties. -

Page 6: Accepting A Corded Tool

Set-Up Guide Accepting a Corded Tool Fig. 1-2 Run Screen When the controller has finished booting up it should advance to the Run screen. The screen is a touch screen. At the lower right corner of the screen press <Navigator>. Fig. - Page 7 Set-Up Guide Fig. 1-4 Tool Setup – Tool List Touch the horizontal bar indicating the Primary tool to highlight it. Touch <Tool Settings>. Fig. 1-5 Tool Setup Tool Settings Verify that the tool shown is the tool connected. Check the Model number and Serial Number. If the tool is correct press <Accept>.

-

Page 8: Accepting A Livewire Tool

Set-Up Guide Accepting a LiveWire Tool Live wire communication requires three items; Tool, Controller, and Access point. Each item will require an IP address. All the IP addresses will be similar in structure such as 192.168.0.100, 192.168.0.110, 192.168.0.120, etc. The access point will also have a SSID name, which will need to be entered in the con- troller. - Page 9 Set-Up Guide 1.6.2 RF (Radio Frequency) Settings Setting Up the LiveWire Tool Fig. 1-7 Tool Setup – RF Settings Select Navigator Menu > Tool Setup > RF Settings > IRDA Serial. Correct port depending on the port connected to at the base of the controller. (CON 1 and CON 2 are X4 and X5 respectively at the con- troller.) If serial connectivity has been made the SSID, Encryption, and remaining fields will become avail- able for programming.

- Page 10 Set-Up Guide Fig. 1-9 Tool Setup – Install Press <+ Install> and select the LiveWire w/WLAN choice from the popup screen that appears. Enter the Live Wire IP Address for the tool. Without DHCP this should be the same address as entered in Step 2, 1.6.2 RF (Radio Frequency) Settings, page 9.

-

Page 11: Programming A Basic Fastening Strategy

Set-Up Guide Programming a Basic Fastening Strategy Fig. 1-11 Tool Application Fastening Strategy Select Navigator Menu > Basic and the Basic Application Builder screen with appear. Verify that the Tool and Application are correct. Select a Fastening strategy, Torque Control/Angle Monitor or Angle Control/Torque Monitor. -

Page 12: Manual Programming

Set-Up Guide Fig. 1-13 Torque Control/Angle Monitor Select Navigator Menu > Basic > Auto Progr…. Enter the desired final stage torque value using the virtual keypad. Press <Enter> to close the keyboard. Press <OK> from the Auto Program screen. Lim- its of ±15% will be provided. - Page 13 Set-Up Guide Fig. 1-15 Manual Programming Touch the Torque High Limit field and a keyboard will appear. Enter the desired High Torque value. Whole numbers do not require decimal points. They will be added automatically. Use the Tab key on the keyboard to move the keyboard to the next field.

- Page 14 Position Description Position Description System Bus Connector Serial Connector #2 Tool Connector Anybus Fieldbus Power Connection Serial Connector #1 Mounting Bracket Screw 11 USB ports (2) Mounting Bracket Screw 12 Ethernet Connector #2 I/O Connectors Ethernet Connector #1 Anybus Fieldbus Fig.

- Page 15 10.38" (263 mm) 4× 1.315" 4× 7.750" (33.4 mm) (197 mm) 1.825" (46.4 mm) 2× 1.250" (31.8 mm) 2× 12.500" 14.88" (318 mm) (378 mm) 0.075" (1.9 mm) 10×.270“ (6.86 mm) 10×.503“ (12.8 mm) 10×.313“ (1.95 mm) Fig. 1-17 Mounting Information PL12EN-1004 2011-01 en02d441_bedingt.fm, 02.02.2011...

- Page 16 1.9.1 Primary/Master Configuration Note: Pins are numbered exactly as they are on the controller, Pins 1 and 13 at the bottom, Pins 12 and 24 at the top. Pin 24 Pin 12 Pin 13 Pin 1 Fig. 1-18 Primary / Master Pin Configuration Pin # Description Pin #...

- Page 17 Pin 24 Pin 12 Pin 13 Pin 1 Fig. 1-19 Secondary Pin Configuration Pin # Description Pin # Description Common GND2 Common GND Common GND Common GND Output O 03 Output O 07 Output O 02 (Yellow LED) Output O 06 Output O 01 (Green LED –...

- Page 18 Pins 2 and 14 must be connected to Pins 1 and 13 respectively. Connector 1 Connector 2 Pin # Description Pin # Description GND2 GND2 Common GND Common GND Output O 03 Output O 07 Output O 02 Output O 06 Output O 01 Output...

-

Page 20: Sales & Service Centers

Sales & Service Centers Note: All locations may not service all products. Please contact the nearest Sales & Service Center for the appropriate facility to handle your service requirements. Dallas, TX Detroit, MI Houston, TX Lexington, SC Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group...

Need help?

Do you have a question about the DGD mPro400GC and is the answer not in the manual?

Questions and answers