HEROSE 7111 Operating Instructions Manual

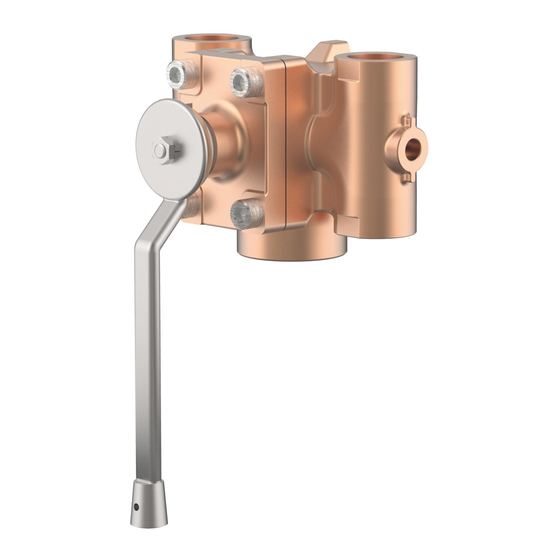

Diverter plug valve

Hide thumbs

Also See for 7111:

- Operating instructions manual (68 pages) ,

- Operating instructions manual (72 pages)

Summary of Contents for HEROSE 7111

- Page 1 HEROSE GMBH ARMATUREN UND METALLE Operating instructions Diverter plug valve Type 7111...

- Page 3 Operating instructions IMPORTANT Read carefully before use. Keep for future reference. © 2020 HEROSE GMBH ARMATUREN UND METALLE Elly-Heuss-Knapp-Straße 12 23843 Bad Oldesloe Germany Phone: +49 4531 509 – 0 Fax: +49 4531 509 – 120 E-mail: info@herose.com Web: www.herose.com...

-

Page 4: Table Of Contents

Operating instructions Table of contents About these instructions.....................1 Safety ..........................1 Transport and storage......................4 Description of the valve......................4 Assembly ..........................7 Operation..........................8 Maintenance and service ....................8 Disassembly and disposal ....................10 Phone +49 4531 509-0... -

Page 5: About These Instructions

People could be seriously injured or killed if the operating instructions are not followed. Read and observ e the operating instructions before using the valve. Retain the operating instructions and make sure they are available. Pass on the operating instructions to subsequent users. herose.com... - Page 6 Operating instructions Instructions for people who work with the valve People could be seriously injured or killed if the v alve is used improperly. In order to av oid accidents, all persons who work on the v alv e must meet the following minimum requirements: ...

- Page 7 Tools f or increasing the torque of the lever are not permitted. Exceeding the maximum permissible operating conditions. Damage to the v alv e! The maximum permissible operating pressure must not be exceeded, and the minimum and maximum allowable operating temperatures must be observed. herose.com...

-

Page 8: Transport And Storage

The v alv es are provided with an indiv idual marking for identification. Symbol Explanation Nominal size Rated working pressure (max. permissible operating pressure) -…..°C+…..°C Temperature, min. / max. Manuf acturer’s mark “HEROSE” 01/16 Date of manuf acture, MM/Y Y 12345 Ty pe 01234567 Serial no. e.g. EN1626... - Page 9 Operational data Nominal Valv e Temperature Max. operating pressure pressure -196 °C to +120 °C 50 bar 7111 PN50 -196 °C to +60 °C 40 bar with O application -196 °C to +120 °C 25 bar with O application Media...

- Page 10 See catalogue page. Lifetime The user is obligated to use Herose products only for their intended purpose. In this case, a technical service life may be assumed in accordance with the underly ing product standards (e.g. EN1626 f or shut-off valves and EN ISO 4126-1 f or safety valves).

-

Page 11: Assembly

Temperature-dependent changes in length in the pipework sy stem must be compensated with expansion joints. Fasten the v alve in the body with the existing threads. The v alv e must be protected against dirt and damage during construction work. Check the leak-tightness. herose.com... -

Page 12: Operation

Operating instructions Tightening torques Number of Tightening torque (Nm) layers of PTFE tape 7111 1.1/4 1.1/2 Screw plug test thread Operation Prior to start-up Check the f ollowing points prior to start-up: All mounting and installation work are completed. - Page 13 Remov e lev er lock Spare parts We require the f ollowing details f or your spare part orders: Article no. of the spare part package, desired deliv ery quantity, dispatch and deliv ery address, desired method of dispatch. herose.com...

-

Page 14: Disassembly And Disposal

Operating instructions Returns / complaints Use the Serv ice f orm in case of returns/complaints. Contact in case of service: Herose.com › Serv ice › Product service › Complaints E-mail: serv ice@herose.com Fax: +49 4531 509 – 9285 Disassembly and disposal Notices regarding the disassembly ...

Need help?

Do you have a question about the 7111 and is the answer not in the manual?

Questions and answers