HEROSE 01312 Operating Instructions Manual

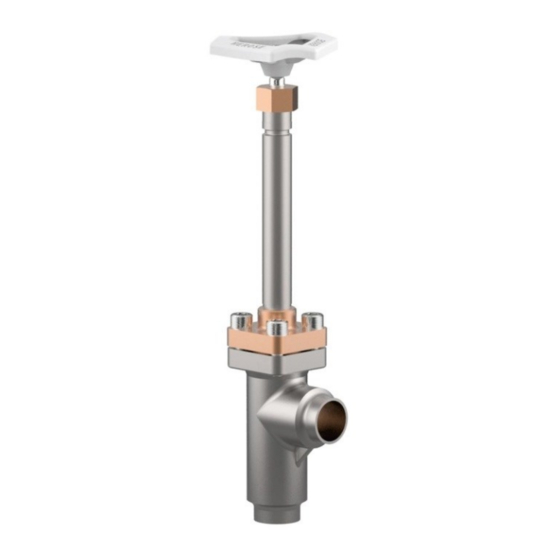

Cryogenic shut-off valves, angled type

Hide thumbs

Also See for 01312:

- Operating instructions manual (92 pages) ,

- Operating instructions manual (18 pages)

Summary of Contents for HEROSE 01312

- Page 1 HEROSE GMBH ARMATUREN UND METALLE Operating instructions Cryogenic shut-off valves angled type...

- Page 3 Operating instructions READ CAREFULLY BEFORE USE! RETAIN FOR FUTURE REFERENCE! © 2018 HEROSE GMBH ARMATUREN UND METALLE Elly-Heuss-Knapp-Straße 12 23843 Bad Oldesloe Germany Phone: +49 4531 509 – 0 Fax: +49 4531 509 – 120 E-mail: info@herose.com Web: www.herose.com 1st issue 09/2018 The transmission or duplication of this document and the use or communication of its content are forbidden unless expressly permitted.

-

Page 4: Table Of Contents

Operating instructions Table of contents About these instructions ....................1 Safety ..........................1 Transport and storage ....................4 Description of the valve ....................4 Assembly ........................7 Operation ........................10 Maintenance and service ..................... 11 Disassembly and disposal ................... 12 Phone +49 4531 509-0... -

Page 5: About These Instructions

People could be seriously injured or killed if the operating instructions are not followed. Read and observe the operating instructions before using the valve. Retain the operating instructions and make sure they are available. Pass on the operating instructions to subsequent users. herose.com... -

Page 6: Safety Instructions

Operating instructions Instructions for people who work with the valve People could be seriously injured or killed if the valve is used improperly. In order to avoid accidents, all persons who work with the valve must meet the following minimum requirements. ... - Page 7 When carrying out electric welding work, do not use functional parts of the valves for earthing. Exceeding the maximum permissible operating temperature. Damage to the valve! Create the welding/soldering stepwise so that the warming in the middle of the body does not exceed the maximum permissible operating temperature. herose.com...

-

Page 8: Transport And Storage

The valves are provided with an individual marking for identification. Symbol Explanation DN….. Nominal size Rated working pressure (max. permissible operating PN….. pressure) -…..°C +…..°C Temperature Manufacturer's mark "HEROSE" 01/18 Date of manufacture MM/YY 12345 Type 01234567 Serial no. EN1626 Standard CE-mark and number of the notified body... -

Page 9: Intended Use

Recommended Max. Rated Valve operating operating operating pressure temperature temperature pressure 01312 PN50 -196 °C to +120 °C 50 bar 01322 PN50 -196 °C to +120 °C 50 bar 01332 PN50 -196 °C to +120 °C -60 °C to +120 °C... -

Page 10: Scope Of Delivery

See catalogue page. Lifetime The user is obligated to use Herose products only for their intended purpose. In this case, a technical service life may be assumed in accordance with the underlying product standards (e.g. EN1626 for shut-off valves and EN ISO 4126-1 for safety valves). -

Page 11: Assembly

Driven valves: Mounting/dismounting the bonnet in the centre position of the actuator. The valve must be protected against dirt and damage during construction work. If available: Remove the blocking bushing after mounting. Check the leak-tightness. herose.com... - Page 12 Operating instructions Welding / soldering Welding / soldering of the valves and any heat treatment that may be required are the responsibility of the contracting construction company or operating company. Before welding / soldering Loosen the bolts Direction of rotation: counter clockwise ...

- Page 13 After welding / soldering Insert a new seal Mount the bonnet Do not damage the seal Mount the bolts Tighten the bolts to the specified tightening torque in a criss-cross pattern Direction of rotation: clockwise herose.com...

-

Page 14: Operation

Operating instructions Assembly sequence for the bolts Nominal Cap bolt bonnet/ bonnet/ bonnet/ size RG-body SS-body body [Nm] [Nm] [Nm] DN 10 Bonnet / body tightening torques DN 15 DN 20 DN 25 DN 32 DN 40 DN 50 ... -

Page 15: Maintenance And Service

of the valve seat Opening and closing of the valve Static pressure test with clean water or another suitable liquid Visual inspection of the plant components for cracks, inadmissible changes in shape or leaks herose.com... -

Page 16: Disassembly And Disposal

Returns / complaints Use the Service form in case of returns/complaints. Contact in case of service: Herose.com › Start › Service › Product service › Complaints E-mail: service@herose.com Fax: +49 4531 509 – 9285 Disassembly and disposal Notes regarding the disassembly ... - Page 17 Operating instructions Disposal Dismount the valves. Collect greases and lubricating fluids during dismantling. Separate the valve materials: Metal Plastic Electronic scrap Greases and lubricating fluids Carry out a sorted disposal of the materials. herose.com...

- Page 18 Operating instructions Phone +49 4531 509-0...

Need help?

Do you have a question about the 01312 and is the answer not in the manual?

Questions and answers