HEROSE 093 Series Operating Instructions Manual

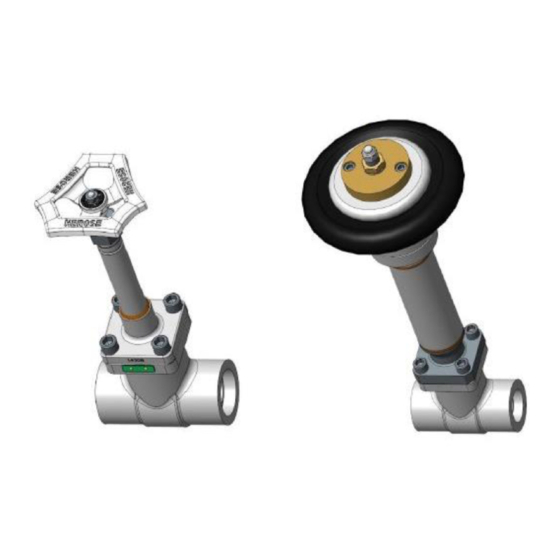

Cryogenic gate valve

Hide thumbs

Also See for 093 Series:

- Operating instructions manual (18 pages) ,

- Operating instructions manual (92 pages)

Subscribe to Our Youtube Channel

Summary of Contents for HEROSE 093 Series

- Page 1 HEROSE GMBH ARMATUREN UND METALLE Operating instructions Cryogenic gate valve 093xx / 094xx...

- Page 3 Operating instructions IMPORTANT Read carefully before use. Retain for later use. © 2020 HEROSE GMBH ARMATUREN UND METALLE Elly-Heuss-Knapp-Straße 12 23843 Bad Oldesloe Germany Phone: +49 4531 509 – 0 +49 4531 509 – 120 Fax: E-mail: info@herose.com Web: www.herose.com...

-

Page 4: Table Of Contents

Operating instructions Table of contents About these instructions ....................1 Safety ..........................1 Transport and storage ....................4 Description of the gate valve ..................4 Assembly ........................7 Operation ........................10 Maintenance and service ..................... 11 Disassembly and disposal ................... 13 Phone +49 4531 509-0... -

Page 5: About These Instructions

People could be seriously injured or killed if the operating instructions are not followed. Read and observe the operating instructions before using the gate valve. Retain the operating instructions and make sure they are available. Pass on the operating instructions to subsequent users. herose.com... - Page 6 Operating instructions Requirements for persons who work with the gate valve Persons could be seriously injured or killed if the gate valve is used improperly. In order to avoid accidents, all persons who work with the gate valve must meet the following minimum requirements. ...

- Page 7 Remove contaminants from the pipes. Incorrect earthing during welding work in the pipeline. Damage to the gate valve (burned spots)! Remove bonnet during welding. When carrying out electric welding work, do not use functional parts of the gate valve for earthing. herose.com...

-

Page 8: Transport And Storage

The gate valve is provided with an individual valving marking for identification. Symbol Explanation DN….. Nominal diameter PN….. Rated working pressure (max. permissible working pressure) -…..°C +…..°C Temperature min. / max. Manufacturer’s mark “HEROSE” 01/18 Year of construction MM/YY 12345 Type 01234567 Serial no. EN1626 Standard... - Page 9 +120 °C 094xx Media Gases, cryogenic liquefied gases and their gas mixtures, such as: Name Argon, Chlorotrifluoromethane, Nitrous oxide, Ethane, Ethylene, Helium, Carbon dioxide, Carbon monoxide, Liquid krypton, deep-cooled, LNG, LPG, Air, Methane, Neon, Oxygen, Nitrogen, Trifluoromethane, Hydrogen, Xenon, herose.com...

- Page 10 See catalogue page. Lifetime The user is obligated to use Herose products for their intended purpose. In this case, a technical service life may be assumed in accordance with the underlying product standards (e.g. EN1626 for shut-off valves and EN ISO 4126-1 for safety valves).

-

Page 11: Assembly

Open the packaging only directly before the mounting. Free of oil and grease for oxygen (O Gate valves for oxygen are permanently marked with “O ”. Take note of the HEROSE information sheet "O instructions". Only install the gate valve if the working pressure and operating conditions of the plant correspond to the valving marking on the gate valve. - Page 12 Operating instructions Welding / soldering Welding / soldering of the gate valves and any heat treatment that may be required are the responsibility of the contracting construction company or operating company. Before welding / soldering Lifting screw, AF 27, loosen to the stop Direction of rotation: counter clockwise...

- Page 13 After welding / soldering Insert a new seal Assemble the bonnet Do not damage the seal Assemble the screws Tighten the screws to the specified tightening torque in a criss-cross pattern Direction of rotation: clockwise herose.com...

-

Page 14: Operation

Operating instructions 4 screws 6 screws Assembly sequence for the screws 8 screws 12 screws Tightening Nominal Cheesehe torque diameter ad screws [Nm] DN 25 DN 40 Bonnet / body tightening torques DN 50 DN 65 DN 80 DN 100 ... -

Page 15: Maintenance And Service

Take note of the specifications in the safety data sheet, the general occupational health and safety rules and the HEROSE information sheet "Use with oxygen" if degreasers are used for process-related reasons for the cleaning of bearing parts, unions and other precision parts. - Page 16 Returns / complaints Use the Service form in case of returns/complaints. Contact in case of service: Herose.com › Service › Product service › Complaints E-mail: service@herose.com Fax: +49 4531 509 – 9285 Phone +49 4531 509-0...

-

Page 17: Disassembly And Disposal

Aerate / flush the pipework system in the case of corrosive and aggressive media. Disposal Dismount the gate valve. Collect greases and lubricating fluids during dismantling. Separate the materials: Metal Synthetic material Electronic scrap Greases and lubricating fluids Carry out a sorted disposal of the materials. herose.com... - Page 18 Operating instructions Phone +49 4531 509-0...

Need help?

Do you have a question about the 093 Series and is the answer not in the manual?

Questions and answers