Summary of Contents for HEROSE 0653X

- Page 1 HEROSE GMBH ARMATUREN UND METALLE Operating instructions Diverter valve 0651X/0652X/0653X...

- Page 3 Operating instructions READ CAREFULLY BEFORE USE! RETAIN FOR FUTURE REFERENCE! © 2019 HEROSE GMBH ARMATUREN UND METALLE Elly-Heuss-Knapp-Straße 12 23843 Bad Oldesloe Germany Phone: +49 4531 509 – 0 Fax: +49 4531 509 – 120 E-mail: info@herose.com Web: www.herose.com 1st issue 04/2019 The transmission or duplication of this document and the use or communication of its content are forbidden unless expressly permitted.

-

Page 4: Table Of Contents

Operating instructions Table of contents About these instructions ....................1 Safety ..........................1 Transport and storage ....................4 Description of the diverter valve..................4 Assembly ........................7 Operation ........................9 Maintenance and service ..................... 10 Disassembly and disposal ................... 12 Phone +49 4531 509-0... -

Page 5: About These Instructions

They understand the operating principles of the diverter valve within the scope of their work and are able to recognise and avoid the hazards of the work. They have understood the operating instructions and are able to implement the information of the operating instructions accordingly. herose.com... - Page 6 Operating instructions Personal protective equipment Missing or unsuitable personal protective equipment increases the risk of damage to health and injuries to people. The following protective equipment is to be provided and worn during work: Protective clothing Safety shoes ...

- Page 7 Injury due to the safety valve being flung away! Depressurise and empty all supply lines before dismounting the safety valve. Make sure that the system is depressurised. Secure against being pressurised again. Do not bend over the safety valve when dismounting. herose.com...

-

Page 8: Transport And Storage

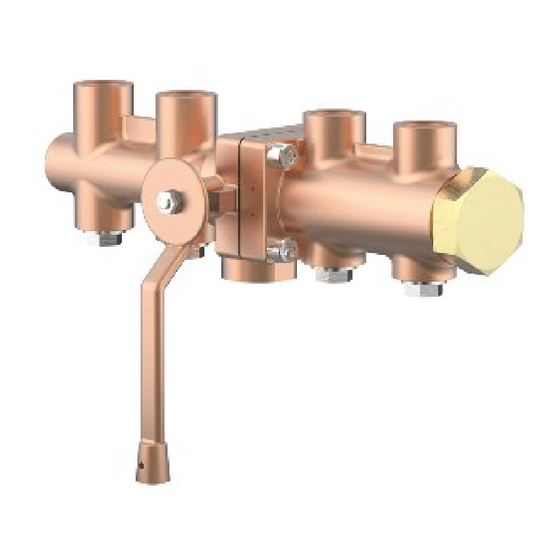

The diverter valves are provided with an individual marking for identification. Symbol Explanation Nominal diameter Nominal pressure (max. permissible operating pressure) -…..°C +…..°C Temperature, min. / max. Manufacturer's mark "HEROSE" 01/16 Date of manufacture, MM/YY 12345 Type 01234567 Serial no. - Page 9 06530 PN50 -196 °C to +120 °C 50 bar 06531 Media Gases, cryogenic liquefied gases and their gas mixtures, such as: Name Argon, Chlorotrifluoromethane Nitrous oxide, Ethane, Ethylene, Carbon dioxide, Carbon monoxide, Krypton, LPG, LNG, Methane, Oxygen, Nitrogen, Trifluoromethane, herose.com...

- Page 10 See catalogue page. Lifetime The user is obligated to use Herose products only for their intended purpose. In this case, a technical service life may be assumed in accordance with the underlying product standards (e.g. EN1626 for shut-off valves and EN ISO 4126-1 for safety valves).

-

Page 11: Assembly

Temperature-dependent changes in length in the pipework system must be compensated with expansion joints. Fasten the diverter valve with the existing threads in the body. The diverter valve must be protected against dirt and damage during construction work. Check the leak-tightness. herose.com... - Page 12 Operating instructions Tightening torques Number of Tightening torques (Nm) layers of PTFE tape 06510 / 06511 / 06512 / 06513 1.1/4 1.1/2 06520/ 06530 06521/ 06531 Plug screw Test thread Phone +49 4531 509-0...

-

Page 13: Operation

Dirt and residues have been removed from the pipeline and diverter valve in order to prevent leaks. Lever position Outlet Outlet Inlet Standard position Lever position left Outlet closed Inlet Lever position right Outlet closed Inlet herose.com... -

Page 14: Maintenance And Service

Operating instructions Maintenance and service Safety during cleaning Take note of the specifications in the safety data sheet and the general occupational health and safety rules if degreasers are used for process-related reasons for the cleaning of bearing parts, fittings and other precision parts. - Page 15 desired method of dispatch. Returns / complaints Use the Service form in case of returns/complaints. Contact in case of service: Herose.com › Service › Product service › Complaints E-mail: service@herose.com Fax: +49 4531 509 – 9285 herose.com...

-

Page 16: Disassembly And Disposal

Operating instructions Disassembly and disposal Notes regarding the disassembly Take note of all national and local safety requirements. The pipework system must be depressurised. The medium and the diverter valve must be at ambient temperature. Aerate / flush the pipework system in the case of corrosive and aggressive media. Disposal Dismount the diverter valve.

Need help?

Do you have a question about the 0653X and is the answer not in the manual?

Questions and answers