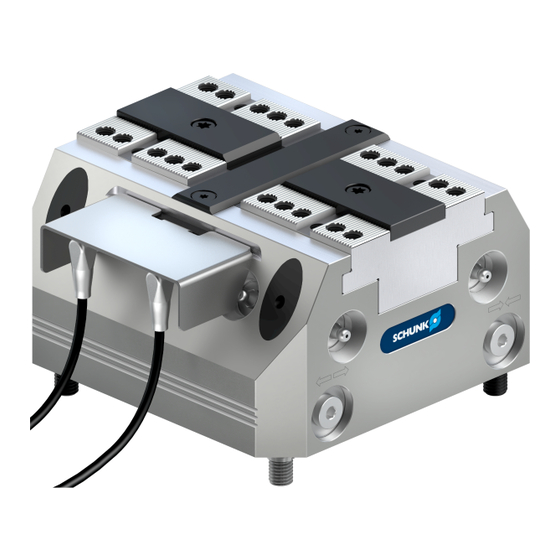

SCHUNK TANDEM KSH3-LH IM Assembly And Operating Manual

Clamping block

Hide thumbs

Also See for TANDEM KSH3-LH IM:

- Assembly and operating manual (49 pages) ,

- Assembly and operating manual (52 pages) ,

- Translation of original operating manual (48 pages)

Summary of Contents for SCHUNK TANDEM KSH3-LH IM

- Page 1 Translation of Original Operating Manual TANDEM Clamping Block KSH3 IM, KSH3-LH IM Assembly and Operating Manual...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1477686 Version: 03.00 | 20/12/2022 | en...

-

Page 3: Table Of Contents

Table of Contents Table of Contents General........................ 5 About this manual.................... 5 1.1.1 Presentation of Warning Labels............... 5 1.1.2 Applicable documents ................ 6 1.1.3 Sizes ...................... 6 1.1.4 Variants.................... 6 Warranty ...................... 6 Scope of delivery.................... 6 Accessories...................... 6 Basic safety notes .................... 7 Intended use ...................... - Page 4 Table of Contents Maintenance and care .................... 32 Notes........................ 32 Maintenance and lubrication intervals .............. 32 Greasing areas/lubricants .................. 32 Maintenance work ..................... 33 7.4.1 Lubrication ..................... 33 7.4.2 Basic cleaning.................. 35 7.4.3 Testing the leakage and tightness of the hydraulic system .... 38 7.4.4 Assembly devices piston seals ...............

-

Page 5: General

General 1 General 1.1 About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

• General terms of business * • Catalog data sheet of the purchased product * The documents labeled with an asterisk (*) can be downloaded from schunk.com. 1.1.3 Sizes This operating manual applies to the following sizes: • KSH3 IM 100, 140, 160, 200 •... -

Page 7: Basic Safety Notes

• Structural changes should only be made with the written approval of SCHUNK. 03.00 | KSH3 IM, KSH3-LH IM | TANDEM Clamping Block | en | 1477686... -

Page 8: Spare Parts

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 2.5 Use of special chuck jaws Requirements of the chuck jaws When using special chuck jaws, please observe the following rules: •... -

Page 9: Personnel Qualification

Basic safety notes 2.7 Personnel qualification Inadequate qualifications of the personnel If the personnel working with the product is not sufficiently qualified, the result may be serious injuries and significant property damage. • All work may only be performed by qualified personnel. •... -

Page 10: Notes On Safe Operation

Basic safety notes 2.9 Notes on safe operation Incorrect handling of the personnel Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. • Avoid any manner of working that may interfere with the function and operational safety of the product. -

Page 11: Disposal

Basic safety notes 2.12 Disposal Handling of disposal The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. • Follow local regulations on dispatching product components for recycling or proper disposal. 2.13 Fundamental dangers General •... -

Page 12: Protection During Commissioning And Operation

Basic safety notes 2.13.2 Protection during commissioning and operation Falling or violently ejected components Falling and violently ejected components can cause serious injuries and even death. • Take appropriate protective measures to secure the danger zone. • Never step into the danger zone during operation. 2.13.3 Protection against dangerous movements Unexpected movements Residual energy in the system may cause serious injuries while... - Page 13 Basic safety notes WARNING Risk of injury from falling parts during transport, assembly and disassembly of the product and its accessories. Use suitable load handling equipment for transport • Do not remain in the danger zone • Wear protective equipment (protective shoes) •...

-

Page 14: Technical Data

Technical data 3 Technical data Installation position Operating temperature +5 °C to +60 °C Noise emission [dB(A)] ≤ 70 Pressure medium Hydraulic oil Requirement for the pressure filtered (10 μm), viscosity 46 mm/s at 40 °C in line medium with ISO VG Volumetric flow max. - Page 15 Technical data KSH3 IM / KSH3-LH IM KSH3-LH IM Dimension Ø C 6H7 x 12 8H7 x 14 8H7 x 14 8H7 x 14 10H7 x 20 10H7 x 20 200 x 180 29.5 25 (2x) 64.5 45 (off- center) 40.0 64.5 34.5...

- Page 16 Technical data Optional Z variant ±0.01 mm to clamping center Clamping sleeve ±0.04 mm to clamping center Clamping sleeve fitting screw ±0.02 mm to clamping center 03.00 | KSH3 IM, KSH3-LH IM | TANDEM Clamping Block | en | 1477686...

-

Page 17: Tightening Torques For Screws

Tightening torques for screws 4 Tightening torques for screws Tightening torques for mounting the clamping system on the machine table (screw quality 10.9) Screw size M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 Tightening torque 120 160 200 290 400 500 (Nm) Tightening torques for mounting top jaws on the TANDEM clamping force block (screw quality 12.9) -

Page 18: Assembly And Connection

Assembly and connection 5 Assembly and connection The numbers shown for individual components refer to the illustrations for assembly or connections of the clamping force } 9 [ / 45] block and to the "Drawings" chapter. WARNING Danger of crushing due to the product approaching the machine table during assembly. - Page 19 Assembly and connection NOTE • For vertical installation, the openings of the coolant drain (V) must always face downwards • Surface >>X<< is parallel to the guideway of the base jaws (item 2) in order to be able to align the clamping force block on the machine table or check the positioning.

-

Page 20: Connecting The Clamping Block

Assembly and connection 5.2 Connecting the clamping block OPEN (front) CLOSED (front) OPEN (bottom) CLOSED (bottom) Coolant drainage/connection for air purge (front) No use No use No use No use Bottom connection for coolant drain or use for air purge Bottom connection for lubrication (one-sided supply, left) Bottom connection for lubrication (one-sided supply, right) No use... -

Page 21: Supply Lines

Assembly and connection 5.2.1 Supply lines The clamping force block has four hydraulic connections: I, II, III, Two connections for OPEN (I and III) and two connections for CLOSE (II and IV). Which of the two hydraulic connections has to be opened for actuation depends on the specific application: •... -

Page 22: Hydraulic Circuit Diagram

Assembly and connection 5.2.2 Hydraulic circuit diagram Electronic symbol 4/2 directional control valve Pressure regulator Flow control valve Hydraulic supply 03.00 | KSH3 IM, KSH3-LH IM | TANDEM Clamping Block | en | 1477686... -

Page 23: Monitoring Of The Jaw Position Via Inductive Proximity Switches

The monitoring result is: The clamping force block is open or closed (for I.D. or O.D. clamping depending on the application). • Information on handling sensors is available at schunk.com or from SCHUNK contact persons. • Technical data for the sensors can be found in the data sheets (included in the scope of delivery or at schunk.com). -

Page 24: Construction Concept And Dimensions Of Inductive Proximity Switches With Screw-On Connection Cable

Assembly and connection 5.3.1 Construction concept and dimensions of inductive proximity switches with screw-on connection cable Pin 1: Brown Pin 2: Blue Pin 3: Black IN-S-M8-1 IN-S-M8-2 IN-S-M8-3 Size M8 x 1 x 40 mm M5 x 0.5 x 41mm M8 x 1 x 55m Switching function Closer... -

Page 25: Assembly And Adjustment Of The Proximity Switches

Assembly and connection 5.3.2 Assembly and adjustment of the proximity switches For TANDEM KSP3-IM/KSP3-LH-IM, two inductive proximity switches have been fitted. The proximity switches can be moved on the retaining plate (item 12) so that the switching point can be individually adjusted. - Page 26 Assembly and connection Test the function by clamping and opening the clamping system. If necessary, adjust the switching position. Then link the plug connection between the proximity switch and connection cable. NOTE The sensor head of the proximity switches may not touch the base jaws under any circumstances during operation.

-

Page 27: Circuit And Functional Diagram For External Workpiece Clamping

Assembly and connection 5.3.3 Circuit and functional diagram for external workpiece clamping Circuit diagram and monitoring/control functions for external workpiece clamping The circuit diagram and the functional diagram show the recommended settings of the proximity switches for monitoring "End position open" and "Clamping position reached." The circuit diagram can also be adjusted for monitoring "Stroke end position closed"... - Page 28 Assembly and connection Functional diagram for O.D clamping »S1« Monitoring the jaw »S2« Monitoring troke end position for of the clamping O.D. and I.D. clamping position Stroke end position open Edges in front and behind depression serve as position transducers Raised intermediate rail as position transducer Jaw end position »Open«...

-

Page 29: Circuit And Functional Diagram For Internal Workpiece Clamping

Assembly and connection 5.3.4 Circuit and functional diagram for internal workpiece clamping Circuit diagram and monitoring/control functions for internal workpiece clamping The circuit diagram and the functional diagram show the recommended settings of the proximity switches for monitoring "End position closed" and "Clamping position reached." The circuit diagram can also be adjusted for monitoring "Stroke end position open"... - Page 30 Assembly and connection Functional diagram for I.D clamping Stroke end position closed Jaw end position »Open« S1 and S2 adjusted just in front of the signal output »S1« assigned signal »S1« assigned signal output »1« LED lit output »1« LED lit Clamping position Clamping position S2 adjusted just above the switching point »S1«...

-

Page 31: Troubleshooting

Troubleshooting 6 Troubleshooting Clamping force block chuck jaws will not move Possible cause Solution(s) Oil supply interrupted Check the hydraulic supply System pressure too low Increase system pressure according to clamping system technical specifications Connections mixed up Check connections and functions and connect properly Hydraulic connections that are in use Check connections and open... -

Page 32: Maintenance And Care

Replacement of the housing and base jaws The base jaws and the guides in the housing are matched to each other. To replace these parts, send the entire product to SCHUNK with a repair order. 7.2 Maintenance and lubrication intervals... -

Page 33: Maintenance Work

Maintenance and care 7.4 Maintenance work 7.4.1 Lubrication CAUTION Allergic reactions or irritation due to skin or eye contact with lubricants on the product. Wear protective equipment (protective gloves, protective • goggles) in case of foreseeable contact with lubricants on the product (e.g. - Page 34 Maintenance and care Central lubrication • To use central lubrication, the set-screws of the factory sealed connections (6, 7) must be removed. • For proper lubrication, both supply lines must be connected. • The central lubrication system must be suitable for greases of NLGI 2 classification. •...

-

Page 35: Basic Cleaning

Maintenance and care 7.4.2 Basic cleaning For basic cleaning, the product must be disassembled, cleaned and reassembled. Disassembly Before disassembling the product, switch off the machine and secure it against being switched on again. Then remove all compressed air lines. No residual energy may be left in the product. •... - Page 36 Maintenance and care • Remove screws (item 64) and take off the cover strip (item 8) • Remove screws (item 66) and take off the guide strip (item 6) Remove screws (item 65) and pull out cover (item 5) together with O-ring (item 45) and flat gaskets (item 48) out of the housing.

- Page 37 Maintenance and care • Unscrew the screw (item 69) by holding it against the cylinder piston (item 4) • Pull the chuck piston (item 3) out of the housing via its extraction thread • Push the cylinder piston together with the quad ring (item 40) out of the housing.

-

Page 38: Testing The Leakage And Tightness Of The Hydraulic System

Maintenance and care 7.4.3 Testing the leakage and tightness of the hydraulic system The following is needed to check for leaks: hydraulic unit or manually actuated hydraulic pump, pressure gauge, shut-off valve and quick couplers. • Check for tightness in the clamping system in the OPEN and CLOSED positions Connect the components for the leakage and tightness test on the clamping system in the following order:... -

Page 39: Assembly Devices Piston Seals

To assemble the seal (item 40), a multi-part assembly tool is required. If no assembly tool is available, repair work on the TANDEM clamping force block should be carried out by SCHUNK. 1. Assembly • Disassemble the two-part seal (item 40) and grease with Renolit HLT 2 or an equivalent grease. - Page 40 Maintenance and care A cone sleeve Material: steel +0.15 +0.3 KSH3 Piston Ø 36.5 51.5 59.5 76.5 250/315 106.5 105 B expansion sleeve Material: POM, Nylon® or similar KSH3 Piston Ø 34.64 30.64 26.64 17 120° 48.94 44.94 40.94 25 4 x 90°...

-

Page 41: Sealing Kits, Accessory Packs And Parts Lists

Sealing kits, accessory packs and parts lists 8 Sealing kits, accessory packs and parts lists When ordering spare parts, the type, size and, if possible, the serial number of the clamping force block must always be stated to avoid delivery mistakes. Seals, sealing elements, fittings, springs, bearings, screws, wiper bars and parts that come into contact with the workpiece are not covered by the warranty. -

Page 42: Parts Lists

Sealing kits, accessory packs and parts lists 8.3 Parts lists Item Description Quantit Body >Housing< ● Base jaw ● Chuck piston ● Cylinder piston ● Cover ● Guide strip ● Covering strip ● Retaining plate ● Counter-support ● Cover ● Cupped-type lubrication ●... - Page 43 Sealing kits, accessory packs and parts lists Item Description Quantit Cylindrical screw ● Washer ● Cylindrical screw ● ● Plug ● ● Fitting screw ● ● O-ring DIN ISO 3601 ● ● ● Screw ● ● Clamping sleeve ● ● Screw ●...

-

Page 44: Proximity Switches And Supply Cables For Single Or Replacement Orders

Sealing kits, accessory packs and parts lists 8.4 Proximity switches and supply cables for single or replacement orders The IN inductive proximity switch consists of an angular supply cable type KA-M12 and self-customizable plug connector. Inductive proximity switch IN – M8 plug connection Designation ID number IN S-M8-1... -

Page 45: Assembly Drawing

Assembly drawing 9 Assembly drawing Centering with fitting screw Centering with clamping sleeves Centering with cylindrical pins (Z variant) 03.00 | KSH3 IM, KSH3-LH IM | TANDEM Clamping Block | en | 1477686... -

Page 46: Translation Of The Original Declaration Of Incorporation

Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Distributor Lothringer Str. 23 D-88512 Mengen We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the directive 2006/42/EC of the European Parliament and of the Council on machinery. -

Page 47: Appendix On Declaration Of Incorporation, As Per 2006/42/Ec, Annex Ii, No. 1 B

Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 11 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B 1. Description of the basic safety and health protection requirements, as per 2006/42/EC, annex I, that apply to and are fulfilled for the scope of the incomplete machine: Product designation TANDEM clamping force block, pneumatic (with inductive proximity switches) - Page 48 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Protection against mechanical hazards 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 1.3.7 Risks related to moving parts 1.3.8 Choice of protection against risks arising from moving parts 1.3.8.1 Moving transmission parts 1.3.8.2 Moving parts involved in the process 1.3.9...

- Page 49 Appendix on Declaration of Incorporation, as per 2006/42/EC, annex II, No. 1 B Information 1.7.1 Information and warnings on the machinery 1.7.1.1 Information and information devices 1.7.1.2 Warning devices 1.7.2 Warning of residual risks 1.7.3 Marking of machinery 1.7.4 Instructions 1.7.4.1 General principles for the drafting of instructions 1.7.4.2 Contents of the instructions 1.7.4.3 Sales literature...

- Page 52 Translation of Original Operating Manual H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49–7572-7614-0 Fax +49-7572-7614-1099 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the TANDEM KSH3-LH IM and is the answer not in the manual?

Questions and answers