Table of Contents

Summary of Contents for TLV LEX3N-TZ

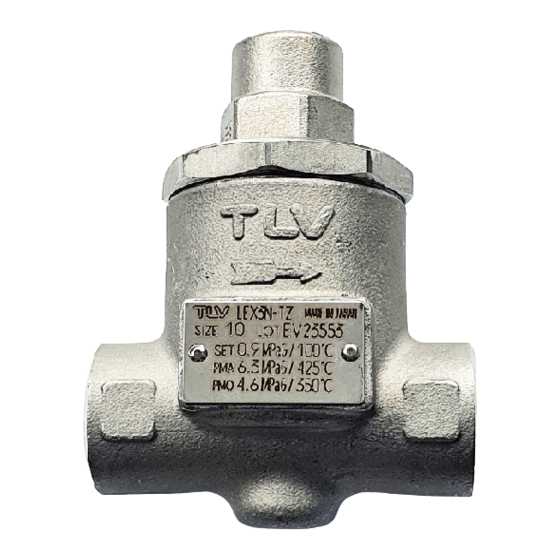

- Page 1 172-65381M-03 (LEX3N-TZ) 22 April 2009 ISO 9001/ ISO 14001 Manufacturer Kakogawa, Japan is approved by LRQA LTD. to ISO 9001/14001 Temperature Control Trap (with Bimetal Element) LEX3N-TZ Copyright © 2009 by TLV CO., LTD. All rights reserved...

-

Page 2: Table Of Contents

This instruction manual is intended for use with the model(s) listed on the front cover. It is needed not only for installation, but for subsequent maintenance, disassembly/reassembly and troubleshooting. Please keep it in a safe place for future reference. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... -

Page 3: Safety Considerations

The three types of cautionary items above are very important for safety: be sure to observe all of them as they relate to installation, use, maintenance and repair. Furthermore, TLV accepts no responsibility for any accidents or damage occurring as a result of failure to observe these precautions. - Page 4 Use only under conditions in which no water hammer will occur. The impact of water hammer may damage the product, leading to fluid discharge, which may cause burns or other injury. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

-

Page 5: Checking The Piping

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS. ** Valve No. is displayed for products with options. This item is omitted from the nameplate when there are no options. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... -

Page 6: Configuration

Overexpansion Spring Thrust Plate √ √ √ Return Spring Cap Nut Gasket √ Snap Ring Flange (Flanged type only) Replacement parts are available only in the following kits: M = Maintenance Kit; R = Repair Kit 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... -

Page 7: Installation

(Upside-down installation is not permissible.) 5. Open the inlet valve gradually and check to make sure that the product functions properly. If there is a problem, determine the cause using the “Troubleshooting” section in this manual. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... -

Page 8: Adjusting The Set Temperature

The trap set temperature will be approximately 10 to 20 °C higher than the surface reading. If the resultant temperature is not as required, repeat procedure from step “2” above. 15. Fully open the outlet isolation valve slowly. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... - Page 9 100 °C at 0.9 MPaG. Change from this to the desired setting, as indicated in the Adjustment Chart. Operating Pressure (MPaG) 2.1 MPaG Specification 4.6 MPaG Specification Temperature Setting Range (°C) Operating Pressure (MPaG) 2.1 MPaG Specification 4.6 MPaG Specification 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

- Page 10 2.1 MPaG Specification 4.6 MPaG Specification Operating Pressure (MPaG) For this example, the number of turns is -1½. Because this is a negative number, turn the adjusting screw clockwise (tighten) one and a half turns. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

-

Page 11: Cleaning Function

15. Slowly open the inlet isolation valve carefully checking for any steam leaks that might occur. In the event steam leaks are detected, immediately close the inlet isolation valve, then the outlet isolation valve, and repair the source of leakage. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... - Page 12 10 to 20°C higher than the temperature reading on the trap body surface. 28. If the resultant temperature is no as desired, use the above instructions for adjusting temperature settings. (See “Adjusting the Set Temperature”) 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

-

Page 13: Maintenance

(When conducting a visual inspection, flash steam is sometimes mistaken for steam leakage. For this reason, the use of a steam trap diagnostic instrument [such as TLV TrapMan if appropriate] in conjunction with the visual inspection is highly recommended.) -

Page 14: Disassembly / Reassembly

Element attention to the proper orientation (2 discs) 5 sets (the TLV marks on the outside) Washer Remove the washer from the valve Place 1 washer between each stem by lifting up and off pair of bimetal disks... - Page 15 1 N⋅m ≈ 10 kg⋅cm NOTE: - Coat all threaded portions with anti-seize. - If drawings or other special documentation were supplied for the product, any torque given there takes precedence over values shown here. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

- Page 16 Cap Nut Gasket TLV Mark Locknut Washer Bimetal Element Cover Unit Thrust Plate Cover Gasket Return Spring Washer Snap Ring Valve Unit Spring Guide Overexpansion Spring Body Unit Screen Valve Seat Valve Seat Gasket Body Nameplate 172-65381M-03 (LEX3N-TZ) 22 Apr 2009...

-

Page 17: Troubleshooting

NOTE: When replacing parts with new, use the parts list for reference, and replace with parts from the Maintenance Kit, Repair Kit, etc. Please note that replacement parts are only available as part of a replacement parts kit. 172-65381M-03 (LEX3N-TZ) 22 Apr 2009... -

Page 18: Product Warranty

One year following product delivery. 2. Warranty Coverage TLV CO., LTD. warrants this product to the original purchaser to be free from defective materials and workmanship. Under this warranty, the product will be repaired or replaced at our option, without charge for parts or labor.

Need help?

Do you have a question about the LEX3N-TZ and is the answer not in the manual?

Questions and answers