Summary of Contents for ROBOTIQ ETF-CB-UR-KIT

- Page 1 Original Notice © 2019 Robotiq Inc. Robotiq External Tool Finishing Kit on Universal Robots robot iq.com | leanrobot ics.org Instruction Manual...

-

Page 2: Table Of Contents

3.4.1. Installing the fingers/ fingertips/holders on the Hand-E Gripper 3.4.2. Installing the Hand-E Gripper onto e-Series robots 3.4.3. Installing the FT Sensor and the Hand-E onto CB-Series robots Step 1: Installation of the Robotiq Force Torque Sensor Power Supply Specifications Wiring... - Page 3 4.1. Hand-E Gripper control with Universal Robots 4.1.1. Gripper Dashboard Overview on e-Series robots Overview on CB-Series robots Features 4.1.2. Gripper Calibration menu and wizard 4.1.3. Gripper Toolbar Overview On e-Series robots On CB-Series robots On e-Series and CB-Series robots Features Gripper operation window 4.1.4.

- Page 4 4.2.5. Multipoint path node How to set up a Multipoint Path Step 1 Step 2 4.2.6. Path Generator 4.2.7. ActiveDrive Toolbar Overview Toolbar collapsed Toolbar expanded Features Error Messages Overview 4.2.8. Insertion nodes Child nodes Features (Spiral) Features (Rotational) Features (Linear) 4.2.9.

- Page 5 5.1.1. Fingers and fingertips Rack Flat Rubber (NBR) Overmolded Fingers Fingertip holders Flat aluminum finger Grooved fingertips 5.2. Mechanical specificationsof the External Tool Finishing Kit 5.2.1. Specifications of the FT Sensor on CB-Series robots 5.2.2. Specifications of the Hand-E Gripper Payload and force Maximum payload/External force vs.

-

Page 6: Revisions

This manual and the product it describes are protected by the Copyright Act of Canada, by laws of other countries, and by international treaties, and therefore may not be reproduced in whole or in part, whether for sale or not, without prior written consent from Robotiq. -

Page 7: General Presentation

1 . General Presentation The Robotiq External Tool Finishing Kit, is an application Kit that allows you to automate finishing tasks with the combination of a Robotiq Hand-E Gripper and a Finishing Copilot software. The Robotiq Finishing Copilot enables you to program an external TCP and let the robot knows that the finishing tool is external to the robot. - Page 8 When ordered as a kit, a fingertip starting kit is included. Please refer to the Spare Parts, Kits and Accessories section of the Hand-E Instruction Manuel available at robotiq.com/support. These fingertips should be mounted onto fingertip holders. Fig. 1-3: Mounting a fingertip on a fingertip holder...

-

Page 9: Object Picking

1 .1 .2. Object picking The Hand-E Gripper has a single actuator for opening and closing the fingers. It also allows internal gripping: fingers can pick hollow parts from inside by applying pressure with the outer surface of the fingers. See the figure below for a representation and refer to the Picking Features section for details on available position commands for your gripper. -

Page 10: Robotiq Finishing Copilot Software On E-Seriesrobots

1 .2. Robotiq Finishing Copilot software on e-Series robots The Robotiq Finishing Copilot is a software package designed for using the force and torque values read by a force torque sensor embedded in the e-Series robot wrist. The software interface provides force and torque feedback that can be used for robotic applications suh as hand guiding, force control processes, assembly tasks, product testing, and much more on e-Series robot. - Page 11 Details on the bolt pattern and indexing pin for the tool side and the robot side can be found in the Specifications section of the Force Torque Sensor Instruction Manual available on support.robotiq.com. The screw positioning for the coupling and the robot mountings are shown in orange. See the Spare Parts section of the FT Sensor Instruction Manual for a list of available Couplings.

- Page 12 Fig. 1-8: FT 300 Force Torque Sensor options. The figure above represents various options available. They can be found in the Spare Parts, Kits and Accessories section of the FT Sensor Instruction Manual. Couplings are meant to install the FT 300 Force Torque Sensor on various robot models, see available models. Sensor Cable is used for power and communications with the FT 300 Force Torque Sensor and is available in different lengths.

-

Page 13: Safety

2. Safety Info The term " operator" refers to anyone responsible for any of the following operations on the Robotiq Hand-E Gripper: installation, control, maintenance, inspection, calibration, programming or decommissioning. Caution The operator must have read and understood all of the instructions in the Hand-E Instruction manual before handling the Robotiq Gripper. -

Page 14: Risk Assessment And Final Application

2.1 .1 . Risk assessment and final application The Robotiq Hand-E Gripper is meant to be used on industrial and collaborative robots. The robot, the Gripper and any other equipment used in the final application must be evaluated via a thorough risk assessment. It is the robot integrator's duty to ensure that all local safety measures and regulations are met. -

Page 15: Installation

3. Installation The following subsections will guide you through the installation and general setup of your Robotiq External Tool Finishing Kit. Warning Before installing: Read and understand the safety instructions related to the Hand-E Gripper. Verify your package according to the scope of delivery and your order. -

Page 16: Required Toolsand Equipment

3.2. Required Tools and Equipment The following tools are required to install the Hand-E Gripper: 4 mm hex key to mount the Gripper onto its coupling . 3 mm hex key to install the wrist connection protector (for the e-Series Hand-E Gripper only) 2.5 mm hex key 3.3. -

Page 17: Ft Sensor For Cb-Series Robots

FT Sensor for CB-Series robots The FT Sensor is designed for industrial applications. Always respect the following specified storage, transport and operating environmental conditions: Conditions Values Minimum storage / transit temperature -30°C Maximum storage / transit temperature 70°C Minimum operating temperature 5°C Maximum operating temperature 40°C... - Page 18 Fig. 3-1: Mounting fingers on racks Fig. 3-2: Mounting fingertips on holders and then on racks...

-

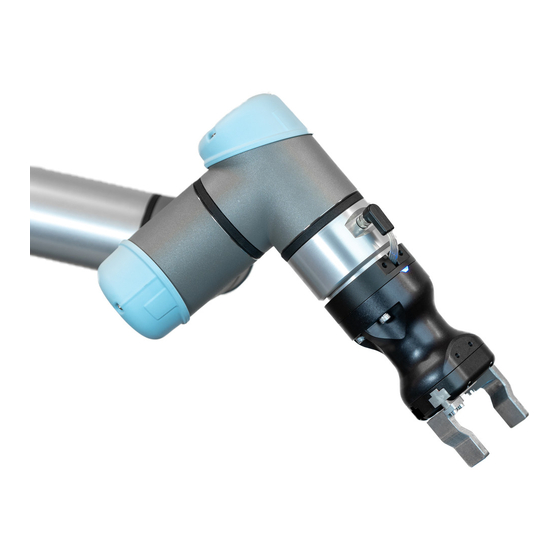

Page 19: Installing The Hand-Egripper Onto E-Series Robots

3.4.2. Installing the Hand-EGripper onto e-Series robots The use of a coupling to attach the Hand-E Gripper to the robot is necessary. Please consult the Spare Parts, Kits and Accessories section in the Hand-E Instruction Manual to consult the list of couplings available. Here are the steps to mount the Hand-E on the robot (exploded view in the figure below). -

Page 20: Installing The Ft Sensor And The Hand-Eonto Cb-Series Robots

Info The FT 300 coupling is mandatory, you can customize yours from a blank provided by Robotiq. Here are the steps to follow for the installation of the Sensor (see figure below). Note that all screws must be locked in place using medium strength threadlocker, such as Loctite 248 or a similar product. -

Page 21: Power Supply Specifications

Maximum output voltage tolerance is 10%, exceeding this limit, 26.4 V DC could damage the Sensor. Info Robotiq recommends the use of the following power supply: TDK-Lambda DPP Series, 15W Single Output DIN Rail Mount Power Supply, DPP15-24 External Tool Finishing Kit - Instruction Manual... -

Page 22: Wiring

Always protect the controller side of the cable connection with a strain relief cable clamp. Fig. 3-5: Pinout of the Robotiq Force Torque Sensor FT 300 and color code for the respective cable type. Info Power pins 2 &... -

Page 23: Step 2: Installation Of The Hand-E Gripper Onto The Ft Sensor

Use a coupling to attach the Gripper to the CB-Series robot. Be sure to use the appropriate coupling for your robot model. If there is no coupling for your robot, you can process a blank coupling or Robotiq can create a custom version for you. Some couplings may require an additional adapter plate. -

Page 24: Installation Of The External Tool Finishing Kit Urcap Package For E-Series

3.4.4. Installation of the External Tool Finishing Kit URCap Package for e-Series Robotiq provides you with a Universal Robots URCap package that enables direct serial communication to your UR controller. The External Tool Finishing Kit URCap installation, consists in the installation of the Hand-E Gripper and Finishing Copilot software URCap Packages. - Page 25 The URCap for the Gripper; The Gripper toolbar; The Gripper node The GripCheck Gripper Activate For details on controlling the Gripper, please refer to the Control section in the Robotiq Hand-E Instruction manual available on www.support.robotiq.com. External Tool Finishing Kit - Instruction Manual...

- Page 26 For e-Series robots: Hand-E + Finishing Copilot URCaps For CB-Series robots: Hand-E + FT Sensor URCaps Make sure that your PolyScope version is up-to-date. Go to www.support.robotiq.com, select Browse by product, click on the External Tool Finishing Kit product page and then Universal Robots Click on Software →...

-

Page 27: Uninstalling Urcap Package

Tap the Restart button to complete the URCap install- ation.By doing so, you accept the license agreement detailed in the URCap information textbox. 3.4.5. Uninstalling URCap Package If you wish to uninstall the Hand-E, the Finishing Copilot or the FT Sensor URCaps, please follow this procedure: On the teach pendant, tap the triple bar icon. - Page 28 Select System in the navigation pane on the left. Select URCaps. In the Active URCaps box, select the URCap to uninstall. Tap the minus (-) button to uninstall the URCap. Restart PolyScope to complete the uninstallation pro- cess.

-

Page 29: Software

4. Software The following subsections provide instructions for the use of the Finishing Copilot software package. 4.1 . Hand-EGripper control with Universal Robots The URCap package contains many features to program and control the Gripper. The package provides: Gripper toolbar: The Gripper toolbar is automatically installed with the URCaps package. It allows jogging and testing of the Gripper. It is a great tool to try grasps with the Gripper while programming. -

Page 30: Gripper Dashboard

Tap the Gripper button. Select the Dashboard tab. If the Gripper is connected to the robot wrist (and not to the robot controller or via a Robotiq Wrist Camera) tick the " Gripper cable is connected to the wrist box. -

Page 31: Overview On Cb-Series Robots

Overview on CB-Series robots Open or create a robot program Go the Installation tab Select Gripper in the left pane Tap the Dashboard button In no Gripper is found, tap the Scan button to detect any Gripper that might be connected to the robot Tap the Activate button Fig. -

Page 32: Features

Info The E-Open and E-Close buttons allow the user to open and close the Gripper even if the latter is not activated. These emergency commands use very low speed and force settings. Features Icon Functionality Name Description After selecting Gripper in the left pane of the Installation tab, tap this button to access the Gripper Dashboard Dashboard. -

Page 33: Gripper Calibration Menu And Wizard

Icon Functionality Name Description E-Open Tapping this button sends an emergency open command to the corresponding Gripper, whether it is activated or not. E-Close Tapping this button sends an emergency close command to the corresponding Gripper, whether it is activated or not. 4.1 .2. - Page 34 Tapping the Calibrate button in the Gripper Calibration menu launches the Calibration wizard. Follow the instructions on the screen of the teach pendant. Depending on the PolyScope settings defined by the user, the units of measurement can either display according to the metric or imperial system.

- Page 35 Fig. 4-6: Second step of the calibration wizard Icon Functionality Name Description Calibration After selecting the Gripper in the left pane of the Installation tab, tap this button to access the Gripper Calibration menu. Calibrate/Recalibrate The Calibrate and Recalibrate buttons launch the Gripper Calibration wizard.

- Page 36 Icon Functionality Name Description Fully closed dimension table header Visual aid above the fully closed dimensions in the Calibration menu. Fully open dimension table header Visual aid above the fully open dimensions in the Calibration menu Close Tap this button to close the Gripper in the Calibration wizard.

-

Page 37: Gripper Toolbar

4.1 .3. Gripper Toolbar The Gripper Toolbar is generally used to test and jog the Gripper, meaning it has no effect on the programming of the robot. Overview Prior to using the Gripper Toolbar, the user needs to go to the Gripper Dashboard and tick the Show Gripper Toolbar. Please refer to the Gripper Dashboard Software section On e-Series robots Following the proper installation of the Gripper URCap, the user can tap the UR+ button at the top of the screen to expand the Gripper... -

Page 38: Features

Info The Emergency open and Emergency close buttons allow the user to open and close the Gripper even if the latter is not activated. The emergency commands use very low speed and force settings. Tap the Activate button to enable the Gripper Caution If the Gripper has not been calibrated at this point, the Open and Close values will remain in percentage. - Page 39 Icon Functionality Name Description UR+ Menu Tap to toggle between the expanded (blue) and collapsed (black) Gripper Toolbar. (Gripper Toolbar on e-Series robots) Activate Tap to activate the Gripper. The Gripper will fully open and close to set the zero of the position value. Emergency open Slowly moves the Gripper to its fully closed position.

-

Page 40: Gripper Operation Window

Gripper operation window Primary Icon Functionality Name Description Tap to toggle between expanded and collapsed Gripper toolbar. Gripper toolbar When greyed out, the functionality is not available. (On CB-Series robots) UR+ Menu Tap to toggle between the expanded (blue) and collapsed (black) Gripper Toolbar. -

Page 41: Gripper Node

Primary Icon Functionality Name Description Plus Tap to increase the corresponding parameter. Minus Tap to decrease the corresponding parameter. No object detected Icon shown when no object is detected during a grasp. Object detected The icon shows a green checkmark when an object is detected during a grasp. -

Page 42: Command Window

Info The Gripper needs to be activated before it can receive a command. To do so, use the rq_activate_and_wait() function script at the beginning of the program or activate with the Gripper toolbar. Starting from Gripper URCap version 1.0.2, the Gripper activation script command (rq_activate() or rq_activate_and_wait()) must be preceded by the reset command (rq_reset()). -

Page 43: Features

When the Gripper action is set to close, a green " Close" icon appears. When the Gripper action is set to open, a green " Open" icon appears. Features Icon Functionality Description Name Requested Shows the position requested for the current Gripper node. Read only. position Requested Shows the speed requested for the selected Gripper node. - Page 44 Icon Functionality Description Name Do not complete Selected by default. motion Unselected: As soon as the Gripper starts moving, PolyScope will execute the next action on the program tree. This allows you to move the Gripper and robot at the same time. Warning message section Gripper not “...

-

Page 45: Edit Action Screen

Edit action screen Tap Edit action from the Command window and use the Edit action screen to edit the Gripper’s parameters and adjust its position, speed and force. In normal usage conditions, the Gripper will move as soon as you change the position setting. The Gripper will not move if it is not properly powered, connected and activated. - Page 46 Primary Icon Functionality Name Description Shows the position request for the selected Gripper node. Requested position Shows the speed requested for the selected Gripper node. Use the Plus and Minus icons to modify. Requested speed Shows the force requested for the selected Gripper node. Use the Plus and Minus icons to modify.

-

Page 47: Grip Check Node

Change speed and force when grasping fragile objects or other specific parts. In all other cases, it is recommended to use maximum speed and force. Grip Check node In order to add and edit a Grip Check node: On e-Series On the teach pendant, at the top of the screen, tap the New icon to create a program or the Open icon to load a program. -

Page 48: About

Fig. 4-12: Grip Check node interface Fig. 4-13: Grip Check node interface with dimension validation Given that the Grip Check node is an If statement, tapping the actual node in the Command tab brings up the option to add an Else instruction to the program tree. - Page 49 Select Gripper in the left pane Tap the About sub-menu Caution On CB-Series only: If the Gripper version is obsolete, a warning message will display and an Upgrade firmware button will prompt the user to upgrade the firmware to the latest available version. Fig.

-

Page 50: Error Messages Overview

Error messages overview If a program is running without the Gripper being activated, the program will stop at the execution of a Gripper node and the following message will be displayed in a pop-up. Tap Stop Program and activate the gripper with the toolbar to continue or add an activation command in the program (please refer to the Advanced Gripper Functions Software section of the Hand-E Instruction Manual). -

Page 51: Copilot Control With Universal Robots

4.2. Copilot control with Universal Robots CB-Series Universal Robots e-Series Universal Robots License Type Nodes/Features FT 300 Force Torque Sensor Force Machine Tending Finishing Copilot Copilot Copilot Collision Detection Find Surface Finishing Tool Control Force Event Force Control Insertion node Find Contact Offset Apply Contact Offset Path Generator... -

Page 52: Find Contact Offset Node

Two nodes are introduced with the External Tool Finishing Kit: Find Contact Offset Apply Contact Offset The Find Contact Offset and Apply Contact Offset nodes integrate the Multipoint Path and Find Surface nodes as part of Touch sequences. The current Instruction Manual includes information on those nodes. 4.2.1 . - Page 53 3. Insert a Find Contact Offset node. 4. Tap Teach sequence. 5. From the " Feature to offset" dropdown list, select the feature point you previously created. For more information, select the help button. 6. Select Add translation or Add orientation to determ- ine by how much the feature has been offset.

-

Page 54: Add Translation

Nodes must be inserted under the Apply Contact Offset node to be affected by the offset value. Add Translation Fig. 4-15: Select this button to insert a Translation node. Fig. 4-16: Translation node Fig. 4-17: Add Translation program tree Follow these steps to setup a Translation node. 1. - Page 55 2. Tap Transition_Point from the Robot Program, move the robot to the required position, and select Set waypoint . Info Transition Point : feature point used to move between waypoints without colliding with the object. 3. Repeat for Approach_Point . 4.

-

Page 56: Add Orientation

Info The offset value is stored under the Universal Robots Installation tab. As such, this value can be reused either in the same robot program where it was first calculated, or in a different robot program altogether. Add orientation Fig. 4-18: Select this button to insert an Orientation node. Fig. -

Page 57: Apply Contact Offset

Fig. 4-20: Add Orientation program tree. The Orientation node can be set up in the same way as a Translation node. However, the Orientation node contains two Touch nodes. Configure each node as described in section Add translation. The two offset values will be used to calculate a rotation angle. 4.2.2. -

Page 58: Finishing Tool Control Node

This strategy will reduce the frequency at which nodes are run in the course of your robot program. 4.2.3. Finishing Tool Control node When running a program that uses a Robotiq end-effector, you can send a command to either start or stop this tool. The Finishing Tool Control node offers two commands: Start tooland Stop tool. - Page 59 From the Program tab, tap URCaps, the Finishing Tool Control. Select the output to which your tool is connected in the robot controller. In addition, you must ensure that your finishing tool stops running on an emergency stop (e-stop), protective stop (p-stop) or program stop.

-

Page 60: Path Recording Node

You can enable e-stops, p-stops and program stops with options from the following window. Select the input and output ports to which your tool is wired, then make sure to select Low when not running from the dropdown list. Other settings will not enforce stops. 4.2.4. - Page 61 In the ribbon at the top of the PolyScope interface, tap the New button to create a program or tap the Open button to load an existing program. Select the URCaps menu. Tap the Path button. In the Command tab, select the required option for the desired Path: Tool on robot : i.

-

Page 62: Overview

When the Tool on robot is selected: If you check the Path relative to a feature box to choose between the Actual pose of the robot or go configure a Feature point in Installation tab → Features → Point. When the External Tooling is selected: Configure the position and the orientation of your Tool Center Point (TCP) in Installation tab →... -

Page 63: Features

Path options. Warning section. Displayed whenever a setting results in a duration different than the original path duration. Features* Primary icon Description Starts and stops the path recording. Press and hold in order to move the robot at the path’s start. Press and hold in order to move the robot at the path’s end. -

Page 64: Multipoint Path Node

Try inserting a Multipoint Path node in a Robotiq Force Control node. The former will perform the movements that were taught while taking into consideration the parameters set in the latter. - Page 65 Fig. 4-21: Multipoint Path options If the Tool on robot option is selected, check the Path relative to a feature option and choose in the dropdown list the required pos- ition. You can select Actual pose to continue with the actual position of the robot or you can create a feature point in Installation tab →...

-

Page 66: How To Set Up A Multipoint Path

Fig. 4-23: Multipoint Path node External tooling option Info Please note that a Multipoint Path parent node is always followed by a MoveJ command leading to the starting waypoint of the path sequence. How to set up a Multipoint Path Step 1 Select the MoveJ To waypoint child node in the program tree. - Page 67 Tap the Set waypoint button. The UR waypoint interface will pop up and ask you to define the waypoint. Adjust the position if needed, then press OK. At this point, the interface will look like this: Tap the Edit button to open the UR waypoint interface and adjust the position of the robot arm (this works for every waypoint of the Multipoint Path) Tap the Delete button to cancel the waypoint (deleting the starting waypoint will turn it to unassigned) Tap and hold the Move here button to make the robot arm travel to the corresponding waypoint...

- Page 68 Important The curve segments are not generated and/or represented according to a spline model; they are rather based on Bézier curves. Info For describing the continuity of the curves used in the Multipoint Path node, control points are generated on the bisector of each waypoint junction (angle).

-

Page 69: Path Generator

Select the waypoint in the program tree and tap the appropriate radio button in the Command tab. Repeat step 2 until you complete your Multipoint Path. Fig. 4-25: Representation of a six-waypoint Multipoint Path with both curves and straight lines. 4.2.6. - Page 70 Tool Center Point (TCP) in Installation tab → Features → Point Select the required path depending on your sur- face : 4-point: for a surface between two lines 6-point: for a surface between two arcs 9-point : for a surface between four arcs Follow the steps bellow.

- Page 71 gram. Note: this will make your robot move, make sure its workspace is clear. 6-Point Path 1. Define the six points that represent your sur- face. 2. Each point has its own node. 3. Choose Set Waypoint to define your way- point (bring the robot to where your corner is).

- Page 72 selected. 9-Point Path 1. Define the nine points that represent your sur- face. 2. Each point has its own node. 3. Choose Set Waypoint to define your way- point (bring the robot to where your corner is). 4. Make sure the point you are teaching fits the point sequence on the illustration.

-

Page 73: Activedrive Toolbar

You can decide if you want to do vertical or horizontal passes. The illustration will show you the one you selected. To finish complex shapes, it is possible to put one path generator node after the other. If the first one’s end point is the second one’s starting point, both paths will be followed by the robot without interruption. -

Page 74: Toolbar Expanded

Toolbar expanded (Tap the mode selector to expand.) Features Primary icon Functionality Description name Tap to toggle between the expanded and collapsed ActiveDrive Toolbar. When grey, the functionality is not available. Tap the button to see why it is not available. ActiveDrive Tap to start or stop ActiveDrive. -

Page 75: Error Messages Overview

Primary icon Functionality Description name Plane motion: horizontal translations and horizontal rotations (twist) are allowed (no vertical motions are allowed). Plane Tap this button to stop the robot from drifting (resets the sensor’s offset) and to remove all forces applied on the robot. Drift Control Motion speed control is toggled between fast and slow, allowing precise movement in slow motion. -

Page 76: Insertion Nodes

Message: Solution: The robot is not initialized: Tap OK and go to PolyScope’s home page. Tap Setup Robot and go to Initialize Robot to start the robot. Message: Solution: A program is already running: The ActiveDrive Toolbar cannot be used while a program is running. Stop the program to enable the ActiveDrive feature. -

Page 77: Child Nodes

Info The parent Insertion node is automatically followed by a Zero Sensor child node. Child nodes Spiral button to insert a Spiral child node Rotational button to insert a Rotational child node Linear button to insert a Linear child node Spiral Rotational Linear... - Page 78 Teach position button (Destination): Tapping this button saves the object's destination as a waypoint in the robot program Reference frame dropdown menu (Direction): Menu used to select the frame according to which the tool will move in space Axis dropdown menu (Direction): Menu used to select the direction in which the tool will go to reach the destination Advanced parameters box: Box that expands the advanced parameters menu when ticked Speed parameter: Textbox for the user to enter a speed value Force initiating spiral move parameter: Textbox for the user to enter a force threshold value that triggers the spiral move, after the...

-

Page 79: Features (Rotational)

Parameter Unit of measurement Default value Force initiating spiral move Force initiating insertion Radius increment per turn Maximum radius (Error condition) Features (Rotational) Teach position button (Destination): Tapping this button saves the object's destination as a waypoint in the robot program Reference frame dropdown menu (Direction): Menu used to select the frame according to which the tool will move in space Axis dropdown menu (Direction): Menu used to select the direction in which the tool will go to reach the destination Advanced parameters box: Box that expands the advanced parameters menu when ticked... -

Page 80: Features (Linear)

Enable peck mode box: Box that enables the retraction of the tool between points of contact Maximum rotation angle (Error condition): Textbox for the user to enter the maximum angle of the rotation motion, considering that no path of least resistance has been found Default values and units of measurement Parameter Unit of measurement... -

Page 81: Find Surface Node

Speed parameter: Textbox for the user to enter a speed value for the approach motion towards the destination Force threshold parameter: Textbox for the user to enter a force threshold value that completes the linear motion Maximum travel distance (Error condition): Textbox for the user to enter the maximum distance value which, upon being reached, means the force threshold has never been reached in the linear motion 4.2.9. - Page 82 Insert instruction textbox: Checkbox that inserts the corresponding stop condition in the robot program when ticked; its main func- tion is to facilitate the programming and improve the user experience Maximum distance traveled (Stop condition): Textbox for the user to enter the maximum distance value which, upon being reached, means the force threshold has never been reached in the linear motion Insert instruction textbox: Checkbox that inserts the corresponding stop condition in the robot program when ticked;...

-

Page 83: Force Control Node

Warning UR Move nodes (MoveL, MoveJ, MoveP) and Force nodes cannot be executed as child of the Robotiq Force Control node. Where a UR Move node would normally be used, the user shall record a Robotiq Path emulating the desired Move. -

Page 84: Parameters

Fig. 4-27: Force Control node with Reference Feature drop-down highlighted. Parameters Enable control: each checkbox corresponds to the enablement of force feeding along an axis (upper three options) or torque feeding around an axis (lower three options) Force/Torque: depending on which options were checked at step 1, the corresponding textboxes here should be filled with the desired force/torque values Force values applied are in newtons (N) –... - Page 85 Info Tapping the text boxes brings up a numpad used to enter the values. Stiffness: the stiffness settings act directly on the Sensor's directional compliance depending on the orientation of the end- effector and the axes selected at step 1. A stiffness value closer to 0% will provide greater compliance along/around the corresponding axis A stiffness value of 100% offers no compliance along/around the corresponding axis Deviation range: the deviation range limits the flexibility allowed along/around the corresponding axis.

-

Page 86: Current Vs Targeted Position

entered at steps 2a and/or 2b. It will then go back to the surface and apply the same force/torque values while pulling back less and less over time. Fig. 4-29: End-effector experiencing adaptive stiffness upon repeated contact with a surface on CB-Series Current vs targeted position From the Force Control node, you can choose to either: Apply force at the current position... - Page 87 Fig. 4-30: Force control for e-Series Fig. 4-31: Force control for CB-Series External Tool Finishing Kit - Instruction Manual...

-

Page 88: Motion Frame

Use the targeted position option when your defined trajectory is close to the actual part that will be processed within the Force Control node. Use the current position option when your defined trajectory may not resemble to the actual part that is being processed. Motion Frame From the Force Control node, it is possible to choose your feature among: Tool... -

Page 89: Test

Fig. 4-32: Motion Frame The motion frame option allows to apply constant forces and torques along a path. The X axis represents the motion direction, the Z axis is perpendicular to the X axis and is close to the robot’s Z axis. Test The Test button applies the user-defined settings of the Force Control node to the sensor, therefore moving along/around the corresponding axes, if the control had been enabled for the latter, regardless of other instructions entered before or after the Force... -

Page 90: Force Event

You can also test in real time your preset values by holding the Test button for the Tool and the Base features. 4.2.1 1 . Force Event The Finishing Copilot software package includes Force Event, which can be used to perform a click detection or to wait for a specific force or torque. - Page 91 Select Force Event Tap the Force Event node in the robot program to edit it Select an operation to add to the Force Event sequence Wait for Force function Click detection function Wait for Force Click Detection The Wait for force feature is used to detect a specific force or The Click Detection feature is used to detect a drop that is torque inside a Force Control node.

-

Page 92: Features (Click Detection)

Features (Click Detection) The Click Detection feature monitors forces and torques throughout the nodes placed within it. This feature senses if a drop in the force or torque is then followed by a sudden rise, thus making a " click" . If a click is detected within the Click detection node, the program then skips the remaining instruction lines that are included in the Click detection node. -

Page 93: Collision Detection

4.2.1 2. Collision Detection The Collision Detection feature is used to stop a program when the forces and the torques, monitored by the FT Sensor for CB-Series or by the embedded e-Series sensor, exceed the defined limits. By default, the program does not monitor forces and torques. How to add a Collision Detection On CB-Series:From the PolyScope home page, tap Program Robot and create or load a robot program On e-Series:On the teach pendant, tap the New button to create a program or the Open button to load a program... - Page 94 From the Program tab: Tap the URCaps button in the navigation pane on the left Select Collision Detection Tap the Collision Detection node to edit it You can either choose to halt (stop) or suspend (pause) the program when a collision is detected. The forces and torques monitored in the collision detection node are the ones measured by the embedded e-Series sensor or theFT Sensor for CB-Series robot.

-

Page 95: Force And Torque Script Functions

Force and torque script functions Force Torque Sensor functions are made available in the Script drop-down menu. The rq_zero_sensor() function can be called at any point in a robot program to zero the force and torque values of the Force Torque Sensor. -

Page 96: Specifications

5. Specifications 5.1 . Technical dimensions of the Hand-EGripper The figure below represents the gripper dimensions with axes X, Y, Z, and origin referenced for finger motion. Info All technical drawings in the current section depict aluminum fingers. Fig. 5-1: General dimensions of Hand-E (open) External Tool Finishing Kit - Instruction Manual... -

Page 97: Fingers And Fingertips

The contact grip points for Hand-E are its two fingertip pads. Fingertip options are supplied by Robotiq (please refer to the Spare Parts, Kits and Accessories section of the Hand-E Instruction Manual). Users can create their own fingertips from scratch. The figure below represents the fingertip holder, the permanent, non customizable part of the gripper finger on which the fingertip must be mounted. -

Page 98: Flat Rubber (Nbr) Overmolded Fingers

Flat Rubber (NBR) Overmolded Fingers The figure below represents flat NBR overmolded fingers (HND-FIN-MLD-KIT). For more details, refer to the Spare Parts, Kits and Accessories section of the Hand-E Manual. This finger allows a 0-50 mm stroke. Fig. 5-3: Flat NBR overmolded finger. Fingertip holders To install fingertips on racks use fingertip holders (HND-TIP-HLD-KIT), and refer to the Spare Parts, Kits and Accessories section of the Hand-E Instruction Manual. -

Page 99: Grooved Fingertips

Fig. 5-5: Flat aluminum finger. Grooved fingertips The figure below the available grooved fingertip (HND-TIP-VGR-KIT); please refer to the Spare Parts, Kits and Accessories section. This fingertip has a grooved surface with an optimal shape for picking cylindrical parts (by its horizontal and vertical grooves). This fingertip must be mounted on the racks using the fingertip holder (HND-TIP-HLD-KIT). -

Page 100: Mechanical Specificationsof The External Tool Finishing Kit

5.2. Mechanical specifications of the External Tool Finishing Kit 5.2.1 . Specifications of the FT Sensor on CB-Series robots Specifications Value Approximate weight 300 g Overload capacity A combined load exceeding 500% of the measuring range will permanently damage the Force Torque Sensor (Fx/300 + Fy/300 + Fz/300 + Mx/30 + My/30 + Mz/30 <... -

Page 101: Payload And Force

Gripper diameter 75 mm 2.95 in Gripper weight (including coupling) 1070 g 2.3 lbs Grip force 20 - 130 N 4.5 - 27 lbf Finger speed 20 to 150 mm/s 0.8 to 5.9 in/s Info All specs are measured with coupling GRP-CPL-062 and aluminum fingertips (HND-FIN-ALU-KIT). Payload and force Actuation force model used to calculate the recommended friction payload (W): where:... -

Page 102: Maximum Payload/External Force Vs. Custom Finger Design

Info For example, if the silicone fingertips (HND-TIP-SLC-KIT) are used to lift a lubricated steel part (machine tending with cutting oils), the friction coefficient would be 0.3 (tested static coefficient of friction). Maximum weight with a safety factor of 2.4 and maximum force would be: W = (2 x 130 N x 0.3) / 2.4 = 32.5 N This calculation means that a 3.3 kg part will be held by the gripper when not moving (standing still). - Page 103 Fig. 5-9: Graph illustrating Maximum Payload/External Force vs. Z-Offset on Custom finger The blue curve in the graph represents the maximum force/payload (F) recommended at given Z offset for a custom finger design mounted directly on the rack with two (2) M3 screws. The red curve in the graph represents the maximum force/payload (F) recommended at given Z offset for a custom finger design mountend on a fingertip holder with two (2) M3 screws.

-

Page 104: Friction Grasp And Form-Fit Grasp

Caution In order to address other custom specific cases with regards to your own application, the main item to address is the strength of the screws used for mounting the fingers. Friction grasp and form-fit grasp Fig. 5-10: Hand-E grasps Maximum payload by grasp type Grasp Type Maximum Payload... -

Page 105: Center Of Mass And Tool Center Point Of The Ft Sensor And The Hand-Egripper

5.2.3. Center of mass and tool center point of the FT Sensor and the Hand-EGripper Couplings are included when Grippers are not mounted on the Camera. -

Page 106: Moment And Force Limits

5.2.4. Moment and force limits The Hand-E Gripper has limits for moment and force values. The maximum moment and force values are independent of the grasp force applied by the Gripper on its payload. For payload calculation, please refer to the Payload and Force Specifications section. Warning The following limits must be respected at all times. -

Page 107: Electrical Specificationsof The Ft Sensor

5.3. Electrical specifications of the FT Sensor SPECIFICATION VALUE Input voltage 5 to 24 V DC ± 10% Max power consumption Communication electrical interface RS-485 Recommended fuse Phoenix #0916604 (UT6-TMC M 1 A) Recommended power supply TDK-Lambda DPP Series 15W Single Output DIN Rail Mount Power Supply, DPP15-24 5.4. -

Page 108: Maintenance

6. Maintenance The Robotiq Hand-E Gripper requires only external maintenance with limited downtime. Please refer to the Maintenance section of the Hand-E Instruction Manual available on www.support.robotiq.com External Tool Finishing Kit - Instruction Manual... -

Page 109: Spare Parts, Kitsand Accessories

Item Description Ordering Number External Tool Finishing Kit 1 x Hand-E Gripper and FT 300 Sensor Kit for UR [HND-FTS-UR-KIT] ETF-CB-UR-KIT for UR CB-Series 1 x Hand-E Gripper Kit for UR e-Series External Tool Finishing Kit ETF-ES-UR-KIT 1 x Application Copilot License Dongle... -

Page 110: Troubleshooting

8. Troubleshooting Please refer to the Troubleshooting section of the Hand-E Instruction Manual available on www.support.robotiq.com External Tool Finishing Kit - Instruction Manual... -

Page 111: Warranty

9. Warranty Please refer to the Warranty section of the Hand-E and the FT Sensor Instruction Manuals available on www.support.robotiq.com External Tool Finishing Kit - Instruction Manual... -

Page 112: Harmonized Standards, Declarations And Certificates

1 0. Harmonized Standards, Declarationsand Certificates For more details about the original EC declaration of incorporation, the applied standards and the Ingress Protection Certificate of the Hand-E Gripper, please refer to this section in the Hand-E Instruction Manual. External Tool Finishing Kit - Instruction Manual... -

Page 113: License Agreement

“ Licensor” means Robotiq inc., a corporation incorporated under the laws of Quebec, having its registered office at 500-966 chemin Olivier, Lévis, Québec, Canada, G7A 2N1, which specializes into the conception, advanced manufacturing and sale of robotic products (the “... - Page 114 Software, which Software shall be used in accordance with such documentation. This documentation, if applicable, will be provided, wholly or in part, within (i) this Agreement, (ii) the Licensor’s Web site http://robotiq.com/ (iii) the Licensor’s Products and the Purchase Agreement therewith, or (iv) any other agreement, document, support, whatsoever decided by the Licensor.

- Page 115 Exclusion of Warranty on Software. The End-User expressly acknowledges and agrees that use of the Software is at the End-User sole risk. The Software is provided “ as is” . The Licensor warrants that, during the term of this Agreement and except if modified by the End- User, the Software will meet in all material respects the specifications provided for in the Licensor’s website.

- Page 116 The parties confirm that they have agreed that this Agreement and all related documents be drafted in English only. Les parties aux présentes confirment qu’elles ont accepté que la présente convention et tous les documents y afférents soient rédigés en anglais seulement.

-

Page 117: Contact

1 2. Contact www.robotiq.com Contact Us Phone 1-888-ROBOTIQ (762-6847) (01) 418-380-2788 Outside USand Canada Technical support and engineering option 3 Sales option 2 Head office Robotiq: 966, chemin Olivier Suite 500 St-Nicolas, Québec G7A 2N1 Canada Where automation Pros come to share their know-how and get answers.

Need help?

Do you have a question about the ETF-CB-UR-KIT and is the answer not in the manual?

Questions and answers