Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Dantherm BasX

- Page 1 BasX Service manual No. 039073 • rev. 1.0 • 08.03.2007...

- Page 2 Der tages forbehold for trykfejl og ændringer Dantherm can accept no responsibility for possible errors and changes Irrtümer und Änderungen vorbehalten Dantherm n’assume aucune responsabilité pour erreurs et modifications éventuelles...

-

Page 3: Introduction

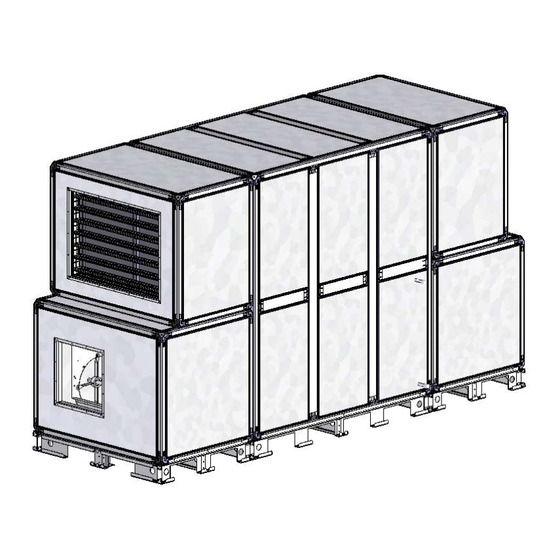

Introduction Overview Introduction This is the service manual for the Dantherm Air Handling BasX unit. The index below shows the main sections of the manual. For further information see the complete table of contents on page 4. Warning It is the operator’s responsibility to read and understand this manual as well as other information and to use the correct operation and maintenance procedure. -

Page 4: Table Of Contents

Table of contents Introduction This is the complete table of contents covering all sections in this service manual. Each main section will begin with an introduction including a separate table of contents covering the specific section. Table of contents This service manual covers the following topics: Topic See page Introduction... -

Page 5: General Information

Dantherm Air Handling reserves the right to make changes and improvements to the product and the service manual at any time without prior notice or obligation. EC-Declaration of Dantherm Air Handling A/S declares that the BasX units comply with the following Conformity directives:... -

Page 6: Service Guide

Service guide Overview Introduction This section contains any relevant information for the service of the BasX unit. It includes: • a survey for the planning of service inspections • a description of all the components that require preventive maintenance • general information on spare parts, fault finding etc. -

Page 7: Scheduling Service Inspections, Overview

Read more in each section of each part about what kind of service is necessary and how to carry out this service inspection. Categories Dantherm Air Handling has categorized the service inspections to be carried out: • Four times a year • Every 5000 operating hours or at least once a year •... - Page 8 Scheduling service inspections, overview, continued Once a year, Component Service Reference continued Cooling coil Check the condition of the coil Page 21 Vent the coil which use water Clean the drip tray, drain and water trap Check the droplet eliminator Check the fan impeller Page 11 Check the vibration isolators and flexible...

-

Page 9: Preventive Maintenance

Preventive maintenance Introduction In order to achieve the best possible operation and long lifetime of the air handling unit it is necessary to perform preventive maintenance of the various parts of the air handling unit within the necessary intervals. Read more about intervals in the section “Scheduling service inspections, overview”, page 7 Condition for The factory warranty is only valid if documented preventive maintenance has been... -

Page 10: How To Service The Cabinet

Dry it off with a dry cloth or use water mixed with a cleaning product Clean the seals and inspection doors, and check for leakage. Dantherm Air Handling recommends treating the seals with a moisture repellent agent Check the seals and closing mechanisms... -

Page 11: How To Service Fans And Fan Motors

How to service fans and fan motors Interval Fan and motor are serviced in accordance with the following intervals: 4 times annually: • Belt drive Once annually: • Fan wheel • Vibration dampers and flexible connections Warning! Do not forget to disconnect all current to the unit and the unit parts before service. Illustrations Belt-driven fans Direct-driven fans... - Page 12 (mm). The deflection strength of each belt depends on the belt profile type used and the centre distance. Dantherm Air Handling recommend the use of special-purpose tools for the measuring of the belt tightening in order to ensure the control of the values...

-

Page 13: How To Service The Cross-Flow Heat Exchanger

How to service the cross-flow heat exchanger Interval The cross-flow heat exchanger is serviced once annually. Before start The following should be available before start: • A soft brush • Fat-dissolving detergent • High-pressure cleaner with atomizer Warning! Do not forget to disconnect all current to the unit and its parts before service. Take care when cleaning the exchanger so that you do not damage the surface of the heat exchanger. - Page 14 How to service the cross-flow heat exchanger, continued Procedure, The preventive maintenance is done as described below: preventive maintenance Step Action Check the heat exchanger plates and inlet for dirt. (You may use a torch to see through it from both sides) Dust should be removed from the inlet edges.

-

Page 15: How To Service The Rotary Heat Exchanger

Illustration Rotary heat exchanger: Interval To ensure a long lifetime and continuous operation of the BasX unit, the rotary exchanger should be maintained once annually as described below. See ”Procedure”. The rotary heat exchanger should be serviced once annually. Before start The following should be available before service: •... - Page 16 How to service the rotary heat exchanger, continued Procedure, The rotary heat exchanger is serviced as described below: preventive maintenance Step Action Check that the brushes are intact Use a soft brush to remove dust on the edges of the rotary heat exchanger Wash with fat-dissolving detergent to remove fat or dirt on the edges of the heat exchanger If necessary, clean the heat exchanger by compressed air.

-

Page 17: How To Service Run-Around Heat Exchangers

How to service run-around heat exchangers Intervals Once annually. Before start The following must be available before service: • Compressed air or vacuum cleaner • a soft brush Warning! Do not forget to disconnect all current to the unit and the unit parts before service. Take care not to damage the slats of the coils. - Page 18 How to service run-around heat exchangers, continued Procedure, Step Action continued Clean the condensate tray, the drain and the drain trap from the drip tray under the cooling coil Check and clean the eliminator plate (if the unit is equipped with one). Use compressed air and a soft brush...

-

Page 19: How To Service The Filter

How to service the filter Interval Replace the filter when the pressure loss exceeds recommended end pressure, see the table. The intervals are dependent on the concentration of dust in the air passing through the filter. Use the following ways to determine if the filter needs to be replaced: •... -

Page 20: How To Service The Heating Coil

How to service the heating coil Intervals Once annually. Before start The following must be available: • Compressed air or a vacuum cleaner • A soft brush Warning! Do not forget to disconnect all current to the unit and the unit parts before service. Take care not to damage the slats of the coils. -

Page 21: How To Service The Cooling Coil

How to service the cooling coil Interval Cooling coils are serviced once annually. Before start The following should be available before start: • High-pressure cleaner with atomizer or compressed air Warning! Do not forget to disconnect all current to the unit and the unit parts before service. Take care not to damage the slats of the coils during cleaning. -

Page 22: How To Service Dampers

How to service dampers Introduction There are different kinds of dampers, but they are serviced in the same way. Intervals Once annually. Before start No special tools are needed. Warning! Do not forget to disconnect all current to the unit and the unit parts before service! Exception from The bearings into which the damper plates are fixed do not need lubrication. - Page 23 A too tight adjustment of V-belt tension produces heavy wearing on ball bearings thus belt tension reducing useful life of the bearings. Dantherm Dantherm Air Handling A/S recommends using special tools for tightening V-belts in recommends order to check the values of the table below. Correct tension of...

-

Page 24: Spare Parts

Tove I. Kristensen +45 9614 4762 Spare Part Manager tik@dantherm.com Or contact Dantherm Air Handling A/S’s desk at the company number and you will be put through to the relevant contact person: Tel: +45 9614 3700 Fax: +45 9614 3800... -

Page 25: Fault Finding Guide

Fault finding guide Fault finding Identify the problem in the left column, read the cause in the middle column, and follow the instructions in the right column: Problem Probable cause Solution Rotor exchanger is not Driver for the rotor Contact a technician running exchanger is defect or with incorrect settings. -

Page 26: Service Agreement

Therefore the unit will need preventative maintenance on a regular basis. Hotline The After Sales Support Department of Dantherm Air Handling A/S is ready to help you in case of a problem. To be able to offer quick and efficient help, please have the following information ready when contacting Dantherm Air Handling A/S: •... -

Page 27: Technical Information

Technical information Overview Contents This section covers the following topics: Please contact Dantherm Air Handling A/S for further technical information. Topic See page Dimensions Driver for rotor exchanger Flow calculation for plug fans... -

Page 28: Dimensions

Dimensions Dimension table All measurements are in mm: BasX2 BasX4 BasX6 BasX10 BasX14 Height 1440 1700 1920 2180 2440 Width 1220 1220 1440 1440 1700 Width with rotary heat exchanger 1220 1220 1440 1700 2180 Length, cross-flow heat exchanger 1440 1440 1440 1995... -

Page 29: Driver For Rotor Exchanger

It is imperative, that the jumpers are set for the current operating situation Rotation guard – jumper 3 Setting The unit is fitted with a rotation guard as standard Max. motor speed – jumper 2 Rotor diameter, Setting Model Motor speed, RPM BasX 2 BasX 4 1050 Continued overleaf... - Page 30 Jumpers, Max. motor speed – jumper 2 continued J2 Setting Rotor diameter, Model Motor speed, RPM BasX 6 1250 BasX 10 1550 BasX 14 1950 Jumper 1, motor Direction of motor rotation for rotor exchanger – jumper 1 rotation...

- Page 31 Driver for rotor exchanger, continued Controller This table shows the controller environmental data: environmental data Power consumption Motor size , Nm Power, W Standby/holding torque Max. load/150RPM 2 Nm 45 W 4 Nm 90 W 6 Nm 150 W Actual size is apparent from the motor name plate Functions The functions below are available in the control: Purging operation...

-

Page 32: Flow Calculation For Plug Fans

Flow calculation for plug fans Flow calculation BasX modules with plug fans are fitted with a measuring device on the suction side and the inlet ring of the fan. The flow through the fan can be calculated by measuring the differential pressure between these two points. -

Page 33: Index

..............23 plug fan ..............11 belt-driven fan .............11 preventive maintenance ..........6;9 CE-Delaration of Conformity .........5 recycling ............... 5 contact Dantherm Air Handling ........26 remprofil ..............12 cooling coil ..............21 reservations..............5 copyright ...............5 rotary heat exchanger ..........15 cross-flow heat exchanger ..........13...

Need help?

Do you have a question about the BasX and is the answer not in the manual?

Questions and answers