Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Keysight Technologies Infiniium V Series

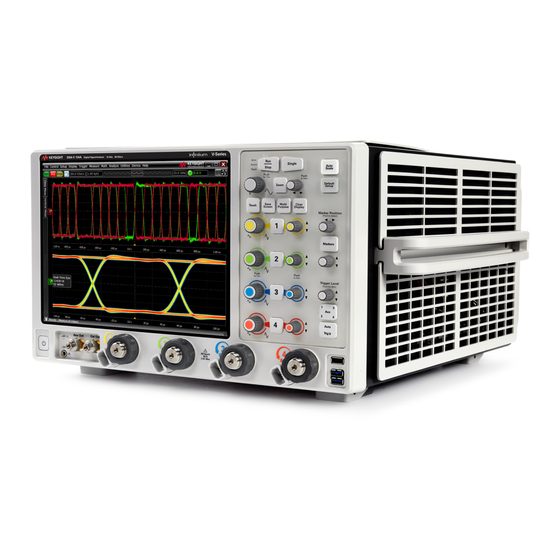

- Page 1 Keysight Infiniium V-Series Oscilloscopes Service Guide...

- Page 2 Notices Technology Licenses Safety Notices © Keysight Technologies 2015-2017, 2021, 2022 The hardware and/or software described in No part of this manual may be reproduced in this document are furnished under a license CAUTION any form or by any means (including elec-...

-

Page 3: Table Of Contents

Contents 1 General Information / 7 Instruments Covered by this Service Guide / 8 Accessories Supplied / 8 Specifications and Characteristics / 9 Measurement Category / 11 Measurement Category / 11 Measurement Category Definitions / 11 Preventing Damage to the Oscilloscope Inputs / 12 Power Considerations / 13 2 Calibration / 15 What is a Calibration? / 16... - Page 4 Before You Contact Keysight / 84 5 Replacing Assemblies / 85 Replacing Assemblies / 86 Returning the oscilloscope to Keysight Technologies for service / 87 Removing and replacing the top panel and bottom panel / 88 Removing and replacing the front panel assembly / 90...

- Page 5 Replacing an acquisition board / 123 Setting the calibration factors after replacing an acquisition board / 126 Removing and replacing the hard disk drive / 127 Removing and replacing the power supply / 128 Removing and replacing fans / 129 Removing and replacing the optional GPIB port / 131 6 Replaceable Parts / 133 Ordering Replaceable Parts / 134...

- Page 6 Infiniium V-Series Oscilloscopes Service Guide...

-

Page 7: General Information

Keysight Infiniium V-Series Oscilloscopes Service Guide 1 General Information Instruments Covered by this Service Guide Accessories Supplied Specifications and Characteristics Measurement Category Preventing Damage to the Oscilloscope Inputs Power Considerations... -

Page 8: Instruments Covered By This Service Guide

The release date of this manual is shown on the back of the title page. This manual will be revised when necessary. If you have an oscilloscope that was manufactured after the release of this manual, please check the Keysight Technologies website at www.keysight.com to see whether a newer version of this manual is available. -

Page 9: Specifications And Characteristics

General Information Specifications and Characteristics The following table contains a partial list of specifications and characteristics for the Keysight Infiniium V-Series oscilloscopes. For a complete list, see the data sheet at www.keysight.com/find/V-series. Warranted specifications are tested in Chapter 3, “Testing Performance”. °... - Page 10 General Information Pollution Degree Definitions Pollution Degree 1: No pollution or only dry, non-conductive pollution occurs. The pollution has no influence. Example: A clean room or climate-controlled office environment. Pollution Degree 2. Normally only dry non-conductive pollution occurs. Occasionally a temporary conductivity caused by condensation may occur.

-

Page 11: Measurement Category

General Information Measurement Category Measurement Category The Infiniium V-Series oscilloscopes are not intended to be used for measurements in Measurement Category II, III, or IV. The product is for use only on circuits that are NOT directly connected to mains. It is WARNING NOT intended for measurements on CAT II, CAT III, or CAT IV circuits. -

Page 12: Preventing Damage To The Oscilloscope Inputs

General Information Preventing Damage to the Oscilloscope Inputs Avoid damaging the oscilloscope inputs by knowing the approximate signal level to be measured. Overpowering the front end can cause damage to the front end components. The maximum input signal level of V-Series oscilloscopes is ±5 V. When connecting probes, adapters, or cables to the Infiniium V-Series oscilloscope, use caution to avoid damaging the oscilloscope’s channel input circuits due to electrostatic discharge (ESD). -

Page 13: Power Considerations

General Information Power Considerations Do not use this instrument with a power cord other than the one provided by Keysight. CAUTION The power cord provided is matched to the country of the origin of the order. Other power cords may not have appropriate ratings. Therefore, you must not replace the detachable MAINS supply cords by inadequately RATED cords. - Page 14 General Information Infiniium V-Series Oscilloscopes Service Guide...

-

Page 15: Calibration

Keysight Infiniium V-Series Oscilloscopes Service Guide 2 Calibration What is a Calibration? Running an Environmental Calibration Running a User Calibration... -

Page 16: What Is A Calibration

Calibration What is a Calibration? A calibration is simply an oscilloscope self-adjustment. The purpose of a calibration is performance optimization. There are four levels of calibrating an Infiniium V-Series oscilloscope, with each successive level being a superset of the previous one: •... -

Page 17: Running An Environmental Calibration

Calibration Running an Environmental Calibration The oscilloscope must be warmed up (with the oscilloscope application running) for at least N OTE 30 minutes at ambient temperature before starting the calibration procedure. Failure to allow warm up may result in inaccurate calibration. The environmental calibration uses signals generated in the oscilloscope to calibrate response. - Page 18 Calibration Clear this check box before beginning calibration Click here to run a quick environmental calibration Click Start Quick Env Cal, then follow the instructions on the screen. The routine will prompt you to follow these steps: Disconnect everything from all inputs and Cal Out. Connect the calibration cable from Cal Out to channel 1.You must use the 54916-61626 cable assembly with two connector saver adapters.

-

Page 19: Running A User Calibration

Calibration Running a User Calibration The oscilloscope must be warmed up (with the oscilloscope application running) for at least N OTE 30 minutes at ambient temperature before starting the calibration procedure. Failure to allow warm up may result in inaccurate calibration. The user calibration uses signals generated in the oscilloscope to calibrate channel scale, offsets, and trigger parameters. -

Page 20: Procedure

Calibration Procedure Let the oscilloscope warm up before running the self calibration. The self calibration should be done only after the oscilloscope has run for 30 minutes at ambient temperature. Calibration of an oscilloscope that has not warmed up may result in inaccurate calibration. Choose Utilities >... - Page 21 Calibration Connect the calibration cable from Cal Out to each channel input as requested. When instructed, connect the calibration cable from the Cal Out on the front panel of the oscilloscope to the 1250-1200 SMA(m) to BNC(f) adapter and then connect the other end of the 1250-1200 adapter to the 8120-1840 BNC cable.

- Page 22 Calibration Infiniium V-Series Oscilloscopes Service Guide...

-

Page 23: Testing Performance

Keysight Infiniium V-Series Oscilloscopes Service Guide 3 Testing Performance Verifying System Performance Vertical Performance Verification Offset Accuracy Test DC Gain Accuracy Test Analog Bandwidth—Maximum Frequency Test Time Scale Accuracy (TSA) Test Performance Test Record Full performance verification for V-Series oscilloscopes consists of three main procedures: Performing the internal oscilloscope self tests to ensure the measurement system is functioning properly. -

Page 24: Verifying System Performance

Contact Keysight Technologies for more information about the Keysight products in these lists. Infiniium V-Series Oscilloscopes Service Guide... -

Page 25: Vertical Performance Verification

Testing Performance Vertical Performance Verification This section describes the following vertical performance verification tests: • Offset Accuracy Test • DC Gain Accuracy Test • Analog Bandwidth—Maximum Frequency Test • Time Scale Accuracy (TSA) Test Infiniium V-Series Oscilloscopes Service Guide... -

Page 26: Offset Accuracy Test

Testing Performance Offset Accuracy Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V. CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for N OTE at least 30 minutes prior to the start of any performance test. Specifications ≤... - Page 27 Testing Performance Zero Error Test Procedure Disconnect all cables from the oscilloscope channel inputs. Click Control > Factory Default. Click Setup > Acquisition..In the Acquisition dialog box, enable averaging and set # of Averages to 256. Configure the oscilloscope to measure the average voltage (V avg) on channel 1 as follows: Change the vertical scale of channel 1 to 10 mV/div.

- Page 28 Testing Performance Average measurement (V avg) Press [Clear Display] on the oscilloscope and wait for the number of averages display (top right area of the screen) to return to 256. Record the oscilloscope’s mean V avg reading in the Offset Accuracy—Zero Error Test section of the Performance Test Record.

- Page 29 Testing Performance Change the vertical scale of channel 1 to 20 mV/div, wait for the number of averages to return to 256, and then record the V avg reading in the Offset Accuracy—Zero Error Test section of the Performance Test Record. Repeat step 6 for the remaining vertical scale settings for channel 1 in the Zero Error Test section of the Performance Test Record.

- Page 30 Testing Performance Offset Gain Test Procedure Make the connections to oscilloscope channel 1 as shown below. Oscilloscope channel input Cal Out on oscilloscope front panel Connector saver Connector saver BNC (f) to SMA (m) adapter BNC (f) to SMA (m) adapter •...

- Page 31 Testing Performance Set the Cal Out voltage (V ) to +400.0 mV as follows: Cal Out Click Utilities > Calibration Output..Change the Signal Output function to DC. Set the Level to 400.0 mV. Configure the oscilloscope to measure the average voltage on the channel under test as follows: Make sure the channel under test is enabled.

- Page 32 Testing Performance Calculate the offset gain error using the following expressions and record the value in the Offset Accuracy—Offset Gain Test section of the Performance Test Record. The offset gain error is the greater (maximum magnitude) of either: – V ...

-

Page 33: Dc Gain Accuracy Test

Testing Performance DC Gain Accuracy Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for N OTE at least 30 minutes prior to the start of any performance test. Specifications ±2% of full scale at full resolution channel scale (±2.5% for ≤... - Page 34 Testing Performance Procedure Make the connections to oscilloscope channel 1 as shown below. Oscilloscope Channel Input Cal Out on Oscilloscope Front Panel Connector Saver Connector Saver BNC (f) to SMA (m) adapter BNC (f) to SMA (m) adapter • Where the BNC Tee adapter is used, it is important to connect it directly to the oscilloscope N OTE channel input using the BNC (f) to SMA (m) adapter and the connector saver to minimize ground potential differences and to ensure that the DMM measures the input voltage to the...

- Page 35 Testing Performance Click Control > Factory Default, then configure the oscilloscope as follows: Click Setup > Acquisition..In the Acquisition dialog box, enable averaging and set # of Averages to 256. Set the Cal Out voltage (V ) to +30 mV as follows: Cal Out Click Utilities >...

- Page 36 Testing Performance Press [Clear Display] on the oscilloscope, wait for the number of averages to return to 256, and then record the DMM voltage reading as V and the DMM- scope V avg reading as V in the DC Gain Accuracy Test section of the Scope- Performance Test Record.

-

Page 37: Analog Bandwidth-Maximum Frequency Test

Testing Performance Analog Bandwidth—Maximum Frequency Test Ensure that the input voltage to the oscilloscope never exceeds ±5 V CAUTION The oscilloscope under test must be warmed up (with the oscilloscope application running) for N OTE at least 30 minutes prior to the start of any performance test. Specifications Analog Bandwidth (-3 dB) MSO/DSO/DSAV084A... - Page 38 Testing Performance Connections Microwave CW Generator E8257D Power meter E4418A or E4419A Oscilloscope Power splitter 11667C connector saver Power sensor 11901A adapter cable Microwave cable Power sensor 11901C adapter E4413A • Connect output 1 of the 11667C splitter to the scope channel N input directly using the N OTE 11901A adapter and a connector saver, without any additional cabling or adapters.

- Page 39 Testing Performance Click Control > Factory Default, then configure the oscilloscope as follows: Ensure the channel under test is displayed and all other channels are turned off. Set the vertical scale of the channel under test to 10 mV/div. Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform).

- Page 40 Testing Performance Set the generator to apply a 50 MHz sine wave with a peak-to-peak amplitude of about four divisions. Use the following table to determine the approximate required signal amplitude. The amplitude values in the tables are not absolutely required. If your generator is unable to produce the recommended amplitude, then set the generator to the highest value that does not produce a vertically clipped signal on the oscilloscope.

- Page 41 Testing Performance out @50 MHz --------------------------------- - Gain 50 MHz in @50 MHz Record this value in the Calculated Gain @50 MHz column in the Analog Bandwidth—Maximum Frequency Check section of the Performance Test Record. Change the generator frequency to the maximum value for the model being tested as shown in the table below.

- Page 42 Testing Performance Calculate the gain at the maximum frequency using the expression: ⁄ out Max Freq in Max Freq ----------------------------------------------------------------------------------- - 20 log Gain Max Freq Gain 50 MHz For example, if (Vout @ Max Frequency) = 13.825 mV, (Vin @ Max Frequency) = 13.461 mV and Gain @ 50MHz = 1.0023, then: ⁄...

- Page 43 Testing Performance Move the splitter to channel 3 and change the oscilloscope configuration as follows: Press [Default Setup]. Ensure channel 3 is displayed and all other channels are turned off. Set the vertical scale of channel 3 to 10 mV/div. Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform).

-

Page 44: Time Scale Accuracy (Tsa) Test

Testing Performance Time Scale Accuracy (TSA) Test This procedure verifies the maximum TSA specification for the oscilloscope. Description TSA refers to the absolute accuracy of an oscilloscope’s time scale. Because TSA depends directly on frequency of a crystal oscillator, it is comprised of two components: an initial accuracy component and an aging component. - Page 45 Testing Performance Connections Connect the equipment as shown here. Procedure Configure the sine wave source to output a 0 dBm (600 mVpp) sine wave into 50 ohms with a frequency of 10.00002000 MHz. Adjust the source amplitude such that the displayed sine wave is 600 mVpp. Click Control >...

- Page 46 Testing Performance Record the time since calibration (in years) in the table. The calibration date can be found in the Calibration window (Utilities > Calibration...). Calculate the test limits using the following formula and record them in the table. Test Limits = ±(0.100 + 0.100 x Years Since Calibration) Record the results in the Performance Test Record.

-

Page 47: Performance Test Record

Testing Performance Performance Test Record Keysight Technologies Keysight Infiniium V-Series Oscilloscopes Model Number _____________________ Tested by________________________ Serial Number ___________________________ Work Order No.___________________ Recommended Test Interval—1 Year/2000 hours Date_____________________________ Recommended next test date ___________________ Ambient temperature ______________ Offset Accuracy—Zero Error Test... - Page 48 Testing Performance Offset Accuracy—Offset Gain Test Vertical Scale Calc. Offset Offset Gain Error Cal Out DMM+ Scope+ DMM- Scope- DMM0 Scope0 Setting Gain Error Test Limits Channel 1 10 mV/div ±400 mV ±2 % 20 mV/div ±400 mV ±2 % 50 mV/div ±700 mV ±2 %...

- Page 49 Testing Performance DC Gain Accuracy Test Vertical Scale Calc. DC DC Gain Error Cal Out DMM+ Scope+ DMM- Scope- Setting Gain Error Test Limits Channel 1 10 mV/div ±30 mV ±2 % 20 mV/div ±60 mV ±2 % 50 mV/div ±150 mV ±2 % 100 mV/div...

- Page 50 Testing Performance Max frequency: MSO/DSO/DSAV084A = 8 GHz, MSO/DSO/DSAV134A = 13 GHz, MSO/DSO/DSAV164A = 16 GHz, MSO/DSO/DSAV204A = 20 GHz, MSO/DSO/DSAV254A = 25 GHz, MSO/DSO/DSAV334A = 32 GHz, Analog Bandwidth—Maximum Frequency Check Measurement Vout Calculated Gain Vout Calculated Gain Vertical @ 50 MHz @ 50 MHz @ 50 MHz...

- Page 51 Testing Performance Time Scale Accuracy Measured Time Scale Years Since Calibration Low Test Limit High Test Limit Pass/Fail (years) (ppm) (ppm) Error (ppm) ___________ ___________ ___________ ___________ ___________ Infiniium V-Series Oscilloscopes Service Guide...

- Page 52 Testing Performance Infiniium V-Series Oscilloscopes Service Guide...

-

Page 53: Troubleshooting

Keysight Infiniium V-Series Oscilloscopes Service Guide 4 Troubleshooting Service Strategy Verifying Basic Operation Power Supply Troubleshooting Setting Up the BIOS Motherboard Verification Display Troubleshooting Acquisition/Backplane Assembly Troubleshooting Keyboard Troubleshooting Front Panel LED Troubleshooting Touch Screen Troubleshooting Checking Probe Power Outputs MSO Assembly Troubleshooting Hardware Serial Trigger Assembly Troubleshooting Before You Contact Keysight... -

Page 54: Service Strategy

Troubleshooting Service Strategy The service strategy for troubleshooting Infiniium V-Series oscilloscopes is to isolate problems to a faulty assembly, then use the disassembly and assembly procedures in Chapter 5, “Replacing Assemblies", to replace the defective assembly. Read the Safety booklet that came with the oscilloscope before servicing the oscilloscope. -

Page 55: Verifying Basic Operation

Troubleshooting Verifying Basic Operation Follow the procedures in this section to verify the basic operation of the oscilloscope. Where problems occur, you are directed to the section that provides detailed troubleshooting help. Power Up the Oscilloscope Connect the power cord to the rear of the oscilloscope, then to a suitable AC voltage source. -

Page 56: Check The Display

Troubleshooting If the oscilloscope turns off without you pressing the front panel power button, go to the “Power Supply Troubleshooting" section of this chapter. If the oscilloscope does not start up at all, unplug the oscilloscope, wait 30 seconds, plug the oscilloscope back in, and turn the power on. If it still does not start up, go to the “Setting Up the BIOS"... - Page 57 Troubleshooting Knob and key self-test screen Press each key on the keyboard until you have pressed all keys. When you press a key or push a knob, the bar above the corresponding key/knob symbol on the display should change from red to green. Turn each knob in both directions until you have turned all knobs.

- Page 58 Troubleshooting LED test screen Repeatedly press the [Single] button on the front panel to step through and highlight each LED symbol in the test screen. You can also step through the LEDs by pressing the << Prev or Next >> buttons on the screen. Verify that the corresponding LEDs on the front panel are the only ones illuminated.

-

Page 59: Run A User Calibration

Troubleshooting Run a user calibration Complete a user calibration by following the procedures in chapter 2. If the calibration test fails, look at the details to find the channel associated with the failure. • If the failure is associated with channel 1, look at the specific calibration that failed. -

Page 60: Power Supply Troubleshooting

Troubleshooting Power Supply Troubleshooting This section provides information to help you isolate the problem to the assembly level when the power system is not operating properly. There are three main types of faults: • Under-voltage faults • Over-temperature faults • Over-voltage faults To determine what type of fault is occurring, and what assembly needs to be replaced, follow these steps: Unplug the oscilloscope so the +5 V standby power supply can fully discharge. - Page 61 Troubleshooting The first set of LEDs is located in the upper right corner of the backplane assembly (see the following two figures). Six of the LEDs indicate an under-voltage fault, and four indicate an over-temperature fault. Another LED in this group is BULK SUPPLY FAIL, located below NEG SUPPLY FAIL.

- Page 62 Troubleshooting The other three groups of LEDs indicate over-voltage faults. One group is located near the center of the top edge of the backplane assembly just above the blue and red SATA cables (see the two figures below). Over-voltage indicator LEDs on backplane assembly If any of these LEDs are lit, the backplane assembly must be replaced.

- Page 63 Troubleshooting Locate the other two groups of over-voltage fault LEDs along the edges of the two acquisition assemblies. They are visible through the bottom fan opening located on the left side of the oscilloscope, nearest the rear panel (see the following figures).

- Page 64 Troubleshooting The following tables show each LED, the type of fault it indicates, and what to do if that LED indicator is illuminated. Table 1 Group of 11 LEDs on backplane assembly Typs of Fault What To Do L-ACQ TEMP FAIL Over-temperature Go to “If the L-ACQ TEMP FAIL or...

-

Page 65: If The L-Acq Temp Fail Or U-Acq Temp Fail Led Is Lit

Troubleshooting Table 3 LEDs on each acquisition board Typs of Fault What To Do U1101 oV Over-voltage Replace acquisition assembly U303L oV Over-voltage Replace acquisition assembly U1600 oV Over-voltage Replace acquisition assembly U1100 oV Over-voltage Replace acquisition assembly U300 3.3 V oV Over-voltage Replace acquisition assembly U300 2.5 V oV... -

Page 66: If The Fp Supply Fail Led Is Lit

Troubleshooting If the FP SUPPLY FAIL LED is lit If the FP SUPPLY FAIL LED is the only one lit, there might be a problem with one of the supplies that goes to the front panel assembly, or a problem on the front panel assembly. - Page 67 Troubleshooting It is also possible that there is a short circuit on the bulk +12 V supply trace somewhere in the system, which would also cause the unit not to power on. If so, you need to isolate the assembly that is shorted. You do not need to remove the acquisition or backplane assemblies to perform the following steps.

- Page 68 Troubleshooting If there is a short, disconnect the power cable to the front panel and redo the resistance measurement. If the short is gone, replace the front panel assembly and verify that the oscilloscope now powers on. If there is still a short circuit, disconnect the two large connectors that provide power to the motherboard (J1201 and J1202) from the backplane assembly as shown below and redo the resistance measurements across the FET (Q1409) or the bulk supply input pins on the backplane assembly.

-

Page 69: If The Main Fan Fail Led Is Lit

Troubleshooting Measuring the acquisition assembly resistance between +12 V and ground If no shorts are found on the bulk +12 V supply trace or if you have fixed all the shorts and the oscilloscope still will not turn on, follow these steps, which include replacing parts with known good parts until you discover the problem. -

Page 70: If The Pred Fan Fail Led Is Lit

Troubleshooting Follow these steps to diagnose a main fan failure: Reset the sensing and shutdown logic by removing the AC power until the green LED on the motherboard goes out (or just wait 30 seconds). Move to the left side of the oscilloscope so you can see the case fans. Apply AC power to the oscilloscope and turn it on if it does not start up automatically. - Page 71 Troubleshooting Trigger ICs fan on backplane assembly Apply AC power and turn the oscilloscope on if it does not start up on its own. Notice whether the trigger ICs fan is turning. If it is not, replace it and redo this part of the diagnostic test.

-

Page 72: Setting Up The Bios

Troubleshooting Setting Up the BIOS If the BIOS settings become corrupt, the Infiniium oscilloscope PC motherboard will not recognize the hard drive and the oscilloscope may not start. To configure the motherboard BIOS parameters to the default settings, follow these steps: Connect the power cable to the oscilloscope. -

Page 73: Motherboard Verification

Troubleshooting Motherboard Verification If you have been through the Power Supply Troubleshooting section of this chapter and the oscilloscope still does not stay powered up, the problem may be with the motherboard. To diagnose this problem, follow these steps. Remove the top panel. Turn the oscilloscope on. - Page 74 Troubleshooting Be aware that there could be a fault on the motherboard that caused the backplane assembly to fail, so before you plug the motherboard cables back into the PCIe-to-SATA converter on the new backplane assembly, measure the resistance to the chassis from the pin 9 contact in the connector that plugs into J1201.

-

Page 75: Display Troubleshooting

Troubleshooting Display Troubleshooting Connect external monitor to VGA port. Turn on power. Does display Replace appear on ext. motherboard monitor? Check display cable Is front panel connection to display display and scrambled? motherboard Is front panel Still scrambled? display black? Check LED backlight cable, Replace front panel power cable, and... -

Page 76: Acquisition/Backplane Assembly Troubleshooting

Troubleshooting Acquisition/Backplane Assembly Troubleshooting This section describes which board assembly to replace if any of the scope self tests fail. A self-test error message file is generated and is sent to this location: C:\ProgramData\Infiniium\selftest\SelfTestLog.txt The error message usually indicates the channel with the error. When identifying which acquisition assembly to replace, remember that the acquisition assembly nearest the bottom of the oscilloscope is for channels 1 and 2. -

Page 77: Keyboard Troubleshooting

Troubleshooting Keyboard Troubleshooting Use this procedure only if you had keyboard failures in the keyboard self-test procedure. If any knobs fail, replace the front panel board. Remove the front panel assembly. (See Chapter 5, “Replacing Assemblies” instructions.) Unclip the front panel board from the keyboard assembly. Separate the elastomeric keypad from the keyboard assembly. -

Page 78: Front Panel Led Troubleshooting

Troubleshooting Front Panel LED Troubleshooting If you see a failure with the on/off switch backlight LED, replace the On/Off board. If the LED will still not illuminate, replace the motherboard and see if this fixes the problem. If the LED still does not work, check the on/off cable connecting the On/Off board to the motherboard, and check the connections of all cables on the on/off board and the motherboard. -

Page 79: Touch Screen Troubleshooting

Troubleshooting Touch Screen Troubleshooting Is the Touch key lit? Press Touch key Perform Touch Screen Test Did test pass? Is USB front/ Replace touch cable USB cable damaged? Replace Do knobs and display/touch keys work? screen Does touch Done screen work? Replace motherboard Touch screen troubleshooting flowchart... -

Page 80: Checking Probe Power Outputs

Troubleshooting Checking Probe Power Outputs Probe power outputs are on the front panel, in the lower left corner of the 3.5 mm inputs. Refer to the following figure to check the power output at the connectors. Measure the voltages with respect to the ground terminal on the front panel. Measure the voltages at pins 2 and 5 only (+12 V and -12 V). -

Page 81: Mso Assembly Troubleshooting

Troubleshooting MSO Assembly Troubleshooting This section describes problems that may occur when an MSO assembly is installed, and how to troubleshoot them. The MSO printed circuit assembly is located below the lower acquisition board, with the components facing downward. LEDs on MSO assemblies The MSO printed circuit board has two sets of LEDs. - Page 82 Troubleshooting MSO Cable Connection When the MSO cable is connected it must be oriented as shown on the label on the back of the oscilloscope (see the following figure). If the cable is upside-down, the pins may bend and cause a faulty connection. Make sure the cable is connected properly and that the pins remain straight.

-

Page 83: Hardware Serial Trigger Assembly Troubleshooting

Troubleshooting Hardware Serial Trigger Assembly Troubleshooting This section describes problems that may occur when an optional hardware serial trigger assembly is installed, and how to troubleshoot them. If a signal appears on screen but the eye scan diagram consists of only a solid blue box, check the semi-rigid cable connections from the acquisition boards to the serial trigger assembly. -

Page 84: Before You Contact Keysight

This information will be useful when you contact Keysight Technologies. To find and save system information, follow these steps: Click Help > About Infiniium.. -

Page 85: Replacing Assemblies

Keysight Infiniium V-Series Oscilloscopes Service Guide 5 Replacing Assemblies Returning the oscilloscope to Keysight Technologies for service Removing and replacing the top panel and bottom panel Removing and replacing the front panel assembly Removing and replacing front panel assembly parts... -

Page 86: Replacing Assemblies

Replacing Assemblies Replacing Assemblies Use the procedures in this chapter when removing and replacing assemblies and parts in the Infiniium V-Series oscilloscopes. The pictures in this chapter are representative of the oscilloscope at the time of this printing. Your unit may look different. Tools required The following tools are required for these procedures. -

Page 87: Returning The Oscilloscope To Keysight Technologies For Service

Replacing Assemblies Returning the oscilloscope to Keysight Technologies for service Before shipping the oscilloscope, contact Keysight Technologies for more details. Write the following information on a tag and attach it to the oscilloscope. • Name and address of owner •... -

Page 88: Removing And Replacing The Top Panel And Bottom Panel

Replacing Assemblies Removing and replacing the top panel and bottom panel Disconnect the power cable, all probes and BNC input cables, and any other cables including those for a mouse, keyboard, printer, USB, and LAN. Remove the four M3 screws from the rear edge of the top panel. When replacing, use a Torx T10 to torque to 5 in-lbs. - Page 89 Replacing Assemblies To replace the top and bottom panels, reverse this procedure. All sheet metal holes that are supposed to have screws placed in them are marked by lines on N OTE four sides of the hole. Figure 3 Infiniium V-Series Oscilloscopes Service Guide...

-

Page 90: Removing And Replacing The Front Panel Assembly

Replacing Assemblies Removing and replacing the front panel assembly Disconnect the power cable and remove the top panel as described earlier. Disconnect the on/off cable and the display cable from the motherboard. Figure 4 Disconnect the USB 3.0 cable from the motherboard. Figure 5 Infiniium V-Series Oscilloscopes Service Guide... - Page 91 Replacing Assemblies Disconnect the USB front touch screen cable from the USB connector on the motherboard. Figure 6 Disconnect the display cable’s 4-pin connector from the connector on the rear of the front panel board. Figure 7 Infiniium V-Series Oscilloscopes Service Guide...

- Page 92 Replacing Assemblies Remove the two screws from the front panel deck. Figure 8 Turn the oscilloscope upside down and remove the three M3 screws from the rear of the bottom panel. Remove the remaining 13 screws from the bottom panel and lift the bottom panel off the chassis. Disconnect the two Cal Out/Aux Out cables from the backplane board.

- Page 93 Replacing Assemblies Disconnect each input cable. (When reconnecting, you can determine the appropriate connections by matching the colored o-ring to the bezel color. Tighten to 8 in-lbs using a calibrated 5/16” open end torque wrench.) Figure 10 Remove the attenuator power cable from each input channel attenuator as shown below.

- Page 94 Replacing Assemblies Remove the probe comp cable from the backplane board. Figure 12 Remove the two M3 screws that attach the bottom of the chassis and the front panel assembly. Figure 13 Infiniium V-Series Oscilloscopes Service Guide...

- Page 95 Replacing Assemblies Pull up and tilt the front panel to see the cables connected to it. Route the display cable and on/off cable through the grommet on the chassis after disconnecting them from the other side of the connections. Figure 14 Remove the front panel.

-

Page 96: Removing And Replacing Front Panel Assembly Parts

Replacing Assemblies Removing and replacing front panel assembly parts To replace any of the front panel assembly parts, first remove the front panel assembly as described in the previous section. Removing front panel clutches, bezel, and keyboard This step will ruin the clutches. You will need to replace them with new ones. WARNING Use a thin item such as a ribbon to protect the oscilloscope from scratches, and pull on the dark gray plastic clutches to pop them off the oscilloscope. - Page 97 Replacing Assemblies To remove the keyboard, unlatch the two clips from the back of the front panel deck and unsnap the board from the deck, pulling out the side closest to the display first, as shown below. Figure 17 If you are replacing the keyboard or keypad, grasp and pull all of the knobs off of the front panel.

- Page 98 Replacing Assemblies Disengage the four tabs holding the board to the keypad as shown below. Figure 19 To reassemble the front panel board, reverse these steps. Removing the display assembly Remove the front panel assembly and front panel bezel as described previously. Remove the four screws connecting the display to the deck.

- Page 99 Replacing Assemblies Disconnect the backlight cable from the controller assembly. Figure 21 Disconnect any cables connected to the display. If you are replacing the display, you may need to loosen the four screws in back to align the N OTE display with the bezel.

-

Page 100: Removing And Replacing The Motherboard

Replacing Assemblies Removing and replacing the motherboard Disconnect the power cable and remove the top panel as described previously. Disconnect the blue and red SATA cables from the PCIe-to-SATA adapter board. When replacing the motherboard, be careful to reconnect the blue SATA cable to the connector marked BLUE on the adapter board, and the red cable to the other SATA connector. - Page 101 Replacing Assemblies If the instrument has the optional GPIB board, remove it from the PCIe slot. Figure 24 Disconnect the USB front touch screen cable from the USB connector on the motherboard. Figure 25 Disconnect the other connector (with the red wire) from the USB connector on the motherboard.

- Page 102 Replacing Assemblies Disconnect the PC power cable 4-pin connector from the motherboard. Figure 27 Disconnect the largest connector of the PC power cable from the connector on the motherboard. Figure 28 Disconnect the solid state drive SATA cable from the SATA connector on the motherboard.

- Page 103 Replacing Assemblies Disconnect the on/off cable and the display cable from the motherboard. Figure 30 Disconnect the USB 3.0 cable from the motherboard. Figure 31 Infiniium V-Series Oscilloscopes Service Guide...

- Page 104 Replacing Assemblies Remove the six screws from the motherboard. When replacing, torque the screws to 5 in-lbs using a power driver and T-10 bit. Figure 32 Slide the motherboard out, away from the chassis. Remove the support bracket from the bottom of the motherboard. Figure 33 To replace the motherboard, reverse these procedures.

- Page 105 Replacing Assemblies DANGER OF EXPLOSION WARNING If you replace the ADLINK lithium battery on the motherboard, there is a danger of explosion if the battery is incorrectly replaced. Replacement with only with the same or equivalent type recommended (BR2023 3V lithium). Discard used batteries according to manufacturer’s instructions.

-

Page 106: Removing And Replacing The Acquisition Boards/Backplane/Mso Assembly

Replacing Assemblies Removing and replacing the acquisition boards/backplane/MSO assembly Disconnect the power cable, top panel, and bottom panel as described previously. From the top side of the oscilloscope, remove the eight cables connected to the backplane board. One of these cables is the IC fan cable, circled in the photo below. - Page 107 Replacing Assemblies Using a hand screwdriver first and then a torque driver, loosen the two screws located at the bottom of the power supply and then push the power supply to the side to disengage its connection to the backplane board. With it pushed to the side, use a hand screwdriver to carefully start the screws back down into a set of new holes to keep the power supply in place when you flip the oscilloscope over in an upcoming step.

- Page 108 Replacing Assemblies Loosen the two screws near the motherboard and rear panel. One of the screws is circled below. Figure 38 Turn the oscilloscope upside down and remove the SMA connections to the bottom of the backplane board. When reconnecting, route these cables underneath the input cables.

- Page 109 Replacing Assemblies Disconnect the two Cal Out / Aux Out cables from the backplane board. Pull the cables straight back to remove them from the backplane board. Be sure to pull the cables straight back to avoid bending or breaking the connection to CAUTION the backplane board.

- Page 110 Replacing Assemblies Remove the attenuator power cable from each input channel attenuator and route the cable through the grommet in the backplane. The attenuators are keyed to match the connectors. Figure 42 Remove the rear panel BNCs. The bottom figure shows the rear panel of a DSO/DSA model with the hardware serial trigger option.

- Page 111 Replacing Assemblies Remove the two M4 screws from the top of the backplane board and two M4 screws from the rear of the oscilloscope. Figure 44 Ensure all cables are disconnected from the backplane board. Look from both the top and bottom of the oscilloscope to see and reach them all. Lift the entire acquisition/backplane assembly out of the chassis.

- Page 112 Replacing Assemblies The following figures show the removed assemblies in DSOV and DSAV models (first photo) and MSOV models (second photo). Figure 46 Digital channels Acquisition boards (MSO) board Backplane board Figure 47 Infiniium V-Series Oscilloscopes Service Guide...

-

Page 113: Removing The Backplane Assembly From The Acquisition Assembly

Replacing Assemblies Removing the backplane assembly from the acquisition assembly Remove the entire acquisition/backplane/MSO assembly as described in the previous section. Remove the four M4 screws (two on each side) from the rear panel of the assembly (six M4 screws if the oscilloscope has the hardware serial trigger option or is an MSO model, as shown below). - Page 114 Replacing Assemblies Disconnect the two attenuator cables shown below. Figure 50 Disconnect the two semi-rigid cables from the acquisition boards, circled below. Figure 51 Infiniium V-Series Oscilloscopes Service Guide...

- Page 115 Replacing Assemblies Remove the four M4 screws (two per acquisition assembly) on the side of the backplane assembly (six M4 screws if the oscilloscope has the hardware serial trigger option or is an MSO model, as shown below). Figure 52 Remove the top acquisition board (channels 3 and 4) first, carefully guiding the input cables through the slots.

- Page 116 Replacing Assemblies The following figure shows a DSO model with the top acquisition assembly removed. Figure 54 For oscilloscopes with the hardware serial trigger option, disconnect both of the SMP/SMP cables from the connectors on the serial trigger board and the acquisition board.

- Page 117 Replacing Assemblies Figure 56 Remove the bottom acquisition board (channels 1 and 2) from the backplane frame assembly. To reassemble the backplane/acquisition assembly, reverse this procedure. Infiniium V-Series Oscilloscopes Service Guide...

-

Page 118: Replacing The Backplane Board

Replacing Assemblies Replacing the backplane board The new backplane board does not come with an oscillator and splitter assembly or a backplane frame, so you will need to remove them from the old board and place them on the new board. Remove the backplane assembly from the acquisition assembly as described in the previous section. - Page 119 Replacing Assemblies Remove the 2 or 3 guide posts (3 for MSO and serial trigger boards) from the old backplane board using an open-end wrench. Install them onto the new board and torque to 5 in-lbs. Figure 58 Install the oscillator assembly into the backplane board, using the bracket to guide the orientation.

- Page 120 Replacing Assemblies Connect the cable from the oscillator to connector J303 on the backplane board. Figure 60 Connect the SR oscillator reference cable to its connector on the oscillator Reference IN connector. Torque to 8 in-lbs using a hand torque wrench. Figure 61 Infiniium V-Series Oscilloscopes Service Guide...

- Page 121 Replacing Assemblies Connect one end of the semi-rigid SR Backplane Clock Out cable to connector J300 on the backplane board, and the other end to the clock splitter as shown. Torque both ends to 8 in-lbs. The semi-rigid cable must be installed correctly as shown below.

- Page 122 Replacing Assemblies Connect the SR Clock CH1 + CH2 cable to its connector closest to the edge of the splitter. Finger tighten. Connect the SR Clock CH3 + CH4 cable to its connector on the splitter, closest to the fan. Finger tighten. Figure 64 Dress both cables toward the outside edge.

-

Page 123: Replacing An Acquisition Board

Replacing Assemblies Replacing an acquisition board New acquisition boards do not come with input cables or an acquisition frame, so you will need to remove them from the old board and place them on the new one. Remove the acquisition assembly from the backplane assembly as described earlier. - Page 124 Replacing Assemblies Slide the heat shrink with the cable part number toward the SMPM connector as far as it will go for cable input. Figure 67 For the following steps, be careful not to crimp or pinch the input cables. Also, to CAUTION ensure the weight of the assembly does not rest on the cables, support the tray from underneath.

- Page 125 Replacing Assemblies Snap the SMPM connector into its mating connector on the Oak module (U34000). Use needle-nosed pliers to guide the right-angle SMPM into place. You will hear a double-snap sound when the connector is properly seated. Figure 69 Repeat the previous step for the second input cable. Figure 70 Press the cables gently to relieve possible strain on the connections.

-

Page 126: Setting The Calibration Factors After Replacing An Acquisition Board

Replacing Assemblies Setting the calibration factors after replacing an acquisition board After replacing an acquisition board you must perform a service calibration, including the interleave response correction, and then perform a self test procedure. Refer to Chapter 2, “Calibration”, for details. The oscilloscope under test must be warmed up (with the oscilloscope application running) for N OTE at least 30 minutes prior to the start of any calibration or test. -

Page 127: Removing And Replacing The Hard Disk Drive

Replacing Assemblies Removing and replacing the hard disk drive Loosen the two screws on back of the hard disk drive. Figure 72 Pull the hard drive out. Figure 73 Remove the four screws connecting the disk drive to the plate. To replace the hard disk drive, reverse this procedure. -

Page 128: Removing And Replacing The Power Supply

Replacing Assemblies Removing and replacing the power supply SHOCK HAZARD! If the power supply is defective it could have a dangerous charge WARNING on some capacitors. This charge could remain for many days after removing power from the supply. Disconnect the power cable and remove the top panel as described previously. Disconnect the AC power cable from the bulk 12 V power supply. -

Page 129: Removing And Replacing Fans

Replacing Assemblies Removing and replacing fans AVOID INJURY! The fan blades are exposed both inside and outside the chassis. WARNING Disconnect the power cable before working around the fan. Remove the top panel, bottom panel, and front panel as described earlier. Remove the four M3 screws (2 from each side) connected to the fan bracket. - Page 130 Replacing Assemblies To replace a fan, reverse this procedure. AVOID OVERHEATING THE OSCILLOSCOPE. When replacing the fan, be sure the CAUTION direction of the fan air flow is coming from the inside to the outside of the oscilloscope. Check the flow arrows on the fan and check for proper flow once power is applied to the oscilloscope.

-

Page 131: Removing And Replacing The Optional Gpib Port

Replacing Assemblies Removing and replacing the optional GPIB port Disconnect the power cable and remove the top panel. Remove the screw from the top edge of the chassis. Pull the port out of the slot. Figure 78 If you are replacing the GPIB port with a new one (82351B or newer), you will need to use a N OTE V-Series Profile Bracket (54919-00105). - Page 132 Replacing Assemblies Infiniium V-Series Oscilloscopes Service Guide...

-

Page 133: Replaceable Parts

Keysight Infiniium V-Series Oscilloscopes Service Guide 6 Replaceable Parts Ordering Replaceable Parts Exploded Views Replaceable Parts List This chapter describes how to order replaceable assemblies and parts for the Infiniium V-Series oscilloscopes. Service support for this oscilloscope is replacement of parts to the assembly level. -

Page 134: Ordering Replaceable Parts

Replaceable Parts Ordering Replaceable Parts Listed Parts To order a part in the parts list, quote the Keysight Technologies part number, indicate the quantity desired, and address the order to the nearest Keysight Technologies Sales Office. Unlisted Parts To order a part not listed in the parts list, include the oscilloscope part number, oscilloscope serial number, a description of the part (including its function), and the number of parts required. -

Page 135: Exploded Views

Replaceable Parts Exploded Views MP21 MP20 MP19 MP18 MP10 MP17 MP11 MP16 MP12 MP13 MP14 MP15 Front frame and front panel Infiniium V-Series Oscilloscopes Service Guide... - Page 136 Replaceable Parts MP27 MP26 MP28 MP22 MP24 MP23 MP25 Fan and acquisition assembly Infiniium V-Series Oscilloscopes Service Guide...

- Page 137 Replaceable Parts MP29 MP30 MP31 MP32 Power supply and PC motherboard Infiniium V-Series Oscilloscopes Service Guide...

- Page 138 Replaceable Parts MP41 MP33 MP34 MP35 MP40 MP36 MP37 MP38 MP39 External parts Infiniium V-Series Oscilloscopes Service Guide...

-

Page 139: Replaceable Parts List

Replaceable Parts Replaceable Parts List The following table is a list of replaceable parts. The information given for each part includes: • Reference designation in exploded views • Keysight part number • Total quantity (QTY) in the oscilloscope or an assembly •... - Page 140 Replaceable Parts Replaceable parts Ref. Des Part number Description 1813-2449 Crystal - oscillator 10 GHz with cable 54919-66413 PCA - PCIe to SATA paddle board 3160-4454 Fan with heat sink 54919-66515 Motherboard - 16 GB with modified BIOS bits (Without Audio) 54964-83515 Imaged 480 GB SSD...

- Page 141 Replaceable Parts Replaceable parts Ref. Des Part number Description MP4, 54932-47400 Outer and Inner Clutch Assembly 54916-42001 Casting - probe mate 54932-47450 Knob - 18 mm slate plain 54932-47410 Knob - 18 mm slate yellow 54932-47420 Knob - 18 mm slate green MP10 54932-47430 Knob - 18 mm slate blue...

- Page 142 Replaceable Parts Replaceable parts Ref. Des Part number Description MP32 54904-41202 Clamp - SATA MP33 54919-21002 Foot - rear MP34 54919-04108 Cover - serial trigger MP35 54916-04107 Cover - serial (blank) MP36 54919-24902 Handle MP37 54919-00206 Panel - bottom MP38 54916-41001 Foot - tilt base MP39...

- Page 143 Replaceable Parts Replaceable parts Ref. Des Part number Description N2815-68701 Cable - serial card 8121-2445 Cable - SATA straight to straight, red 8121-2446 Cable - SATA straight to straight, blue 54919-61607 Cable - USB 3.0 54919-61609 Cable - backlight 54919-61618 Cable - AC input 54916-68716 Connector assembly - SMA female to female (kit of 5)

- Page 144 Replaceable Parts Replaceable parts Ref. Des Part number Description 8120-1632 Power cord - China 8121-1660 Power cord - Thailand 8121-1858 Power cord- Brazil 8121-1636 Power cord - Taiwan 8121-1640 Power cord - Cambodia 54919-00105 V-Series Profile Bracket Infiniium V-Series Oscilloscopes Service Guide...

-

Page 145: Theory Of Operation

Keysight Infiniium V-Series Oscilloscopes Service Guide 7 Theory of Operation Motherboard assembly Acquisition assembly Backplane assembly Front Panel Assembly Power Supply Assembly MSO assembly Hardware Serial Trigger Assembly... - Page 146 Theory of Operation Pwr Conn Sig Conn Pwr Conn Sig Conn V-Series oscilloscope block diagram Infiniium V-Series Oscilloscopes Service Guide...

-

Page 147: Theory Of Operation

Theory of Operation Theory of Operation This chapter describes the basic structure of the Infiniium V-Series oscilloscope and how the parts interact. The oscilloscopes are comprised of five or six main assemblies, depending on the model: a motherboard assembly, an acquisition assembly, a backplane assembly, a front panel assembly, and a power supply assembly for all models, plus a Mixed Signal Oscilloscope (MSO) assembly for all MSO models. -

Page 148: Motherboard Assembly

Theory of Operation Motherboard assembly The motherboard assembly provides all system control and interface functions for the oscilloscope. The motherboard contains a microprocessor, a hard disk drive interface, ROM, RAM, keyboard and mouse interfaces, connections to the front panel board, and serial and parallel interfaces. Pressing the on/off button sends a signal to the motherboard. -

Page 149: Acquisition Assembly

Theory of Operation Acquisition assembly The acquisition assembly consists of two identical acquisition boards. These two boards connect to the backplane board as shown below. Backplane assembly Top: Ch 3 & 4 Acquisition boards Bottom: Ch 1 & 2 Acquisition and backplane assemblies The upper acquisition board circuitry samples, digitizes, and stores the signals for channels 3 and 4;... - Page 150 Theory of Operation To Trigger (on backplane) Power and Control Memory Trigger Attenuator Coax Preamp Memory Sampler Attenuator Coax Preamp Trigger Memory Power and Control Oak Module To Trigger (on backplane) Memory Coax Differential Signal Coupler 10 GHz Clock Acq FPGA Oak B module and acquisition components The acquisition front end starts at the front panel input connectors, then goes through the attenuators, cabling, and Oak B module.

-

Page 151: Backplane Assembly

Theory of Operation Backplane assembly The backplane assembly is a device on the PCI Express (PCIe) bus connected by two SATA cables that connect to a PCIe-to SATA adapter board that is connected to the motherboard. The backplane assembly receives +12 V DC power through a power interface board from the bulk supply, and all voltages are derived from switching power regulators and other circuitry. - Page 152 Theory of Operation Main FPGA The main FPGA is the only communication link from the oscilloscope hardware to the PC system. All system controls and data pass through the main FPGA. The following figure shows the connections to the main FPGA. Config Memory Memory...

- Page 153 Theory of Operation The main FPGA can be used to control peripherals and fan speed, configure and communicate with other FPGAs, and pass sampled data to the PC for reconstruction of the measured waveform on the oscilloscope display. In addition, the FPGA generates PCI interrupts for all oscilloscope-related special events such as a front-end overload or a stopped cooling fan.

- Page 154 Theory of Operation Time Base PS Filter Memory controller Preamp/ Sampler/ Splitter Trigger Hybrid Trig[3:2] PS Filter Memory controller Preamp/ Sampler/ Splitter Trigger Hybrid Master Trig[1:0] Ext 10 MHz Ref SampClk[2] 10 GHz (10GHz CW) Clock Power coax coax Splitter Splitter RefClk TbClk (1GHZ CW)

- Page 155 Theory of Operation SysTrig is the primary output from the trigger system. It is synchronous to the trigger event and asynchronous to the time base clock, TbClk. Wahoo synchronizes SysTrig to the timebase clock with low probability of metastability, producing the TbTrig signal. TbTrig pulses high once immediately after every rising edge of SysTrig.

- Page 156 Theory of Operation circuit consisting of a detector diode and a non-inverting op-amp gain stage followed by a window comparator ensures the user supplies a 10 MHz signal of the correct amplitude (-5 dBm minimum to +10 dBm maximum). The detector circuit produces a warning if the external reference input signal is too small or too large, but not if the signal is within the specified operating range.

-

Page 157: Front Panel Assembly

Theory of Operation Front Panel Assembly The front panel assembly consists of a front panel board, on/off board, display board, touch screen and controller, AutoProbe II interface board for probe power and probe control, backlight inverter board, front panel connectors, and cabling connectors for the AutoProbe II interface. -

Page 158: Power Supply Assembly

Theory of Operation Power Supply Assembly The power supply assembly consists of a power interface board and a bulk +12 V power supply. The power interface board does filtering and provides a 60 Hz line trigger to the oscilloscope. Infiniium V-Series Oscilloscopes Service Guide... -

Page 159: Mso Assembly

Theory of Operation MSO assembly The MSO assembly consists of a printed circuit assembly that fits below the lower acquisition board. It provides digital channel capability. The first figure below shows the circuitry of the MSO board. The second figure shows how the FPGA on the MSO board communicates with the Main FPGA on the backplane board. - Page 160 Theory of Operation Config PROM JTAG Conn JTAG Conn MSO Board Philips PCIe SATA Cables Conn Main 1011A FPGA FPGA Trigger FPGA Misc I/Cs Backplane Board MSO board FPGA Infiniium V-Series Oscilloscopes Service Guide...

-

Page 161: Hardware Serial Trigger Assembly

Theory of Operation Hardware Serial Trigger Assembly The optional hardware serial trigger assembly consists of a printed circuit assembly that fits below the lower acquisition board. Available for DSO and DSA models, it provides the capability for users to trigger on a specific portion of a serial stream of data at up to 12.5 Gbps. - Page 162 Theory of Operation Infiniium V-Series Oscilloscopes Service Guide...

- Page 164 This information is subject to change without notice. © Keysight Technologies, Inc. 2015-2017, 2021, 2022 Eighth edition, July 2022 *54919-97018* 54919-97018 www.keysight.com...

Need help?

Do you have a question about the Infiniium V Series and is the answer not in the manual?

Questions and answers