Summary of Contents for Beckhoff AMP8500

- Page 1 Operating instructions | EN AMP8000 and AMP8500 Distributed servo drives 11/15/2022 | Version 1.1...

-

Page 3: Table Of Contents

Version numbers............................... 7 Scope of the documentation .......................... 7 Staff qualification .............................. 8 Safety and instruction ............................. 10 Explanation of symbols........................... 10 Beckhoff Services ............................ 12 For your safety.............................. 13 Safety pictograms ............................ 13 General safety instructions .......................... 16 Product overview............................... 18 AMP8620 ................................ - Page 4 Assembly tool AF27............................ 100 Decommissioning............................ 101 Disassembly .............................. 101 Disposal ................................ 102 Guidelines and Standards .......................... 103 Standards .............................. 103 Guidelines.............................. 104 EU conformity ............................... 105 CCC conformity ............................ 105 UL certification .............................. 106 Index ................................. 107 ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 5: Documentation Notes

Documentation notes Disclaimer Beckhoff products are subject to continuous further development. We reserve the right to revise the operating instructions at any time and without prior announcement. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in these operating instruc- tions. - Page 6 • Use of untrained personnel • Use of unauthorized spare parts Copyright © Beckhoff Automation GmbH & Co. KG, Germany 1.1.4 The copying, distribution and utilization of this document as well as the communication of its contents to others without express autho- rization is prohibited.

-

Page 7: Version Numbers

Product features Only the product properties specified in the current operating in- structions are valid. Further information given on the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative. Scope of the documenta- Apart from these operating instructions, the following documents are... -

Page 8: Staff Qualification

Trained special- ists can: • apply relevant standards and directives • assess tasks that they have been assigned • recognize possible hazards • prepare and set up workplaces ─── AMP8000 and AMP8500 Version: 1.1... - Page 9 • independently recognize, avoid and eliminate sources of danger • implement specifications from the accident prevention regula- tions • assess the work environment • independently optimize and carry out their work Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 10: Safety And Instruction

1.6.1 DANGER Failure to observe will result in serious or fatal injuries. WARNING Failure to observe may result in serious or fatal injuries. CAUTION Failure to observe may result in minor or moderate injuries. ─── AMP8000 and AMP8500 Version: 1.1... - Page 11 In the case of documentation on a monitor screen, use the zoom function to enlarge the QR code and reduce the distance. Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 12: Beckhoff Services

Beckhoff and the worldwide partner companies offer comprehensive support and service. Support The Beckhoff Support offers technical advice on the use of individ- ual Beckhoff products and system planning. The employees support 1.7.1 you in the programming and commissioning of complex automation systems. -

Page 13: For Your Safety

Safety pictograms On Beckhoff products you will find attached or lasered safety pic- tograms, which vary depending on the product. They serve to pro- tect people and to prevent damage to the products. Safety pic- tograms must not be removed and must be legible for the user. - Page 14 For your safety Coupling module 2.1.2 2.1.2 Warning of high voltage! The DC link on the coupling modules can carry a life-threatening voltage of over 848 V ─── AMP8000 and AMP8500 Version: 1.1...

- Page 15 60 °C. Allow the motor housing to cool for at least 15 minutes. Avoid shocks to the shaft Impacts on the shaft may cause the maximum permissible axial and radial values to be exceeded. Optical encoder systems can thus be destroyed. Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 16: General Safety Instructions

Observe tightening torques Mount and repeatedly check connections and components, comply- ing with the prescribed tightening torques. Use the original packaging only Use the original packaging for dispatch, transportation, storage and packing. ─── AMP8000 and AMP8500 Version: 1.1... - Page 17 De-energize and switch off components before working on them 2.2.3 Check the functionality of all safety-relevant devices. Secure the working environment. Secure the machine or plant against being in- advertently started up. Observe the chapter: "Decommissioning". Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 18: Product Overview

X20 and X21: fieldbus output for EtherCAT P; M8 Display of the status LEDs Pressure compensation element Ground connection X40 to X44: AMP8000 system output B23 Only for AMP8620-2005-0200 [+]: X71: connection for external brake resistor X01: connection of the supply network ─── AMP8000 and AMP8500 Version: 1.1... - Page 19 Product overview Name plate 3.1.1 3.1.1 Item number Explanation Product name Order number Beckhoff Traceability Number, BTN Input voltage Nominal input current Input frequency Nominal output voltage Nominal output current Output control voltage Maximum output control current Maximum ambient temperature...

- Page 20 05 = 5 outputs Version 0 = standard Braking resistor 0 = no brake resistor 1 = mounted brake resistor 2 = external brake resistor Input voltage range 0 = 3 x 400…480 V Not defined ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 21: Amp8805

Product overview AMP8805 Item number Explanation Housing X20: fieldbus output EtherCAT P; M8 Status LEDs Pressure compensation elements Ground connection X40 to X44: AMP8000 system output B23 X02: AMP8000 system input B23 Version: 1.1 AMP8000 and AMP8500 ───... - Page 22 Product overview Name plate 3.2.1 3.2.1 Item number Explanation Product name Order number Beckhoff Traceability Number; BTN Input voltage Nominal input current Nominal output voltage Nominal output current Output control voltage Maximum output control current Maximum ambient temperature Protection rating...

- Page 23 05 = 5 outputs Number of M8-EtherCAT P outputs 1 = 1 output Not defined DC link voltage 0 = 430…848 V Not defined Version 0 = standard Nominal input current 0 = 20 A Not defined Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 24: Ax883X

AX-Bridge: quick coupling of the DC link and the functional earth AX8832: X02: AMP8000 system output; L/A LED AX8832: X01: AMP8000 system output; L/A LED AX8831: X01: AMP8000 system output; L/A LED Grounding bolt AX bridge: DC link; FE AX bridge: 24 V ─── AMP8000 and AMP8500 Version: 1.1... - Page 25 Name plate 3.3.1 3.3.1 Item number Explanation Product name Order number Beckhoff Traceability Number; BTN Input supply Maximum DC link voltage / nominal output current Nominal control voltage / nominal output voltage Maximum ambient temperature Protection rating EtherCAT conformity cURus approval...

-

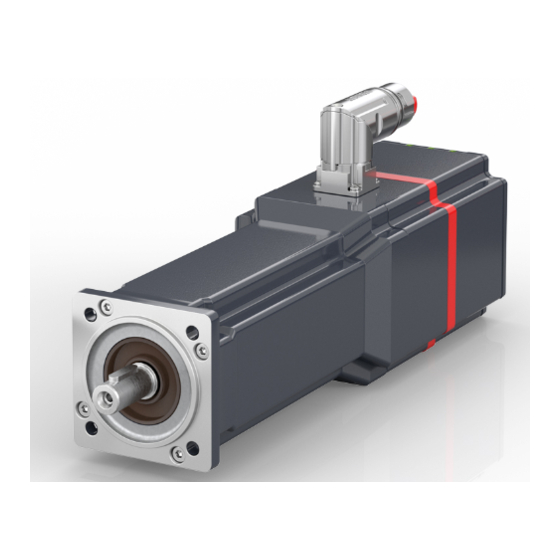

Page 26: Amp80Xx

Product overview AMP80xx Item number Explanation Housing Radial shaft-sealing ring [+] AMP8000 system input B23 Status LEDs: Link/Activity, Run, AXIS Motor shaft ─── AMP8000 and AMP8500 Version: 1.1... - Page 27 Maximum input voltage and power Standstill torque Nominal speed at 400 V AC supply voltage Protection rating Ambient temperature cURus approval TÜV test mark DataMatrix code with Beckhoff TN CE conformity EAC approval Country of manufacture Disposal according to WEEE directive Version: 1.1 AMP8000 and AMP8500...

- Page 28 2 = Multi-turn absolute encoder, resolution 24-bit, STO, SS1 3 = Single-turn absolute encoder, resolution 24-bit, extended safety functions 4 = Multi-turn absolute encoder, resolution 24-bit, extended safety functions Holding brake 0 = without holding brake 1 = with holding brake ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 29: Amp8040

Nominal output voltage Nominal output current Output frequency range Ambient temperature Protection rating EtherCAT conformity Disposal according to WEEE directive cULus approval EAC approval Country of manufacture CE conformity DataMatrix code with Beckhoff TN Version: 1.1 AMP8000 and AMP8500 ───... - Page 30 Distributed servo drive; flange size 4 Safety functions 0 = no safety functions 1 = STO 3 = extended safety functions Version 1 = special version Dual Use 0 = limitation 599 Hz 8 = no limitation Variant number ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 31: Product Characteristics

3000 rpm with a maximum of three times the in- trinsic inertia of the motor. These maximum values may vary due to increased load inertia. The function check of the holding brake can be performed with a torque wrench or with TwinCAT Scope. Version: 1.1 AMP8000 and AMP8500 ───... -

Page 32: Ordering Options

Safe speed range Safe maximum speed Position functions Safely-limited position Safe cam Safely-limited increment Acceleration functions Safe acceleration range Safe maximum acceleration Direction of rotation functions SDIp Safe direction positive SDIn Safe direction negative ─── AMP8000 and AMP8500 Version: 1.1... - Page 33 Safely-limited position Safe cam Safely-limited increment Acceleration functions Safe acceleration range Safe maximum acceleration Direction of rotation functions SDIp Safe direction positive SDIn Safe direction negative Brake functions Safe brake control Safe brake test Version: 1.1 AMP8000 and AMP8500 ───...

- Page 34 DIN ISO 21940-32:2012-08. Holding brake 3.7.3 3.7.3 A holding brake blocks the rotor in the de-energized state. The hold- ing brake increases the motor length and the rotor moment of iner- tia. ─── AMP8000 and AMP8500 Version: 1.1...

- Page 35 Compressed air re- according to DIN ISO 8573-1 Class 3:2010 quirement [A:B:C] Operating pressure 0.1 ± 0.05 bar Maximum pressure 0.3 bar Air connection Quick-release coupling Required air line e.g. PA hose 6 mm x 4 mm Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 36: Intended Use

• Areas with ionizing radiation and nuclear plants • Aerospace industry • Product areas that are not protected from abrasion The relevant standards and directives for EMC interference emis- sions must be complied with in residential areas. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 37: Dual Use

According to the published EU Regulation 1382/2014, commercially available frequency converters are categorized as products with a double purpose of use. This makes the Beckhoff AMP8000 distrib- uted servo drive system one of the dual-use products. The goods list, Annex 1 of the Dual Use directive 428/2009 has been amended accordingly: •... -

Page 38: Technical Data

S1 for an unlimited period of time. Voltage constant K [mVmin] Erms Indication of the induced motor EMF at 20 °C, based on 1000 rpm. This is specified as the sine RMS value between two terminals. ─── AMP8000 and AMP8500 Version: 1.1... - Page 39 Release delay time / application delay time of the holding brake t [ms]/t [ms] Specification of the response times of the holding brake [+] when operated with the nominal voltage Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 40: Data For Operation And Environment

AMP8000 distributed servo drive sys- tem. Beckhoff products are designed for operation under certain environ- mental conditions, which vary according to the product. The follow- ing specifications must be observed for operation and environment in order to achieve the optimum service life of the products. -

Page 41: Amp8620

∑ max. 20 Braking resistor Installation integrated external Continuous braking 1600 power [W] Mechanical data AMP8620 -2005-0000 -2005-0100 -2005-0200 Weight [kg] 8.70 Protection rating IP 65 Protection rating con- NEMA 12 forms to UL Version: 1.1 AMP8000 and AMP8500 ───... - Page 42 Technical data Dimensional drawing • All figures in millimeters 4.3.1 AMP8620-2005-0000 4.3.1.1 4.3.1.1 ─── AMP8000 and AMP8500 Version: 1.1...

- Page 43 Technical data AMP8620-2005-0100 4.3.1.2 4.3.1.2 Version: 1.1 AMP8000 and AMP8500 ───...

- Page 44 Technical data AMP8620-2005-0200 4.3.1.3 4.3.1.3 ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 45: Amp8805

Output current [A ∑ max. 20 Mechanical data AMP8805-1000-0000 Weight [kg] 4.50 Protection rating IP 65 Protection rating conforms to UL NEMA 12 Dimensional drawing • All figures in millimeters 4.4.1 AMP8805-1000-0000 4.4.1.1 4.4.1.1 Version: 1.1 AMP8000 and AMP8500 ───... -

Page 46: Ax883X

Nominal output current 24 VDC [A 2 x 10 DC link voltage [V 430…848 Mechanical data AX8831 AX8832 Weight [kg] 1.80 1.90 Protection rating IP20 IP20 Dimensional drawing • All figures in millimeters 4.5.1 AX8831-0000-0000 4.5.1.1 4.5.1.1 ─── AMP8000 and AMP8500 Version: 1.1... - Page 47 Technical data AX8832-0000-0000 4.5.1.2 4.5.1.2 Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 48: Amp803X And Amp853X

5.20 Flange according to IEC DIN 42955 Tolerance class Protection rating Standard housing version IP65 Standard shaft feedthrough IP54 / IP20 in mounting position V3 version Shaft feedthrough with ra- IP65 dial shaft-sealing ring ─── AMP8000 and AMP8500 Version: 1.1... - Page 49 Optional holding brake [+] AMP80xx AMP85xx Holding torque at 120 °C [Nm] Supply voltage U 24; +6 % to -10 % Electrical power P Current I 0.33 0.36 0.33 Release delay time t [ms] Application delay time t [ms] Version: 1.1 AMP8000 and AMP8500 ───...

- Page 50 Technical data Dimensional drawing • All figures in millimeters 4.6.1 Motor type Z with holding brake AMP8031-xxxx-1001 225.0 mm 264.5 mm AMP8032-xxxx-1001 250.5 mm 290.0 mm AMP8033-xxxx-1001 276.0 mm 325.0 mm AMP8531-xxxx-1001 264.5 mm 290.0 mm AMP8532-xxxx-1001 290.0 mm 325.0 mm AMP8533-xxxx-1001 325.0 mm 360.0 mm ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 51: Amp804X And Amp854X

6.20 [kg] Weight with brake [kg] 4.90 7.10 Flange according to IEC DIN 42955 Tolerance class Protection rating Standard housing ver- IP65 sion Standard shaft IP54 / IP20 in mounting position V3 feedthrough version Version: 1.1 AMP8000 and AMP8500 ───... - Page 52 Without holding brake Control voltage input 18 to 31 Current consumption of 0.19 the control voltage [A With holding brake Control voltage input 21.6 to 25.4 Current consumption of 0.99 the control voltage [A ─── AMP8000 and AMP8500 Version: 1.1...

- Page 53 Technical data Dimensional drawing • All figures in millimeters 4.7.1 Motor type Z with holding brake AMP8041 225.5 mm 273.0 mm AMP8042 255.5 mm 303.0 mm AMP8043 285.5 mm 333.0 mm AMP8541 273.0 mm 303.0 mm AMP8542 303.0 mm 333.0 mm AMP8543 333.0 mm 363.0 mm Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 54: Amp805X & Amp855X

Weight with brake [kg] 6.30 9.80 11.50 11.2 Flange according to IEC DIN 42955 Tolerance class Protection rating Standard housing ver- IP65 sion Standard shaft IP54 / IP20 in mounting position V3 feedthrough version ─── AMP8000 and AMP8500 Version: 1.1... - Page 55 Without holding brake Control voltage input 18 to 31 Current consumption of 0.19 the control voltage [A With holding brake Control voltage input 21.60 to 25.40 Current consumption of 0.99 the control voltage [A Version: 1.1 AMP8000 and AMP8500 ───...

- Page 56 Dimensional drawing • All figures in millimeters 4.8.1 Motor type Z with holding brake AMP8051 230.0 mm 277.0 mm AMP8052 263.0 mm 310.0 mm AMP8053 296.0 mm 345.0 mm AMP8054 329.0 mm 378.0 mm AMP8551 277.0 mm 310.0 mm AMP8552 310.0 mm 345.0 mm AMP8553 345.0 mm 378.0 mm ─── AMP8000 and AMP8500 Version: 1.1...

-

Page 57: Scope Of Supply

AMP8620 and AX883x AMP8805 and AMP8000 Depending on the application, the scope of delivery may consist of different components. Please check the delivery: Components Connector AMP8620-2005-0200 Mating connector including crimp contacts Connection for external brake resistor Version: 1.1 AMP8000 and AMP8500 ───... -

Page 58: Packaging

Depth [mm] AMP (with brake) Dimension 803x- 8033- 8041- 804x- 805x- 8054- 8531- 853x- 584x- 855x- 8553- xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 xxx1 Height [mm] Width [mm] Depth [mm] ─── AMP8000 and AMP8500 Version: 1.1... -

Page 59: Transport And Storage

Do not remove the yellow protective cap on the drive shaft of the distributed servo drive. The protective cap protects against mechanical damage and envi- ronmental influences. If you remove the protective cap, the shaft may be damaged. Version: 1.1 AMP8000 and AMP8500 ───... -

Page 60: Conditions

14 per layer; 7 layers per pallet AMP804x-xxxx AMP853x-xxxx AMP8531-xxx1 AMP8541-xxx0 AMP8033-xxx1 9 per layer; 6 layers per pallet AMP804x-xxx1 AMP805x-xxxx AMP8533-xxx0 AMP853x-xxx1 AMP854x-xxx0 AMP854x-xxx1 AMP8054-xxx1 4 per layer; 4 layers per pallet AMP8553-xxx1 ─── AMP8000 and AMP8500 Version: 1.1... -

Page 61: Transport

High mechanical stresses will damage the distributed servo drive system and individual components. AMP8000 Transport of the components of the distributed servo drive system of the AMP8000 series without aids. 6.2.1 Version: 1.1 AMP8000 and AMP8500 ───... -

Page 62: Long-Term Storage

Prevent the formation of condensation Keep the ambient temperature constant. Avoid solar radiation and high air humidity. Condensation water can lead to damage during subsequent opera- tion or to rust formation. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 63: Technical Description

If you do not observe the maintenance intervals, the motor may overheat depending on the installation position. Ingress and leak- age of liquids may damage the motor. The standard installation position of the motors is the design IM B5 according to DIN 60034-7. Version: 1.1 AMP8000 and AMP8500 ───... -

Page 64: Dimensioning

7.2.1 Module combination Maximum cable length [m] AMP8620 with AMP8805 AMP8805 with AMP8805 AX883x with AMP8805 AMP8620 with AMP80xx AMP8805 with AMP80xx AX883x with AMP80xx AMP8620 with AMP85xx AMP8805 with AMP85xx AX883x with AMP85xx ─── AMP8000 and AMP8500 Version: 1.1... -

Page 65: Wide Voltage Range

Single-phase Three-phase supply networks supply networks Japan 1 x 100 V 3 x 200 V North Amer- 1 x 115 V 3 x 480 V Europe 1 x 230 V 3 x 400 V Version: 1.1 AMP8000 and AMP8500 ───... -

Page 66: Display

No 24 V power supply at outputs X20/X21 L/A = Link/Activity to display the communication state Status LINK: connection to the con- nected EtherCAT module Flashes ACT: communication with con- nected EtherCAT module No connection to the connected EtherCAT module ─── AMP8000 and AMP8500 Version: 1.1... - Page 67 No 24 V power supply at output L/A = Link/Activity to display the communication state Status LINK: connection to the con- nected EtherCAT module Flashes ACT: communication with con- nected EtherCAT module No connection to the connected EtherCAT module Version: 1.1 AMP8000 and AMP8500 ───...

- Page 68 Flashes quickly The axis is disabled and is being initialized Flashes slowly The axis is disabled and error- free No 24 V connection or the axis is in the EtherCAT operating state INIT or Error ─── AMP8000 and AMP8500 Version: 1.1...

- Page 69 AX883x L/A = Link/Activity to display the communication state 7.4.3.1 Status LINK: connection to the con- nected EtherCAT module Flashes ACT: communication with con- nected EtherCAT module No connection to the connected EtherCAT module Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 70: Mechanical Installation

Note that when dimensioning you may have to mount input filters, mains chokes and brake resistors for your application. Appropriate space should be provided for these components, so that adequate ventilation is ensured. ─── AMP8000 and AMP8500 Version: 1.1... - Page 71 The following figure shows recommended dimensions that you should observe when mounting the coupling module on the machine or plant: Item number Explanation Machine or plant Conductive and galvanized mounting plate Cable channel Cable channel Version: 1.1 AMP8000 and AMP8500 ───...

- Page 72 8.1.1 Power supply modules and dis- Information is given in the figure below on how to make tapped 8.1.1.1 tribution modules holes in accordance with the drilling pattern. ─── AMP8000 and AMP8500 Version: 1.1...

- Page 73 Mechanical installation Coupling modules Beckhoff universal drilling pattern 8.1.1.2 You have the possibility – at any time and without having to drill new holes – to change the configuration of the coupling modules if you provide the mounting plate with the universal drilling pattern.

-

Page 74: Modules

► Guide the screws [1] through the rectangular cut-outs in the module housing [2] ► Screw all the screws tight in the elongated holes in the module housing ► Observe tightening torques: Components Tightening torque [Nm] Screws M5 x 5 Strength class 8.8 ─── AMP8000 and AMP8500 Version: 1.1... - Page 75 [2] ► Bay further modules and screw all remaining screws tight on the module housings ► Observe tightening torques: Components Tightening torque [Nm] Screws M5 x 5 Strength class 8.8 Version: 1.1 AMP8000 and AMP8500 ───...

- Page 76 [1] and place them in the 90° position ► Slide all bars [2] for the AX bridge to the left ► Close all quick connectors again The modules are now connected to one another. ─── AMP8000 and AMP8500 Version: 1.1...

- Page 77 • AMP8620: M5 x 145 mm • AMP8805: M5 x 85 mm ► Prepare support with drilling pattern ► Place the module [1] on the respective support [2] according to the drilling pattern ► Insert and tighten the screws [3] Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 78: Drives

Ensure adequate grounding via the protective conductor The thermal connection of the motor flange determines the power loss. Ensure adequate grounding via the protective conductor or the mo- tor flange. ─── AMP8000 and AMP8500 Version: 1.1... - Page 79 A side; shaft output side of the distributed servo drive. Oscillatory bearing movements < 180 ° shaft rotation are not permissible. Use the Beckhoff load/force calcu- lator for a detailed calculation of the bearing forces on the motor shaft.

- Page 80 ► Insert washer [3] with screw [4] of strength class 8.8 and nut [5] into the locking thread [6] of the motor shaft ► Tighten nut [5] The output element is pulled onto the motor shaft by the nut. ─── AMP8000 and AMP8500 Version: 1.1...

- Page 81 ► Screw puller [3] and intermediate disc [2] into the locking thread of the motor shaft ► Place the puller fully on the drive element [1] ► Pull the output element [1] with the puller [3] from the motor shaft Version: 1.1 AMP8000 and AMP8500 ───...

-

Page 82: Electrical Installation

The project planning is the detailed planning of your drivetrain. Tak- ing into account various views, you can design your drive system with the help of the following information. Please note that this sup- port is only an example. ─── AMP8000 and AMP8500 Version: 1.1... - Page 83 The Beckhoff software "TC Motion Designer" is avail- able for energy management purposes. Drivetrain...

-

Page 84: Connection

Electrical installation Connection Beckhoff offers various power connectors. All plugs are IP65 rated. A protective conductor connection according to VDE 0627 is pro- vided on the housing. The following tables show the pin assignment of the input connector on the motor side: 9.2.1... -

Page 85: Fieldbus System

• X40 to X44 connection on the AMP8620 power supply module and the AMP8805 distribution module 9.5.1 Terminal point Connection TX+; GND RX+; GND RX-; U TX-; U 24 V -DC Link +DC Link GND; 24V Version: 1.1 AMP8000 and AMP8500 ───... -

Page 86: System Input

For the connection of an external brake resistor, the optional con- nection X71 is available for the AMP8620 power supply module. • X71 connection on the AMP8620 power supply module 9.7.1 Terminal point Connection -DC Link / +DC Link ─── AMP8000 and AMP8500 Version: 1.1... -

Page 87: Supply Networks

The AMP8620 power supply modules are equipped with a wide- range voltage input and can be connected to the following voltage systems: • Three-phase 3 x 400 to 480 -20% Version: 1.1 AMP8000 and AMP8500 ───... - Page 88 IEC 60309-2 KU = 6 Achieved in relation to interruption: With permanently connected conductors ≥ 10 mm ; the type of connection and routing must comply with the standards applicable to PE conductors ─── AMP8000 and AMP8500 Version: 1.1...

- Page 89 Electrical installation Three-phase connection 9.8.1 TN network 9.8.1.1 9.8.1.1 TT network 9.8.1.2 9.8.1.2 Version: 1.1 AMP8000 and AMP8500 ───...

- Page 90 The AMP8000 distributed servo drive system and the components can be damaged if this is ignored. Asymmetrically grounded net- 9.8.1.3 9.8.1.3 work with star point Asymmetrically grounded delta 9.8.1.4 9.8.1.4 network IT delta network 9.8.1.5 9.8.1.5 ─── AMP8000 and AMP8500 Version: 1.1...

- Page 91 Motion Designer Check the isolating transformer power rating with the design soft- ware TC3 Motion Designer. This can be found on the Beckhoff homepage: • TC3 Motion Designer The power supply modules are assigned to the isolating transform- ers in the following tables.

-

Page 92: Fuse Protection

For alternatives to the UL fuses of the class "J", be sure to refer to the UL standard "UL 508A, chapter SB4.2.3, exception no.1". External fuse protection Fuse protection AMP8620 Maximum AC supply 25 A ─── AMP8000 and AMP8500 Version: 1.1... -

Page 93: Commissioning

• Check protective measures against moving and live parts Configuration Beckhoff recommends the use of the latest TwinCAT version and the TwinCAT Drive Manager 2 for the configuration of new projects. • Create a new TwinCAT project and select the target system •... -

Page 94: Prerequisites During Operation

Make sure that all moving parts on the machine or plant come completely to a standstill. After switching off the power supply, the components of the dis- tributed servo drive system may perform uncontrolled movements and cause serious injuries. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 95: Maintenance And Cleaning

Clean the components carefully with a damp cloth or a brush. 11.1 Use grease-dissolving and non-aggressive cleaning agents such as isopropanol for cleaning. Not applicable Cleaning agents Chemical formula 11.1.1 Aniline hydrochloride Bromine Sodium hypochlorite; bleaching NaCIO solution Mercury (II) chloride HgCl Hydrochloric acid Version: 1.1 AMP8000 and AMP8500 ───... -

Page 96: Accessories

Use accessories with UL approval UL approval is required for operation of the AMP8000 distributed servo drive system in the USA or Canada. Further and more detailed information on accessories can be found on the Beckhoff homepage. Brake resistors IP65 12.1 12.1... -

Page 97: Connectors B23

ZB7306-xxxx EtherCAT P ca- ble. EtherCAT P pin 12.3.3 12.3.3 The ZS7300-0001 connector for field assembly is used to connect the system output to the ZB7306-xxxx EtherCAT P cable. Version: 1.1 AMP8000 and AMP8500 ───... -

Page 98: Crimping Tool

Crimp contact version ZS7000-C001 Ethernet element, pin, AWG22/0.34 mm² ZS7000-C002 Ethernet element, socket, AWG22/0.34 mm² ZS7000-C010 B23, socket, 4 mm², for AMP8620 X01 ZS7000-C015 B23, pin, 1.5 mm² ZS7000-C016 B23, socket, 1.5 mm² ZS7000-C017 B23, pin, 2.5 mm² ZS7000-C018 B23, socket, 2.5 mm² ─── AMP8000 and AMP8500 Version: 1.1... -

Page 99: Color Coding

12.7.1 12.7.1 You have the possibility to purchase the protective caps ZS7300- B001 made of plastic. Metal IP67 12.7.2 12.7.2 You have the possibility to purchase the protective caps ZS7300- B002 made of metal. Version: 1.1 AMP8000 and AMP8500 ───... -

Page 100: Assembly Tool Af27

Accessories Assembly tool AF27 12.8 12.8 The ZB8802-0003 assembly tool is used for convenient locking of the bayonet lock of the B23 connectors. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 101: Decommissioning

Leaking oil can cause slips and falls, resulting in serious or fatal injury. Impermissible removal of gear unit components These components may only be dismantled by Beckhoff Automa- tion GmbH & Co. KG. Contact Beckhoff Service for further information. Removal of the components from the control cabinet and the machine or plant •... -

Page 102: Disposal

The trans- 13.2.1 port costs are borne by the sender. Send the used devices with the note "For disposal" to: Beckhoff Automation GmbH & Co. KG "Service" Building Stahlstrasse 31 D-33415 Verl In addition, you have the option to contact a local certified specialist company for the disposal of used electrical and electronic appli- ances. -

Page 103: Guidelines And Standards

"Adjustable speed electrical power drive systems" Part 5-1: Safety requirements – Functional RoHS: EN IEC 63000 "Technical documentation for the assessment of electrical and elec- tronic products with respect to the restriction of hazardous sub- stances" Version: 1.1 AMP8000 and AMP8500 ───... -

Page 104: Guidelines

This guarantees secure shock pro- tection on all terminals in the control unit, even without further mea- sures. The air gaps and creepage distances conform to EN 50178 / VDE 0160. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 105: Eu Conformity

Guidelines and Standards EU conformity Provision 14.3 Beckhoff Automation GmbH & Co KG will be pleased to provide you with EU declarations of conformity and manufacturer's declara- tions for all products on request. Send your request to: info@beckhoff.com CCC conformity Export to Chinese Economic Area 14.4... -

Page 106: Ul Certification

• The AX883x coupling module may be used in an environment 14.5.1.1 with non-conductive dirt. This corresponds to the degree of pollu- tion 2. • The wiring must be done using copper conductors with a thermal conductivity of at least 60 to 75 °C. ─── AMP8000 and AMP8500 Version: 1.1... -

Page 107: Index

Intended use 36 Target group 8 Technical data 38, 40 Tightening torques Flange 78 Label, see Safety pictograms 13 Total motor cable length 64 Transport 59 Maintenance 95 106 Operating conditions 40 Ordering options 32 Version: 1.1 AMP8000 and AMP8500 ───... - Page 109 More Information: www.beckhoff.com/amp8000 Beckhoff Automation GmbH & Co. KG Hülshorstweg 20 33415 Verl Germany Phone: +49 5246 9630 info@beckhoff.com www.beckhoff.com...

Need help?

Do you have a question about the AMP8500 and is the answer not in the manual?

Questions and answers