Table of Contents

Advertisement

Quick Links

TMC389-EVAL MANUAL (V. 1.10 / 2011-Mar-01)

®

TRINAMIC

Motion Control GmbH & Co. KG

Hamburg, GERMANY

www.trinamic.com

1 Features

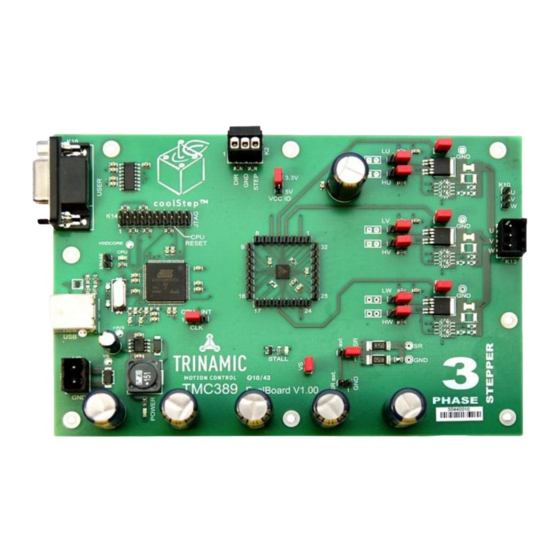

The TMC389 evaluation board features a TMC389 with external power MOSFETs plus a

microcontroller, which allows interfacing to a PC for visualization and control of all parameters. The

motor can be operated via the step and direction interface, using either an external source, or using

the integrated microcontroller as a step pulse generator.

Highlights

Evaluate all features of the TMC389

Use stallGuard2™ with your motor

Use coolStep™ with your motor

Control all parameters from a PC

Motor current can be set to up 6A depending on sense resistor selection.

Supply voltage up to 40V (MOSFETs can be exchanged against 60V 2A types)

Access all pins of the TMC389

Motor type

3 phase Stepper

Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG

TMC389-EVAL manual

Evaluation board for the TMC389 three phase

stepper motor driver IC with coolStep

1

Advertisement

Table of Contents

Summary of Contents for Trinamic TMC389-EVAL

-

Page 1: Features

Motor current can be set to up 6A depending on sense resistor selection. Supply voltage up to 40V (MOSFETs can be exchanged against 60V 2A types) Access all pins of the TMC389 Motor type 3 phase Stepper Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 2: Table Of Contents

Using stallGuard2™ and coolStep™ ................10 6.1.6 Optimizing the chopper settings ..................11 ORE SCREEN SHOTS ........................12 RITING THE SETTINGS TO A FILE ....................12 REVISION HISTORY ........................14 OCUMENTATION EVISION ......................14 Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 3: General Description

3.3V regulator figure 1: application block diagram as realized on TMC389-EVAL The TMC389-EVAL board features the TMC389 plus a microcontroller, which realizes an interface to a 3.1 Power driver stage The power MOSFETs on resistance mainly influences the current and voltage capability of the board. -

Page 4: Sense Resistors And Current Setting

There are optional filter components designed in on the board. These allow experimenting with EME filters, e.g. RC and LC filter with RC dampening. Please see the board schematic for sample values. Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 5: Board Pinning

Attention: Do not pull or plug the motor connector during operation, as inductive spikes could destroy the driver. First disable the driver (there is a button in the Eval software) or switch off the power supply. Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 6: Step And Direction Input K2

Setting Function Description sense Normal operation, the TMC389 uses the shunt resistors for current resistor sensing external Sense resistor signals can be supplied via J6 for testing purpose input Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 7: Gate Jumpers Lu, Hu, J10, J7, Etc

BM open This setting allows testing of the short to GND condition without shorting the bridge output. 4.2.6 Erase Jumper J14 Erases the CPU Setting Function Description Attention: Erases the processor. Reprogram it via RS232 using the Erase SAMBA tool. open operation Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 8: Electrical Characteristics

Supply voltage (with the original 40V MOSFETs soldered on the board) Supply voltage (with 60V MOSFETs SI4559ADY) Step and Direction input voltage high level VVIO 2.40 VIO+0.7 (Attention: The maximum high level depends on the VIO jumper setting) Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 9: Getting Started

In case you want faster motion, stop the motor, go to the tab DRVCTRL and reduce microstep resolution. Best performance is achieved in 256 times microstepping, or in 16 times microstepping with step interpolation active (please check INTPOL). Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 10: Clock Frequency Setting

SGSCONF tab and decrease the stallGuard threshold value (SGT). A good starting value is zero. You can apply negative values and positive values. If the values leave a Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 11: Optimizing The Chopper Settings

(should not come into the audible range) for different HYST settings to improve motor behavior. Chopper synchronization (CSYNC) will improve behavior at higher motor velocity. figure 7: Evaluation software: Chopper settings Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... -

Page 12: More Screen Shots

In order to transfer the settings into your own software, there is a C language export function. This will write out the initialization values for the TMC262 in a C syntax form, which allows easy sending via a microcontroller SPI interface. Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG... - Page 13 TMC389-EVAL MANUAL (V. 1.10 / 2011-Mar-01) figure 9: .c file opened in text editor Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG...

-

Page 14: Revision History

7 Revision History 7.1 Documentation Revision Version Author Description 0.10 Initial version of documentation, based on TMC262 eval board docu Initial documentation adapted to final TMC389 evaluation board Table 1: Documentation Revisions Copyright © 2010 TRINAMIC Motion Control GmbH & Co. KG...

Need help?

Do you have a question about the TMC389-EVAL and is the answer not in the manual?

Questions and answers