Summary of Contents for HYVA AMCO VEBA NG Series

- Page 1 7845429-00 09/17 subject to change without notice ORIGINAL INSTRUCTIONS...

-

Page 3: Table Of Contents

USER MANUAL ONTROL LATFORM NDEX WARNINGS ........................A.1 CRUSHING HAZARD ..........................A.1 IMPACT HAZARD ............................. A.2 SLIPPING AND FALLS ..........................A.2 ERGONOMIC HAZARDS .......................... A.3 A.4.1 VISIBILITY ..............................A.3 A.4.2 PHYSICAL CHARACTERISTICS ......................A.3 TRANSPORT AND INSTALLATION ......................A.3 USER MANUAL ....................... B.1 PREMISE .............................. -

Page 4: Warnings

USER MANUAL ONTROL LATFORM ARNINGS WARNINGS CRUSHING HAZARD Crushing hazards derive from moving components of the crane and from devices used to access the platform: • upper limb crushing during opening/closing the ladder • upper limb crushing during opening/closing the safety gate •... -

Page 5: Impact Hazard

USER MANUAL ONTROL LATFORM ARNINGS IMPACT HAZARD In case of NOT CE crane, impact hazards derive from platform unfolded: • impact between crane's boom and platform during boom's folding in crossed position. WARNINGS - Before folding the boom into crossed position, make sure that the protection bar is fully tilted toward the platform controls (see figure below). -

Page 6: Ergonomic Hazards

USER MANUAL ONTROL LATFORM ARNINGS ERGONOMIC HAZARDS A.4.1 VISIBILITY WARNINGS - When operating the crane the user shall have a perfect view of work area: in particular, make sure that the the column and other parts of vehicle do not obstruct the view. A.4.2 PHYSICAL CHARACTERISTICS WARNINGS... -

Page 7: Buser Manual

USER MANUAL ONTROL LATFORM USER MANUAL PREMISE Dear Customer, Please follow the instructions given below to ensure that your crane operates safely: - Follow carefully all instructions in this manual. - Always keep this manual in a safe place with the crane so that it is always accessible to the user. - Refer to an authorised Service Centre in the event of damage or loss of this manual. -

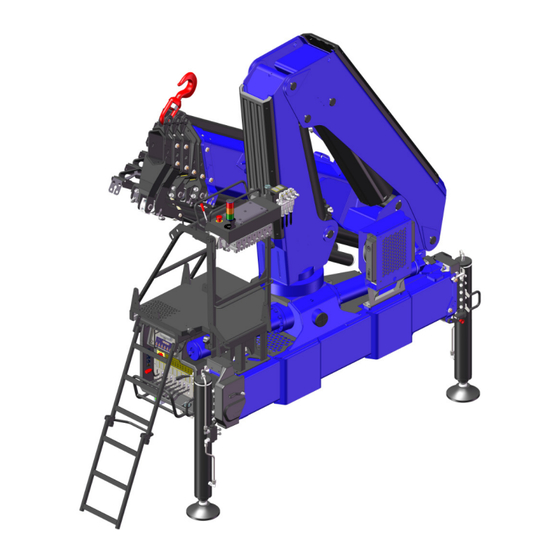

Page 8: Main Components

USER MANUAL ONTROL LATFORM MAIN COMPONENTS A list of the main crane components is given below in accordance with EN 12999: MAIN COMPONENTS Control platform Foldable ladder Locking gate Safety gate Tiltable protection bar Controls on platform 7845429-00 09/17 subject to change without notice... -

Page 9: Controls

USER MANUAL ONTROL LATFORM CONTROLS B.4.1 TYPES OF PLATFORM CONTROLS MANUAL CONTROLS WITH FLEXBALL CABLES This version is equipped with control levers fitted on platform and main distributor mounted on crane's base: the control levers are connected to distributor with flexball cables. MANUAL CONTROLS WITH DISTRIBUTOR ON PLATFORM This version is equipped with main distributor fitted on platform: the control levers are connected directly to distributor. -

Page 10: Auxiliary Controls On Crane's Base

USER MANUAL ONTROL LATFORM CRANE CONTROLS (OPTION) (OPTION) Column boom boom Hydraulic Grab / Hoist Rotator slewing articulation articulation extensions Bucket STABILIZERS CONTROLS Stablizer leg Stablizer leg on opposite on platform platform side side B.4.3 AUXILIARY CONTROLS ON CRANE'S BASE Auxiliary controls include all controls of a standard crane, except these operating the stabilizers legs on platform side. -

Page 11: Safety Devices

USER MANUAL ONTROL LATFORM SAFETY DEVICES B.5.1 LADDER LOCKING DEVICE LOCKING DEVICE Locking device engaged (transport position) Locking device disengaged Holder Purpose of this device is to lock the ladder in its folded position under the platform. In order to unlock the ladder, the user shall grasp, pull and rotate the locking device and then secure by inserting its curved end into the holder. -

Page 12: Safety Sensors

USER MANUAL ONTROL LATFORM B.5.3 SAFETY SENSORS CE cranes are equipped with the following sensors: SAFETY SENSORS Presence sensor Protection bar sensor SENSOR FOR MONITORING THE PROTECTION BAR This sensor detects if the protection bar is inclined in closed position. Before folding the crane (see B.7.2), the operator must incline the bar to closed position (see figure below): the sensor detects that the bar is inclined and allows to fold fully the crane boom into crossed position. - Page 13 USER MANUAL ONTROL LATFORM PRESENCE SENSOR This sensor detects the presence of the operator on the platform and limits the crane movements (e.g. boom slewing over the platform) to avoid that the operator bumps against the crane: the electronic control system creates a safe zone (see the green zone around the platform in the figure below) over the platform which the crane's moving parts (booms, extensions) can not enter.

-

Page 14: Indicators On Platform

USER MANUAL ONTROL LATFORM INDICATORS ON PLATFORM B.6.1 LOAD INDICATORS SIGNAL TOWER (STANDARD FOR CE CRANES) (see UM for standard crane) PRESSURE GAUGE (OPTION FOR NO CE CRANES) (see UM for standard crane) 7845429-00 09/17 subject to change without notice... -

Page 15: 3Xl Auxiliary Dashboard

USER MANUAL ONTROL LATFORM B.6.2 3XL AUXILIARY DASHBOARD This dashboard is a standard equipment for CE cranes. It is mounted near the control levers. (see UM for 3XL) B.6.3 LEVEL INDICATOR Near the stabilizers controls there is a level indicator that shows the inclination of the platform and of the crane's base. -

Page 16: Operating The Crane From Platform

USER MANUAL ONTROL LATFORM OPERATING THE CRANE FROM PLATFORM The use of a crane with platform requires to pay close attention because the control stations and the stabilizer control levers are located in positions different from the standard ones. B.7.1 HOW TO ENTER AND LEAVE THE PLATFORM Procedure to open and enter the platform: 1) Disengage the ladder locking device, and put it in the holder (see B.5.1). -

Page 17: Cmaintenance Of Platform

USER MANUAL ONTROL LATFORM AINTENANCE MAINTENANCE OF PLATFORM ORDINARY MAINTENANCE The following routine maintenance shall be performed by the operator: - cleaning Before performing any maintenance operation check that: - the vehicle is switched OFF - the parking brake is applied - the crane's power supply is switched OFF PLANNED MAINTENANCE The owner of the crane is responsible for contacting an authorised assistance centre to perform... -

Page 18: Dtechnical Sheet

USER MANUAL ONTROL LATFORM NNEXES TECHNICAL SHEET 7845429-00 09/17 subject to change without notice... -

Page 19: Control Platform's Technical Data

USER MANUAL ONTROL LATFORM NNEXES CONTROL PLATFORM'S TECHNICAL DATA Control platform weight, without distributor Distributor weight Length (X) Height (Y) 1440 (radio version) (1370) Width (Z) Max. allowable load 7845429-00 09/17 subject to change without notice... -

Page 20: Hydraulic Schematics

USER MANUAL ONTROL LATFORM NNEXES HYDRAULIC SCHEMATICS DISTRIBUTOR ON PLATFORM NO RDC - CE HPCO 25µ 10µ 1.7 bar 6 bar 1030196 Settings: See UM parameters for standard crane with NO RDC - CE control valve. 7845429-00 09/17 subject to change without notice... -

Page 21: Warning Labels

USER MANUAL ONTROL LATFORM NNEXES WARNING LABELS Label Position Description Seal sticker Do NOT use emergency At RDC controls controls under normal work conditions At controls Power supply voltage of crane 7845429-00 09/17 subject to change without notice... -

Page 22: Maintenance Register

USER MANUAL ONTROL LATFORM NNEXES MAINTENANCE REGISTER CRANE'S IDENTIFICATION DATA Model: Serial number: Year of manufacturing: Installer: MAINTENANCE SCHEDULE SERVICE 500 Platform mounting bolts Safety devices and sensors Inspection and maintenance operations performed by Authorized assistance center Signature Date MAINTENANCE SCHEDULE SERVICE _000 General condiitons of the platform Platform mounting bolts... -

Page 23: Extraordinary Maintenance Module

USER MANUAL ONTROL LATFORM NNEXES EXTRAORDINARY MAINTENANCE MODULE CRANE'S IDENTIFICATION DATA Model: Serial number: Year of manufacturing: Installer: FAULT DETECTED INTERVENTION DESCRIPTION MATERIALS NEEDED ADDITIONAL NOTES Inspection and maintenance operations performed by Authorized assistance center Signature Date 7845429-00 09/17 subject to change without notice...

Need help?

Do you have a question about the AMCO VEBA NG Series and is the answer not in the manual?

Questions and answers