Creality Ender-3 Neo User Manual

Hide thumbs

Also See for Ender-3 Neo:

- User manual (24 pages) ,

- Instructions for assembly (16 pages) ,

- Manual book (12 pages)

Advertisement

Advertisement

Table of Contents

Summary of Contents for Creality Ender-3 Neo

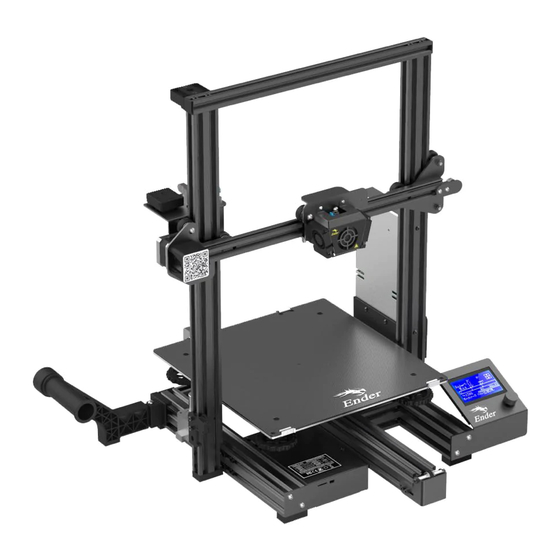

- Page 1 CREATE REALITY,ACHIEVE DREAMS Ender-3 Neo Ender-3 Neo 3D Printer User Manual V1.2...

- Page 2 Creality is always ready to provide you with high-quality services. If you encounter any issues or have any questions when using our products, please use the contact information at the end of this manual to contact us. To further improve your user experience, you can find more about our devices via the following methods:...

- Page 3 Instructions for Use Do not use this printer by methods or operations that are not described in this manual, otherwise it may result in accidental injury or property damage. Do not place this printer near flammable materials, explosive materials or high heat sources. Please place this printer in a ventilated, cool and low-dust environment. Do not place this printer in a vibrating or any other unstable environment, as the printing quality will be compromised when the printer shakes.

-

Page 4: Table Of Contents

Table of Contents 01-01 About the Printer 02-02 Device Specifications 03-04 List of Parts 05-12 Installing the 3D Printer 13-13 On-screen information 14-14 Auxiliary leveling 15-15 Auto Leveling 16-17 Filament infill 18-19 Start Printing 20-20 Circuit Wiring... -

Page 5: About The Printer

1. About the Printer X-axis limit switch Y-axis tensioner X-axis tensione X-axis motor Material rack and Power switch and CR-Touch Z-axis motor material barrel socket Printing platform Extrusion kit Screen Y-axis motor Storage card slot Nozzle kit E-axis motor Power supply module... -

Page 6: Device Specifications

2. Equipment Parameters General Specifications Model Ender-3 Neo Modeling Dimensions 220*220*250mm Modeling Technology Number of Nozzles Slice Thickness 0.05mm-0.35mm Nozzle Diameter 0.4mm (standard) Precision ±0.1mm Printing Material PLA/ABS/PETG Supported File Format STL/OBJ/AMF Printing Method TF card/USB on-line printing Supported Slicing Software... -

Page 7: List Of Parts

3. Parts List Parts List Screen Base component Power supply module Z-axis passive block Nozzle kit Extrusion kit X-axis passive Z-axis motor block component Material barrel Material rack 2020 profile cover Z-axis profile (Right) Z-axis profile (Left) Top gantry profile X-axis profile T-type screw Note: The components above are for reference only. - Page 8 3. Parts List Tool list TF Card and Wrench and Nozzle Cleaner Cutting plier Card Reader screwdrive power cable Blade Blue clip×2 Nozzle Quick release claw Cable tie X-axis timing belt Filament M4×20Hexagon Socket M4×16Hexagon Socket M5×8 Hexagon Socket M5×45Hexagon Socket Button Head Screw Button Head Screw×4 Head Cap Screw×2...

-

Page 9: Installing The 3D Printer

4. Install the Printer 4.1 Assemble Z-axis profiles Make sure that the Z-axis profile is perpendicular to the profile of machine base, placed in the slot of the base frame and flush with both left and right sides of the base profile, and tighten the four M5 x 45 screws from the bottom upwards. - Page 10 4.Install the Printer 4.3 Install Z-axis motor component and T-type screw rod Insert the T-rod onto the Z-axis motor assembly and tighten to secure. Lock the Z-axis motor assembly to the profile using two M4 × 18 screws. 4.4 Install the extrusion kit Back Fix the extrusion kit to the left end of the X-axis profile using two M4 x 16 screws.

- Page 11 4. Install the Printer 4.5 Install the X-axis timing belt Thread the X-axis timing belt through the XE-axis assembly. (As shown in the diagram below) 4.6 Install the nozzle kit 4.7 Install Z-axis passive block Slide the nozzle kit into the X-axis profile. Fix the Z-axis passive block to the right end of the X-axis profile using two M4 x 16 screws.

- Page 12 4. Install the Printer 4.8 Install X-axis passive block Snap the brass sleeve on the left side of the X-axis timing belt into the extruder back support plate. Fix the X-axis passive block to the X-axis profile. (Be careful not to screw it down and make sure the X-axis passive block can slide along the X-axis profile.) After winding the X-axis timing belt around the X-axis passive block, snap the brass sleeve at its right end into the extruder back support plate.

- Page 13 4.Install the Printer 4.9 Install the X-axis kit and adjust tightness Fit the X-axis kit into the Z-axis profile, with the V-wheels on the left and right sides aligned with the slot in the profile and the T-rod nut aligned with the T-rod.

- Page 14 4.Install the Printer 4.12 Equipment Wiring X-axis limit Mainboard X,E,Z-axis motor port Display cable switch power cable 6pin (4 wires) 3pin (2 wires) A1.Follow the yellow label on the 6pin (4 wires) port to connect the X-axis stepper motor; A2.Follow the yellow label on the 6pin (4 wires) port to connect the E-axis stepper motor; A3.Follow the yellow label on the 6pin (4 wires) port to connect the Z-axis stepper motor;...

- Page 15 4.Install the Printer 4.13 Install the Teflon Tube Quick release Wire clip (blue) claw...

- Page 16 4.Install the Printer 4.14 Adjusting pulley tightness Check the pulley looseness before switching on the machine. X/Y/Z axis pulley adjustment: Gently turn the pulley to check whether it is idling or jammed. If this phenomenon occurs, use an open-end wrench to adjust the tightness of the hexagonal eccentric isolation column to make it rotate smoothly.

-

Page 17: On-Screen Information

5. On-screen information Displayed information Info screen Moving Axis Move X/Y/Z/Extruder Motion Auto home/Level Bed Z offset/Motor Off Nozzle/ Bed/ Fan Speed/ Temperature Preheat PLA/ Preheat ABS Set Home Offsets / Velocity / Acceleration / Jerk /Probe Offsets / rabbit.gcode ADV.SET. -

Page 18: Auxiliary Leveling

6. Auxiliary leveling Info → Motion → Auto Home. (Waiting for the end of the CR-Touch detection platform) Home Moving axis Z offset Info → Motion → Moving axis → Move Z. (Adjust the value to 0) Home Moving axis Moving axis Z offset Info →... -

Page 19: Auto Leveling

7.Auto Leveling Info → Motion→ Level Bed → Manually return to info screen. Home Moving axis Z offset Sensing point 3/16 Info → Configuration → Save settings. (Save Z-axis compensation data) CR Touch Recovery: Preheat PLA settings Preheat ABS settings Save settings The nozzle is too far away from the platform, and the filaments cannot stick to the platform. -

Page 20: Filament Infill

8. Filament infill Preheating Method 1 Method 2 Home... - Page 21 8. Filament infill Loading the Filament When you wait for the temperature to rise, hang the filament over the filament holder. Press the extrusion clamp and insert the filaments along the extruder hole up to the nozzle. When the temperature hits the target value, a flow of filaments can be seen at the nozzle, meaning that the filaments have been loaded.

-

Page 22: Start Printing

9.Start Printing Ender-3 Neo Creality Slicer 9.1Download the Creality software at www.creality.com, or find it in the memory card and install it. Select in turn Preferences → Basic → Select Language → Close to complete the settings. 新增打印机 Select current model (Ender-3 Neo). - Page 23 9.Start Printing Load Creality Slicer Open the Creality 3D Load (read the file). Slicing Software. Select the file. Ender-3 Neo Insert the memory card → Press the screen Generate the G-code file → Save knob → Select menu → The file to print.

-

Page 24: Circuit Wiring

10.Circuit Wiring Extrusion Motor X-Axis Motor Port Y-Axis Motor Port Z-Axis Motor Port TF card slot Port Micro USB interface Controllable fan port Display port Fuse CR-touch port Power input jack Printhead thermistor interface Filament Cable port X-axis Y-axis Z-axis NO fan port Cable port detection... - Page 25 Due to the differences between differebt machine , the physical objects and the final images can differ .The final explanation rights shall be reserved by Shenzhen Creality 3D Technology Co.,Ltd Add:18F, JinXiuHongDu Building, Meilong Blvd., Longhua Dist., Shenzhen, China 518131 Official Website: www.creality.com Tel: +86 755-8523 4565 E-mail: info@creality.com cs@creality.com...