Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Server CP-MEC3

- Page 1 Stainless Steel Pump with Aluminum Lid MODEL: CP-MEC3 85451 Thank You ...for purchasing our Stainless Steel Pump with gold colored aluminum lid. This quality pump delivers precise portions and lasts for years of service. CONSISTENT PORTIONS—SERVE BETTER...

-

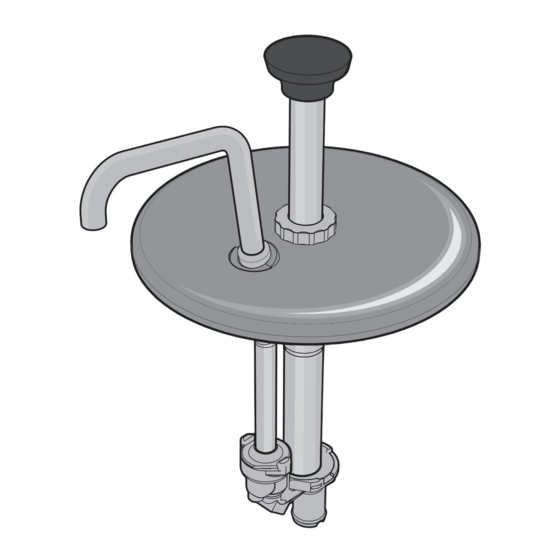

Page 2: Pump Parts

PUMP PARTS KNOB PUMP DELIVERS 82023-000 30 mL PORTIONS LOCKING COLLAR 82021 To reduce portion, add GAGING COLLAR(S) 83529 Smaller collar: 3.7 mL reduction 82022 Larger collar: 7.4 mL reduction HEAD TUBE 82017 HEAD INSERT 82018 PLUNGER SPRING 82016 WASHER 82015 PISTON 82013... - Page 3 Check with local food and safety regulators for specific guidelines. Be aware of the product you are serving and the temperature the product is required to maintain. Server Products, Inc. cannot be responsible for the serving of potentially hazardous product. DISASSEMBLE AND WASH ALL DISASSEMBLY PARTS PROPERLY BEFORE USE.

-

Page 4: Pump Cleaning

PUMP CLEANING FLUSH & RINSE YES! all pump surfaces with hot water. Place lower end of pump into container Use dishwashing of hot water and operate pump until all soap, hot water remaining product is expelled and only hot water is discharged. and nylon brush. -

Page 5: Clean-In-Place

CLEAN-IN-PLACE PROCEDURE FOR PUMPS CLEAN • Pump out all (if any) remaining food product from inside pump body. • Wash and rinse off outside of pump body. • Flush out and rinse inside of pump. • Place lower end of pump into container full of water and operate pump until all (if any) remaining product is expelled and only warm water flows from discharge... - Page 6 ASSEMBLY WASH ALL PARTS PROPERLY BEFORE EVERY USE. See page 4. INSTALL SMALL O-RING into seal. Apply food equipment lubricant on o-ring. INSTALL SEAL onto piston head. Apply food equipment lubricant inside seal. TIP: Flared end of seal should face away from piston head. SLIDE WASHER onto piston.

- Page 7 INSTALL LARGE O-RING into valve body. Apply food equipment lubricant on o-ring. INSTALL CYLINDER onto valve body. Rotate cylinder clockwise and press down firmly to secure into slots on valve body. INSTALL MEDIUM O-RING onto discharge tube. Apply food equipment lubricant on o-ring.

-

Page 8: Troubleshooting

Server Products customer service to request a Return Authorization Number. Merchandise must be sent to Server Products with this number. Service is extremely prompt. Typically, units are repaired Server Products equipment is backed by a and ship out within 48 hours.

Need help?

Do you have a question about the CP-MEC3 and is the answer not in the manual?

Questions and answers