Summary of Contents for Sole Diesel SDZ-165

- Page 1 Solé Diesel, S.A. C-24 Manual Marine diesel engines Operator’s manual SDZ-165 SDZ-205 SDZ-280 SDZ-280R U_CTMT165280_EN Revision 0...

-

Page 3: Introduction

Introduction Introduction Presentation Dear Customer, First of all, we would like to thank you for choosing a Solé Diesel product. We recommend that you read this manual carefully before carrying out any of the operations and keep it close at hand, near the engine, as it can be of great use in the future. -

Page 4: Table Of Contents

Table of contents Table of contents Introduction ............................3 Table of contents ..........................4 Safety precautions and instructions ..................... 6 Solé Diesel warranty ..........................9 Section 1 – Engine information ......................12 1.1. Engine Identification ....................... 12 1.2. Engine parts identification...................... 12 Section 2 –... - Page 5 Table of contents Coolant specifications ................................29 Maintenance task. Coolant check ............................29 Maintenance task. Coolant fill/change ..........................29 Maintenance task. Seawater filter inspection ........................29 Maintenance task. Zinc anode inspection ..........................30 5.7. Inlet and exhaust system......................30 Exhaust circuit description..............................30 Maintenance task.

-

Page 6: Safety Precautions And Instructions

Safety precautions and instructions Safety precautions and instructions Solé Diesel is concerned for your safety and your machine’s condition. Safety Precautions and Instructions are one of the primary ways to call your attention to the potential hazards associated with our engine operation. Follow the precautions listed throughout the manual before and during operation and maintenance procedures for your safety, the safety of others and the performance of your engine. - Page 7 Safety precautions and instructions Engine exhaust gases contains carbon monoxide gas. Carbon monoxide is an odourless, colourless, tasteless, no irritating gas that can cause death if inhaled for even a short time. Get fresh air and do not sit, lie down or fall asleep if anyone shows signs of carbon monoxide poisoning: Light-headedness, dizziness Physical fatigue, weakness in joints and muscles.

- Page 8 Safety precautions and instructions Engine labels If the engine does not start after several attempts to crank may cause water entering the engine. In this situation it is recommended: 1) Close the seacock. 2) Drain the water from the exhaust system in the water trap.

-

Page 9: Solé Diesel Warranty

Solé Diesel Warranty Solé Diesel warranty Read the manual and documents delivered with each engine before carrying out any of the operations or presenting any queries. The engine is supplied without any liquids. Ensure that the liquids used match the specifications contained in Solé Diesel manuals. The application of the conditions described in this document shall only be effective for engines or generator sets that have been invoiced after November 4, 2011. - Page 10 Solé Diesel Warranty Restrictions Coverage: a) To validate the warranty is necessary fill and send the inspection prior to the delivery of propulsion engines or genset to Solé Diesel through an official installer. See SECTION 12. b) The warranty covers any failure of the product under normal opera- ting conditions caused by a defect in manufacturing.

- Page 11 Solé Diesel Warranty Responsibilities Responsibilities of the manufacturer: The obligations of Solé Diesel are restricted to repairing the defective parts or, IF DEEMED APPROPRIATE BY SOLÉ DIESEL, returning the amount of the purchase or replacing the parts to prevent poor operation resulting from defective materials or faults in the manufacture covered by the warranty. Solé...

-

Page 12: Section 1 - Engine Information

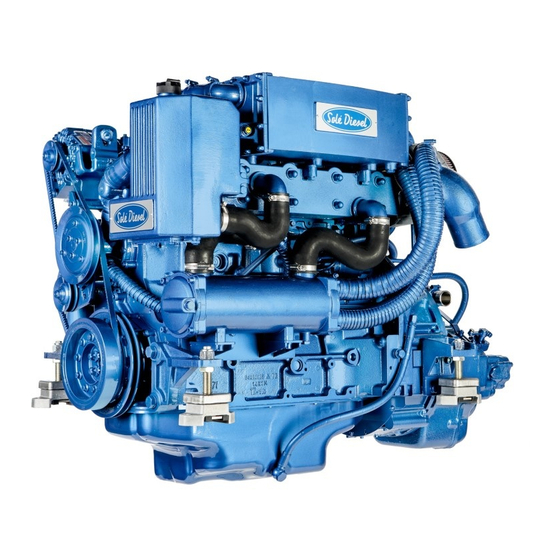

Fuel tubes Air vent tube Intercooler seawater inlet tube Seawater inlet to exchanger tube Oil filler plug Intercooler seawater outlet Oil cooler Intercooler (SDZ-165 / SDZ-280) Injection pumps Turbocharger Starter assy Turbocharger coolant tube Oil pan Turbocharger oil return tube Manual oil pump Flywheel housing (SAE 3”) -

Page 13: Section 2 - Transport, Handling And Storage

Transport, handling and storage Section 2 – Transport, handling and storage 2.1. Reception When the engine is delivered make sure that the packing has not been damaged during transport and that it has not been tampered with or that components inside the packing have been removed (see information marked on covers, bases and cartons). -

Page 14: Transporting And Handling The Unpacked Engine

Transport, handling and storage 2.3. Transporting and handling the unpacked Engine When the engine is unpacked and ready for transport, use EXCLUSIVELY the appropriate lifting eyebolts (A). 2.4. Storage of packed and unpacked engine If the engine is left idle for prolonged periods, the client must check the possible conditions of conservation in relation to the place of storage. -

Page 15: Section 3 - Installation

Section 3 - Installation 3.1. Angle of installation Make sure the engine is installed on a level surface. Otherwise, the following angular operation maximum is permitted: Continuously Temporaly SDZ-165 10º 30º (Max. 30 min.) SDZ-205 10º 30º (Max. 30 min.) SDZ-280 10º... -

Page 16: Section 4 - Operation

Operation Section 4 - Operation 4.1. Prestart checklist Follow these checks and inspections to ensure the correct engine operation. In addition, some checks require verification after unit starts. AIR CLEANER: Check for a clean and installed air cleaner element to prevent unfiltered air from entering the engine. -

Page 17: Stopping Engine

Operation 4. Check for leakage of oil, coolant and fuel. 5. Knocking should die away as coolant temperature rises. No other defective noise should be heard. 6. Check for exhaust colour and abnormal odours. 4.3. Stopping engine 1. REMOVE ENGINE LOAD. Before turning off the engine, it must be freed of all charges (disengaged gearbox to neutral) 2. -

Page 18: Winterization And Preservation

Operation 4.5. Winterization and preservation If the boat is not going to be used for a long period of time or during the winter, certain tasks must be carried out to keep it in perfect operating condition. Follow the steps indicated below carefully: 1. -

Page 19: Section 5 - Systems And Scheduled Maintenance

Systems and scheduled maintenance Section 5 – Systems and scheduled maintenance 5.1. Safety and prevention Information of special tools required and basic safety precautions. Disassembly: ✓ Use the correct tools and instruments. Serious injury or damage to the engine can result from using the wrong tools and instruments. - Page 20 Systems and scheduled maintenance Intervals Every Every Every Every 2 Winter storage and Inspection Item Daily 1st 20h-50h Every year 200h 400h 800h years Preservation Screw tightening, fastening. Engine block. General Valve clearance. Exhaust gas, noise and vibrations. Compression pressure. Lubrication Genset oil.

-

Page 21: General

0,5 mm Inspection (without pressure washer) Do these operations in an authorised Sole Diesel Service. Before adjusting valve clareance, allow the engine to cool for at least 30 minuts. The oil temperature should be below 80ºC. 1. Loosen ventilation valve and swing it to the side. -

Page 22: Maintenance Task. Compression Pressure Inspection

1. Loosen ventilation valve and swing it to the side. 2. Remove the cylinder head cover. 3. Do these operations in an authorized Sole Diesel Service. Before adjusting valve clareance, allow the engine to cool for at least 30 minutes. The oil temperature should be below 80ºC. - Page 23 Systems and scheduled maintenance Model Pressure 85 GTC / 100 GTAC 3,0 to 3,8 MPa (30,6 to 38,7 kgf/cm 115 GTC / 120 GTAC 3,0 to 3,8 MPa (30,6 to 38,7 kgf/cm 165 GTC / 180 GTAC 3,0 to 3,8 MPa (30,6 to 38,7 kgf/cm It is not a good practice to measure the compression pressure on only few cylinders and presume the compression on the remaining cylinders.

-

Page 24: Lubrication System

Systems and scheduled maintenance 5.4. Lubrication system Circuit description The lubrication circuit is forced by the trochoid gear pump, and it is composed of the following elements. PIECE ELEMENT Oil pan Scroop Oil pump Valve, flow control Valve, máximum pressure Engine oil cooler Oil filter Oil pipe... -

Page 25: Maintenance Task. Oil Level Check

Systems and scheduled maintenance Maintenance task. Oil level check Check the oil level in the crankcase daily or before each start-up to ensure that the level is between the upper (Max mark) and lower (Min mark) lines on the dipstick. To check the oil level: 1. -

Page 26: Fuel System

Systems and scheduled maintenance 5.5. Fuel system Circuit description The fuel system is based on a fuel feed pump and an in-line mechanical injection pump. PIECE ELEMENT Circuit compensation valve Return fuel tube Nozzle Injection pump Fuel pump Fuel filter Fuel hose Fuel filter (water separator) Valve... -

Page 27: Maintenance Task. Water Separator Filter Purge

Systems and scheduled maintenance Maintenance task. Water separator filter purge The fuel system must have a water separator filter (supplied as accessory) to avoid the inlet of water in the fuel circuit. According to the maintenance plan it is necessary to purge the filter to eliminate water periodically. This is the procedure: 1. -

Page 28: Cooling System

PIECE ELEMENT Seawater pump Intercooler¹ Heat exchanger Exhaust elbow ¹ Only for SDZ-165 and SDZ-280. Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... -

Page 29: Coolant Specifications

Systems and scheduled maintenance Coolant specifications It is recommended use SOLÉ DIESEL 50% coolant or another coolant with similar specifications. On the other hand, distilled water with an anti-freezing agent is also suitable. The anti- freezing agent concentration according to operating conditions is specified in anti-freezing agent package labels. -

Page 30: Maintenance Task. Zinc Anode Inspection

Systems and scheduled maintenance 9. Inspect the cover plate and gasket for corrosion and/or damage. Replace components as necessary. 10. Lubricate the gasket with silicon grease and attach the gasket and cover plate to the seawater pump housing. 11. Open the seacock. 12. -

Page 31: Maintenance Task. Air Filter Inspection

Systems and scheduled maintenance Type 1 installation. When between water injection point of wet exhaust and waterline is minimum 150 mm Type 2 installation. When between water injection point of wet exhaust and waterline there is less than 150 mm or the point of injection is below waterline. The wet exhaust is the engine’s standard equipment. - Page 32 Systems and scheduled maintenance Maintenance task. Turbocharger cleaning and inspection Turbocharger maintenance To extend turbocharger life and efficiency, some basically important are given below: Inspect for possible oil leaks in the inlet and outlet ducts, as well as inside the turbo. A lack of lubrication or the appearance of oily residue could lead to shaft seizure and premature seal wear.

-

Page 33: Electrical System

Systems and scheduled maintenance 5.8. Electrical system Control Panel You can find all information related to the control panel in Control Panel Operator’s Manual of your engine. Sensors and switches Coolant temperature sensor: Function table Temperature Resistance Tolerance Operating voltage: 6-24V (ºC) (ohm) (ohm) -

Page 34: Battery

Positive battery is connected to the starter. Genset model capacity (Ah) • Negative battery is connected to the relay support. 24 V SDZ-165 The connection of the battery for an earth isolated SDZ-205 engine. SDZ-280 • Positive battery is connected to the starter. -

Page 35: Circuit Protection - Fuse

Systems and scheduled maintenance Circuit protection – Fuse - The electrical installation of the engine has a fuse that protects all the electronics in case of overload or short circuit. It is located in the wire harness next to the starter motor. Relays The relays of the electrical installation are located inside the electrical protective box where it is shown in the follow image. -

Page 36: Maintenance Task. Battery Level

Systems and scheduled maintenance Maintenance task. V-belt replacement In the event that replacement of the belt (s) is required, carry out the following procedure: Fully distension old belt so that is removal can be made easier. Fuel pump 1. To adjust the belts, loosen the screws (1) and (2). Push the fuel pump (3) to the left until the belt is correctly tensioned. -

Page 37: Section 6 - Troubleshooting

Troubleshooting Section 6 - Troubleshooting If a fault occurs in the engine, proceed as follows: ❖ Within the period of warranty • Contact to Solé Diesel Official Service. See SOLÉ DIESEL WARRANTY ❖ Outside the period of warranty • Contact to Solé Diesel Official Service. See SOLÉ DIESEL WARRANTY. •... - Page 38 Troubleshooting ENGINE FAILURE SYSTEM PROBABLE CAUSES RECOMMENDED ACTIONS Replace the fuse in the installation. If fuse blows again, check Power cable fuse (red). electrical system for overloads or short circuits. Discharged or empty battery. Charge the battery or replace it with a new one. ELECTRICAL SYSTEM Loose or corroded battery connections.

- Page 39 Troubleshooting ENGINE FAILURE SYSTEM PROBABLE CAUSES RECOMMENDED ACTIONS GENERAL The fuel regulator is not operational. Contact an Official Solé Diesel Service. Faulty or clogged fuel pump Check fuel pump inlet. Clogged fuel filter Replace fuel filter. FUEL SYSTEM Air in fuel system Bleed fuel system.

- Page 40 Troubleshooting ENGINE FAILURE SYSTEM PROBABLE CAUSES RECOMMENDED ACTIONS OIL PRESSURE TOO Strangled oil pressure-relief valve Clean the valve and check its operation. Faulty oil pressure valve Contact an Official Solé Diesel Service. LUBRICATION SYSTEM Oil level too high. Reset oil level. Obstruction of oil lines.

- Page 41 Troubleshooting ENGINE FAILURE SYSTEM PROBABLE CAUSES RECOMMENDED ACTIONS Faulty coolant water pump. Check coolant pump (impeller, pump sealing). Clean the tap, check if the salt water pump impeller is Plugged or restricted-pitch salt water tap. damaged. Faulty salt water pump. Check sea water pump (impeller, pump sealing).

-

Page 42: Section 7 - Technical Specifications

Technical specifications Section 7 - Technical specifications Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... - Page 43 SDZ-165 Specifications No. Of Strokes: Number of cylinders: Layout of cylinders: In line Cylinder diameter (mm): Stroke (mm): Total displacement (cc): 4764 Compression ratio: 17,5:1 Continuous power (kW): 106,2 Intermittent Power (kW): Max RPM: 2300 Rotation (viewed from flywheel side):...

- Page 44 SDZ-205 Specifications No. Of Strokes: Number of cylinders: Layout of cylinders: In line Cylinder diameter (mm): Stroke (mm): Total displacement (cc): 7146 Compression ratio: 17.5:1 Continuous power (kW): 129,5 Intermittent Power (kW): 143,9 Max RPM: 2300 Rotation (viewed from flywheel side): Counterclockwise Idle RPM: 750 (±50)

- Page 45 SDZ-280 Specifications No. Of Strokes: Number of cylinders: Layout of cylinders: In line Cylinder diameter (mm): Stroke (mm): Total displacement (cc): 7146 Compression ratio: 17.5:1 Continuous power (kW): Intermittent Power (kW): Max RPM: 2300 Rotation (viewed from flywheel side): Counterclockwise Idle RPM: 750 (±50) Intake system:...

- Page 46 SDZ-280R Specifications No. Of Strokes: Number of cylinders: Layout of cylinders: In line Cylinder diameter (mm): Stroke (mm): Total displacement (cc): 7146 Compression ratio: 17.5:1 Continuous power (kW): Intermittent Power (kW): Max RPM: 1600 Rotation (viewed from flywheel side): Counterclockwise Idle RPM: 750 (±50) Intake system:...

-

Page 47: Section 8 - Tightening Torques

Tightening torques Section 8 – Tightening torques Important nuts and screws: SDZ-165 / 205 / 280 / 280R Valores de apriete N·m kgf·m 1st Phase 50 1st Phase 5 Cylinder head bolt 2nd Phase 130 2nd Phase 13 Retighten 90º... -

Page 48: Section 9 - Wiring Diagrams

Wiring diagrams Section 9 – Wiring diagrams Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... - Page 49 TRANSMISOR DE TEMPERATURA / TEMPERATURE SENSOR N.S. TRANSMISOR DE PRESIÓN / PRESSURE SENSOR N.S. MODELO MOTOR / ENGINE MODEL: SDZ-165 / SDZ 205 / SDZ-280 LEYENDA / LEGEND: VOLTAGE MOTOR / ENGINE VOLTAGE: - N.S.: NO SUMINISTRADO / NOT SUPPLIED VERIFICADO FECHA CREACIÓN...

- Page 50 TRANSMISOR DE TEMPERATURA / TEMPERATURE SENSOR TRANSMISOR DE PRESIÓN / PRESSURE SENSOR N.S. N.S. MODELO MOTOR / ENGINE MODEL: SDZ-165 / SDZ-205 / SDZ-280 LIBRE MASA / ISOLATED LEYENDA / LEGEND: VOLTAGE MOTOR / ENGINE VOLTAGE: - N.S.: NO SUMINISTRADO / NOT SUPPLIED VERIFICADO FECHA CREACIÓN...

-

Page 51: Section 10 - Overall Dimensions

Overall dimensions Section 10 – Overall dimensions Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... - Page 55 Inspection prior to the delivery of propulsion engines Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual...

-

Page 56: Section 11 - Instructions To Replace And Remove

Inspection prior to the delivery of propulsion engines Section 11 – Instructions to Replace and Remove When you decide to replace the engine, please contact SOLÉ S.A.; will provide relevant instructions regarding the laws in force at the time. When disposing of the whole or parts of this engine, meets LAWS IN FORCE IN THE COUNTRY OF INSTALLATION. -

Page 57: Section 12 - Inspection Prior To The Delivery Of Propulsion Engines

Inspection prior to the delivery of propulsion engines Section 12 - Inspection prior to the delivery of propulsion engines Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... - Page 58 Inspection prior to the delivery of propulsion engines Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual...

-

Page 59: Maintenance Log

Maintenance log Maintenance log DATE HOURS DESCRIPTION SERVICE NAME Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual... - Page 60 Maintenance log Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual...

- Page 62 Maintenance log U_CTMT165280_EN Revision 0 03/2022 Solé, S.A. C-243 b, km 2 · 08760 Martorell (Barcelona) ·Tel. +34 93 775 14 00 · www.solediesel.com · info@solediesel.com Marine diesel engines. Operator’s manual...

Need help?

Do you have a question about the SDZ-165 and is the answer not in the manual?

Questions and answers