Table of Contents

Advertisement

Quick Links

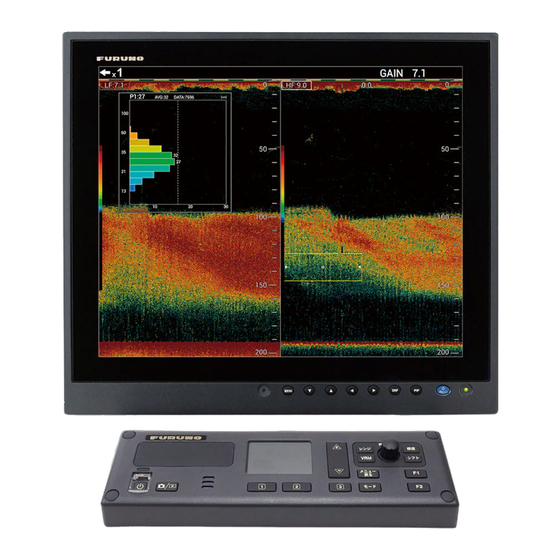

FISH FINDER/HI-RES FISH FINDER

FCV-1900/FCV-1900B/FCV-1900G

Model

SAFETY INSTRUCTIONS ........................i

SYSTEM CONFIGURATION ...................ii

EQUIPMENT LISTS................................iii

1. MOUNTING.........................................1

1.1 Processor Unit ....................................... 1

1.2 Control Unit ............................................ 2

1.3 Transducer............................................. 4

1.4 External Monitor..................................... 4

1.5 Interface Unit.......................................... 5

1.6 Ethernet HUB......................................... 5

1.7 Booster Box ........................................... 6

1.8 Temperature Sensor .............................. 6

2. WIRING...............................................7

2.1 Interconnection ...................................... 7

2.2 Processor Unit ....................................... 8

2.3 Interface Unit........................................ 15

2.4 Net Sonde ............................................ 17

2.5 Ethernet HUB....................................... 18

2.6 Booster Box ......................................... 18

2.7 Input/Output Sentences ....................... 19

3. INITIAL SETTINGS...........................20

3.1 Installation Menu.................................. 20

3.2 Monitor Setting..................................... 21

3.3 Transducer Setting............................... 22

3.4 NMEA Port Setting............................... 26

3.5 Communication Port Monitor ............... 27

3.6 Calibration Setting................................ 28

3.7 Stabilization Setting ............................. 30

3.8 Telesounder Setting............................. 31

3.9 Side Looking Setting ............................ 32

3.10 TX Triggering ....................................... 33

3.11 Reset to Default Setting ....................... 33

3.12 Upgrading to FCV-1900B/1900G......... 34

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Installation Manual

FISH SIZE INDICATOR

APPENDIX 1 JIS CABLE GUIDE.....AP-1

PACKING LISTS ................................. A-1

OUTLINE DRAWINGS ........................ D-1

INTERCONNECTION DIAGRAMS ..... S-1

www.furuno.com

(Product Name: FISH FINDER)

Advertisement

Table of Contents

Summary of Contents for Furuno FCV-1900G

-

Page 1: Table Of Contents

Installation Manual FISH FINDER/HI-RES FISH FINDER FISH SIZE INDICATOR FCV-1900/FCV-1900B/FCV-1900G Model (Product Name: FISH FINDER) SAFETY INSTRUCTIONS ......i APPENDIX 1 JIS CABLE GUIDE..AP-1 SYSTEM CONFIGURATION ....ii APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS .....AP-2 EQUIPMENT LISTS........iii APPENDIX 3 FISH SIZE PARAMETER ........AP-7 1. -

Page 2: Safety Instructions

The installer of the equipment carefully, following the guidelines is solely responsible for the proper below. installation of the equipment. FURUNO will assume no responsibility for any - Keep fuels and oils away from the damage associated with improper cable. -

Page 3: System Configuration

SYSTEM CONFIGURATION Monitor Ethernet HUB USB connector HUB-101 converter (for brill-control) Network Fish Finder External KP DFF series, BBDS1 Processor Unit Net Sonde FCV-1901 Interface Unit NMEA0183 device FCV-1903 (Sonar, Current Indicator Satellite Compass Telesounder* INTERFACE UNIT FCV-1903 Chart Plotter, etc.) TS-85 TS-80M2, Tankenmaru System*... -

Page 4: Equipment Lists

EQUIPMENT LISTS Standard Supply Name Type Code No. Remarks Processor unit FCV-1901 Control unit FCV-1902 Spare parts SP02-05801 001-372-670 1 set For Processor unit Installation materials CP02-09110 000-029-472 1 set For Processor unit CP02-09101+Adapter CP03-34401 001-194-530 1 set For Control unit Optional Supply Name Type... - Page 5 EQUIPMENT LISTS Transducer (option) The contents in the table below are for your information only. Some tanks are not RoHS compliant. Output Frequency Transducer Hull Material Thru-hull pipe Tank (kHz) 1 k/ 1 k 28/50 28F-8, 50B-6/6B Steel/ FRP 28F-8, 50B-9B Steel TWB-6000 (2) T-656...

- Page 6 EQUIPMENT LISTS Output Frequency Transducer Hull Material Thru-hull pipe Tank (kHz) 3 k/ 3 k 28/38 28BL-12HR, 38BL- Steel TFB-7000 (2) or T-681 15HR TWB-6000 (2) TRB-1100 (2) T-681-F 28/50 28BL-12HR, 50BL- Steel TFB-7000 (2) or T-681 24HR TWB-6000 (2) TRB-1100 (2) T-681-F 28/88...

- Page 7 EQUIPMENT LISTS Output Frequency Transducer Hull Material Thru-hull pipe Tank (kHz) 28F-8 Steel TFB-5000 (1) T-604 TRB-1000 (1) or T-604-F TRB-1200 50B-6/6B Steel TFB-5000 (1) T-605 TRB-1000 (1) T-605-F 50B-9B Steel TFB-5000 (1) T-603 TRB-1000 (1) or T-603-F TRB-1200 68F-8H Steel TFB-5000 (1) T-621...

- Page 8 EQUIPMENT LISTS Output Frequency Transducer Hull Material Thru-hull pipe Tank (kHz) 1 k/ 1 k 42-65/130- Steel T-711 CM265LH T-711-F 42-65/85- CM265LM Steel TFB-7000 (1) T-711 T-711-F 42-65/150- Steel TFB-7000 (1) T-711 CM275LH-W T-711-F 2 k/ 2 k 38-75/130- Steel TFB-7000 (1) T-712 PM111LH...

-

Page 9: Mounting

MOUNTING Processor Unit 1.1.1 Installation considerations The processor unit can be installed on a desktop or a bulkhead. When selecting a mounting location, keep in mind the following points: • Locate the unit out of direct sunlight. • Select an installation location that is well ventilated. •... -

Page 10: Control Unit

1. MOUNTING Control Unit 1.2.1 Installation considerations The control unit is designed to be mounted on a tabletop. When selecting a mounting location, keep in mind the following points: • Locate the unit where shock and vibration are minimal. • Leave sufficient space around the unit for maintenance and servicing. •... - Page 11 1. MOUNTING 4. Fit the cosmetics caps (removed at step 2) to the control unit. Cosmetic caps Self-tapping screws Method 2: Modified cable entry 1. Follow the steps outlined in steps 1 and 2 of "Method 1: Factory default" on page 2. 2.

-

Page 12: Transducer

1. MOUNTING Transducer The performance of the fish finder depends upon the transducer position. A place least affected by air bubbles should be selected since turbulence blocks the sounding path. Further, select a place least influenced by engine noise. It is known that air bubbles are fewest at the place where the bow first falls and the next wave raises, at usual cruising speed. -

Page 13: Interface Unit

1. MOUNTING Interface Unit The interface unit FCV-1903 enables connection of a telesounder. Keep in mind the following points when selecting a mounting place. • Locate the unit away from areas subject to water splash. • The length of the cable to the processor unit is 5 m. •... -

Page 14: Booster Box

1. MOUNTING Booster Box The booster box (BT-5, option) enables connection of 5 kW transducers in 28.8 and 50 kHz. For dual frequencies, use the model BT-5-2. 1. Unfasten four binding screws to remove the cover. 2. Select a mounting location, referring to the figure below. Fixing holes 4-φ6 terminal... -

Page 15: Wiring

WIRING Interconnection Refer to the interconnection diagram at the back of this manual for detailed informa- tion. Control unit External monitor FCV-1902 Rectifier unit RU-1746B-2 Junction box Grounding wire converter RJB-002 AC/DC power IV-1.25sq. supply unit (local supply) PR-240 Processor unit NMEA0183 FCV-1901 (Tankenmaru system*) -

Page 16: Processor Unit

2. WIRING Processor Unit LAN cable Monitor cable USB cable LAN cable Tankenmaru system Power cable Temperature Control cable sensor Transducer cable NMEA1/2 TD/ID transducer Satellite Compass cable Interface unit Net sonde signal cable Location of the connectors in the processor unit 2.2.1 Power cable and grounding Depending on the cable length, use either a DPYC-1.5 or a DPYC-2.5 cable (Japa-... - Page 17 2. WIRING 3. Unfasten four binding screws Super Binding screws (4 pcs.) to detach the filter cover from gland the power terminal. (CN-1) 4. Unfasten and remove the seal nut from the power cable’s su- per-gland, then remove the gasket and fixture from the su- per-gland.

- Page 18 2. WIRING An optional DVI-D cable is available for monitors with a DVD-D port. For MU-190/231/ 150HD monitors, brilliance control is available by connecting the optional USB cable (RNS-08-132, pictured below) and USB cable (CP013638-07-A (550MM)). The following procedure shows how to connect the processor unit to the MU-190 mon- itor unit.

- Page 19 2. WIRING 5. Pass the A-TO-D ADAPTER cable and USB cable through the super-gland from inside. 6. Pass the gasket assembly onto the cable. 7. Insert the assembly into the seal nut, then tighten the seal nut. Super-gland Seal nut Gasket assembly 8.

- Page 20 2. WIRING 2.2.3 Transducer Lay the transducer cable well away from power cables to prevent interference. Con- nect the cable to the transducer port (for high frequency and/or low frequency) on the processor unit. Fabricate the cables as shown below. Note: Only use the specified optional cables when extending the transducer cable.

- Page 21 2. WIRING 3. Connect the transducer cable to the WAGO NOTICE connector referring to the interconnection di- agram at the back of this manual. For dual frequency connections, connect both trans- When connecting the transducer ducer cables to the WAGO connector. cable, do not do reverse the The terminal opener is attached to the con- transducer cable polarity.

- Page 22 2. WIRING Satellite compass ™ Connect Satellite Compass SC-30/50/70/110/130 to the connector CN-12. The ca- ble assembly MJ-A6SPF0003 (available as an optional extra) is required for connec- tion. Set as follows. 1. Press the MENU/ESC key, then open the [Setting] or [External fish finder] tab. 2.

-

Page 23: Interface Unit

2. WIRING Interface Unit The interface unit FCV-1903 (option) is used to connect the FCV-1900 system to the telesounder TS-7100, TS-80M2 or TS-85. To connect the unit to the processor unit, use the S02-22-5 cable assembly attached to the interface unit. Note 1: The telesounder products are sold only in Japan. - Page 24 2. WIRING 10. Connect the harness plug 7P to the socket J7 on the PWR board and the harness plug 16P to the socket J8. Fix the wire from connector J7 with a locking wire sad- dle in the unit. 02P6391 Locking wire J7 B7B-XH-A...

-

Page 25: Net Sonde

2. WIRING Net Sonde Connect the net sonde FNZ-18 or FNZ-28 to the WAGO connector CN-6 in the con- nector box inside the processor unit. Connect the net sonde to the display unit with a TTYCSLA-4 cable (Japanese Industrial Standards cable or equivalent cable). The fol- lowing procedure shows how to connect the cables from the net sonde to the proces- sor unit. -

Page 26: Ethernet Hub

2. WIRING Ethernet HUB Use the Ethernet HUB (HUB-101, option) to connect the DFF1, DFF3 or BBDS1 net- work sounders. No other network sounder can be connected. 1. Open the cover of the processor unit. 2. Remove super-gland CN3 and CN4. 3. -

Page 27: Input/Output Sentences

2. WIRING Input/Output Sentences This equipment can input/output the following NMEA data sentences. Data Sentence Time, position Input GNS>GGA>GLL Course over the ground (COG) and Input speed over the ground (SOG) Water speed and heading Input Time and date Input Water depth Output DBS, DBT, DPT... -

Page 28: Initial Settings

INITIAL SETTINGS This chapter covers the initial setup of the equipment. Note 1: After all wiring is complete (including cable extensions with junction box RJ- 002), perform the initial setup. Do not connect the USB flash memory and the USB cable for brilliance control. -

Page 29: Monitor Setting

3. INITIAL SETTINGS Monitor Setting Depending on your monitor, the resolution setting may need to be changed. The res- olutions available are XGA (1024×768), SXGA (1280×1024), SXGA (1024×1280, por- trait type) and Full HD (1920×1080). SXGA monitors (1280×1024) are set to the correct resolution and do not require this initial setting. -

Page 30: Transducer Setting

3. INITIAL SETTINGS 5. Rotate the ENTER knob to select the resolution of Display resolution was your monitor, then push the knob. changed. The confirmation massage shown to the right appears. The controls will be inoperable and the screen will go dark for 6. - Page 31 3. INITIAL SETTINGS 4. Press the power key to turn the power on. The [XDCR Setting] menu appears. Own XDCR Setting DFF1,DFF3,BBDS1 XDCR Setting Telesounder Side Looking HF XDCR Select XDCR Type HF Connection Connected Freq 200kHz Transducer CM265LH Tx Power Freq ---kHz Band Width...

- Page 32 3. INITIAL SETTINGS Transducer lists The table below lists the narrow band transducers which are compatible with the FCV- 1900. Select the appropriate setting. For external sounders, select the transducers connected to the external sounder. Output Frequency Model Remarks power (kW) (kHz) 28F-8 50B-6...

- Page 33 3. INITIAL SETTINGS Dual frequency transducers Output Frequency (kHz) Model Remarks power (kW) 42-65/130-210 CM265LH ™ ACCU-FISH compatible 42-65/85-135 CM265LM 42-65/150-250 CM275LH-W Wide beam type 38-75/130-210 PM111LH ™ ACCU-FISH compatible 38-75/80-130 PM111LM 28-60/130/210 CM599LH ™ ACCU-FISH compatible 28-60/80-130 CM599LM Manual setting For transducer not listed in the table above, set [HF XDCR Select] to [Manual], then set the TX power, frequency and bandwidth.

-

Page 34: Nmea Port Setting

3. INITIAL SETTINGS NMEA Port Setting The [NMEA Port Set&Monitor] menu sets up the NMEA port and shows the data input/ output from the NMEA ports. Rotate the ENTER knob to select the port that you want to set up and push the knob to open the [Setting] window. -

Page 35: Communication Port Monitor

3. INITIAL SETTINGS Communication Port Monitor The communication port monitor provides information about data input/output. 1. Press the MENU/ESC key to open the menu. 2. Confirm that the [Setting] tab is selected, then rotate the ENTER knob to select [System]. Push the ENTER knob. 3. -

Page 36: Calibration Setting

3. INITIAL SETTINGS Calibration Setting The [Calib] menu mainly lets you apply offsets to speed, water temperature, and bot- tom level. For [Setting] tab For [External fish finder] tab Sound Speed 1500.0 m/s Bottom Level* Temp 0.0ºF Zero Line Rejection Bottom Level* Zero Line Area 4.5ft... - Page 37 3. INITIAL SETTINGS [Draft]: The default depth display shows the distance from the transducer. If you would rather show the distance from the sea surface, set your ship’s draft. The draft line for HF and LF can be set respectively. [Gain ADJ]: If the gain is too high or too low, or the gain for the low and high frequen- cies appears unbalanced, you can compensate it here.

-

Page 38: Stabilization Setting

Antenna to Transducer distances (bow-stern, port-starboard, height) are not set, Have a FURUNO technician adjust your settings. ™ 4. Set the antenna position for the Satellite Compass • TD fore-aft: Distance (m) from antenna to transducer on the fore-aft line. -

Page 39: Telesounder Setting

3. INITIAL SETTINGS • ANT TD height: Vertical distance (m) between the antenna and the transducer. To enter the number, move the cursor onto the column of the value and push the knob, then rotate the knob to change the number, and push the knob to set the number. -

Page 40: Side Looking Setting

3. INITIAL SETTINGS 6. Select [Input 1], [Input 2] or [Output], then push the knob. • [Input 1]: Select when this unit is on the mother ship. This unit receives two dif- ferent frequency information from one sister ship. • [Input 2]: Select when this unit is on the mother ship. When [Telesounder] is set to [TS-80 MARK2], this unit receives two different frequency information from two sister ships. -

Page 41: Tx Triggering

3. INITIAL SETTINGS 4. Rotate the ENTER Knob to select [Save Setting], then push the knob. The message shown below appears when the setting is not adequate. Side looking is not available (HF/LF transducer faces port/ starboard and external fish finder HE/LE transducer faces downword). -

Page 42: Upgrading To Fcv-1900B/1900G

3. INITIAL SETTINGS 3.12 Upgrading to FCV-1900B/1900G The FCV-1900 can be upgraded to FCV-1900B or FCV-1900G with an “upgrade key”. To obtain an upgrade key, consult your local dealer. The upgrade procedure requires a USB flash memory, USB cable (micro-A/B and type A connectors attached) and USB type A conversion adapter (female to female). - Page 43 Program version 10. At the first line of the [Display unit] section of the test result, confirm that the up- grading is complete. “Product Grade” shows FCV-1900B or FCV-1900G depend- ing on the upgrade. 11. Press the MENU/ESC key three times to close the test window.

-

Page 44: Appendix 1 Jis Cable Guide

EX: TTYCYSLA - 4 MPYC - 4 TTYCSLA-4 # of cores Designation type Designation type # of twisted pairs The following reference table lists gives the measurements of JIS cables commonly used with Furuno products: Cable Core Core Cable Diameter Type... -

Page 45: Appendix 2 Installation Of Temperature Sensors

APPENDIX 2 INSTALLATION OF TEM- PERATURE SENSORS The installation instructions in this chapter are copied from the manufacturer’s (AIRMAR Technol- ogy Corporation) installation guide, which is included with your sensor. The model numbers mentioned within the documentation should be read as follows: T42: T-04MSB, T80: T-04MTB OWNER’S GUIDE &... - Page 46 APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS 9-12 mm (3/8-1/2") pour in larger than the casting hole through the epoxy hull’s outer skin inner skin core hull thickness hull nut hull solid or hollow cylinder outer skin bedding Figure 1. Bedding and installing Figure 2.

- Page 47 APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS Maintenance & Replacement Aquatic growth can accumulate rapidly on the sensor’s surface reducing its performance within weeks. Clean the surface with a ® Scotch-Brite scour pad and mild household detergent taking care to avoid making scratches. If the fouling is severe, lightly wet sand with fine grade wet/dry paper.

- Page 48 APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS OWNER’S GUIDE & INSTALLATION INSTRUCTIONS Surface Mount, Analog Record the information found on the cable tag for future reference. Part No._________________Date___________ Temperature Sensor Model T80 Follow the precautions below for optimal product performance and to reduce the risk of property damage, personal injury, and/or death.

- Page 49 APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS Cable Routing & Connecting Mount the sensor near the centerline and close to the bottom of the transom. 1. Route the cable to the instrument, being careful not to tear the cable jacket when passing it through the bulkhead(s) and other Route the sensor cable over the transom, through a drain hole, or parts of the boat.

-

Page 50: Appendix 3 Fish Size Parameter

APPENDIX 3 FISH SIZE PARAMETER The table below shows the setting ranges and default settings for the parameters for fish size in- formation and school of fish density. Generally, the default values are suitable for most applica- tions. However, if you have customized the parameters and need to restore certain default settings, refer to the table to find the default settings. - Page 57 15/Jan/2015 H . M A KI...

- Page 64 The paper used in this manual is elemental chlorine free. ・FURUNO Authorized Distributor/Dealer 9-52 Ashihara-cho, Nishinomiya, 662-8580, JAPAN A : APR 2015 Printed in Japan All rights reserved. K2 : JUN . 18, 2019 Pub. No. IME-23860-K2 ( ETMI ) FCV-1900/1900B/1900G...

Need help?

Do you have a question about the FCV-1900G and is the answer not in the manual?

Questions and answers