Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pilz PSEN opII4H Series

- Page 1 PSEN opII4H Series PSEN sensor technology Operating Manual-1003501-EN-02...

- Page 2 Preface This document is a translation of the original document. All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made for internal purposes. Suggestions and comments for improving this documentation will be gratefully received.

-

Page 3: Table Of Contents

Attach the safety light grid to the installation surface Orientation General guidelines Safety light grid alignment Wiring General guidelines Connector pin assignment Earthing the safety light grid Commissioning System connection Checking the safety light grid Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 4 Technical details Order no. 632066-632068 Technical details Order no. 632069-632071 Safety characteristic data Order reference Order reference for safety light grids Order reference for accessories Order reference: Component parts Appendix Check list EC declaration of conformity Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 5: Introduction

PSEN opII4H Series Introduction Validity of documentation This documentation is valid for the product PSEN opII4H Series. It is valid until new docu- mentation is published. This operating manual explains the function and operation, describes the installation and provides guidelines on how to connect the product. -

Page 6: Overview

Overview Safety light grids in the PSEN opII4H Series constitute electrosensitive protective equip- ment (ESPE type: 4) in accordance with DIN EN 61496-1 and DIN EN 61496-2 (AOPD) for workspaces in which machines, robots, and automated systems might pose a physical danger to their operators. - Page 7 PSEN opII4H Series – Protected field heights of 750-1200 mm, including: 1 PSEN opII Adv Bracket Kit-3 (=3 clamping units per transmitter and receiver) – Protected field heights of 1350-1800 mm, including: 2 PSEN opII Adv Bracket Kit-2 (=4 clamping units per transmitter and receiver) Operating Manual PSEN opII4H Series 1003501-EN-02...

-

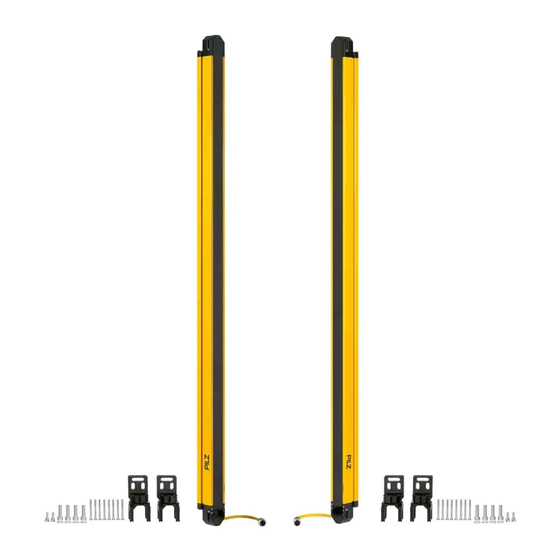

Page 8: Unit View

Fig.: Front view of the safety light grid transmitter and receiver, protected field height 300-1800 mm with connection cable Legende [1] Protected field height [2] Effective protected field height [3] Tinted front panel [4] LEDs for status information Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 9 Fig.: Front view of the safety light grid transmitter and receiver, protected field height 150 mm with connection cable Legende [1] Protected field height [2] Effective protected field height [3] Tinted front panel [4] LEDs for status information [5] Connection cable, M12 connector [6] Optical centre axis Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 10: Scope

Holder for connecting the transmitter/re- ceiver end caps to the flexible bracket Tightening screw M3x33.4 oval-head screw, self-tapping Clamping screw with ISO 4762 M4x10 8.8 cylinder screw with Mounting screw ISO 4762 M6x20 8.8 cylinder screw with washer Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 11: Safety

PSEN opII4H Series Safety Intended use Safety light grids of the PSEN opII4H Series are electrosensitive protective equipment of the 4. They are used to protect personnel and systems. The safety light grids are designed securing hazardous areas within buildings and securing access within buildings with a resolution of 30 mm. -

Page 12: Safety Regulations

In safety-related applications, please comply with the mission time T in the safety-re- lated characteristic data. When decommissioning, please comply with local regulations regarding the disposal of electronic devices (e.g. Electrical and Electronic Equipment Act). Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 13: Function Description

[ of the safety light grid. The safety light grid of the PSEN opII4H Series offers the following functions: automatic start automatic restart Operation of 2 safety light grids that are parallel to one another and are installed with... - Page 14 Check is begun to determine whether the protected field is clear and whether there are errors Response time required for the OSSDs to switch to the OFF state (see Tech- nical details [ 42]) Minimum time that the OSSDs remain in the OFF state: 80 ms Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 15: Project Configuration

Additional distance of 128 mm for safety light grids with hand protection Resolution The safety light grids may only be used for protected fields in which a detection capability of 30 mm is sufficient. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 16: Protected Field Perimeters

The transmitters and receivers of two different safety light grids must not be synchron- ised. Avoid strong electromagnetic interference when operating the safety light grid. When operating the safety light grid, avoid the development of smoke, mist, or dust that would reduce the grid’s operating range. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 17: Distance From Reflective Surfaces

This means that there must be a certain minimum distance between the safety light grid and reflective surfaces. Fig.: Interference with the function of the safety light grid due to reflective surfaces – top view Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 18 The minimum distance D depends on two factors: Working distance between transmitter and receiver the maximum opening angle [ of the light beams emitted by the safety light grid 5° = ± 2.5° in relation to the optical axis Operating Manual PSEN opII4H Series 1003501-EN-02...

- Page 19 For a working distance of 3 m or more: D = working distance in m x tan ⍺ 0,35 0,174 0,131 Fig.: Relationship between minimum distance and working distance Legende [1] Working distance in m [2] Minimum distance D to reflective surfaces in m Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 20: Minimum Distance Between Parallel, Aligned Safety Light Grids

[5] Minimum distance of 2 x D between two safety light grids that are aligned [6] Working distance [7] Minimum distance D, dependent on the working distance [8] Working distance (= 3 m) with constant minimum distance D = 0.131 m Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 21: Installation Of Several Adjacent Safety Light Grids

Please consider this reduc- tion when positioning the safety light grid. You should not use more than two mirrors per device. Any dust or dirt on the mirror’s reflective surface will drastically reduce the operating range. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 22: Dead Zones

If you want to use the safety light grid without dead zones, use the PSEN opII Adv Bracket Kit for safety light grid installation (see Dead-zone-free installation [ 6]). Use the installation information provided in the PSEN opII Adv Bracket Kit operating manual. Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 23 PSEN opII4H Series Fig.: Placement of the dead zones in vertical safety light grid installation Legende [1] Last light beam (wiring side) [2] Last light beam (cable side) [3] Wiring-side dead zone [4] Cable-side dead zone Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 24: Installation And Orientation

(see Technical details [ 42]). The installation surface must be at least as wide as the standard installation kit The installation surface may have a flatness imperfection of no more than 1.5 mm. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 25: Attach The Safety Light Grid To The Installation Surface

Feed the cable [2] through the opening in the holder. Ensure that the holder is flush with the end cap (see diagram). Attach the holder to the end cap with the tightening screws included in delivery. [1] Torque setting 0,7 Nm Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 26 [1]: The angle [4] of the flexible bracket [3] on the holder [2] may not be more than 2°. The flexible bracket [3] must be seated on one side of the holder [2]. Operating Manual PSEN opII4H Series 1003501-EN-02...

- Page 27 Ensure that the transmitters and receivers are properly installed in a suitable place. Ensure that the transmitters and receivers are posi- tioned at the same height and parallel to one another. Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 28: Orientation

[2] Horizontal: by horizontal shifting of position in the elongated holes in the top and bot- tom flexible brackets [3] The axis orientation can be changed by rotating the flexible bracket right or left Pilz recommends that modifications to the orientation of the transmitter/receiver be made in the following sequence: 1. Vertical modification 2. -

Page 29: Safety Light Grid Alignment

Tighten the clamping screws [1] and the nuts [2] on the flexible bracket to a torque of 1,1 Nm. Tighten the brackets’ mounting screws [3] on the installation surface to a torque of 3 Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 30: Wiring

The transmitters and receivers must be electrically isolated from the ma- chine/system. The use of the flexible bracket (swivel mount) provides this electrical isolation. Connection to PDP67 – Use the order reference of the cable listed (see Accessories, connection to PDP67 [ 52]) Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 31: Connector Pin Assignment

(such as EN 60204-1, NFPA 79:17-7, NEC: Article 250). Connections should be protected from corrosion. Flexible earthing straps should be used on moving earth parts (e.g. machine parts, gates). Ensure these earthing straps are as short and wide as possible. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 32: Commissioning

2-channel with feasibility monitoring OSSD signals are evaluated A test pulse lasting no longer than 300 µs is bridged Suitable Pilz evaluation devices are, for example: PNOZelog for monitoring safety light grids PNOZsigma for monitoring safety light grids PNOZ X for monitoring safety light grids... -

Page 33: Checking The Safety Light Grid

Fig.: Dual-channel connection of the safety light grid to the input circuit of an evaluation device CAUTION! When considering the examples, please note that Pilz accepts no respons- ibility for the specific application. In particular, they may not be used without testing and approval. - Page 34 In the centre of the protected field 2. Place the test rod at rest in a position in the protected field that is considered critical for the safety assessment results Legend [1] Test rod Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 35: Operation

The safety light grid’s operating status is indicated with LEDs in the end caps of the con- nection side of the receiver and on the transmitter. Device status Reception quality: III: best quality OSSD status (protected field LED) I: worst quality LED indicator on the receiver Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 36: Status Information

An error has occurred. Perform a safety light grid restart [ 38]. Interfering light warning Warns of the OSSDs’ change to green green green green green the OFF state due to incident inter- fering light. Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 37 [ 38]. Indicators on the transmitter Meaning Safety light grid is started green green green Safety light grid in operation green green An error has occurred. Perform a safety light grid restart [ 38]. Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 38: Safety Light Grid Restart

Regular checks can bring to light changes to the plant/machine, safeguards and ambient conditions. Regular check Pilz recommends that the safety light grid be checked every six months. Check the safety light grid’s front panel. – Scratched front panel: Replace the safety light grid. -

Page 39: Check After Plant/Machine Modification

Moist cotton cloths should be used for cleaning. Avoid using Alcohol, Solvents, Cloths made of wool, Cloths made of synthetic material. Clean the lens covers during the regular check of the safety light grid [ 38]. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 40: Dimensions

Fig.: Front view of the safety light grid transmitter, protected field height 150 mm with connection cable Legende [1] Total length of transmitter (without cable) [2] Effective protected field height [3] Protected field height (see Technical details [ 42]) Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 41 Fig.: Relationship between the effective protected field height and the safety light grid dimensions (schematic representation) Legende [1] Resolution [2] Last light beams on the connection and wiring sides [3] Protected field height [4] Effective protected field height [5] Transmitter [6] Receiver Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 42: Technical Details Order No. 632060-632062

-25 - 70 °C -25 - 70 °C -25 - 70 °C Climatic suitability Humidity 95 % r. h. at 50 °C 95 % r. h. at 50 °C 95 % r. h. at 50 °C Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 43 0,7 Nm 0,7 Nm 0,7 Nm Dimensions Height 229 mm 304 mm 454 mm Width 35 mm 35 mm 35 mm Depth 40 mm 40 mm 40 mm Weight 765 g 1.010 g 1.415 g Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 44: Technical Details Order No. 632063-632065

632064 632065 Ambient temperature Temperature range -10 - 60 °C -10 - 60 °C -10 - 60 °C Storage temperature Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 45 Aluminium Aluminium Aluminium End caps Front screen Max. torque setting Clamping screw 1,1 Nm 1,1 Nm 1,1 Nm Installation screw 3 Nm 3 Nm 3 Nm Fixing screw 0,7 Nm 0,7 Nm 0,7 Nm Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 46: Technical Details Order No. 632066-632068

Switching current per out- 100 mA 100 mA 100 mA Times 632066 632067 632068 Test pulse duration, safety outputs 300 µs 300 µs 300 µs Supply interruption before de-energisation 600 µs 600 µs 600 µs Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 47 Transmitter M12, 5-pin male con- M12, 5-pin male con- M12, 5-pin male con- nector nector nector Max. cable length 50 m 50 m 50 m Material Housing Aluminium Aluminium Aluminium End caps Front screen Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 48: Technical Details Order No. 632069-632071

Inputs 632069 632070 632071 Max. overall line capacit- ance Clmax 40 nF 40 nF 40 nF Semiconductor outputs 632069 632070 632071 OSSD safety outputs Switching current per out- 100 mA 100 mA 100 mA Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 49 M12, 5-pin male con- M12, 5-pin male con- nector nector nector Transmitter M12, 5-pin male con- M12, 5-pin male con- M12, 5-pin male con- nector nector nector Max. cable length 50 m 50 m 50 m Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 50: Safety Characteristic Data

A safety function's SIL/PL values are not identical to the SIL/PL values of the units that are used and may be different. We recommend that you use the PAScal software tool to calculate the safety function's SIL/PL values. Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 51: Order Reference

Safety light grid for hand protection, protected field height of 1800 mm 632 071 S-30-180 Order reference for accessories Standard installation kit Product type Features Order No. PSEN opII Bracket Standard installation with flexible bracket 632 015 Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 52 Connection 2 Length Order No. PSS67/PDP67 cable straight, M12, 5-pin, socket straight, M12, 5-pin, con- 380 208 M12-5sf M12-5sm nector 380 209 10 m 380 210 20 m 380 220 30 m 380 211 Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 53: Order Reference: Component Parts

PSEN opII4H- For safety light grid for hand protection, protected field height of 1650 632270 s-30-165 emitter PSEN opII4H- For safety light grid for hand protection, protected field height of 1800 632271 s-30-180 emitter Operating Manual PSEN opII4H Series 1003501-EN-02... -

Page 54: Appendix

INFORMATION Commissioning, recommissioning and regular inspection may only be car- ried out by qualified personnel. We recommend that you keep the completed check list and store it with the machine docu- mentation for reference. Operating Manual PSEN opII4H Series 1003501-EN-02... - Page 55 Are all the electrical connections to the safety light grid wired correctly? Check the effectiveness of the safety light grid during the hazardous move- ment Is the safety light grid effective throughout the whole of the plant/machine's hazardous movement? Operating Manual PSEN opII4H Series 1003501-EN-02...

-

Page 56: Ec Declaration Of Conformity

European Parliament and of the Council. The complete EC Declaration of Conformity is available on the Internet at www.pilz.com/downloads. Representative: Norbert Fröhlich, Pilz GmbH & Co. KG, Felix-Wankel-Str. 2, 73760 Ost- fildern, Germany Operating Manual PSEN opII4H Series... - Page 57 Back cover Support Technical support is available from Pilz round the clock. Americas Australia Scandinavia Brazil +61 3 95446300 +45 74436332 +55 11 97569-2804 Spain Canada Europe +34 938497433 +1 888-315-PILZ (315-7459) Austria Switzerland Mexico +43 1 7986263-0 +41 62 88979-30...

Need help?

Do you have a question about the PSEN opII4H Series and is the answer not in the manual?

Questions and answers