Ender 3 S1 Faq

Issue about installation

Hide thumbs

Also See for 3 S1:

- Quick installation manual (12 pages) ,

- Quick installation manual (11 pages)

Advertisement

Quick Links

How long does it take to assemble the

1

machine?

Where is the consumables rack mounted

2

to?

What about the nozzle kit shaking

3

after the machine is installed?

Why is the platform a little shaky

4

after the machine is installed?

What about the Z-axis movement lag

5

after the machine is installed?

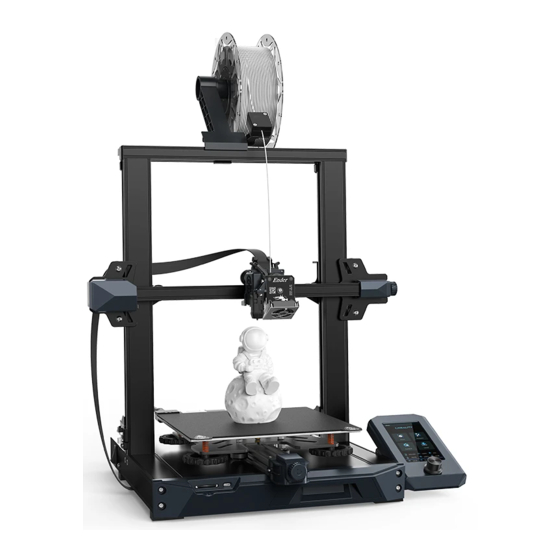

Ender-3 S1 FAQ

Issue about installation

Here is our suggestion for you problem:

Ender-3 s1 product is 96% pre-assembled.

Generally, the printer can be assembled in 5-20 minutes.

We hope this helps you.

If you need further assistance with this issue, please feel free to contact us

Here is our suggestion for you problem:

The consumables rack is fixed to the top of the gantry.

It is placed vertically on top and secured with screws.

We hope this helps you.

If you need further assistance with this issue, please feel free to contact us

Here is our suggestion for you problem:

Please tighten the eccentric nut on the back plate of the nozzle kit.

After commissioning you can test by sliding it from side to side.

Tight is stuck, loose is shaky

We hope this helps you.

If you need further assistance with this issue, please feel free to contact us

Here is our suggestion for you problem:

Please adjust the eccentric nut at the V-wheel of the hot bed.

After commissioning you can test by sliding it

Tight is stuck, loose is shaky

We hope this helps you.

If you need further assistance with this issue, please feel free to contact us

Here is our suggestion for you problem:

Once the screw is installed, the screw nut needs to be adjusted

The axis of movement up and down needs to be the same to maintain a smooth movement.

We hope this helps you.

If you need further assistance with this issue, please feel free to contact us

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Ender 3 S1

- Page 1 Ender-3 S1 FAQ Issue about installation Here is our suggestion for you problem: Ender-3 s1 product is 96% pre-assembled. How long does it take to assemble the Generally, the printer can be assembled in 5-20 minutes. machine? We hope this helps you.

- Page 2 Here is our suggestion for you problem: Please check that the V-wheel is not stuck, What about the X-axis movement get Then adjust the V-wheel until it moves smoothly. stuck, after the machine is installed or left for a period of time? We hope this helps you.

- Page 3 Here is our suggestion for you problem: The printer only supports 1.75mm diameter consumables 11 Does it support 3mm consumables? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: The printer can print PLA, TPU and PETG filaments (ABS requires a constant temperature What consumables does this printer environment to print).

- Page 4 Here is our suggestion for you problem: What is the maximum temperature that Nozzles can reach a maximum temperature of 260 degrees the nozzle can reach? Hot bed can reach a maximum temperature of 100 degrees We hope this helps you. What is the maximum temperature that If you need further assistance with this issue, please feel free to contact us can be reached in a hot bed?

- Page 5 Here is our suggestion for you problem: The fastest printing speed of the printer is 150mm/s. What is the printing speed of the We recommend using 50-100mm/s printing speed is the best machine? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Issue about the product operation Here is our suggestion for you problem: After turning on the power, press the power switch to turn on the machine.

- Page 6 Here is our suggestion for you problem: The machine supports automatic leveling, the specific steps can refer to the SD card in the unboxing video debugging tutorial 28 How to level the printer? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: You can select the PLA preheat option or select Control - Temperature - Printhead/Hotbed Temperature (up to 260 for the printhead and 100 for the hotbed) and just wait for the...

- Page 7 Here is our suggestion for you problem: The machine has the function of power off and continue to print. What about the power suddenly goes You can continue to print after re-powering out, before the model is finished printing? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: The printer can be used at the usual room temperature.

- Page 8 Here is our suggestion for you problem: The nozzle is heated to a high temperature. Children and the elderly need to use in the case of someone to guide the use to avoid Is the machine suitable for children burns and the elderly? We hope this helps you.

- Page 9 Here is our suggestion for you problem: Slicing software such as Cura and Simplify can be used Is there any other slicing software I can use? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: 1))Normal mode Generally, after opening the STL file normally, this is what is displayed.

- Page 10 Here is our suggestion for you problem: Please refer to the following common parameter settings Layer height 0.15mm Wall thickness 1.2mm Top bottom layer thickness 1.2mm Filling 15%~25% Printing speed 50~60 Nozzle temperature 200~210 What are the common settings for Hot bed 45~55 slicing and printing parameters? Support type (all support)

- Page 11 Here is our suggestion for you problem: 1. You can import the model through the open/import function inside the file How does the slicing software import 2. You can directly drag the model into the software models? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: 1.

- Page 12 Here is our suggestion for you problem: Set the nozzle multiplier as a reference For example: 0.4 nozzle, set 0.8 / 1.2 is appropriate 55 How to set the wall thickness? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: Nozzle temperature 200-210 What is the print temperature setting...

-

Page 13: Other Issues

Here is our suggestion for you problem: The support itself has a small contact surface, and it is difficult to bond with the platform directly. Why does the bottom support always Please add a base to the model can be a good solution to the problem stick and fall easily? We hope this helps you. - Page 14 Here is our suggestion for you problem: Available through 3D scanner, own modeling, website download 65 How do I get the model? We hope this helps you. If you need further assistance with this issue, please feel free to contact us Here is our suggestion for you problem: You can just change the material when you find that the supplies are almost not enough to What do I do if I run out of material...

- Page 15 Here is our suggestion for you problem: 1. Check whether the extrusion gear above the motor is loose, and tighten the top wire. 2. Check whether the consumables are knotted or stuck, and straighten them out. 70 No extruding? 3. Please check whether the nozzle is blocked, need to clean the throat We hope this helps you.

- Page 16 Here is our suggestion for you problem: 1. Please use a multimeter to measure the voltage of the hot bed port of the motherboard (there is a schematic diagram of the motherboard in the manual). 2. In the case of no heating indication, if there is 24V voltage, it is a motherboard What about the hot bed automatic failure and needs to be replaced with a new motherboard.

- Page 17 Here is our suggestion for you problem: 1. Try gently rotating the button and pulling it out 2mm. 2. If this does not solve the problem, the knob or screen needs to be replaced. 78 What about the knob failure? We hope this helps you.

Need help?

Do you have a question about the 3 S1 and is the answer not in the manual?

Questions and answers