Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for TRI tool SEVERMASTER 576AC

- Page 1 Operation Manual...

- Page 2 Our products are backed by a company totally committed to service, integrity, and customer satisfaction. Tri Tool Services has developed a solid reputation as a trusted provider of dependable and cost-effective on-site service solutions including turnkey project management, machining services, and mechanized and manual code welding services using experienced and well-trained machinists and welders.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Tri Tool Inc Warranty Tool Bit Resharpening Policy About the Manual Safety General Description Specifications 8 Maintenance Operation Cutting Feed and Speeds Collets Tool Bits 18 Installation Troubleshooting Accessories Illustrated Parts Breakdown... -

Page 4: Tri Tool Inc Warranty

TRI TOOL INC. TRI TOOL INC. Warranty LIMITED WARRANTY: All products manufactured by Seller are warranted to be free from defects in materials and workmanship under normal use. The period of this warranty shall be three years from the date of shipment for all products, except for welding and Non- Standard Products which shall be one year from the date of shipment. -

Page 5: Tool Bit Resharpening Policy

Model 576AC SEVERMASTER™ Buyer’s notice of a defective Goods must identify the specific Goods affected, and the nature of the defect. It is required when returning the defective Goods, that it is suitably packed, fully insured, and transportation and insurance prepaid in accordance with instructions issued by Seller. -

Page 6: About The Manual

The instructions and descriptions in this manual were accurate when the manual was written. However, the information in the manual is subject to change without notice. Check for updated information before you start any job. The Tri Tool Inc. web site has the most current information. -

Page 7: Safety

Model 576AC SEVERMASTER™ 2. SAFETY PRECAUTIONS 2.1 In General Use standard safety equipment such as: hard hats, safety shoes, safety harnesses, protective clothes, and other safety devices when appropriate. Operate this tool only in accordance with specific operating instructions. WARNING: Do not override the dead-man switch on the power unit. Locking down, obstructing, or in any way defeating the dead-man switch on the power drive unit may result in serious injury. - Page 8 Before you start operating the equipment, do no-load tests and feed function checks. 2.7 Tool Use Use the right tool and tool bit for the job. Contact Tri Tool to help with your application. Keep the tool bits fully engaged in the tool bit holders. Loose bits are sharp and can cause cuts or punctures.

-

Page 9: General Description

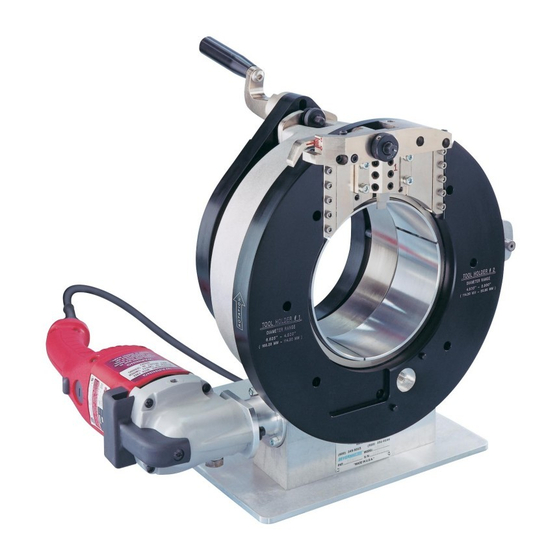

Model 576AC SEVERMASTER™ 3. GENERAL DESCRIPTION The Model 576AC SEVERMASTER™severs 2.00” to 6.63” (50.8mm to 168.3mm) diameter tubes and thin wall pipe within the size range. This machine enhances productivity by incorporation of an Auto-Cycle Tool Module and Quick Lock Collet Closure. The Auto-Cycle Tool Module incorporates a cam cycle tool bit feed mechanism which automatically returns the tool bit to the home position ready to start the next cut. -

Page 10: Specifications

TRI TOOL INC. 4. SPECIFICATIONS WEIGHT 93 lbs (42.2 kg) MOUNTING Manually actuated collet clamping system. DRIVE SYSTEMS Pneumatic Available on request. Electric 115 vac, 20 to 60 hz, 11.0 amp 220 vac, 50/60 hz 15.70" (398.8MM) 16.54" (ROTATING PARTS (420.1MM) - Page 11 Model 576AC SEVERMASTER™ SPEED Maximum cutting head free speed: (Electric) 40 rpm FEED Autofeed system adjustable from .001" (.02mm) to .005" (.13mm). DESIGN AND OPERATING FEATURES The Model 576AC accepts its own torque through the collet clamping system. The collet provides accurate centering and full diameter support for minimum distortion of thin wall tubing.

-

Page 12: Maintenance

TRI TOOL INC. 5. MAINTENANCE All components should be cleaned and coated with a light film of oil prior to use. Use a clean, non-detergent oil, preferably SAE 10 (90 SSU) or lighter. The air supply for the Model 576AC (pneumatic drive) should include an adequate filter, regulator and lubricator (FRL). - Page 13 Model 576AC SEVERMASTER™ TOOL HOLDER Clean the slide rails, the tool holder, and the feed components. Inspect these parts for damage and replace as required. Lubricate and reassemble. Adjust the adjustable slide rail to provide a firm, but not excessive pressure on the tool holder.

-

Page 14: Operation

TRI TOOL INC. 6. OPERATION Read the operating instructions carefully before attempting to operate the Model 576AC SEVERMASTER™. INSERTING THE COLLET Select the desired size collet for the pipe or tube to be worked on. Raise the handle to release pressure on the adjust nut. - Page 15 Model 576AC SEVERMASTER™ Engage the feed by pushing the tripper shaft in. Monitor the cutting operation and apply cutting fluid as necessary. The machine operation is finished when the tool holder returns home, release the lever in order to turn off the motor. Loosen the collet by rotating the handle up.

-

Page 16: Cutting Feed And Speeds

TRI TOOL INC. 7. CUTTING FEEDS AND SPEEDS The table below shows RPM required to obtain a specified Tool Bit cutting speed on the surface of a pipe or tube. Use 200 surface inches per minute (5080 surface millimeters per minute) for stainless steels in general when no coolant is allowed, all heavy wall tube, and some chrome/molybdenum alloys. - Page 17 Mild steels, chrome steels (Rc 35 max.), stainless steel, copper-nickel and aluminum without limitations other than size and wall thickness as specified. Inconel and some other high-temperature alloys may require special procedures as a function of wall thickness. Contact TRI TOOL INC’s Engineering Department for details. 92-1924 Orig. 201016...

-

Page 18: Collets

TRI TOOL INC. 8. COLLETS NOTE: The size of the collet is determined by the outside diameter of the tube or pipe to be severed or squared. 92-1924 Orig. 201016... - Page 19 Model 576AC SEVERMASTER™ Collets, Continued 92-1924 Orig. 201016...

-

Page 20: Tool Bits

TRI TOOL INC. 9. TOOL BITS 92-1924 Orig. 201016... -

Page 21: Installation

Model 576AC SEVERMASTER™ 10. INSTALLATION WARNING: Make sure that the Model 576AC is disconnected from its power source before installing a tool bit. WARNING Install a collet into the Model 576AC. Insert a tube into the collet and bring it flush to the front of the collet and clamp the tube in place. - Page 22 TRI TOOL INC. WARNING: A feed rate of .002” to .003” (.05mm to .08mm) will accommodate most tube materials. WARNING When the desired feed rate is set, tighten the feed lock screw. (DO NOT overtighten.) FEED RATE ADJUSTMENT GRADUATION SCREW...

-

Page 23: Troubleshooting

Model 576AC SEVERMASTER™ 11. TROUBLESHOOTING Problem: The Tool Bit Chatters The tool bit is loose or overextended. The tool bit is damaged. The tool holder is too loose in the slides. The cutting speed is too fast. The clamping pads are loose on the pipe or tube. Cutting fluid is required. - Page 24 TRI TOOL INC. Problem: The Tool Bit is diving and the SEVERMASTER is stalling The tool bit is dull, chipped, etc. The tool holder adjustment slide is too loose. The tool bit is over-extended Problem: The pipe or tube is slipping in the collet The clamping pressure is not tight enough.

-

Page 25: Accessories

2. SQM-2AC Squaring Module Kit (P/N 05-0320) 3. Extended Tool Holder #3 (P/N 49-0326*) *Available by Special Order Only. A portable Air Caddy (FRL) is required to protect the warranty on all TRI TOOL INC air driven tools. 92-1924 Orig. 201016... -

Page 26: Illustrated Parts Breakdown

TRI TOOL INC. 13. ILLUSTRATED PARTS BREAKDOWN MODEL 576AC SEVERMASTER , 110V (P/N 01-2513) ™ 7 9 11 Parts List, Model 576AC SEVERMASTER , 110V (P/N 01-2513) ™ Item Part Description 02-3130 MODEL 576AC SUBASSY. 05-1319 KIT, WRENCH 30-0483 LABEL, LOGO, SMALL 30-0660 LABEL, “WARNING, TOOL BIT”... - Page 27 MODEL 576AC SUBASSY. 05-1319 KIT, WRENCH 30-0483 LABEL, LOGO, SMALL 30-0660 LABEL, “WARNING, TOOL BIT” 30-2061 LABEL, TRI TOOL 30-2488 PLATE, DATA, SEVERMASTER 33-0514 SCREW, SET, 5/16 - 18 X 3/8”, CUP PT. 33-0995 SCREW, DRIVE, #2 X 3/16” 33-1986 SCREW, SET, 5/16 - 18 X 1/2”, CONE PT.

- Page 28 TRI TOOL INC. This Page Intentionally Left Blank 92-1924 Orig. 201016...

- Page 29 Model 576AC SEVERMASTER™ MODEL 576AC SUB-ASSEMBLY (P/N 02-3130) (PAGE 1 OF 2) CONTINUED ON NEXT PAGE 92-1924 Orig. 201016...

- Page 31 Model 576AC SEVERMASTER™ MODEL 576AC SUB-ASSEMBLY (P/N 02-3130) (PAGE 2 OF 2) CONTINUED FROM PREVIOUS PAGE 92-1924 Orig. 201016...

- Page 33 Model 576AC SEVERMASTER™ Parts List, Model 576AC Sub-Assembly (P/N 02-3130) Item Part Description 19-0778 HOUSING, FEED 19-1901 HOUSING, MAIN 20-0633 SHAFT, CLAMP 20-0637 SHAFT, TRIPPER 20-0644 SHAFT, CAM (.230”/5.84MM) 20-0651 SHAFT, DRIVE 20-1787 SHAFT, MAIN 24-1511 PLATE, CLAMP 24-1515 PLATE, TOOL 24-1525 PLATE, STAND 24-5031...

- Page 34 TRI TOOL INC. Parts List, Model 576AC Sub-Assembly (P/N 02-3130) (Continued) Item Part Description 33-1147 SCREW, SET, 5/16 - 18 X 1”, HALF DOG 33-1950 SCREW, SHOULDER, 1/2” X 2 1/2” 33-1985 SCREW, CAP, #10 - 32 X 1/2”, BRASS TIP 33-1986 SCREW, SET, 5/16 - 18 X 1/2”, CONE PT.

- Page 35 Model 576AC SEVERMASTER™ MOTOR ASSEMBLY, ELECTRIC, 110V (P/N 58-0112) 2 3 8 Parts List, Motor Assembly, Electric, 110V (P/N 58-0112) Item Part Description 27-0576 ADAPTER, DRIVE 30-0508 LABEL, “WARNING,DISCONNECT” 30-0961 LABEL, WARNING, SAFETY SWITCH 33-0041 SCREW, CAP, 1/4 - 20 X 7/8” 33-0660 SCREW, SET, 1/2 - 20 X 1/2”, CUP PT.

- Page 36 TRI TOOL INC. MOTOR ASSEMBLY, ELECTRIC, 220V (P/N 58-0340) Parts List, Motor Assembly, Electric, 220V (P/N 58-0340) Item Part Description 27-0602 ADAPTER, DRIVE 27-1555 ADAPTER, MOTOR 30-0508 LABEL, “WARNING,DISCONNECT” 30-0961 LABEL, WARNING, SAFETY SWITCH 33-0054 SCREW, CAP, 5/16 - 18 X 3/4”...

- Page 37 Model 576AC SEVERMASTER™ Parts List, Kit, Wrench, 576AC (P/N 05-1319) Item Part Description 36-0007 WRENCH, L, 5/32” HEX 36-0008 WRENCH, L, 3/16” HEX 36-0020 WRENCH, T, 5/32” HEX X 6” 36-0052 WRENCH, COMBINATION, 3/8” 92-1924 Orig. 201016...

- Page 38 TRI TOOL INC. This Page Intentionally Left Blank 92-1924 Orig. 201016...

- Page 40 • Disconnect power sources before servicing or moving the equipment. • Remove all loose articles of clothing and jewelry before operating the equipment. Be Safety Conscious! 3041 Sunrise Blvd. Rancho Cordova, CA 95742 (916) 288-6100 • (800) 345-5015 www.tritool.com ©Copyright Tri Tool Inc. All rights reserved.

Need help?

Do you have a question about the SEVERMASTER 576AC and is the answer not in the manual?

Questions and answers