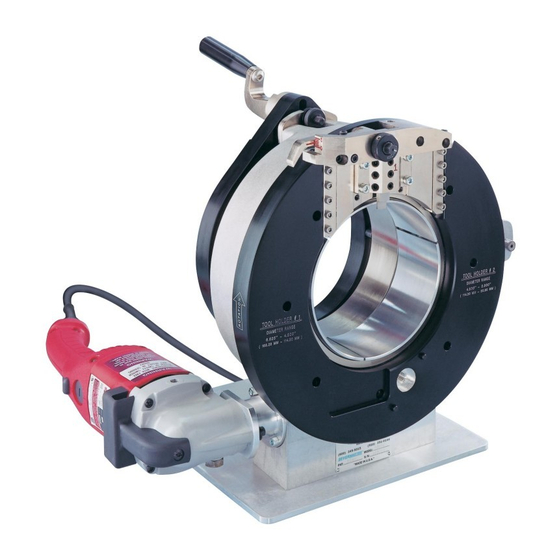

TRI tool SEVERMASTER 576AC Manual

With air motor

Hide thumbs

Also See for SEVERMASTER 576AC:

- Operation manual (40 pages) ,

- Quick start manual (2 pages)

Summary of Contents for TRI tool SEVERMASTER 576AC

-

Page 1: Table Of Contents

TABLE OF CONTENTS CUSTOMER MESSAGE Inside Front Cover SAFETY PRECAUTIONS MACHINE SPECIFICATIONS COLLETS TOOL BITS OPERATION CUTTING SPEEDS AND FEEDS MAINTENANCE TROUBLESHOOTING PARTS LIST ACCESSORIES TOOL BIT RESHARPENING POLICY Inside Back Cover WARRANTY INFORMATION Inside Back Cover... - Page 2 Copyright 1996 proprietary property of TRI TOOL Inc. No reproduction, use, or duplication of the infor- mation shown hereon is permitted without the express written consent of TRI TOOL Inc.

-

Page 3: Safety Precautions

576AC SEVERMASTER with Air Motor SAFETY PRECAUTIONS SAFETY PRECAUTIONS IN GENERAL: When using rotating head cutting equipment, basic safety precautions should always be followed to reduce the risk of personal injury. Operate this tool only in accordance with specific operating instructions. Do not override the deadman switch on the power unit. - Page 4 TRI TOOL INC. Electric motors. Use only with proper AC voltage power sources and observe all normal electric shock hazard procedures. Do not abuse power and control cords. Pulling or running over cords and cables can result in electrical shock hazards and malfunctions. Keep control and power cords out of all cutting fluids and water.

-

Page 5: Machine Specifications

576AC SEVERMASTER with Air Motor MACHINE SPECIFICATIONS SPECIFICATIONS IN GENERAL: The Model 576AC SEVERMASTER™ severs 2.00" to 6.63" (50.8mm to 168.3mm) diameter tubes and thin wall pipe within the size range. This machine enhances productivity by incorporation of an Auto-Cycle Tool Module and Quick Lock Collet Closure. - Page 6 TRI TOOL INC. ° Inconel and some other high-temperature alloys may require special procedures as a function of wall thickness. Contact TRI TOOL INC’s Engineering Department for details. MACHINE FEATURES: ° Pneumatic drive system: 55 cfm at 90 psi (26 it/sec at 6.3 Kg/cm °...

-

Page 7: Collets

576AC SEVERMASTER with Air Motor COLLETS SELECTION: The size of the collet is determined by the outside diameter of NOTE the tube or pipe to be severed or squared. Decimal Part Decimal Part Inches Equiv. Number Inches Equiv. Number 3.750 95.3 30-2592 2.000... -

Page 8: Tool Bits

TRI TOOL INC. TOOL BITS SELECTION: Pipe Wall Tube Range Mat’l Notes: The following tool bits leave the burr on the piece on which the machine is mounted on: .016” thru .040” 99-5482 Tool Bit, Sever, Right Hand, .040” wide .040”... - Page 9 576AC SEVERMASTER with Air Motor Screw in the feed limit adjustment screw until the end of the cutting edge of the tool bit just clears the OD of the tube. Rotate the cam feed knob counter-clockwise to pick up the feed slack. Loosen the collet and re-position the tube to sever.

-

Page 10: Operation

TRI TOOL INC. OPERATION IN GENERAL: Read the operating instructions carefully before attempting to operate the Model 576AC SEVERMASTER™. Inserting the collet: Select the desired size collet for the pipe or tube to be worked on. Raise the handle to release pressure on the adjust nut. - Page 11 576AC SEVERMASTER with Air Motor Mount tool holder #1 for tube ranging from 4.50” to 6.625” (114.3 mm to 168.3 mm). Mount tool holder #2 for tube ranging from 2.00” to 4.50” (50.8 mm to 114.3 mm). MACHINING INSTRUCTIONS: Turn the motor on to full speed by depressing the lever. Engage the feed by pushing the tripper shaft in.

-

Page 12: Cutting Speeds And Feeds

TRI TOOL INC. CUTTING SPEEDS & FEEDS CUTTING SPEEDS: The table below shows RPM required to obtain a specified Tool Bit cutting speed on the surface of a pipe or tube. Cutting Speeds approximately RPM for RPM for RPM for... -

Page 13: Maintenance

576AC SEVERMASTER with Air Motor MAINTENANCE IN GENERAL: All components should be cleaned and coated with a light film of oil prior to use. Use a clean, non-detergent oil, preferably SAE 10 (90 SSU) or lighter. The air supply for the Model 576AC (pneumatic drive) should include an adequate filter, regulator and lubricator (FRL). - Page 14 TRI TOOL INC. Apply fresh lubrication to the tripper shaft assembly and reinstall it in the bracket. Screw in the half-dog setscrew until it locates itself in the slot on the tripper shaft. Try turning the tripper shaft assembly to insure that the setscrew is in the slot of the tripper shaft assembly and is preventing it from rotating.

-

Page 15: Troubleshooting

576AC SEVERMASTER with Air Motor TROUBLESHOOTING PROBLEM: The tool bit chatters. The tool bit is loose or overextended. The tool bit is damaged. The tool holder is too loose in the slides. The cutting speed is too fast. The collet is loose on the pipe or tube. Cutting fluid is required. - Page 16 TRI TOOL INC. PROBLEM: The pipe or tube is slipping in the collet. The clamping pressure is not tight enough. Scale and/or other foreign material is present on the pipe or tube. Weld seams, swelling, or bumps are preventing full contact of the collet.

-

Page 17: Parts List

576AC SEVERMASTER with Air Motor PARTS LIST Model 576AC Sub-assembly, Group B (P/N 02-2438) 92-1176 : Orig. 041012... - Page 18 TRI TOOL INC. Model 576AC Sub-assembly, Group B (P/N 02-2438) Item Part Description 19-0777 Housing, Main 20-0651 Shaft, Drive 20-0652 Shaft, Main 27-0633 Adaptor, Motor 28-0264 O-Ring 28-0245 Seal, Grease 28-0263 O-Ring 29-0020 Bearing, Ball 29-0096 Bearing, Ball 30-2612 Ball, Bearing, Steel (3/8 dia)

- Page 19 576AC SEVERMASTER with Air Motor Model 576AC Sub-assembly, Group C (P/N 02-2438) 92-1176 : Orig. 041012...

- Page 20 TRI TOOL INC. Model 576AC Sub-assembly, Group C (P/N 02-2438) Item Part Description 19-0777 Housing, Main 20-0633 Shaft, Clamp 20-0637 Shaft, Tripper 24-1511 Plate, Clamp 24-1525 Plate, Stand 29-0031 Cam Follower 30-0125 Plunger, Ball (1/4-20 x .53) 30-2611 Button, Spherical 32-0118 Pin, Dowel (3/8 dia x .75)

- Page 21 576AC SEVERMASTER with Air Motor PNEUMATIC MOTOR ASSEMBLY (P/N 57-0254) Drive Assy, Pneumatic (P/N 57-0254) Item Part Description 27-0576 ADAPTER, DRIVE 33-1295 SCREW, CAP, 1/4-20 X .88 54-0128 COUPLING, QD 57-0255 MOTOR, AIR 53-0046 FLOW CONTROL VALVE 54-0705 ADAPTER, 3/8” NPT X 1/4” NPT 92-1176 : Orig.

- Page 22 TRI TOOL INC. ACCESSORIES 57-0100 Portable Air Filter Caddy A FRL is required to protect the warranty on all TRI TOOL INC. air driven tools. 05-0320 SQM-2AC Squaring Module 92-1176 : Orig. 041012...

Need help?

Do you have a question about the SEVERMASTER 576AC and is the answer not in the manual?

Questions and answers