Table of Contents

Advertisement

Quick Links

HIROSE ELECTRIC CO.,LTD.

REVISIONS

Designer

YK.SATAKE

:

TITLE

:

PRODUCT

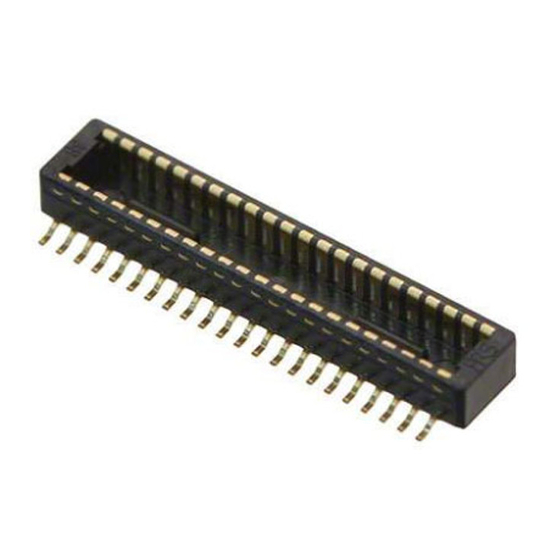

BOARD TO BOARD/FPC CONNECTOR,

DF40 Series Guideline

Approver

Checker

Designer

DIS-H-00010192

Checker

TS.MIYAZAKI

Copyright© 2007 Hirose Electric Co., Ltd. All rights reserved.

DF40 Series Guideline

Pitch: 0.4mm, Width: 3.38mm,

Stacking height: 1.5-4.0mm

WR.FUKUCHI

TS.MIYAZAKI

PAN YIWEI

Approver

WR.FUKUCHI

ETAD-H1015-00

1

18

PAGE:

OF

ETAD-H1015-00

20210331

20210330

20210330

RevNo

1

DATE

20210713

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for HRS DF40 Series

- Page 1 TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm DF40 Series Guideline ETAD-H1015-00 Approver WR.FUKUCHI 20210331 Checker TS.MIYAZAKI 20210330 Designer PAN YIWEI 20210330 REVISIONS DIS-H-00010192 RevNo Designer Checker...

-

Page 2: Table Of Contents

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm TABLE OF CONTENTS PAGE NUMBER Design requirements ............................3 1.1 Mechanical requirements ..........................3 1.1.1 FPC mounting ...........................3 1.1.2 Unexpected disengaging prevention ....................3 1.1.3... -

Page 3: Design Requirements

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm Design requirements 1.1 Mechanical requirements 1.1.1 FPC mounting Attachment of a stiffener larger than the connector outline is recommended to the reverse face of the connector mounted area. -

Page 4: Fpc Fixing

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 1.1.3 FPC fixing For FPC alignment by guide posts, do not disturb FPC flexibility. Design without flexibility of FPC could apply direct stress to the connector by drop impact etc. -

Page 5: When Using Two Sets Connectors

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 1.1.4 When using two sets connectors When using two sets of connectors on one board receptacle and plug, the following mounting accuracy is required. -

Page 6: Allocation Of Other Components Around The Connector

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 1.1.5 Allocation of other components around the connector Do not locate any other components which may affect on connector mating around the connectors. -

Page 7: Pwb Requirements

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 1.2 PWB requirements 1.2.1 Recommended PWB pattern Recommended PWB pad layout for receptacle (ex. 40 pos.) Y dimension H=1.5, 2.0mm: 1.5mmMAX H=2.5~4.0mm: 0.92mmMAX... -

Page 8: Pwb Pad Layout And Connector Location

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 1.2.2 PWB pad layout and connector location Pad layout and connector position for receptacle Pad layout and connector position for plug 1.2.3 PWB designing... -

Page 9: Mounting Requirements

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm Mounting requirements 2.1 Metal mask design Recommended metal mask dimensions for receptacle (ex. 40 pos.) Recommended soldering paste amount: 0.0135 mm (Per 1 Pad) Recommended metal mask dimensions for plug (ex. -

Page 10: Fillet Forming

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 2.2 Fillet forming For the judgment of fillet forming quality, check side fillet forming as an indication. Fillet forming on receptacle Recommended condition is that fillet thickness is one third of contact thickness (0.13 mm) or more,... -

Page 11: Reflow Profile

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 2.3 Reflow profile 1) Temperature measuring point The temperature indicates the PWB surface temperature at the connector lead area. -

Page 12: Repairing (Hand Soldering)

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 2.4 Repairing (hand soldering) Receptacle Plug Repairing condition: Repairing condition: Soldering iron 350 C, 3 seconds MAX. Soldering iron 350 C, 3 seconds MAX. -

Page 13: Connector Handling Requirements

Stacking height: 1.5-4.0mm Connector handling requirements 3.1 Connector mating operation Make sure to mate DF40 Series connectors by hands. Mating procedures 1) Feel for the mating guide with hands to locate the connectors in the appropriate mating position. 2) When positioned, the connector is led into the mating pair by self alignment function. -

Page 14: Connector Unmating Operation

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm 3.2 Connector unmating operation 1) It is desirable to unmate the connector vertically to the mounted surface. However, in the PWB to FPC connection, the higher the pin counts, and the thinner the FPC is, the more difficult to unmate the connector in vertical direction. - Page 15 TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm Failure caused by removing the connector in the width direction 3) Check the rigidity of the FPC for unmating operation prior to your production, otherwise solder breakage and/or connector breakage may occur during unmating process.

-

Page 16: Pwb And Solder Paste Applied For Evaluation Test

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm PWB and solder paste applied for evaluation test 4.1 PWB applied for evaluation test Glass epoxy board for receptacle FPC for plug Copyright©... -

Page 17: Solder Paste Applied For Evaluation Test

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm Glass epoxy board for plug FPC for receptacle 4.2 Solder paste applied for evaluation test Lead-free solder paste manufactured by Senju Metal Industry Co., Ltd. -

Page 18: Additional Information

TITLE DF40 Series Guideline ETAD-H1015-00 PRODUCT BOARD TO BOARD/FPC CONNECTOR, PAGE: Pitch: 0.4mm, Width: 3.38mm, HIROSE ELECTRIC CO.,LTD. Stacking height: 1.5-4.0mm Additional information 5.1 PWB cleaning 1) Control the cleaning liquid in order not to contaminate the connector contact area by cleaning liquid.

Need help?

Do you have a question about the DF40 Series and is the answer not in the manual?

Questions and answers