Subscribe to Our Youtube Channel

Summary of Contents for Kval 700-DC

- Page 1 KVAL INC. Operation and Service Manual 700-DC Frame Assembly Machine With Hand Controls...

- Page 2 This document, the information in this document, and all rights there to are the sole and exclusive property of Kval, are intended for use by customers and employees of Kval, and are not to be copied, used, or disclosed to anyone, in whole or in part, without the express written permission of Kval.

- Page 3 Copyright 2019 Kval Incorporated. All rights reserved. 825 Petaluma Blvd So. Phone (707)-762-7367 • Fax (707)-762-0485 www.kvalinc.com...

- Page 4 SERIAL No._____________________________________________ DATE OF PURCHASED___________________________________ This manual is designed with safety in mind. We at KVAL want to begin FAST and SAFE production as soon as possible. It is very important that all OPERATORS and MAINTENANCE personal read this manual thoroughly. We have included important safety information that will help prevent serious injury;...

-

Page 5: Table Of Contents

PERATORS RAINING ....................11 THER AZARD ONTROL CTION 700-DC GUARD PLACEMENT AND PURPOSE ..............13 UNPACKING THE KVAL 700-DC ASSEMBLY TABLE ............14 PROPER LIFTING TECHNIQUES.................... 15 ..................16 NCHORING THE ACHINE TO THE LOOR SPECIFICATIONS........................17 ........................18 VAILABLE PTIONS TOUR OF THE MACHINE ...................... - Page 6 LECTRICAL ANEL CONTROLS ........................... 23 ..........................23 ONTROL ....................24 BOUT THE ANDS UTTONS TURNING THE 700-DC ON AND OFF ..................25 700-DC......................25 OWERING P THE 700-DC ...................... 25 OWERING OWN THE OPERATING THE 700-DC ......................26 ................26...

-

Page 7: Customer Service Information

This Manual is confidential and contains proprietary information and intellectual property of KVAL Inc., and is to be used solely by Customer as an operating manual for KVAL Inc. machines. Neither this Manual nor any of the information contained herein may be reproduced or disclosed under any circumstances without the express written permission of KVAL Inc. -

Page 8: Contacting Kval

(NOTE: This is not a customer support email link. For that, please refer to the Customer Service contact information above.) Thank you! This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 9: Product Return Procedure

• Include the packing slip or invoice numbers. • Include the documented reason for return. • Include the RMA number with the parts package. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 10: Getting Started

Our technicians have already performed an initial quality control check before shipping your machine. Please review the checklist and return “Acknowledgment Copy” to KVAL Verifying This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 11: Safety First

This section contains important safety information. Failure to follow these safety guidelines may subject the operator to physical hazards that may result in serious bodily harm, or death. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 12: Safety Responsibility

8. The lock and tag can now be removed (only by the person who place them), and the machine can be re-energized. 9. The tag shall be destroyed and the lock and key returned to the lockout center. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 13: Tag Types

In addition to safety concerns, this policy is required by OSHA regulation 1910.147 and Cal OSHA’S SB198 ruling of July 1991. Tag Types This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 14: Zero Energy Start Up

Replace all guards to the equipment. If adjustments can not be made with the guard on after start-up, leave off only the ones to be adjusted after start-up. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 15: Check Controls

P-R-OP-E-R Lock-0ut/Tag-Out procedures, and that those around you do also. YOUR LIFE MAY DEPEND ON IT. http://www.concrete-pipe.org/sab.htm © 2004 American Concrete Pipe Association (ACPA). All Rights Reserved. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 16 7 0 0 - D C F R A M E A S S E M B L Y M A C H I N E This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 17: Safety Guidelines

This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 18 We will be pleased to review with you any questions you may have regarding the safe operations of this machine. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 19: 700-Dc Guard Placement And Purpose

Possible injuries from getting any part of the body caught by the wheel assembly include: • Broken Bones • Bruises • Cuts and Amputation Never operate the 700 without the guards. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 20: Unpacking The Kval 700-Dc Assembly Table

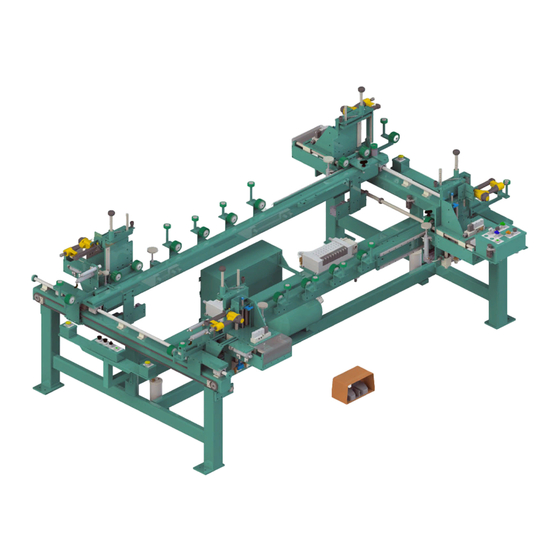

Unpacking the KVAL 700-DC Assembly Table The Kval 700-DC assembles leg jambs to a head jamb to create a door frame. It has no other intended use. The lock side jamb and a header a jamb are inserted by the operator, next a door and attached hinge jamb are rolled into the bed of the machine. -

Page 21: Proper Lifting Techniques

F R A M E A S S E M B L Y M A C H I N E Proper Lifting Techniques This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 22: Anchoring The Machine To The Floor

This insures the epoxy fills voids and crevices. Hardening begins in 7 minutes @ room temperature. • After recommended cure time, bolt in place This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 23: Specifications

750S5-1 (7/16" Crown) and 750S4-1 (1/2" Crown) Duo Fast KS 7648 or MS 7664 Paslode PA 200 S-16 Paslode MA-080-T (T-Nailer) Power Line Senco K or M-11 This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 24: Available Options

Please review with your KVAL consultant to determine your needs. Option: UL Electric panel is built according to Underwriter's Laboratories specifications, and 'UL' Label applied. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 25 Canadian government, no services (including installation or warranty work) can be performed by KVAL technicians in the customer's plant. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 26: Tour Of The Machine

Electrical Panel with Touch Screen Movable Fence Width Collar Bar Fixed Fence Sill End Movable Left hand Gun Fixed Left Hand Gun This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 27: Top View With Control Dual Button Control

Head End Button Control Head Clamp Only Head End Button Control Sill End Sill End Full Control This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 28: Operator Side View

M A C H I N E Operator Side View Movable Fence Adjustable Jamb Height X 4 Operators Station Electrical Panel View Side Fixed Electrical Fence Panel This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 29: Controls

Width Adjust: Pull to allow adjustment of the Width. Push down to lock into place. Foot Pedal Control. Forward and Reverse the process. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 30: Buttons

Reset Left: Press to return the forward with the door process. Press machine to a left hand door setting. both Hands Free Buttons to continue sequence. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 31: Turning The 700-Dc On And Off

2. KVAL recommends turning off the Power Disconnect. This kills power to the machine. Reduce possible damage resulting from power surges from electrical storms. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 32: Operating The 700-Dc

After loading the door, perform these steps to staple the frame with the Hands Free Buttons. If operating a machine with Foot Pedal controls, skip to the next section. Push Both Hands Free Buttons to Sequence This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 33 Hands Free Buttons 8. Push both (drops door to lower position). Hands Free Buttons 9. Set Sill in place. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 34: Using Foot Pedals To Staple A Frame

P E D A L O P E R A T I O N Make Sure Jambs are secure with vertical adjust on all 4 heads This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 35 11. Push the (un-clamps door). Sequence Forward Foot Switch 12. Pull out the Door 13. Press Reset. (Returns machine to start position). This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 36: Adjustments Of The Length And The Width

Head Set for 8’.0” Length 6’6” Length 6’.8”” Length 7’.0” Length 8’.0” Length Head Set for 6’.6” Length 6’6” Length 6’.8”” Length 7’.0” Length 8’.0” Length This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 37: About Width Adjust

To adjust to different jamb widths, pull the knob to the right to unlock, move the clamp down until the desired position locked This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 38: About The Touch Screen Interface

See See “ Programming” See “Maintenance Main Screen on page 26. (below) Screen” on page 55. Programming Program Number Programing Buttons Programming Buttons This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 39 Note: All programming button locations have a tolerance of +/- 1/4” 4 1/2” 4 3/4” 5” 5 1/2” 5 1/2” 5 3/4” 6” 6 1/4” 6 1/2” 6 3/4” 7” 7 1/4” This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 40: Maintenance Schedule

Empty any Dust Collection Units. Clean Check for obstructed flow when excessive sawdust appears. Check Check the air filter water trap. Empty if full. Check This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 41 Clean and lubricate all slides and cylinder rods with dry silicone spray. Clean Tighten all bolts. Tighten Backup computer software. Back-up Lubricate linear bearings and chrome shafts with silicone. LUBE This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 42: Lubrication Schedule

Note: Some CNC Machines drop every 5-10 cycles. • G-C lubricants light AW R&O • Mobile DTE 24 • Shell Tellus32 • Gulf Harmony 32 This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 43: Typical Lucubration Kit

When this is accomplished, place the airline back into its original position. Repeat this same procedure for the back section and other trouble areas. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 44: Limit Switches

“Click”, the switch needs to be adjusted here is how you adjust it follow the following drawings. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. -

Page 45: General Air Circuitry Trouble Shooting

If you wish to keep the valve open, the push button assembly can be removed using and open ended wrench and inserting a 3/8” N.C. cap screw. DO NOT over tight when reassembling the valve. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 46 Please review this drawing as this adjustment is not done in a normal manner. To change cylinder extension speed: To change cylinder retraction speed: This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

-

Page 47: Basic Electrical Trouble Shooting

1. Check that the input power disconnect switch is not turned off. 2. Check that all of the emergency stop buttons are in the normal position. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons. - Page 48 If the computer terminal strips lights, the switch needs to be re-adjusted. For more information on the limit switch see the manufactures information at the end of this manual. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

- Page 49 5. If a solenoid valve is suspected, and not cleared in the air checks section mentioned previously, it can be electrically jumped to check operation. This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

- Page 50 7 0 0 - D C F R A M E A S S E M B L Y M A C H I N E NOTES This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

- Page 51 7 0 0 - D C F R A M E A S S E M B L Y M A C H I N E This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

- Page 52 Contacting KVAL Customer Service Phone and Fax: Mailing address: In the U.S and Canada, call (800) 553-5825 or fax Customer Support Department (707) 762-0485 Kval Incorporated Outside the U.S. and Canada, call (707) 762-7367 825 Petaluma Boulevard South or fax (707) 762-0485 Petaluma, CA 94952 Email: service@kvalinc.com...

Need help?

Do you have a question about the 700-DC and is the answer not in the manual?

Questions and answers