Dorner 2100 Series Installation, Maintenance & Parts Manual

Top mount drive package for standard load 90 industrial 60 hz gearmotors

Hide thumbs

Also See for 2100 Series:

- Installation, maintenance & parts manual (38 pages) ,

- Installation and maintenance manual (28 pages) ,

- Installation & maintenance (16 pages)

Table of Contents

Advertisement

Quick Links

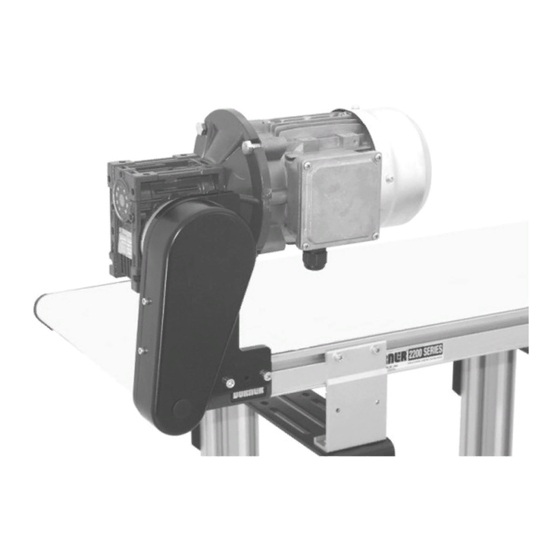

2100, 2200, 4100, 6200, MPB

Series Top Mount Drive

Package for Standard Load

90° Industrial 60 Hz

Installation, Maintenance & Parts Manual

DORNER MFG. CORP.

P.O. Box 20 • 975 Cottonwood Ave.

Hartland, WI 53029-0020 USA

851-257 Rev. J

Gearmotors

For other service manuals visit our website at:

www.dorner.com/service_manuals.asp

INSIDE THE USA

TEL: 1-800-397-8664

FAX: 1-800-369-2440

OUTSIDE THE USA

TEL: 262-367-7600

FAX: 262-367-5827

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Dorner 2100 Series

- Page 1 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Installation, Maintenance & Parts Manual DORNER MFG. CORP. INSIDE THE USA OUTSIDE THE USA P.O. Box 20 • 975 Cottonwood Ave. TEL: 1-800-397-8664 TEL: 262-367-7600...

-

Page 2: Table Of Contents

IMPORTANT 3923148 and corresponding patents and patent applications in other countries. Some illustrations may show guards Dorner 2200, 6200 & MPB Series conveyors are covered by removed. Do NOT operate equipment without patent number 5174435 and corresponding patents and guards. -

Page 3: Warnings − General Safety

A WARNING The safety alert symbol, black triangle with white exclamation, is used to alert you to potential personal injury hazards. Dorner cannot control the physical A DANGER installation and application of conveyors. Taking protective measures is the responsibility of the user. -

Page 4: Product Description

Gearmotor Type = Standard Load, Industrial Output Shaft Type = 90° Industrial Mount Style = Top Mount Language Code = U.S. English 2 = 2100 Series Conveyor 22 = 2200 & MPB Series Conveyor 4 = 4100 Series Conveyor 6 = 6200 Series Conveyor... - Page 5 10.0 – 84.0* * = Nosebar transfers operate at maximum 77 Ft/min (23.5 M/min) belt speed 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp.

- Page 6 11 = 115 V, 1-phase R = With reversing switch 23 = 208−230/460 V, 3-phase (n) = Reversing Capability 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J...

- Page 7 * = Cleated and Sidewall Cleated belts operate at a maximum of 150 ft/min (45.7 m/min) 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp.

-

Page 8: Installation

Figure 2. Gearmotor position on Cleated Belt and MPB Series conveyors shown in Figure 3. Figure 4 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J... - Page 9 Gearmotor similar. is mounted For your reference, the following figures show to Head gearmotor mounting configurations for various Plate conveyor series. Figure 5 2100 Series Figure 8 Figure 9 Gearmotor is mounted to Head Gearmotor Plate is mounted to Head...

- Page 10 Attach mount assembly (Figure 13, item I) with screws (O). Tighten to 80 in-lb (9 N−m). 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J...

- Page 11 0.125¨ (3 mm) deflection for 1.0 lb (456 grams) of force at timing belt mid-point (W). Tighten tensioner screw to 103 in-lb (12 N−m). 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp.

-

Page 12: Preventive Maintenance And Adjustment

Install cover (Figure 17, item K) with four (4) screws (L). Tighten to 35 in-lb (4 N−m). (L). Tighten to 35 in-lb (4 N−m). 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J... -

Page 13: Drive Or Driven Pulley Replacement

Remove two (2) screws (AC) and detach output shaft cover (AD). Remove gear reducer output shaft key (AE). Figure 20 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp. -

Page 14: Motor Replacement

Cleated Belt and MPB Series conveyors death. LOCKOUT POWER BEFORE before shown in Figure 26. wiring. 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J... - Page 15 Remove four screws (Figure 29, item Y). Detach motor (Z) from gear reducer (AA). Retain motor output shaft key (AB). Figure 29 Figure 29 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp.

-

Page 16: Service Parts

Service Parts NOTE For replacement parts other than those shown in this section, contact an authorized Dorner Service Center or the factory. Key Service Parts and Kits are identified by the Performance Parts Kits logo . Dorner recommends keeping these parts on hand. -

Page 17: Industrial Gearmotors

980422M Square Key, 4mm x 22mm 450371MP Drive Pulley, 60Tooth 807-1133 Washer 450445 Spacer 802−046 Bearing 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp. -

Page 18: 4100 Mounting Package

60 hz or when used as an indexing motor. When used as a variable speed motor, the HP rating is reduced to 1/4 hp. 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors Dorner Mfg. Corp. 851-257 Rev. J... -

Page 19: Notes

Notes 2100, 2200, 4100, 6200, MPB Series Top Mount Drive Package for Standard Load 90° Industrial 60 Hz Gearmotors 851-257 Rev. J Dorner Mfg. Corp. -

Page 20: Return Policy

RMA will automatically close 30 days after being issued. To get credit, items must be new and undamaged. There will be a return charge on all items returned for credit, where Dorner was not at fault. It is the customer’s responsibility to prevent damage during return shipping.

Need help?

Do you have a question about the 2100 Series and is the answer not in the manual?

Questions and answers