Table of Contents

Summary of Contents for amiad Filtomat MCFM 12000

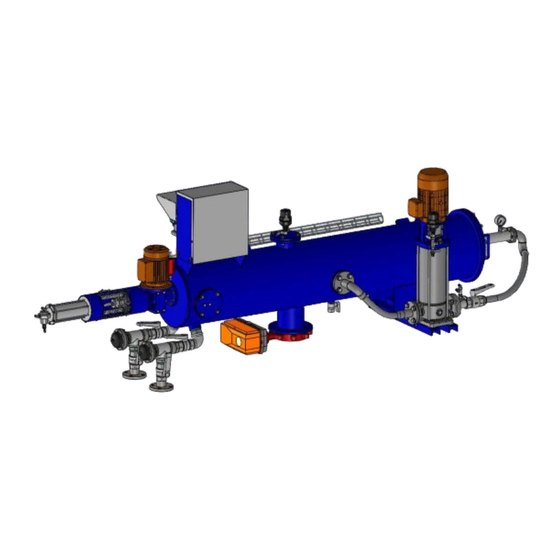

- Page 1 AMIAD Water Systems LTD. 6" Filtomat MCFM 12000 C/ST Filter Serial number: Order Number: Catalog Number: Filtration Degree: Tested By: Installation, Operation and Maintenance Instructions Ref. 6”-12,000/ 06.2020 Original Instructions...

- Page 2 Amiad. While every effort has been made to ensure the information in this manual is accurate and complete, we would appreciate if you can bring any errors or omissions to the knowledge of Amiad or consult Amiad experts or its authorized representatives if you have any questions.

-

Page 3: Table Of Contents

TABLE OF CONTENTS TECHNICAL SPECIFICATIONS ........................6 SAFETY INSTRUCTIONS ..........................7 P&ID DRAWING ............................10 DESCRIPTION AND FILTER OPERATION ....................11 Filtering process ..........................11 Self-cleaning process ........................... 11 Different modes of filtration ....................... 11 INSTALLATION ............................12 Installation instructions ........................12 Important notes on drain pipe configuration!! ................... - Page 4 Definitions of continuous flush sub-modes .................... 42 Program logic steps in continuous flush mode ..................43 PROGRAMMING General Operations ..................... 44 Amiad Limited Warranty ........................59 With any inquiry please quote the Filter Serial Number, located on the filter housing. 6” MCFM - 12000 01.2021...

-

Page 5: Technical Specifications

TECHNICAL SPECIFICATIONS General Flow rate range 150 m³/h Consult supplier for optimum flow depending on filtration degree & water quality. Min. working pressure 1 bar 14.1 PSI Max. working pressure 10 bar 150 psi Inlet/Outlet diameter 150mm,100mm 6",4” AS 4087 PN16 Max. -

Page 6: Safety Instructions

Always observe standard safety instructions and good engineering practices whilst working in the filter’s vicinity. Use the filter only for its intended use as designed by Amiad, any misuse of the filter may lead to undesired damage and may affect your warranty coverage. - Page 7 Operation procedures exactly as described in this manual. Commissioning the filter should be done by an authorized Amiad technician, do not attempt to commission the filter unaccompanied since this may lead to undesired damage and may affect your warranty coverage.

- Page 8 Maintenance Before any maintenance or non-regular operation please read the following: Servicing the filter should be done only by technicians authorized by Amiad. Disconnect the filter from the power supply and lock the Main Power Switch. Disconnect the compressed air supply, release the residual pressure and lock the Pneumatics Main Valve.

-

Page 9: P&Id Drawing

P&ID DRAWING 8” MCFM - Page 10 of 61... -

Page 10: Description And Filter Operation

DESCRIPTION AND FILTER OPERATION Filtering process The MCFM is an automatic, continuous, self-cleaning filter for high flow rates and high dirt loads driven by electrical control combined with pneumatic or hydraulic operation. The MCFM is designed to work with various types of screens in filtration degrees from 3000 to 15 micron, and is available in 4", 6", 8", 10"... -

Page 11: Installation

INSTALLATION Installation instructions 1. Select a convenient location for the installation of the filter where operation and maintenance will be optimum. A lifting auxiliary is recommended for installation. 2. Ensure that the distance between inlet and outlet flanges complies with the data sheet. 3. -

Page 12: Prevention Of Reverse Flow

PREVENTION OF REVERSE FLOW Fine screen collapse is caused by hydraulic pressure acting externally upon the screen. The hydraulic back pressure results from a differential pressure across the screen, where the external pressure is greater than the internal pressure. The process conditions leading to this screen failure have been identified through failure studies of actual installed filters. -

Page 13: Electric Wiring

ELECTRIC WIRING If the control board is not mounted on the MCFM, install the control board in a dry and protected place. Electrical power source preparation 1. Prepare a three-phase (R, S, T, N, G) power supply. The power source parameters are determined by the local main power network voltage and pump size. -

Page 14: Start-Up And First Operation

START-UP AND FIRST OPERATION Prior to operation, completely understand controller settings. Make sure the electric wiring is correct, according to the enclosed drawings. Open the continuous flush valve completely. Open the booster pump vent valve to bleed air. Apply water to the filter. If inlet valve is installed, open valve. Open all manual valves on the outlet tubing system of the booster pump. -

Page 15: Maintenance

MAINTENANCE Schedule of inspections and preventive maintenance. The following schedule of inspections and preventive maintenance is based on continues filtration duty, and therefore should be used as a guideline only. It is recommended having a periodic inspection to see if there is no increase in grease leakage. This indicates wear of the bearings and they need to be replaced in order to prevent damage to the Rod Connection Type6 (Part No46) The user should compile his or her own schedule of maintenance and inspection based on experience gained from using the filter and learning its operation in service. -

Page 16: Dimensional Drawing

Dimensional Drawing 6” MCFM - 12000 01.2021 Page 17 of 61... -

Page 17: Parts Schedule - Section

PARTS SCHEDULE ITEM NO. CAT. NO. DESCRIPTION QTY. MATERIAL 710105-005943 MCFM-12000 HOUSING 6" BSTE PKPK 5010 ST.37-2 POLYESTER ST 37-2 750103-001719 SPOOL MANIFOLD 2" AS4087 S/ST316L 10 BAR S/ST 316 710103-003369 GUIDE PIPE MCFM OKOLON F/DIRT COLLECTOR Akulon 710103-003147 RING RETAINING MCFM-12000 NBR F/DIRT COLLECTOR Rubber 700190-002802 D.C. - Page 18 ITEM NO. CAT. NO. DESCRIPTION QTY. MATERIAL 720103-000703 SOLENOID+LED BURKERT 0330 3WAY 3/2 NO 8W 24VDC 50/60HZ 1/4" 2MM S/ST S/ST 316 NPT NBR SEALS 0-16BAR IP65 720501-001180 ELBOW CONNECTOR 1/4"M X8MM NPT S/ST316 AIGNEP S/ST 316 760101-000841 HEX BOLT FULL THRD M5 10MM S/ST316 DIN933 S/ST 316 760103-000093 FLAT WASHER M5 DIN125 S/ST304...

- Page 19 ITEM NO. CAT. NO. DESCRIPTION QTY. MATERIAL 760101-000585 HEX BOLT PARTIAL TH 5/8"UNCX2 3/4" 316 S/ST 316 760102-000118 HEX NUT 5/8"UNC S/ST316 B18.2.2 S/ST 316 760101-000576 Hex Bolt Partial Thread 1/2"UNCX2 3/4" 316 S/ST 316 720501-001178 STRAIGHT CONNECTOR 1/4"M X8MM NPT S/ST316 AIGNEP S/ST 316 760104-000153 STUD BOLT 5/16"...

- Page 20 Explosion Drawings 6” MCFM - 12000 01.2021 Page 31 of 61...

- Page 21 6” MCFM - 12000 01.2021 Page 32 of 61...

-

Page 22: Lubrication

LUBRICATION Piston gear unit All units are supplied with oil filling, oil level and drain plugs. To fill the gear with oil remove the oil level and oil overflow plugs and fill through oil filling hole until lubricant overflows the oil level plug hole. - Page 23 PRIMARY DISASSEMBLY INSTRUCTIONS Opening the filter and disassembling its inner components is necessary for changing screens, periodic maintenance and repairs. Prior to opening the filter it is recommended to operate a flushing cycle. Prior to disassembling the filter: 1. Isolate, depressurize, and drain the filter 2.

- Page 24 PRIMARY ASSEMBLY INSTRUCTIONS Insertion of dirt collector (J), fine screen (K), and coarse screen (I) 1. Slide the dirt collector (J) into the fine screen (K), taking care not to damage the fine screen mesh. 2. Inspect and grease the fine screen O-rings (L). 3.

- Page 25 In no event shall Amiad be liable to the Buyer or any third party for any damages to property, or for any intangible or economic loss, including loss of profits, loss of customers or damage to reputation, for any damages, including indirect, special, consequential damages, or punitive damage arising out of or in connection with this Warranty, or arising out of or in connection with the product's performance or failure to perform, even if it has been advised of the possibility of such damages.

- Page 26 Manufacturer Amiad Water Systems Ltd. D.N. Galil Elyon 1, 1233500, Israel. Tel: +972 4690 9500 | Fax: +972 48141159 | Email: info@amiad.com European Authorised Representative for CE Obelis s.a. Bd Général Wahis 53, 1030 Brussels, Belgium. Tel: +(32) 2732 5954 | Fax: +(32) 27326003 | Email: mail@obelis.net...

- Page 27 8” MCFM - 12000 06.2020 Page 61 of 61...

- Page 28 8” MCFM - 12000 06.2020 Page 62 of 61...

Need help?

Do you have a question about the Filtomat MCFM 12000 and is the answer not in the manual?

Questions and answers