Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for HMS AnyBus DataTransfer

- Page 1 ® ESIGN UIDE ® RANSFER ARALLEL NTERFACE Doc. No. ABDT-DGP-1.12 HMS F Phone: +46 - 35 - 17 29 00 IELDBUS YSTEMS FAX: +46 - 35 - 17 29 09 Pilefeltsgatan 93-95 e-mail: info@hms.se S - 302 50 Halmstad www: www.hms.se...

-

Page 2: Table Of Contents

1.1 Terminology ..............................6 1.2 Background ..............................6 1.3 Conditions of Trademark Use ........................6 2 Description of the ANYBUS DATATRANSFER Module .................. 7 2.1 Interface to the Application ........................... 7 2.1.1 Parallel Interface............................8 2.1.2 Serial Interface ............................8 3 Introduction to an ANYBUS Application...................... - Page 3 B1.2 Galvanically Isolated Supply for BUS Electronics: ................33 Appendix C Fieldbus Specific Area (3C0h - 3DFh) ..................... 35 C1 InterBus................................35 C2 Profibus-DP ..............................35 Appendix D Data Sheets DPRAM ........................35 HMS F Page 3 (35) IELDBUS YSTEMS...

-

Page 4: Preface

The data and illustrations found in this design guide are not binding. We reserve the right to modify our products in line with our policy of continuous product development. The information in this design guide is subject to change without notice and should not be considered as a commitment by HMS Fieldbus Systems AB. -

Page 5: Revision Notes

Design Guide Revision 1.12 1998-08-12 0 Revision Notes Index Date Chapter Author Revision 97-12-02 Created 0.1 97-12-15 Revision 1.1 98-04-25 Revision 1.11 98-07-14 Future use Revision 1.12 HMS F Page 5 (35) IELDBUS YSTEMS... -

Page 6: Introduction

1.1 Terminology Throughout this document the term "user" refers to the person or persons who are developing a fieldbus product based on the ANYBUS DATATRANSFER module. The end-user of the product is referred to as the "customer". As in all communication systems the terms "read" and "write" can be ambiguous, because their meaning depends on which end of the link is being referenced. -

Page 7: Description Of The Anybus Datatransfer Module

Since different hardware is required for the different interfaces, only one of the above mentioned access methods can be used in one module. Also note that there is one ANYBUS DATATRANSFER module for each fieldbus system. The synchronous interface is only available for development of customer specific products. -

Page 8: Parallel Interface

The serial interface is available as an asynchronous interface, RS232 with TTL level.. The asynchronous serial interface allows the ANYBUS DATATRANSFER module to exchange data asynchronous with external microprocessors. It has a standard non-return to zero (NRZ) format (one start, eight data, one stop and none parity bit). -

Page 9: Introduction To An Anybus Application

480 bytes of output data. If this amount is still not sufficient enough for your application, please ask HMS for a customer specific implementation. Some fieldbus systems can not support large amount of data and can not be configured for the maximum 480 bytes of data inputs/outputs In the following chapters it is described how an implementation when using the DataTransfer module is performed. -

Page 10: Future Use Compatibility

Table 2. Interface connector pin description 3.1.2 Mounting devices (for future use) 11.00mm Hole C. Hole B. Hole A. 4.00mm 59.50mm Figure 4. Mounting holes A) Conductive hole. Used to connect P.E. on carrierboard with fieldbus electronics. HMS F Page 10 (35) IELDBUS YSTEMS... - Page 11 Design Guide Revision 1.12 1998-08-12 B) Isolated hole. For use with non conductive screws. Connect to P.E. on carrierboard. C) Conductive hole. Used for improved GND connection. HMS F Page 11 (35) IELDBUS YSTEMS...

-

Page 12: Dual Ported Ram Interface

3E0h - 3FFh Using the input- and output- length register for I/O data (3F8h - 3Fbh) makes it possible to change the size of the input and output area within the 480 supported bytes. HMS F Page 12 (35) IELDBUS... -

Page 13: Input Area (000H - 1Dfh)

Area containing fieldbus and module status. Status read only (AB-DT ð application) (4 bytes) 3D8h - 3DBh Area containing fieldbus and module status. Bi directional Status read / write (AB-DT ïð application) (4 bytes) 3DCh - 3DFh HMS F Page 13 (35) IELDBUS YSTEMS... -

Page 14: Control Register (3E0H - 3Ffh)

This register gives an ID-number of the board in use. The ID-number can be used to identify the revision of the used board. It is not an unique number! 4 Software version (3F6h) HMS F Page 14 (35) IELDBUS YSTEMS... - Page 15 Any value set by the application that exceeds the maximum value of the fieldbus in use will be adjusted to maximum number of inputs or outputs by the AnyBus module. 3F8h HIGH BYTE 3F9h LOW BYTE 3FAh HIGH BYTE 3FBh LOW BYTE Table 4. Motorola mode representation HMS F Page 15 (35) IELDBUS YSTEMS...

- Page 16 If the application tries to access the DPRAM more than one second the control will be forced back to the AnyBus module. The AnyBus module is indicating this by changing DPRAM-owner from 10 to 01. The AnyBus module waits one millisecond before it starts to accesses the DPRAM again. HMS F Page 16 (35) IELDBUS...

- Page 17 By looking at the high nibble of the register, the application can easy check which side that owns access to the DPRAM according the following: Function Contents: Description 0000 xxxx AnyBus module has control over DPRAM 1111 xxxx application has control over DPRAM Table 8. AB-DT control overview HMS F Page 17 (35) IELDBUS YSTEMS...

-

Page 18: Handshake Procedure

After the initialisation is performed successfully, the DataTransfer module is in data exchange state, and data can be exchanged with the fieldbus. NOTE! The initialisation is only performed once after system reset (e.g. power up) HMS F Page 18 (35) IELDBUS YSTEMS... - Page 19 APP IND = 02 wait until DT WAIT 0.1 ms could have respond APP IND = 01 restart AB_IND initialisation with changed parameters initialisation completed INIT Successfully COMPLETE Fieldbus Running Figure 5. Initialisation HMS F Page 19 (35) IELDBUS YSTEMS...

-

Page 20: Data Exchange Mode

When the last feature is used, the new data flag should be cleared during the access cycle. In order to prevent deadlocks, a time-out function should be implemented by the application, which will either leave the procedure or re-enter it. HMS F Page 20 (35) IELDBUS... - Page 21 1 sec. request release APP_IND = 01 the DPRAM WAIT 0.1 ms AB_IND ERROR encountered; retry release AB_IND release OK? DPRAM accessing STOP completed Figure 6. Poll mode HMS F Page 21 (35) IELDBUS YSTEMS...

- Page 22 1 sec. request release APP_IND = 01 the DPRAM WAIT for wait until DT module INTERRUPT responds AB_IND ERROR encountered; retry release AB_IND release OK? accessing DPRAM STOP completed Figure 7. Interrupt mode HMS F Page 22 (35) IELDBUS YSTEMS...

-

Page 23: Interface Software Design

Design Guide Revision 1.12 1998-08-12 5 Interface Software Design This section is still under development. Please contact HMS for support and application examples of interface software. HMS F Page 23 (35) IELDBUS YSTEMS... -

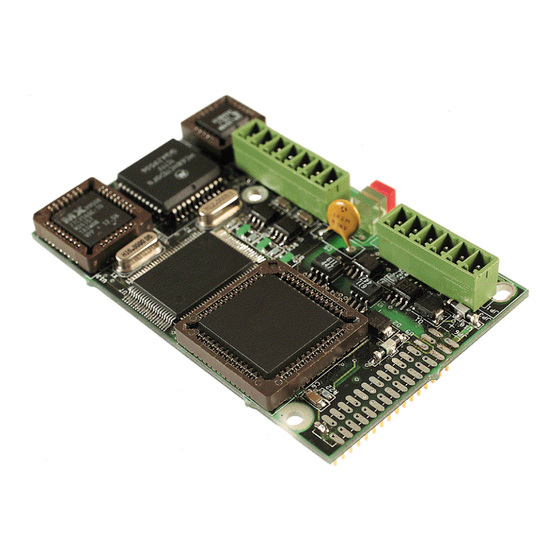

Page 24: Mechanical Specification

6 Mechanical Specification 6.1 Module Mechanical Drawing All ANYBUS DATATRANSFER modules are mechanically compatible i.e. all modules follow the mechanical specification below. The modules can be divided into two different areas: 1. Electronics. Area where General ANYBUS DATATRANSFER hardware like DPRAM, CPU, EPROM etc. -

Page 25: Connectors

For more information regarding the connectors, please see Appendix A. 6.2.2 Fieldbus Connector Only the first fieldbus D-SUB connector is placed in the same position on all ANYBUS DATATRANSFER modules. The placement of the other fieldbus specific components are unique for each ANYBUS module. -

Page 26: Mounting Devices

(PE) connection to the module. Almost every fieldbus system uses this connection for shield installations. Figure 12. Mounting holes A) Isolated hole For use with non conductive screws or similar. B) Connected to PE For use with conductive screws or similar. HMS F Page 26 (35) IELDBUS YSTEMS... -

Page 27: Electrical Specifications

D0 - D7 Data bus to DPRAM /BUSY DPRAM busy signal /IRQ DPRAM interrupt signal DPRAM read signal DPRAM write signal DPRAM chip enable signal /RESET RESET signal RANSFER Table 9. Application connector pin description HMS F Page 27 (35) IELDBUS YSTEMS... -

Page 28: Signal Description

This signal is an active low open collector output. This signal shall be pulled-up via a resistor on the application side. Pin 29 DPRAM Read signal. From application to DPRAM. Active low. Pin 30 DPRAM Write signal. From application to DPRAM. Active low. HMS F Page 28 (35) IELDBUS YSTEMS... -

Page 29: Electrical Characteristics

Please see Appendix C for electrical characteristics of the DPRAM. 7.3.5 RESET Electrical Characteristics Symbol Description Min. Typ. Max. Unit Reset active voltage RESET Reset pulse duration, minimum effective Table 12. Electrical characteristics RESET signal HMS F Page 29 (35) IELDBUS YSTEMS... -

Page 30: Appendix A Connectors

Appendix A Connectors A1 Application Connectors For the application interface of the ANYBUS DATATRANSFER module a standard male strip connector is used. Header for this connector can be ordered both as surface or hole mounted. • Available as surface or hole mounted. - Page 31 Design Guide Revision 1.12 1998-08-12 Table 14. Through hole mounted connectors HMS F Page 31 (35) IELDBUS YSTEMS...

-

Page 32: A2 Recommended Connector Manufactures

Phone: +46 - 8 - 930280 Phone: +1 - 812 - 285 - 0055 FAX : +44 - 1705 - 324010 FAX : +46 - 8 - 949930 FAX : +1 - 812 - 285 - 0056 HMS F Page 32 (35) IELDBUS YSTEMS... -

Page 33: Appendix B Hardware Design Examples

This single power supply is galvanic isolated and built on the DC/DC TRACO TEM2 2411. The circuit has both overload and over temperature protection. Maximum current is 400mA. +5V_BUS +24V 10uF SMBJ24A 100uF 100nF 24V_Gnd TEM2 GND_BUS 2411 TRACO 1N5819 HMS F Page 33 (35) IELDBUS YSTEMS... - Page 34 Design Guide Revision 1.12 1998-08-12 Ref. Component Note Capacitor 10u/50V Electrolyte Capacitor 100n/25V Ceramic Capacitor 100u/16V Electrolyte Diode 1N5819 Diode SMBJ24A Transient protection NFM61R30T472 EMI-filter DC/DC DC/DC TRACO TEM2 2411 HMS F Page 34 (35) IELDBUS YSTEMS...

-

Page 35: Appendix C Fieldbus Specific Area (3C0H - 3Dfh)

C2 Profibus-DP The Profibus-DP module does not support the filedbus specific area in the DPRAM. Appendix D Data Sheets DPRAM The following data sheets are printouts from the Cypress semiconductors www page (www.cypress.com). HMS F Page 35 (35) IELDBUS YSTEMS...

Need help?

Do you have a question about the AnyBus DataTransfer and is the answer not in the manual?

Questions and answers