Table of Contents

Advertisement

Quick Links

REVISION 0

FAX-L1000

FAX-L1000

FAX-L1000

FAX-L1000

FAX-L1000

FAX-L1000

OPTION MEMORY VII (4MB)

VERIFICATION STAMP UNIT1

YELLOW INK TO REFILL

PAPER FEED UNIT PF-52

ENVELOPE FEEDER EF-52

DUPLEX UNIT DU-52

FAX-L1000 ISDN KIT

FAX-L1000 Printer Kit

RAM DIMM MODULE

FAX-L1000 PostScript Kit

FAX-L1000 Network

FEB. 2000

COPYRIGHT © 2000 CANON INC.

FOR VERIFICATION STAMP

Printer Upgrade kit

HY8-10AN-000

CANON FAX-L1000 FEB. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

H12-1613 230V EC

H12-1614 230V UK

H12-1615 230V GER

H12-1617 230V FRN

H12-1618 230V AUS

H12-1619 230V AE

H11-4721

H12-3162

H12-3372

R73-5006

R73-5005

R73-5004

H11-5553

H11-5513

H11-5533

H11-5543

Advertisement

Chapters

Table of Contents

Summary of Contents for Canon FAX L1000

- Page 1 COPYRIGHT © 2000 CANON INC. H12-1613 230V EC H12-1614 230V UK H12-1615 230V GER H12-1617 230V FRN H12-1618 230V AUS H12-1619 230V AE H11-4721 H12-3162 H12-3372 R73-5006 R73-5005 R73-5004 H11-5553 H11-5513 H11-5533 H11-5543 HY8-10AN-000 CANON FAX-L1000 FEB. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

- Page 2 This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.. Copyright © 2000 by Canon Inc.

- Page 3 I. MEANINGS OF MARKS The marks used in this manual have the following meanings. Mark Meaning Indicates a general caution or warning, or otherwise to communicate the presence of a hazard. Warns of the possibility of an electric shock. Informs you of fire-related cautions. Warns against disassembly of parts.

- Page 4 II. ABOUT THIS MANUAL This manual consists of the following five chapters, each providing appropriate information needed to service the product. Chapter 1: Safety and Precautions Provides cautions and warnings needed when servicing the product while ensuring safety, and explains the protective functions built into the product. Be sure to go through the descriptions.

-

Page 5: Revision History

III. REVISION HISTORY REVISION CONTENT Original... -

Page 6: Table Of Contents

IV. TABLE OF CONTENTS Chapter 1: Safety and Precautions Page 1 - 1 1. DANGER TO PERSONNEL 1 - 1 1.1 Electric Shock 1 - 2 1.1.1 AC line (AC 230V household current) 1 - 2 1.1.2 Telephone line 1 - 2 1.1.3 Printer high voltage terminal 1 - 3 1.2 High Temperature Parts... - Page 7 Chapter 2: Operating Instructions 2 - 1 1. NAMES OF PARTS AND THEIR FUNCTIONS 2 - 1 1.1 Main Unit Overview 2 - 4 1.2 Operation Panel 2 - 7 2. BASIC OPERATION 2 - 7 2.1 Copying 2 - 8 2.2 Telephone (Only possible where a handset or telephone are connected) 2 - 9...

- Page 8 3 - 18 2.1.2 Option overview 3 - 19 2.1.3 Consumables 3 - 21 2.2 Mechanical Overview 3 - 21 2.2.1 Unit layout diagrams 3 - 21 2.2.2 Document and recording paper flow 3 - 23 2.2.3 Drive system layout 3 - 25 2.2.4 Electrical system layout 3 - 30...

- Page 9 4 - 7 2. CONSUMABLES REPLACEMENT 4 - 7 2.1 Toner Cartridge 4 - 7 2.2 Recording Paper 4 - 8 2.3 Stamp Ink 4 - 11 3. CLEANING 4 - 11 3.1 Main Unit 4 - 11 3.2 Document Pick-up Roller 4 - 11 3.3 Separation Roller (Upper) 4 - 11...

-

Page 10: Envelope Feeder Ef

5 - 43 2. SERVICE TOOLS 5 - 43 2.1 Printer Driver Tester 5 - 43 2.1.1 Outline 5 - 44 2.1.2 Explanation of LEDs and Switches 5 - 45 2.1.3. Operation 5 - 51 3. OPTION 5 - 51 3.1 Option Memory VII (4M-BYTE) 5 - 51 3.1.1 Safety and precautions... - Page 11 5 - 209 3.8.2 Service operations 5 - 214 3.8.3 Technical Information 5 - 214 3.8.4 Maintenance and service 5 - 215 3.9 RAM DIMM Module 5 - 215 3.9.1 Safety and precautions 5 - 215 3.9.2 Service operations 5 - 217 3.9.3 Technical informations 5 - 218 3.9.4 Maintenance and service...

-

Page 12: Illustration Index

V. ILLUSTRATION INDEX Chapter 1: Safety and Precautions Page 1 - 2 Figure 1 - 3 Figure 1 - 7 Figure 1 - 8 Figure 1 - 9 Figure 1 - 10 Figure 1 - 11 Figure 1 - 13 Figure 1 - 14 Figure... -

Page 13: Chapter 3: Technical Reference

2 - 35 Figure 2 - 29 User Menu Settings (10/13) 2 - 36 Figure 2 - 30 User Menu Settings (11/13) 2 - 37 Figure 2 - 31 User Menu Settings (12/13) 2 - 38 Figure 2 - 32 User Menu Settings (13/13) 2 - 40 Figure 2 - 33 Slide Switch Location on NCU Board... - Page 14 3 - 54 Figure 3 - 24 Drum Cleaning 3 - 55 Figure 3 - 25 High Voltage Terminals 3 - 56 Figure 3 - 26 Transfer 3 - 56 Figure 3 - 27 Separation 3 - 57 Figure 3 - 28 Fixing section 3 - 60 Figure 3 - 29 Function Block Diagram (1)

- Page 15 4 - 19 Figure 4 - 16 Cleaning Location 2 4 - 20 Figure 4 - 17 Preparation for Cleaning 1 4 - 20 Figure 4 - 18 Preparation for Cleaning 2 4 - 21 Figure 4 - 19 Cleaning Location 1 4 - 21 Figure 4 - 20 Cleaning Location 2...

- Page 16 5 - 61 Figure 5 - 14 External View 5 - 61 Figure 5 - 15 Attachment to the Main Unit 1 5 - 62 Figure 5 - 16 Attachment to the Main Unit 2 5 - 62 Figure 5 - 17 Attachment to the Main Unit 3 5 - 63 Figure 5 - 18 Attachment to the Main Unit 4...

- Page 17 5 - 144 Figure 5 - 64 System Data List (7/10) 5 - 145 Figure 5 - 65 System Data List (8/10) 5 - 146 Figure 5 - 66 System Data List (9/10) 5 - 147 Figure 5 - 67 System Data List (10/10) 5 - 148 Figure 5 - 68 System Dump List (1/3)

- Page 18 This page intentionally left blank...

- Page 19 Chapter 1 Safety and Precautions...

-

Page 21: Danger To Personnel

FAX-L1000 Chapter 1: Safety and Precautions 1. DANGER TO PERSONNEL 1.1 Electric Shock Precautions Before disassembling the fax, carry out the following to prevent electric shock: (1) Disconnect the power cord from the outlet. (2) Disconnect the modular jack cord (telephone line) from the fax. Precautions when servicing the fax with the power on When you must service the fax with the power cord plugged in, you must not ground your body with grounding wrist straps. -

Page 22: Ac Line (Ac 230V Household Current)

FAX-L1000 Chapter 1: Safety and Precautions 1.1.1 AC line (AC 230V household current) Power supply unit (primary side) The AC 230V is supplied to the primary side of the power supply unit when the power cord is plugged in. 1.1.2 Telephone line NCU board (primary side) When connected to the telephone line, a line voltage of approx. -

Page 23: High Temperature Parts

1.2 High Temperature Parts Precautions To prevent burns while disassembling the fax, disconnect the power cord at least 10 minutes before starting disassembly, to allow high temperature parts to cool down. How to treat burns Heat of about 122°F (50°C) or more causes burns. Also, the longer the contact, the more severe the burn. -

Page 24: Fire

FAX-L1000 Chapter 1: Safety and Precautions 1.3 Fire Danger Do not throw the lithium battery or the toner cartridge into fire. Lithium battery The lithium battery contain lithium, organic solvents and other combustible substances. If the lithium battery is thrown into fires, it may rupture and burn fiercely. - Page 25 FAX-L1000 Chapter 1: Safety and Precautions This page intentionally left blank...

-

Page 26: Moving And Rotating Parts

FAX-L1000 Chapter 1: Safety and Precautions 1.4 Moving and Rotating Parts Precautions To prevent accidents involving moving or rotating parts during servicing, that disconnect the power cord before starting disassembly. When you must service the fax with the power cord plugged in, you must not wear bracelets, necklaces, neckties, or other objects. - Page 27 Read motor Document feed roller Document eject roller DC motor Read motor Document feed roller Paper feed roller Fixing eject roller Pressure roller Figure 1-3 Moving and Rotating Parts FAX-L1000 Chapter 1: Safety and Precautions Separation roller (Upper) Main motor Pressure roller Separation roller (Upper) Separation roller (Lower)

-

Page 28: Laser Beams

FAX-L1000 Chapter 1: Safety and Precautions 1.5 Laser Beams This fax is a Class 1 Laser Product as defined in the EN60825 (IEC825) Radiation Safety of laser products, equipment classification, requirements and user’s guide. This means that this product uses lasers that do not radiate dangerous laser beam and conforms to the regulations because the laser beam does not affect the user during operations. - Page 29 FAX-L1000 Chapter 1: Safety and Precautions Laser/Scanner unit Laser light Laser shutter FX6 toner cartridge Figure 1-5 Laser Shutter...

-

Page 30: Danger To Equipment

FAX-L1000 Chapter 1: Safety and Precautions 2. DANGER TO EQUIPMENT 2.1 Handling the FAX General Precautions TO AVOID SERIOUS INJURY, NEVER DISASSEMBLE THE FAX. EXPOSED POWER POINTS INSIDE THE FAX CAN CAUSE ELECTRICAL SHOCK IF YOU TOUCH THEM. After you unplug the fax unit, always wait at least 5 seconds before you plug it in again. - Page 31 FAX-L1000 Chapter 1: Safety and Precautions Before you transport the fax, remove the cartridge. To protect the cartridge from bright light, cover it with its original protective bag or a cloth. Keep liquids, cleaners, and other solvents away from the fax unit.

-

Page 32: Storage And Handling Of Fx6 Toner Cartridge

FAX-L1000 Chapter 1: Safety and Precautions 2.2 Storage and Handling of FX6 Toner Cartridge Whether the cartridge is still sealed in its box or installed in the printer, the effect of the natural environment will change it over time regardless of the number of prints. As the progression of this natural change depends on the storage or installation environment, take sufficient care in storing and handling the cartridges. -

Page 33: Storing Unsealed Parts

2.2.2 Storing unsealed parts As an organic photoconductor (OPC) is used in the photosensitive drum, it will deteriorate if exposed to strong light. As there is also toner in the cartridge, be sure to explain to the customer the need to be careful in handling and storing unsealed cartridges. 2.2.3 Storage environment a) Be sure to store in the protective bag. - Page 34 FAX-L1000 Chapter 1: Safety and Precautions After loading the cartridge in the printer, print 3 to 5 sheets of test patterns and check for toner leakage to prevent output image from dirt. (2) Remove the cartridge from the printer before transporting it. During transportation, the cartridge must be kept in the protective bag or thick cloth to prevent direct exposure to light.

-

Page 35: Precautions When Servicing

2.3 Precautions when Servicing 2.3.1 Damage due to electrostatic discharge This fax contains contact sensor and printed circuit boards that use many electrical components such as ROM, RAM and custom ICs. A static charge can damage these components, so, care must be taken to prevent damage caused by electrostatic discharge when disassembling the fax. -

Page 36: Lubrication Points

FAX-L1000 Chapter 1: Safety and Precautions 2.3.2 Lubrication points Do not touch the greased parts. If you do, the grease (applied for smooth operation of the printer mechanism and to increase electrical conductivity) will come off. Use only specified grease. If you use other grease, the grease may oxidize, and weaken plastic parts. -

Page 37: Printer Section

2.3.4 Printer section a) Transfer charging roller If skin, oil or, the like, gets on the rubber section of the transfer charging roller, the rear side of the recording paper can be soiled, and blank patches can occur in printing. During disassembly, hold the shaft at both ends of the transfer charging roller. -

Page 38: Paper Load Section

FAX-L1000 Chapter 1: Safety and Precautions 2.3.5 Paper load section a) Pickup Roller Position When having assembled the paper pickup roller after parts replacement, before setting the cassette 1 or the cassette 2, install the toner cartridge, close the printer cover, connect the power cord, and the cassette pickup roller moves automatically to its initial position. -

Page 39: Control Boards

2.3.6 Control boards a) SCNT board Jumper plug JP3 and J6 are for factory check only. Service technician must not remove it. SCNT board data User data, service data are stored in memory on the SCNT board. Therefore, these data must be printed out before replacing the SCNT board. REFERENCE For details, see this Chapter, 3. -

Page 40: Replacing Rom

FAX-L1000 Chapter 1: Safety and Precautions 2.3.7 Replacing ROM Observe the following precautions when replacing the ROM on the SCNT board, for example, when replacing a defective ROM or when upgrading the software. a) Preparation Print out all battery backed up data. Reception image data in image memory is erased approx. -

Page 41: Precautions For Data Protection

3. PRECAUTIONS FOR DATA PROTECTION 3.1 Battery-backed up Data The SCNT board is provided with a function for backing up data in control processing memory (SRAM) and image storage memory (DRAM) by lithium battery, and rechargeable battery, even if a power interruption occurs, or the power cord is disconnected by accident. The back up time for image data with the secondary vanadium-lithium battery is approximately 12 hours. -

Page 42: Backed Up By Rechargeable Battery

FAX-L1000 Chapter 1: Safety and Precautions 3.2 Backed up by Rechargeable Battery The data stored in the image memory on the SCNT board is backed up for about 12 hours by the secondary vanadium-lithium battery. 3.2.1 Data backed up by rechargeable battery Image data stored in the DRAM: Image Transmission images... -

Page 43: Reception Image Data Transfer

For a sample printout of the memory clear list, see Chapter 2, 3.1 Report Output Function . REFERENCE 3.2.2 Reception image data transfer The received image data cannot be printed out due to printer engine trouble, the received image data can be transferred to another fax and printed. selects Memory Reference 4. -

Page 44: Backed Up By Lithium Battery

FAX-L1000 Chapter 1: Safety and Precautions 3.3 Backed up by Lithium Battery The lithium battery backs up control data registered in the SRAM on the SCNT board for five years with the power turned off. However, when the power is ON, there is no discharge of power from the lithium battery, so the actual life of the battery will be over 5 years. - Page 45 c) Management data Data automatically stored as a record of the operating status. Item Description Activity report Transmission/Reception records for last 40 communications System dump list A record of past communication conditions, error communication, etc. When data have been erased or initialized When backed up user or service data have been erased or initialized, the registered data are erased, and the data item is set to its factory setting.

-

Page 46: Printing The Lithium Battery Backup Data List

FAX-L1000 Chapter 1: Safety and Precautions 3.3.2 Printing the lithium battery backup data list The following data are backed up by lithium battery and can be printed out as a list. When to print out Make sure that you print out a list of the following data before replacing the lithium battery, or before removing the jumper plug (JP2) from the SCNT board with the power turned off. - Page 47 FAX-L1000 Chapter 1: Safety and Precautions Jumper plug caution The lithium battery backup function works when jumper plug JP 2 on the SCNT board is shorted by a jumper plug. This means that registered data will be erased when the power cord is disconnected with the jumper plug removed. Before removing the jumper plug, make sure that you print out all registered data.

-

Page 48: Data Clear/Initialization Using Service Operation

FAX-L1000 Chapter 1: Safety and Precautions 3.4 Data clear/initialization using Service Operation This fax can clear/initialize individual data items with Service Data #8 Clear operation. Below are the data items which can be cleared/initialized. When to print out Before carrying out this operation, make sure that you make print out a list of backed up data. -

Page 49: Master Password

3.5 Master Password This fax has a password for confidential box setting changes and deletions, and passwords for managing each department. For service operations and for when the user forgets a password, there is a master password. Master password: 4559769 The master password can substitute for the passwords required for the following items. -

Page 50: What To Do When A Problem Occurs (All Clear)

FAX-L1000 Chapter 1: Safety and Precautions 3.6 What to do when a Problem Occurs (All clear) Very rarely, during use, the display may go out, all the buttons may stop working, or some other trouble may occur because of strong electrical noise or strong shock. If such trouble occurs, perform All clear operation. -

Page 51: Protective Functions

4. PROTECTIVE FUNCTIONS 4.1 Reception Image Data Transfer Function Reception image data can be transferred to another fax if the image data cannot be printed out due to printer engine trouble. Reception image data transfer For details on the transfer of image data, see this Chapter, 3.2.2 Reception image data transfer . -

Page 52: Built-In Safety Measures

FAX-L1000 Chapter 1: Safety and Precautions 4.3 Built-in Safety Measures 4.3.1 Overcurrent protection This fax is provided with an overcurrent protection circuit with built-in current fuse and thermal fuse, to prevent abnormal rises in temperature if an overcurrent flows to the motors and power supply due to driver IC trouble, software lockup and short circuits. -

Page 53: Power Leakage Protection

FAX-L1000 Chapter 1: Safety and Precautions 4.3.3 Power leakage protection The AC line, telephone line and metal parts of this fax are completely insulated. This fax provides a grounding type (three-wire) power supply cable to prevent electrical shock. Even if electrical leakage should occur, use this fax only with a properly grounded electrical outlet of the correct voltage. -

Page 54: Qualification Required For Installation Work

FAX-L1000 Chapter 1: Safety and Precautions 5. QUALIFICATION REQUIRED FOR INSTALLATION WORK The qualifications for installation must satisfy local laws and regulations. 1-34... - Page 55 Chapter 2 Operating Instructions...

-

Page 57: Names Of Parts And Their Functions

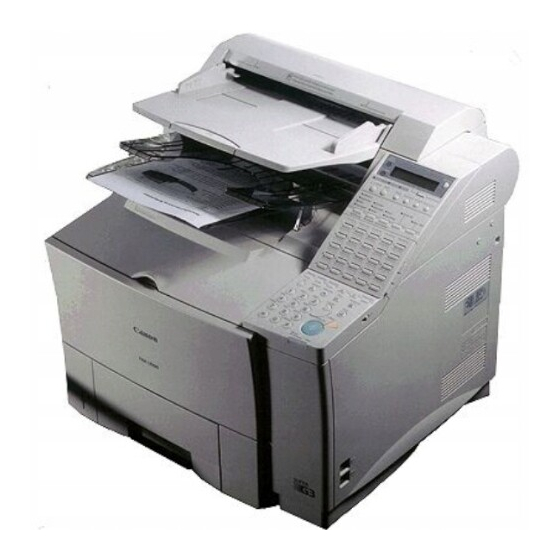

1. NAMES OF PARTS AND THEIR FUNCTIONS 1.1 Main Unit Overview DOCUMENT FEEDER TRAY Holds documents for scanning. DOCUMENT OUTPUT TRAY Holds sent or copied documents. UPPER OUTPUT TRAY Holds printed documents after they are ejected from the fax. PRINTER COVER Covers the toner cartridge. - Page 58 Figure 2-2 Rear View FACE-UP TRAY Holds printed documents after they are ejected from the fax. TEST PRINT BUTTON This button should only be used by authorized Canon dealers. Please do not press this button. POWER SOCKET Connect the power cord here.

- Page 59 FAX-L1000 Chapter 2: Operating Instructions This page intentionally left blank...

-

Page 60: Operation Panel

FAX-L1000 Chapter 2: Operating Instructions 1.2 Operation Panel LCD Display Displays messages and prompts during operation. Displays selections, text, numbers and names when registering information. Change Cartridge Lights when toner in the toner cartridge runs low. Replace the toner cartridge. Rec. - Page 61 Energy Saver Switches the fax out of the energy saver mode. PRT. Message Switches the LCD display between the fax messages and the printer messages. Manual RX Switches the fax between the auto and manual receive mode. Direct TX Sets the fax in the direct sending mode so you can send a document ahead of other documents stored in the fax memory.

- Page 62 Switches the fax in and out of the stamp mode. In the stamp mode, the fax marks all documents scanned for sending in memory mode or direct sending mode. If you want to use the stamp feature, call your authorized Canon dealer and request installation of this option. Pause Enters pauses between digits or after the entire phone number when dialing or registering facsimile numbers.

- Page 63 2. BASIC OPERATION 2.1 Copying (1) Set the recording paper Refer to Chapter 5, 1.4 Assembling the Fax, Loading Paper in Paper cassettes 1 and 2 for the method of setting the recording paper. NOTE (2) Set the document face up on the document feeder tray Adjust the document guides to match the width of the document.

- Page 64 FAX-L1000 Chapter 2: Operating Instructions Figure 2-7 Document Guides Adjustment Figure 2-8 Document Load Limit 2.2 Telephone (Only possible where a handset or telephone are connected) (1) Lift the handset or telephone receiver. The sound of dial tone will be heard. (2) Dial the other party's telephone number using the dial button on the main unit or the telephone.

- Page 65 2.3 Transmission There are two ways to transmit the document: memory transmission and direct transmission. a) Memory transmission The set document is read into memory and then transmitted. Setting method Press the Direct TX button to turn off the Direct TX LED. Even during memory transmission, other documents can be reserved for transmission.

- Page 66 FAX-L1000 Chapter 2: Operating Instructions 2.4 Reception There are 3 reception methods: auto reception, manual reception, and auto reception switching. a) Auto reception This is set when the machine is used exclusively for facsimile. The initial condition of the machine is set to “Auto reception”. Setting method (1) Select “MAN/AUTO SWITCH”...

-

Page 67: Service Operation Functions

3. SERVICE OPERATION FUNCTIONS 3.1 Report Output Function 3.1.1 User report output functions This fax can output user reports manually by user operation, or automatically, according to user data registration. a) Manual output of reports by user operation Report type One-touch dial list 1 One-touch dial list 2 Coded speed dial list 1... - Page 68 FAX-L1000 Chapter 2: Operating Instructions c) Reports output automatically (Memory clear report) When this fax is turned on and the memory clear report is automatically printed out, the image data which appears on the report is the data which was deleted without being able to be backed up.

-

Page 69: Service Report Output Functions

3.1.2 Service report output functions This fax outputs the service data setting status, past communications history reports, detailed error information reports, etc. in service mode. a) List of service reports This fax outputs the service reports shown below. Report type Service data list System dump list Dch log report... - Page 70 FAX-L1000 Chapter 2: Operating Instructions a-1) System data list This list shows service data setting statuses of service soft switches and service parameters. Figure 2-10 System Data List (1/7) 2-14...

- Page 71 FAX-L1000 Chapter 2: Operating Instructions Figure 2-11 System Data List (2/7) 2-15...

- Page 72 FAX-L1000 Chapter 2: Operating Instructions Figure 2-12 System Data List (3/7) 2-16...

- Page 73 FAX-L1000 Chapter 2: Operating Instructions Figure 2-13 System Data List (4/7) 2-17...

- Page 74 FAX-L1000 Chapter 2: Operating Instructions Figure 2-14 System Data List (5/7) 2-18...

- Page 75 FAX-L1000 Chapter 2: Operating Instructions Figure 2-15 System Data List (6/7) 2-19...

- Page 76 FAX-L1000 Chapter 2: Operating Instructions Figure 2-16 System Data List (7/7) “START DATE” records the date when this fax performs its first transmission or reception, after shipment from the factory. NOTE 2-20...

- Page 77 FAX-L1000 Chapter 2: Operating Instructions a-2) System dump list This list shows the past communications statuses and error communications history. Figure 2-17 System Dump List (1/2) 2-21...

- Page 78 FAX-L1000 Chapter 2: Operating Instructions *1 : Date on which data was initialized with service data #8 CLEAR, ALL *2 : Total number of transmission *3 : Total number of pages transmitted for each document size *4 : Total number of reception *5 : Total number of pages received for each document size *6 : Total number of pages transmitted and received for each modem speed *7 : Total number of pages transmitted and received for each mode...

- Page 79 Displays error information for the 3 most recent communications. Figure 2-18 System Dump List (2/2) *1 : Service error code *2 : Communication start date and time (on 24-hour display) *3 : Telephone number sent from other party *4 : Maker code *5 : Machine code *6 : Received V.8 protocol signal *7 : Symbol rate used for the primary channel...

- Page 80 FAX-L1000 Chapter 2: Operating Instructions a-3) Service activity report The ERROR TX REPORT includes appended service error codes and an error dump list. In user data “REPORT SETTINGS”, when the “REPORT WITH TX IMAGE” is set to “ON” in the “TX REPORT”, a section of the first page of transmitted image data is appended when memory transmission is done.

- Page 81 *3 : Number sent from the other party or number dialled (lower 20 digits) *4 : ID sent from the other party, if the other party is a Canon fax *5 : Communication start date and time (on 24-hour display)

-

Page 82: User Data Flowchart

FAX-L1000 Chapter 2: Operating Instructions 3.2 User Data Flowchart Press the Data registration to access User menu. Figures in boldface indicate the default setting. REGISTRATION 1.USER SETTINGS 1. DATA REGISTRATION 1. DATE & TIME 2. UNIT TELEPHONE # 3. UNIT NAME 4. - Page 83 FAX-L1000 Chapter 2: Operating Instructions 2. REPORT SETTINGS 1. TX REPORT PRINT ERROR ONLY OUTPUT YES OUTPUT NO PRINT ERROR ONLY 2. RX REPORT OUTPUT YES OUTPUT NO OUTPUT YES 3. CONFID. RX REPORT OUTPUT NO OUTPUT YES 4. MEMORY BOX REPORT OUTPUT NO 5.

- Page 84 FAX-L1000 Chapter 2: Operating Instructions 3. TX SETTINGS 1. ECM TX 2. MID PAUSE SET (2.) TRANSMISSION MODEL 3. AUTO REDIAL 4. BATCH TX 5. QUICK ON-LINE TX 6. TIME OUT (7.) TX STAMP (7.) START UP DIAL KEY (8.) PHON TIME OUT 4.

- Page 85 FAX-L1000 Chapter 2: Operating Instructions 5. FAX'S PRINTER SET 1. USE MP TRAY SET MP TRAY SIZE 2. # OF RX COPIES (01~99) 01 COPIES 3. SELECT CASSETTE 1. CASSETTE SW A 2. CASSETTE SW B RX REDUCTION 1.RX REDUCTION 5.

- Page 86 FAX-L1000 Chapter 2: Operating Instructions 2. RELAY TX GROUP 1.SETUP FILE 2.CHANGE DATA 3.DELETE FILE Figure 2-24 User Menu Settings (5/13) SET RLY TX GROUP #00 (00~99) 1.GROUP DIAL NAME 2.PASSWORD 3.SUBADDRESS (INPUT) 4.RX PASSWORD (INPUT) 5.SELECT ORIG UNIT 6.PRINT RX DOC. 7.SELECT LOCATIONS 8.TX REPORT 9.TX START TIME...

- Page 87 FAX-L1000 Chapter 2: Operating Instructions 3. MEMORY BOX SET BOX # 00 1.SETUP FILE 1.FILE NAME 2.PASSWORD 3.SUBADDRESS 4.TX PASSWORD 5.RX PASSWORD 6.RECEIVE 7.TRANSMIT 1.SELECT LOCATIONS 2.TX DOCUMENT 1.RECEIVED DOCUMENT NOT TRANSMIT TRANSMIT 2.SCAN DOCUMENT 3.TX START TIME 8.POLLING TX 1.ERASE AFTER TX 2.TX DOCUMENT 1.RECEIVED DOCUMENT...

- Page 88 FAX-L1000 Chapter 2: Operating Instructions 2.CHANGE DATA 1.FILE NAME 2.PASSWORD 3.SUBADDRESS 4.TX PASSWORD 5.RX PASSWORD 6.RECEIVE 7.TRANSMIT 8.POLLING TX 3.DELETE FILE Figure 2-26 User Menu Settings (7/13) SET BOX #00 (00~99) 1.SELECT ORIG UNIT 2.PRINT RX DOC. 1.SELECT LOCATIONS TEL = 2.TX DOCUMENT 1.RECEIVED DOCUMENT NOT TRANSMIT...

- Page 89 FAX-L1000 Chapter 2: Operating Instructions 4. PRESET POLLING SET BOX #00 1.SETUP FILE 1.FILE NAME 2.PASSWORD 3.SELECT LOCATIONS 4.START TIME 2.CHANGE DATA PASSWORD (INPUT) 3.DELETE FILE SET BOX #00 5. POLLING BOX. SET BOX #00 1.SETUP FILE 1.FILE NAME 2.PASSWORD 3.SUBADDRESS 4.TX PASSWORD 5.ERASE AFTER TX...

- Page 90 FAX-L1000 Chapter 2: Operating Instructions 6. TRANSFER 1.SETUP FILE 2.CHANGE DATA Figure 2-28 User Menu Settings (9/13) 1.FILE NAME 2.SELECT LOCATIONS TEL = 3.PASSWORD 4.SELECT ORIG UNIT 5.TIME SETUP 1.START TIME EVERYDAY SELECT DAYS 1.SUN 2.MON 3.TUE 4.WED 5.THU 6.FRI 7.SAT 2.END TIME EVERYDAY...

- Page 91 PASSWORD (INPUT) 3.DELETE FILE 7. SYSTEM SETTINGS (0000~9999) 1.PASSWORD 2.RESTRICTVE CODES 1. TX SETTINGS 2. FAX'S PRINTER SET CODE (INPUT) 3. TEL SETTING 3.MEMORY LOCK RX 1.START TIME 2.END TIME Figure 2-29 User Menu Settings (10/13) 2-35 FAX-L1000 Chapter 2: Operating Instructions DAC SETUP ENTER DAC (19 settings input)

- Page 92 FAX-L1000 Chapter 2: Operating Instructions 4.RX RESTRICTION 5.DATE SETUP 6.DISPLAY LANGUAGE 7.TX START SPEED 8.RX START SPEED 9.RX PASSWORD 10.ENERGY SAVER 11. (10.) PHONE NO. CHECK (11.) TX. CLIP (12.) CHECK RX ID (13.) ISDN SUBADR. SEND (14.) ISDN SUBADR. RX Figure 2-30 User Menu Settings (11/13) MM/DD/YYYY DD/MM YYYY...

- Page 93 2. TEL REGISTRATION 1. 1-TOUCH SPD DIAL (01~72) 1. TELEPHONE NUMBER 2. NAME 3. OPTIONAL SETTING 1. SET TIME 2. TX TYPE 3. LONG DISTANCE 4. TX SPEED 5. ECM (3.) TRANSMISSION MODE (4.) G3 OPT. SETTING Figure 2-31 User Menu Settings (12/13) FAX-L1000 Chapter 2: Operating Instructions (5 time settings) REGULAR TX...

- Page 94 FAX-L1000 Chapter 2: Operating Instructions 1. TELEPHONE NUMBER 2. NAME 3. OPTIONAL SETTING 3. GROUP DIAL (01~72) 1. TELEPHONE NUMBER 2. NAME 3. SET TIME (5 time settings) Figure 2-32 User Menu Settings (13/13) 2. CODED SPD DIAL ( 000~ 127) (5 time settings) 1.

- Page 95 3.3 Service Switches 3.3.1 Hardware switches This fax has the following hardware switches. a) SCNT board Jumper switch (JP1) The secondary vanadium-lithium battery backs up image memory by causing a short with the jumper plug. Jumper switch (JP2) The lithium battery backs up control memory by causing a short with the jumper plug. Refer to Chapter 1, 3.2 Backed up by rechargeable battery and 3.3 Backed up by lithium battery for details regarding jumper switches (JP1 and JP2).

- Page 96 FAX-L1000 Chapter 2: Operating Instructions e) NCU board There are three slide switches on the NCU board. Figure 2-33 Slide Switch Location on NCU Board NCU Board Switch Setting This model has only one connection terminal for extension telephone/handset. Therefore, unlike models with two connection terminals, changing the switch NOTE settings for use in Sweden is unnecessary.

-

Page 97: Service Data Setting

3.3.2 Service data setting Service data can be checked and changed with items on display menus. The effective SSSWs/ parameters and their default values in this fax machine are shown in 3.3.4 Service data flowchart in this chapter. Detailed description of each SSSW/parameter is not given in this manual except the new SSSWs/parameters added to this model. -

Page 98: Service Data Registration/Setting Method

FAX-L1000 Chapter 2: Operating Instructions #8 CLEAR (data initialization mode) Various data are initialized by selecting one of these setting items. There is a setting item for checking/inputting the total number of pages printed and total number of pages scanned by this fax. #9 ROM (ROM management) ROM data such as the version number and checksum are displayed. -

Page 99: Service Data Flowchart

3.3.4 Service data flowchart Service menu #1 SSSW SW01 (Service soft switch setting) SW02 SW03 SW04 SW05 SW06 SW07 SW08 SW09 SW10 SW11 SW12 SW13 SW14 SW15 SW16 SW17 SW18 SW19 SW20 SW21 SW22 SW23 SW24 SW25 SW26 SW27 SW28 SW29 SW30 SW50... - Page 100 FAX-L1000 Chapter 2: Operating Instructions #2 MENU (Menu switch settings) No. 001 to 004, 011 to 020 are not used. Do not change their settings. 001: 002: 003: 004: 005: DIAL 006: SERVICEMAN 007: 10 (-10dBm) 008: 3429 baud 3200 baud 3000 baud 2800 baud 2743 baud...

- Page 101 #3 NUMERIC Param. (Numeric parameter settings) Default Rang 001: 002: 10 (10%) (1~99) 003: 15 (15 times) (2~99) 004: 12 (12 lines) (1~99) 005: 006: 007: 008: 009: 6 (6 digits) (1~20) 010: 5500 (55 seconds) (0~9999) 011: 3500 (35 seconds) (0~9999) 012: 013:...

- Page 102 FAX-L1000 Chapter 2: Operating Instructions #4A SPECIAL SW01 SW30 #4B NCU TONE/PULSE (NCU settings) DIAL TONE 2nd DIAL TONE BUSY TONE 0 BUSY TONE 1 REORDER TONE MULTI AUTO RX CNG DETECT RKEY PBX DIAL TONE PBX BUSY TONE #4C ISDN ISDN BASIC (ISDN settings) SW01 to 30:...

- Page 103 ISDN G4 ISDN G3 EUROPE #5 TYPE (Type setting) #6 GENESIS(UHQ) Bit SW (UHQ function settings) SLICE GAMMA Figure 2-40 Service Data (5/6) #4A SPECIAL, #4B NCU The values of these items are all set to match a specific nation’s communications standards by the #5 TYPE setting.

-

Page 104: Test Mode

FAX-L1000 Chapter 2: Operating Instructions #7 PRINTER (Printer function settings) #8 CLEAR (Data initialization mode settings) #9 ROM (ROM management) TEST MODE For details on test mode, see this Chapter, 3.4 Test Functions . REFERENCE #1. SSSW SW01 SW01~03: – –... -

Page 105: Explanation Of Sssw (Service Soft Switch Settings)

3.3.5 Explanation of SSSW (Service Soft Switch Settings) The items registered and set by each of these switches comprise 8-bit switches. The figure below shows which numbers are assigned to which bits. Each bit has a value of either 0 or 1. SW01 Figure 2-42 Bit Switch Display See the chart in the service menu shown in Section 3.3.4 Service data flowchart to see... -

Page 106: New Sssws/Parameters Added To This Model

FAX-L1000 Chapter 2: Operating Instructions 3.3.6 New SSSWs/parameters added to this model #1 SSSW SW01 (service soft switch 01: error management ) Function Service error code Error dump list Enter password at confidential Rx image data transfer Copy function 4 (New) ##300 series service error code Not used Date &... - Page 107 #1 SSSW SW05 (service soft switch 05: standard function <DIS signal> settings) Function Not used Not used Not used Send DIS signal bits 33 and over Recording paper length availability declared in DIS signal 5 (New) Declare LTR/LGL in DIS signal Not used Not used [Bit 5]...

- Page 108 FAX-L1000 Chapter 2: Operating Instructions #1 SSSW SW06 (service soft switch 06: scan condition settings) Function Document feed after DES on Prescan for document scanning Document length restriction 3 (New) Stamp option Document scan width Recording paper output for long image copy Copy function resolution Superfine mode setting when...

- Page 109 #1 SSSW SW26 (service soft switch 26: transmission function settings) Function Compulsory direct transmission function Not used Not used Not used Not used 5 (New) Transmission error redial function Yes When STOP key is pressed during a sequential boradcastiong communication communication Error transmission report when transmission is stopped [Bit 5]...

- Page 110 FAX-L1000 Chapter 2: Operating Instructions #1 SSSW SW28 (service soft switch 28: V.8/V.34 protocol settings) Function 0 (New) Caller V.8 protocol 1 (New) Called party V.8 protocol 2 (New) Caller V.8 protocol late start 3 (New) Called party V.8 protocol late start 4 (New) V.34 reception fallback 5 (New) V.34 transmission fallback Not used...

- Page 111 #2 MENU Function V.34 max. baud rate V.34 max. transmission speed [No. 008] Select the maximum baud rate for V.34 transmission: 3429, 3200, 3000, 2800, 2743, and 2400. This model cannot use 2743 baud due to its modem specification. If it is set to 2743 baud, the maximum baud rate is 2400 baud.

- Page 112 FAX-L1000 Chapter 2: Operating Instructions #3 NUMERIC PARAM. (numeric parameter settings) Function T0 Timer T1 Timer (Rx) Maximum time to receive one line of image data [No.010] The “wait time after transmission of a dialing signal ends until a significant signal is detected in transmission”...

- Page 113 #7 PRINTER Service soft switch settings SW04 (switch 04: reduction/cassette selection settings) Function 0 (New) When LTR/LGL specification is received by DCS, the cassette is selected according to the specification. Not used Not used Not used Not used Not used Not used Not used [Bit 0]...

- Page 114 FAX-L1000 Chapter 2: Operating Instructions SSSW Default Setting TYPE EUROPE #1 SSSW SW01 00010000 00010000 00010000 00010000 00010000 00010000 SW02 00000000 00000000 00000000 00000000 00000000 00000000 SW03 00000000 00000000 00000000 00000000 00000000 00000000 SW04 10000000 10000000 10000010 10000010 10000010 10000000 SW05 00000000 00000000 00000000 00000000 00000000 00000000 SW06...

- Page 115 SSSW Default Setting TYPE NORWAY HOLLAND BELGIUM AUSTRALIA FINLAND #1 SSSW SW01 00010000 00010000 00010000 SW02 00000000 00000000 00000000 SW03 00000000 00000000 00000000 SW04 10000010 10000010 10000000 SW05 00000000 00000000 00000000 SW06 10000000 10000000 10000000 SW07 00000000 00000000 00000000 SW08 00000000 00000000 00000000 SW09 00000000 00000000 00000000...

- Page 116 FAX-L1000 Chapter 2: Operating Instructions SSSW Default Setting TYPE ITALY #1 SSSW SW01 00010000 00010000 00010000 00010000 00010000 00010000 SW02 00000000 00000000 00000000 00000000 00000000 00000000 SW03 00000000 00000000 00000000 00000000 00000000 00000000 SW04 10000010 10000010 10000010 10000000 10000000 10000000 SW05 00000000 00000000 00000000 00000000 00000000 00000000 SW06...

- Page 117 SSSW Default Setting TYPE GERMAN FRANCE #1 SSSW SW01 00010000 00010000 00010000 00010000 SW02 00000000 00000000 00000000 00000000 SW03 00000000 00000000 00000000 00000000 SW04 00000010 00000010 10000000 10000000 SW05 00000000 00000000 00000000 00000000 SW06 10000000 10000000 10000000 10000000 SW07 00000000 00000000 00000000 00000000 SW08 00000000 00000000 00000000 00000000 SW09...

- Page 118 FAX-L1000 Chapter 2: Operating Instructions SSSW Default Setting TYPE EUROPE #3 NUMERIC Param 5500 3500 1300 #5 TYPE EUROPE U.K. SWEDEN SWISS 5500 5500 5500 3500 3500 3500 1300 1300 1300 U.K. SWEDEN SWISS 2-62 AUSTRIA DENMARK 5500 5500 3500 3500 1300 1300...

- Page 119 SSSW Default Setting TYPE NORWAY HOLLAND BELGIUM AUSTRALIA FINLAND #3 NUMERIC Param 5500 3500 1300 #5 TYPE NORWAY HOLLAND BELGIUM AUSTRALIA FINLAND FAX-L1000 Chapter 2: Operating Instructions 5500 5500 5500 3500 3500 3500 1300 1300 1300 2-63 N.Z. 5500 5500 3500 3500 1300...

- Page 120 FAX-L1000 Chapter 2: Operating Instructions SSSW Default Setting TYPE ITALY #3 NUMERIC Param 5500 3500 1300 #5 TYPE ITALY SPAIN PORTUGAL IRELAND HUNGARY 5500 5500 5500 3500 3500 3500 1300 1300 1300 SPAIN PORTUGAL IRELAND HUNGARY 2-64 5500 3500 3500 3500 1300 1300...

- Page 121 SSSW Default Setting TYPE GERMAN FRANCE #3 NUMERIC Param 9000 3500 1300 #5 TYPE GERMAN FRANCE FAX-L1000 Chapter 2: Operating Instructions CZECH SLOVENIA 5500 5500 5500 3800 3500 3500 1300 1300 1300 CZECH SLOVENIA 2-65...

-

Page 122: Test Mode Overview

FAX-L1000 Chapter 2: Operating Instructions 3.4 Test Functions This fax functions for testing individual operations, such as below. 3.4.1 Test mode overview Test mode can be executed by following the menu items from the display. a) DRAM tests Writes data to DRAM image storage areas and reads that data to check operations. b) Print test Prints nine different patterns within the print area. -

Page 123: Test Mode Flowchart

3.4.2 Test mode flowchart To operate the test mode, after pressing the Data registration button, press the # button and select “SERVICE MODE”. After this, select “TEST MODE” with the press the Set button. To end test mode, press the Stop button followed by the Clear button. TEST MODE [1] D-RAM [2] CS... - Page 124 FAX-L1000 Chapter 2: Operating Instructions (Indicated only when the optional FAX-L1000 ISDN kit is installed.) [9]ISDN TEST [1] DRAM TEST [2] FREQ [3] LOOP TEST [4] G3 Tx TEST [7] V34 G3 Tx TEST [8] DTMF Tx TEST Figure 2-45 Test Mode (2/2) 2-68...

-

Page 125: D-Ram Tests

3.4.3 D-RAM tests Pressing the numeric key 1 from the test mode menu selects the D-RAM tests. D-RAM Test 1 writes data to the entire D-RAM region and reads it out to check that operations are correct. D-RAM Test 2 just reads data at high speed. This test can be used to check operations when optional memory has been added. -

Page 126: Print Test

FAX-L1000 Chapter 2: Operating Instructions 3.4.4 Print test a) Test mode print test The Print Test menu is selected by pressing the numeric key 3 from the test mode menu. In this test, various print patterns are output from the printer. As service print patterns, press the numeric key 2 from the Print Test menu to select “3-2: BLACK”... -

Page 127: Modem And Ncu Tests

3.4.5 Modem and NCU tests These tests test modem and NCU transmission and reception. The modem tests check whether signals are sent correctly from the modem by comparing the sound of the signals from the speaker with the sounds from a normal modem. Also, you check on the display whether or not the modem correctly detected received tone signals and DTMF signals. - Page 128 FAX-L1000 Chapter 2: Operating Instructions b) G3 signal transmission test The G3 signal transmission test menu is selected by pressing the numeric key 4 from the MODEM NCU test menu. The G3 signals below are sent from the modem using the modular jack and the speaker.

- Page 129 c) Tonal and DTMF signal reception tests The tonal and DTMF signal reception test is selected by pressing the numeric key 6 from the MODEM NCU test menu. In these tests, you can check whether the tonal signals and DTMF signals received from the modular jack are detected by the modem. The 462 ±14 Hz test is included because the modem has a 462±14 Hz detection function.

- Page 130 FAX-L1000 Chapter 2: Operating Instructions d) V.34 G3 signal transmission test The V.34 G3 signal transmission test menu is selected by pressing the numeric key 8 from the MODEM NCU test menu. The V.34 G3 signals below are sent from the modem using the modular jack and the speaker by pressing the Start/Scan button.

-

Page 131: Aging Test

FAX-L1000 Chapter 2: Operating Instructions 3.4.6 AGING test If the numeric key 5 is pressed in the test mode menu, the AGING test is selected. In this test, the contact sensor LED is lit, and the document read motor driven in fine mode. Also, the printer will fine print a endurance pattern. -

Page 132: Faculty Tests

FAX-L1000 Chapter 2: Operating Instructions 3.4.7 Faculty tests The faculty tests are selected by pressing the numeric key 6 from the test mode menu. These tests test the following faculties of this fax. Test type Sensor tests Operation panel test Stamp test a) Sensor tests The sensor test is selected by pressing the numeric key 3 from the faculty test menu. - Page 133 6-3 : SENSOR [1] - - - [6] Pressing the 1 key. DS of DES of CMS on DFS of DS : Document sensor on/of: document/no document DES : Document edge sensor DWS : Document width sensor CMS : Cam sensor DFS : Document feed sensor Pressing the 2 key.

- Page 134 FAX-L1000 Chapter 2: Operating Instructions a-1) Toner sensor test check method Use the following methods to test “TN on”, and “TN of”. • "TN on" check (1) Open the printer cover. (2) Insert a cartridge containing toner into the fax. (3) Close the printer cover.

- Page 135 (3) Close the printer cover. If the printer cover is closed without a cartridge being inserted, there will be no “TN of” display, and this will not count as a sensor malfunction. If the printer cover sensor lever is pressed while the cartridge sensor lever is being pressed, high voltage will be applied to the high voltage terminals.

- Page 136 FAX-L1000 Chapter 2: Operating Instructions c) Operation panel tests The operation panel test is selected by pressing the numeric key 7 from the faculty test menu. In this test, check that the display, LED lamps, buttons and the sensors of one-touch speed dialing panel on the operation panel are operating correctly.

- Page 137 FAX-L1000 Chapter 2: Operating Instructions When all the characters displayed have gone out, the system next starts the one-touch speed dialing button test. The letters a to y are displayed, corresponding to one-touch speed dialing button 1 to 25. Each letter displayed goes out when its corresponding one- touch speed dialing button is pressed.

- Page 138 FAX-L1000 Chapter 2: Operating Instructions 6-7:OPERATION PANEL Press Start/Scan button. HHHHHHHHHHHHHHHHHHHH HHHHHHHHHHHHHHHHHHHH Press Start/Scan button. Press Start/Scan button. 6-7:OPERATION PANEL LED TEST Press Start/Scan button. 1 2 3 4 5 6 7 8 9 < > Y ! When the entire display has gone out a b c d e f g h i j k l m n o p q r s t u v w x y z A B...

-

Page 139: Isdn Test

3.4.8 ISDN test When numeric key 9 is pressed on the TEST MODE menu, the ISDN test is selected. An ISDN test and a modem test are carried out. Check whether the signal is correctly transmitted from the modem by comparing the signal sound from the speaker with the sound from the speaker of a normal machine. - Page 140 FAX-L1000 Chapter 2: Operating Instructions c) G3 signal transmission test When numeric key 4 is pressed on the ISDN test menu, the G3 signal transmission test is selected. Press numeric key 1 or 2 to select one of two modems. This test sends a G3 signal from a modem with a speaker.

- Page 141 d) V.34 G3 signal transmission test The V.34 G3 signal transmission test menu is selected by pressing the numeric key 8 from the MODEM NCU test menu. The V.34 G3 signals below are sent from the modem using the modular jack and the speaker by pressing the Start/Scan button. The Baud rate can be changed with the numeric keys, and the Speed can be changed with the search keys.

- Page 142 FAX-L1000 Chapter 2: Operating Instructions This page intentionally left blank 2-86...

- Page 143 Chapter 3 Technical Reference...

-

Page 145: Facsimile Overview

Canon faxes, but fax machines of other manufacturers as well. •Economical and quiet Canon’s RAPID Fusing System™ realizes quiet operation while you save money. If the fax machine remains idle for a specified length of time, the fax machine automatically shuts itself... -

Page 146: Option Overview

You can create up to 50 private memory boxes and set them up to receive documents. If the other party’s fax can use ITU-T subaddresses and passwords, you can set up and use memory boxes even if the other party’s fax unit is not a Canon fax. •JBIG, Improved image data compression JBIG is a new ITU-T standard image data compression method. -

Page 147: External View

1.2 Configuration and Structure 1.2.1 Product names LASER beam printing type G3 facsimile FAX-L1000 1.2.2 External view PAPER FEED UNIT (option) FAX-L1000 Chapter 3: Technical Reference 508 mm 713 mm 828 mm 501 mm 571 mm Figure 3-1 External View HANDSET (option) - Page 148 FAX-L1000 Chapter 3: Technical Reference 1.2.3 Configuration a) Main unit Structural section Control section Scanning section Printing section Operation section Power supply Line interface section b) Accessories • Power Cord (UK, GER, FRN, AUS, AE only) • Document Feeder Tray •...

- Page 149 1.3 Specifications and Functions 1.3.1 Basic specifications Type Desktop facsimile transceiver Body color Art gray Power source Voltage Frequency Power consumption Standby (ESS On) Standby (ESS Off) Operation Maximum Main unit usage environment Temperature Humidity Horizontality Operating noise Measured in accordance with ISO standards Standby Operating Dimensions...

-

Page 150: Communications Specifications

FAX-L1000 Chapter 3: Technical Reference 1.3.2 Communications specifications Applicable lines Analog line (one line) • PSTN (Public Switched Telephone Network) Handset (Option) Handset with no numeric buttons Transmission method Half-duplex Transmission control protocol ITU-T V.8 protocol V.34 protocol/ECM protocol ITU-T T.30 binary protocol/ECM protocol Modulation method G3 image signals G3 procedure signals... - Page 151 Canon express protocol CEP1 Time required for transmission protocol Pre-message Mode Protocol V.8 / V.34 Approx. 6 s T.30 Standard Approx. 18 s CEP1 Approx. 9 s Time from when other facsimile is connected to the line until image transmission begins.

-

Page 152: Scanner Section Specifications

FAX-L1000 Chapter 3: Technical Reference 1.3.3 Scanner section specifications Type Sheets Sheet dimensions Maximum Minimum Thickness ADF capacity A4/Letter Legal B4 (AE only) 11 inch 17 inch Effective scanning width LTR/LGL B4 (AE only) Scanning method Contact sensor scanning method Scanning line density Horizontal: Standard/Fine/Superfine... - Page 153 Copy resolution Memory copy Scanning density adjustment Lighter, Standard, Darker: Scanning density adjustment is only valid in binary image mode. NOTE Image modes Binary Documents containing black-and-white characters Auto halftone Document containing black and white characters, documents containing photographs, mixed black and white characters, and photographs.

-

Page 154: Scanning Range

FAX-L1000 Chapter 3: Technical Reference Scanning range Item Effective 8.19"±0.004" scanning width (208 ±0.1 mm) Effective 11.54"±0.16" scanning length (293 ±4.0 mm) (Fine, Superfine) Effective 11.54"±0.22" scanning length (293 ±5.5 mm) (Standard) Left margin 0.04" ±0.12" (1.0 ±3.0 mm) Right margin 0.04"... -

Page 155: Printer Section Specifications

UPPER tray LOWER tray UPPER tray LOWER tray Printing method Laser beam printer Printing cartridge Product name Canon FX6 Toner Cartridge Product code H11-6431 Strage conditions Temperature Humidity Valid period 2.5 years from date of manufacture displayed on carton. Toner detection... - Page 156 FAX-L1000 Chapter 3: Technical Reference Recommended recording paper Canon Copier LTR/LGL Premium Paper Weight Paper size Manufactured by KANGAS Weight Paper size Manufactured by NEUSIEDLER Canon Paper Weight Paper size Manufactured by 75 g/m Letter, Legal BOISE CASCADE 80 g/m...

-

Page 157: Printing Range

Printing range Item Effective printing width Effective printing length Left margin Right margin Top margin Bottom margin margin Recording paper leading edge Recording paper trailing edge Figure 3-3 Printing Range FAX-L1000 Chapter 3: Technical Reference Letter 8.01 8.24" (203.5 mm) (209.4 mm) 11.34"... - Page 158 1.3.5 Functions FAX/TEL switching None Answering machine connection None Memory reception When receiving Canon FAX Standard Chart No.1 Standard Memory expanded Polling Polling transmission The document is accumulated into memory ahead of time, then transmitted when there is a polling request from the other party.

- Page 159 Auto dialing Telephone number digits One-touch dial Coded speed dial Group dial Redial Delayed transmission Locations Designated time Broadcast transmission Locations Group button addresses Relay broadcasting originating Group No. Subaddress (ITU-T standard) Transmission password (ITU-T standard) Destinations Relay broadcasting Group No. Subaddress (ITU-T standard) Transmission password (ITU-T standard)

- Page 160 FAX-L1000 Chapter 3: Technical Reference Activity management a) User report Activity management report (Every 40 transactions : Can be separated into Tx and Rx) Activity report (sending / receiving) 1-touch spd dial list Coded speed dial list Group dial list Memory clear list User’s data list Multi activity report...

- Page 161 Memory backup Backup contents Dial registration data, user data, service data, time Backup IC 512 kbit SRAM (256 kbit SRAM 2) Backup battery Lithium battery 3.0 V DC / 560 mAh Battery life Approx. 5 years Image data backup Backup contents Memory reception, memory copy, delayed transmission and broadcast transmission image data, activity management report...

-

Page 162: Theory Of Operations

FAX-L1000 Chapter 3: Technical Reference 2. THEORY OF OPERATIONS 2.1 Product Overview 2.1.1 Fax main unit This fax operates on ordinary AC230V household current, and has fax, telephone, and copy functions. The communication functions include 33.6k bps G3 transmission with ECM, contact scanner scanning with an ADF (auto document feeder) that can consecutively transmit multi-page documents, and a LASER beam printer that can print on plain paper. - Page 163 f) 4MB memory kit The image memory can be expanded by installing 4MB memory boards. Two memory boards can be installed in the fax machine. g) Verification stamp unit The verification stamp unit stamps a check mark near the trailing edge of the scanning side of each document to verify that all documents are transmitted correctly without any errors, such as double feeding.

- Page 164 FAX-L1000 Chapter 3: Technical Reference Main unit FAX-L1000 Option PAPER FEED UNIT PF-52 OPTION MEMORY VII (4MB) FAX-L1000 PostScript kit DUPLEX UNIT DU-52 ENVELOPE FEEDER EF-52 FAX-L1000 Printer kit STAMP UNIT RAM DIMM Module Consumables 16MB Figure 3-4 Product Overview 3-20 FAX-L1000 ISDN KIT FAX-L1000 Network Printer...

-

Page 165: Document And Recording Paper Flow

2.2 Mechanical Overview The mechanical section of this fax comprises the scanner section, the pickup section, and the printer section. 2.2.1 Unit layout diagrams a) Scanner section The scanner section has an ADF (auto document feeder) function and can automatically feed 50 sheets of A4 or letter size documents (20 sheets of B4 (AE only) or legal size documents). - Page 166 FAX-L1000 Chapter 3: Technical Reference Document path Scanner Section Printer Section Paper pickup Section Recording paper path Figure 3-5 Paper Path 3-22...

-

Page 167: Drive System Layout

2.2.3 Drive system layout a) Scanner section The power of the document read motor is transmitted by belt and gear to drive the pick-up, separation, feed, and eject rollers. The rotation of pick-up roller is controlled by a cam, DC motor and separation roller arm. - Page 168 FAX-L1000 Chapter 3: Technical Reference Read motor Document feed roller Document eject roller DC motor Read motor Document feed roller Paper feed roller Fixing eject roller Separation roller (Upper) Pressure roller Separation roller (Upper) Separation roller (Lower) Document eject roller Solenoid Main motor Pressure roller...

-

Page 169: Electrical System Layout

2.2.4 Electrical system layout a) Board layout a-1) SCNT board The SCNT board, which contains the system controller which controls the entire fax, is attached to the right side of the main unit. a-2) NCU board The NCU board, which controls the telephone line, is attached to the right side of the main unit behind the SCNT board. - Page 170 FAX-L1000 Chapter 3: Technical Reference Figure 3-7 Electrical System Layout ECNT board Power supply unit NCU board OPCNT board Sensor board Paper size detection boards SCNT board TWINS board Modular board Sensor board OPCNT board ECNT board Power supply unit Paper size detection board 1 Paper size detection board 2 TWINS board...

- Page 171 b) Sensor layout b-1) Contact sensor This contact sensor (CS) horizontally scans documents up to Letter size 8.42" (214mm) (B4 size 10.00" (254 mm) for AE) at a horizontal scanning resolution of 8 dots/mm. b-2) Document sensor (DS) This sensor, which detects the presence/absence of a document, is attached to the ADF section (Upper reader frame unit) sensor board.

- Page 172 FAX-L1000 Chapter 3: Technical Reference b-12) Recording paper eject sensor 1 This sensor, which detects whether or not the recording paper has been fed as far as the fixing unit, is attached to the ECNT board. b-13) Recording paper eject sensor 2 This sensor, which detects whether or not the recording paper has passed through the fixing unit, is attached to the fixing unit.

- Page 173 Document sensor Recording paper overload sensor 2 Recording paper overload release sensor Recording paper overload sensor 1 Recording paper eject sensor 2 Recording paper eject sensor 1 Figure 3-8 Arrangement of Sensors FAX-L1000 Chapter 3: Technical Reference Document width sensor Document feed sensor Document edge sensor Printer cover sensor...

-

Page 174: Document Feed Section

FAX-L1000 Chapter 3: Technical Reference 2.3 Scanner Section The scanner section comprises the document feed section and the optical section. 2.3.1 Document feed section a) Document feed function a-1) ADF (auto document feed) function The ADF feeds up to 50 pages separates each page with the separation roller (upper) and separation roller (lower), passes the page over the contact sensor unit, then ejects the paper to the document output tray. - Page 175 FAX-L1000 Chapter 3: Technical Reference Separation roller(upper) Pick-up roller Document path Separation roller(lower) Document feed roller Document eject roller Contact sensor Figure 3-9 Document Feed Section 3-31...

- Page 176 FAX-L1000 Chapter 3: Technical Reference Document stopper movement (1) When documents are set (Fig. A) The document stopper on the ADF section (Upper reader frame) stops the NOTE document which is inserted into the document insertion opening, preventing it from being pushed in too far. (2) When the stopper goes up (Fig.

- Page 177 FAX-L1000 Chapter 3: Technical Reference Figure 3-10 Stopper Movement 3-33...

- Page 178 FAX-L1000 Chapter 3: Technical Reference b-2) Document jam detection The document edge sensor detects such document jams as pickup jams and document too long errors. A “pickup jam” means the document edge sensor cannot detect the leading edge of the document within 15 seconds after document feeding begins.

-

Page 179: Optical Section

2.3.2 Optical section a) Functions a-1) Document scanning For document scanning, the Contact Sensor (CS) horizontally scans documents up to LTR size 8.42" (214mm)(B4 size 10.00" (254mm) for AE) at a horizontal scanning resolution of 8 dots/mm (Standard, Fine and Superfine) or 16 dots/mm (Ultrafine). Vertical scanning resolution is fixed by selecting resolution button on the operation panel. - Page 180 FAX-L1000 Chapter 3: Technical Reference b) Structures b-1) Contact sensor The contact sensor is designed to be dust-free, so that dust and other such minute particles cannot find their way inside the contact sensor housing, to settle on the sensor surface. The contact sensor consists of an LED array that emits light for scanning, a lens that distributes light from the LED array uniformly in the horizontal direction, a contact glass that refracts the light to the document, a rod lens array that receives the light reflected...

- Page 181 I n c i d e l i g h Incident light Scanning glass Photo transistor Figure 3-11 Contact Sensor FAX-L1000 Chapter 3: Technical Reference Document Contact sensor logic board Document Contact sensor logic board 3-37 Rod rens array Scanning glass Rod rens array...

- Page 182 FAX-L1000 Chapter 3: Technical Reference 2.4 Paper Load Section a) Functions a-1) Recording paper pickup function (From multi-purpose tray) In case of paper pick-up from the multi-purpose tray, while the main motor rotates, the multi-purpose tray pick-up solenoid is turned ON. Then, the multi-purpose pick-up roller rotates, and a sheet of paper is fed into the printer section.

- Page 183 b) Structures b-1) Cassette paper loading In case of paper pick-up from the cassette, while the main motor rotates, the pick-up solenoid (SL101) is turned ON. Then, cassette pick-up roller, cassette feed roller, separation roller and feed rollers rotate, and a sheet of paper is fed into the fax. In case of paper pick-up from the multi-purpose tray, while the main motor rotates, the multi-purpose tray pick-up solenoid (SL102) is turned ON.

- Page 184 FAX-L1000 Chapter 3: Technical Reference Lifting plate Figure 3-12 Cassette Paper Loading Spring Paper pickup roller 3-40 Paper pickup roller Feed roller Feed roller Separation roller Feed roller Separation roller...

- Page 185 b-2) Recording paper pickup jam detection configuration Recording paper pickup jams are detected by the photo-interrupter type recording paper pickup sensor equipped with an actuator arm. There are the following two types of recording paper pickup jams. Recording paper pickup jam 1 a.

- Page 186 FAX-L1000 Chapter 3: Technical Reference b-3) No recording paper detection configuration The presence of paper on the multi-purpose tray is detected by the multi-purpose tray paper sensor (PS105). No recording paper processing When a no recording paper error occurs in the side cassette, the main motor drive is stopped, print operations are stopped, the error is displayed on the display, and the Rec.

-

Page 187: Paper Feeder

FAX-L1000 Chapter 3: Technical Reference Paper size SW601 SW602 No cassette LEGAL LETTER SW600 SW601 SW602 Figure 3-13 Paper Size Detection Configuration (Paper feeder) Paper size SW801 SW802 SW803 No cassette LEGAL Executive LETTER Other Custom SW801 SW802 SW803 Figure 3-14 Paper Size Detection Configuration (Option paper feed unit PF-52) 3-43 SW603... -

Page 188: Printer Section

FAX-L1000 Chapter 3: Technical Reference 2.5 Printer Section The LASER beam printer engine comprises the following sections. Laser/Scanner unit Mirror Toner cartridge Fixing unit Feed belt ECNT board Transfer charging Feed roller roller Figure 3-15 Printer Section 3-44... -

Page 189: Paper Feed/Eject Section

2.5.1 Paper feed/eject section a) Functions a-1) Paper feed/eject The feed section feeds the recording paper fed from the pickup section to the toner transfer section and fixing unit. The eject section ejects the paper from the recording paper eject outlet on the main unit after printing. - Page 190 FAX-L1000 Chapter 3: Technical Reference Pre-transfer roller Photosenstive drum Feed belt Fixing eject roller Paper path Pressure roller ECNT board Feed roller Figure 3-16 Paper Feed/Eject Section 3-46...

- Page 191 b-2) Recording paper jam detection configuration Recording paper jams in the paper feed/eject section are detected by the photo-interrupter type pre-feed sensor, top of page sensor, recording paper eject sensor 1 and 2, which is equipped with an actuator arm. The CPU assesses a delivery delay jam if the recording paper eject sensor 1 (PS501) does not detect the leading edge of the paper within the specified period of time (T) after the top of page sensor (PS103) detects the leading edge of the paper.

-

Page 192: Laser/Scanner Section

FAX-L1000 Chapter 3: Technical Reference 2.5.2 LASER/Scanner section a) Functions Scanning mirror Focusing lens Mirror BD mirror Figure 3-17 LASER/Scanner Section The VIDEO signal (nVDO) is sent from the SCNT board to the laser driver of the laser/ scanner unit through the TWINS board and ECNT board. The laser driver turns the laser diode ON and OFF according to the nVDO signal and generates the modulated laser beam only when the VIDEO DATA ENABLE (nENBL) signal from the ECNT board is “L.”... - Page 193 b) Automatic power control of laser diode The laser driver IC conducts the automatic power control (APC) of the laser diode so that the laser diode emits a beam of constant intensity. When the FORCED LASER ON signal (nLON) becomes “L,” or the VIDEO DATA ENABLE signal (nENBL) and nVDO signal become “L,”...

-

Page 194: Toner Cartridge

FAX-L1000 Chapter 3: Technical Reference 2.5.3 Toner cartridge a) Functions Laser beam Primary charging roller Drum protective shutter Blade Developing cylinder Cleaner blade Photosensitive drum Figure 3-18 Toner Cartridge The image formation system is the central hub of the fax, and consists of the photosensitive drum, developing unit, charging rollers, etc. - Page 195 b) Electrostatic latent image formation block This block follows two steps to produce an electrostatic latent image on the photosensitive drum. When “Laser beam exposure” of this block is completed, negative charge remains in the unexposed “dark” areas; however, those in the exposed “light” areas are eliminated. This image of negative charges on the drum is invisible to the human eye, so it is called an “electrostatic latent image.”...

- Page 196 FAX-L1000 Chapter 3: Technical Reference b-2) Laser beam exposure Figure 3-21 Laser Beam Exposure When the laser beam scans the drum surface, it causes the charges in the areas struck by the laser beam to be neutralized. These areas on the drum surface form the electrostatic latent image.

- Page 197 As shown in Figure 3-23, the developing unit consists of a fixed magnet, a developing cylinder and a rubber blade. The developing cylinder rotates around the fixed imagnet. The single-component toner consists of magnetite and a resin binder, and is held to the cylinder by magnetic attraction.

- Page 198 FAX-L1000 Chapter 3: Technical Reference d-1) Drum cleaning Cleaner blade Photo- sensitive drum Waste toner case Sweeper strip Figure 3-24 Drum Cleaning The residual toner on the drum surface is scraped away with the cleaner blade to clean the drum surface in preparation for the next print. The removed waste toner is collected into the waste toner case.

- Page 199 FAX-L1000 Chapter 3: Technical Reference • The high-voltage terminal of the toner cartridge is shown below. High voltage terminal Figure 3-25 High Voltage Terminals • The AC bias applied to the developing cylinder during development is about 1600 Vp-p. • The DC bias applied to the developing cylinder during development changes with “SELECT DENSITY”...

-

Page 200: Transfer/Separation Section

FAX-L1000 Chapter 3: Technical Reference 2.5.4 Transfer/Separation section In this block, the toner image is transferred from the drum surface to the paper. a) Transfer Positive charges are applied to the back of the paper to attract the negatively charged toner particles to the paper. -

Page 201: Fixing Section

FAX-L1000 Chapter 3: Technical Reference 2.5.5 Fixing section As the toner image transferred onto the paper in the transfer block is only adhered by electrostatic attraction, even a light touch will smear the image. In the fixing block, the toner image is fixed by applying heat and pressure to the paper and the toner. - Page 202 FAX-L1000 Chapter 3: Technical Reference • This fax machine does not have "-ACVIN signal". • If the ECNT board CPU detects with the thermistor that the fixing heater temperature is over 428°F (220°C), it cuts off the power to the fixing heater (Software protection). •...

- Page 203 5. When the thermistor is in the high temperature detection mode and the initial temperature is 185°F(85°C) or more, it does not exceed about 320°F(160°C) (about 284°F(140°C) in case of 1200DPI) within about 6 seconds after the heater is turned ON. 6.

- Page 204 FAX-L1000 Chapter 3: Technical Reference 2.6 Circuit Overview 2.6.1 SCNT board function block diagram FAX-L1000 ISDN kit J700 J701 ECNT board Power supply unit CN22 Document feed motor Communication Speaker section control Operation control Document Drive control edge sensor Modular board J2(T1,T2) Modular...

- Page 205 2.6.2 Functions a) SCNT board The SCNT board performs the following functions. Drive control The drive control section controls the document feed motor in the document scanning section. Operation panel control The operation panel control section serially transfers data to or from the control IC on the OPCNT board, receives button operation status, document status, etc., and sends the display and LED signals to the control IC on OPCNT board.

- Page 206 FAX-L1000 Chapter 3: Technical Reference Memory functions User data, service data, data registered before shipment from the factory, and communications management information, are stored to the SRAM. Image data are stored to the DRAM. Memory backup The SCNT board is provided with a function for backing up data in control/image processing memory (SRAM) and image storage memory (DRAM) by lithium battery, and rechargeable battery, even if a power interruption occurs, or the power cord is disconnected by accident.

- Page 207 d) OPCNT board Buttons detection and LED drive function The control IC on the OPCNT board detects the buttons operation status, and drives the LCD and LEDs. Display The control IC in the LCD module controls the 20-column display signals from the SCNT board. Serial communication Serial communication with the SCNT board is used to send buttons, speaker volume switch, document status, etc., and to receive display, LED drive data, etc..

-

Page 208: Ecnt Board Function Block Diagra

FAX-L1000 Chapter 3: Technical Reference 2.6.3 ECNT board function block diagra SCNT board TWINS board Power supply unit Low-voltage, High-voltage power supply J201 Tonner cartridge Horizontal synchronization signal (-BD) control Fixing unit Recording paper eject sensor1 J103 Recording paper eject sensor2 2bin solenoid Figure 3-30 Function Block Diagram (2) - Page 209 FAX-L1000 Chapter 3: Technical Reference 2.6.4 Functions a) ECNT board Fixing heater control The fixing heater control section monitors the DC voltage supplied from the power supply in response to the AC 187~264 V, and the fixing heater thermistor, and drives the heater so that the temperature reaches the specified level.

- Page 210 FAX-L1000 Chapter 3: Technical Reference Toner detection Signals are received from the antenna type toner sensor, and monitors the remaining toner of the toner cartridge. b) Paper size detection board 1 Sensors The cassette recording paper size sensor (SW600,601,602), and cassette recording paper sensor for cassette1 are attached to the paper size detection board 1.

-

Page 211: Scnt Board Component Block Diagram

2.6.5 SCNT board component block diagram Address bus Data bus Control Signal etc. SCNT board Lithium RESET battery IC16 SRAM SRAM 256K 256K IC31 DRAM DRAM IC18 MM66364FP FUNC System controller 40MHz DC-DC Converter IC23 RESET Driver Rechargeable battery Button IC 1 BU6215KS GATE ARRAY... - Page 212 FAX-L1000 Chapter 3: Technical Reference a) System control section (SCNT board) The system control section consists of the following components and controls the entire facsimile system. a-1) MPU (Micro Processor Unit) (IC 17) The MPU, on NEC UPD70741GC-25-7EA, has the following main functions. •16-bit CPU •24-bit address bus •16-bit data bus...

- Page 213 a-4) DRAM (IC 3, 31) This 16-Mbit DRAM is backed up by rechargeable battery (approx. 12 hour after AC power interruption), and is used as memory for storing image data and MPU work area. a-5) SRAM (IC 5, 6) These 256-kbit SRAMs are backed up by lithium battery. SRAM holds data registered for system control and communications management information.

- Page 214 FAX-L1000 Chapter 3: Technical Reference b-2) CODEC IC (IC 22) The main functions of the CODEC IC are as follows: •Scanner interface •Serial interface to image processing IC •Encoder •Decoder •Printer interface •Serial interface port for the SCNT printer interface b-3) SRAM (IC 21) A 256-kbit SRAM is used as a buffer for the image processing data.

-

Page 215: Ecnt Board Component Block Diagram

2.6.6 ECNT board component block diagram FAX-L1000 Printer Kit(option) Cooling fan TWINS board 2bin solenoid Main motor Multi-purpose sensor ECNT board Recoding paper overload sensor 1 Recoding paper Recording paper overload sensor 2 eject sensor 1 Top of sensor IC502 Feed roller RESET clutch... - Page 216 FAX-L1000 Chapter 3: Technical Reference a) Printer control section (ECNT board) The printer control section consists of the following components and controls the LBP printer. a-1) Single chip microcomputer (IC 501) The single chip microcomputer has the following main functions. •8-bit CPU •24k-byte ROM •512k-byte RAM...

- Page 217 2.6.7 Flow of image signals a) G3 memory transmission (1) The image is scanned by the contact sensor, and the analog image data is sent to the SCNT board. (2) The image processing IC (IC20) converts the analog image data from the contact sensor into digital data.

-

Page 218: Contact Sensor

FAX-L1000 Chapter 3: Technical Reference IC22 IC26 SCNT board CONTACT SENSOR IC20 IC17 NCU board Figure 3-33 Transmission 3-74 A:Image processing IC B:CODEC IC C:DRAM D:MODEM IC E:System control IC F:Main CPU... - Page 219 b) G3 reception (1) The received image signal by L1, L2 is passed through a 2-line - 4-line conversion circuit in the NCU board, and amplified. The encoded data received by the MODEM IC (IC26) is read out by the CPU and then it is written into the DRAM (IC3) reception buffer by the CPU.

-

Page 220: Ncu Board

FAX-L1000 Chapter 3: Technical Reference IC22 IC18 IC26 SCNT board NCU board IC17 A:Image processing IC B:CODEC IC C:DRAM D:MODEM IC E:System control IC F:Main CPU Figure 3-34 Reception 3-76 Print out... -

Page 221: High-Speed Transmission

3. NEW FUNCTION 3.1 High-speed Transmission The image transmission time is reduced drastically compared with the previous models by the V.34 modem (maximum transmission speed 33600 bps) recommended by ITU-T. 3.1.1 V.8/V.34 protocol a) Outline • The V.8 protocol is used as the startup protocol to move to V.34. The V.8 protocol enables connection with fax machines, data modem and equipment using existing V-series modems. - Page 222 FAX-L1000 Chapter 3: Technical Reference 1. The V.34 protocol uses ECM. If the ECM SW in user data is set to OFF, the V.8 protocol is not executed. Therefore, the V.34 protocol is not used, and V.17 or a lower protocol is selected. NOTE 2.

- Page 223 b) Typical protocol Network interaction ANSam (Phase 1) INFO0c INFO0a Probing (Phase 2) INFO0h Primary channel equalizer training (Phase 3) Control channel start-up (Phase 4) flags Control channel flags "1" Primary channel resyncronization procedure Image data Image data Turn-Off Control channel resyncronization procedure (Communication end...

- Page 224 FAX-L1000 Chapter 3: Technical Reference b-1) Network interaction (Phase 1) The V.8 protocol is used as the startup protocol for high-speed modem V.34. The V.8 protocol determines the best modulation method (V-series modem mode) that is available between the transmitter and receiver. •...

- Page 225 b-2) Probing (Phase 2) The line characteristics are measured and modulation-related parameters, such as symbol rate, are set. • Transmitter Abbre- Signal viation INFO sequence INFO0c Tone B Tone B Probing signal Probing signal • Receiver Abbre- Signal viation INFO sequence INFO0a Tone A Tone A...

- Page 226 FAX-L1000 Chapter 3: Technical Reference b-3) Primary channel equalizer training (Phase 3) Filters, such as equalizers, are trained (adjusted) with the parameters set in phase 2. • Transmitter Signal S signal S signal PP signal TRN signal b-4) Control channel start-up (Phase 4) Select the maximum data signalling rate and trellis encoder and set the data signalling rate that can be supported.

- Page 227 b-5) Control channel The conventional T.30 protocol is executed. The transmission speed is 600bps. • Transmitter Abbre- Signal viation Flag flags Non-standard facilities set-up Transmitting subscriber identification Digital command signal ——— • Receiver Abbre- Signal viation Non-standard facilities Called subscriber identification Digital identification signal...

- Page 228 FAX-L1000 Chapter 3: Technical Reference b-6) Primary channel resyncronization procedure Training is performed with the parameters set in phase 4. The transmission speed is 1200bps. • Transmitter Signal S signal S signal PP signal Sequence B1 b-7) Image data Transmit image data. •...

- Page 229 b-8) Control channel resyncronization procedure (Communication end procedure) Protocol for terminating transmission. The transmission speed is 1200bps. • Transmitter Abbre- Signal viation Sh signal Sh signal ALT signal E sequence End of procedures PPS-EOP Flag flags Disconnect signal • Receiver Abbre- Signal viation...

- Page 230 FAX-L1000 Chapter 3: Technical Reference c) Examples of sequences The signals in the shaded areas are important in the protocol. c-1) Late start Since the receiver cannot detect the CM signal while sending the ANSam signal, it sends the DIS signal containing the "V.8 protocol" declaration. The transmitter sends the CI signal to request the receiver to send the ANSam signal again to move to V.8 protocol.

- Page 231 c-2) Between-page sequence The transmitter sends image data, then the PPS-MPS signal in the same as for the T.30 protocol. The receiver sends the MCF signal to receive the next page. Figure 3-37 Between-page Sequence FAX-L1000 Chapter 3: Technical Reference Image data Turn-off...

- Page 232 Mode change The transmitter sends PPS-EOM and the receiver sends the MCF signal. Then the receiver sends the DIS signal and the transmitter sends the DCS signal to change the mode. When Canon fax machines communicate with each other, a special procedure is used, so this protocol is omitted.

- Page 233 c-4) Image transmission speed change from the receiver The receiver returns to the PPh signal in response to the Sh signal from the transmitter. The image transmission speed is then determined by the MPh sequence sent from both modems. Figure 3-39 Image Transmission Speed Change from the Receiver FAX-L1000 Chapter 3: Technical Reference Image...

- Page 234 FAX-L1000 Chapter 3: Technical Reference c-5) Image transmission speed change from the transmitter The transmitter sends image data, and then the PPh signal, and the receiver returns the PPh signal to the transmitter. The image transmission speed is then determined by the MPh sequence sent from both modems.

- Page 235 3.2 JBIG Image Compression Encoding Method 3.2.1 Outline of the JBIG Image Compression Encoding Method The JBIG Image Compression Encoding Method is recommended in ITU-T T.82/T.85 as a new bi-level (bi-level: White and Black) image compression encoding method developed by JBIG (Joint Bi-level Image experts Group).

-

Page 236: Single Progression Sequential Bi-Level Image Compression Method

FAX-L1000 Chapter 3: Technical Reference The characteristics of Progressive Bi-level Image Compression are explained below as a reference. First of all, after the original image has been read in at high resolution, it is converted to low resolution, and this low resolution NOTE image data proceeds to be encoded (compressed). -

Page 237: Encoding Method

3.2.3 Encoding Method In the JBIG encoding used in the Single Progression Sequential Bi-level Image Compression Method, uses in the encoder shown below to encode to the original the results of comparison of the line currently being processed and the previous line, as well as the predicted value of an image pixel (white or black) used in a model template. - Page 238 FAX-L1000 Chapter 3: Technical Reference b) In the model template, the combination (10-bit pixel pattern) of 10 pixels is output to the arithmetic encoding section using the template shown below (inside the bold outline). All of the 10-bit pixel patterns inside this template exist in the study table. This 10-bit pixel pattern is used by the arithmetic encoding section to refer to the predicted value of the pixel and the status number in the study table which correspond to the 10-bit pixel pattern.

- Page 239 3-line model template Figure 3-44 Positions of Pixels in Model Template Table 3-1 Study Table (Initial values) Pixel pattern in the model template 000h 001h 002h 003h 004h 005h 3FBh 1019 3FCh 1020 3FDh 1021 3FEh 1022 3FFh 1023 Table 3-2 Probability Estimation Table NLPS NMPS SWITCH...