Wood Stone TRADITIONAL Series Installation And Operation Manua

Stone hearth oven gas-fired, gas/wood combination, european models

Hide thumbs

Also See for TRADITIONAL Series:

- Installation and operation manual (40 pages) ,

- Service manual (56 pages) ,

- Installation and operation manual (24 pages)

Table of Contents

Advertisement

Quick Links

Installation and

Operation Manual

TRADITIONAL SERIES

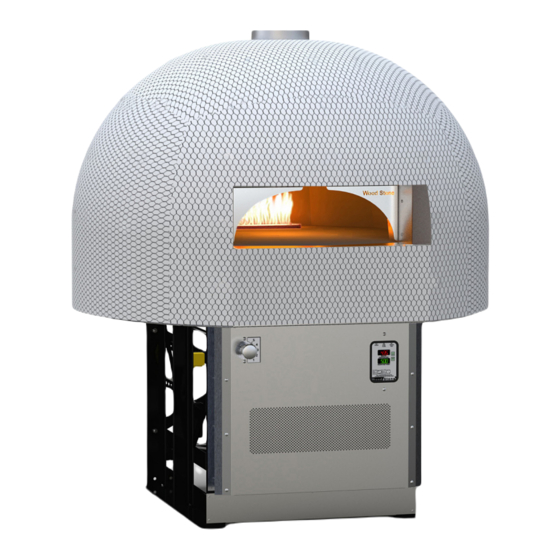

Stone Hearth Oven

Gas-Fired, Gas/Wood Combination,

European Models

TRADITIONAL SERIES

WS-CS-RND-15-(RFG)-(IR)-(W)-S-CE (TS-5)

WS-CS-RND-21-(RFG)-(IR)-(W)-S-CE (TS-6)

WOOD STONE CORPORATION

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

www.woodstone-corp.com

Tel 360.650.1111

Fax 360.650.1166

DOC NO M0324.00

REVISED APRIL 2020

Advertisement

Table of Contents

Summary of Contents for Wood Stone TRADITIONAL Series

- Page 1 Installation and Operation Manual TRADITIONAL SERIES Stone Hearth Oven Gas-Fired, Gas/Wood Combination, European Models TRADITIONAL SERIES WS-CS-RND-15-(RFG)-(IR)-(W)-S-CE (TS-5) WS-CS-RND-21-(RFG)-(IR)-(W)-S-CE (TS-6) WOOD STONE CORPORATION 1801 W. Bakerview Rd. Tel 360.650.1111 Bellingham, WA 98226 USA Fax 360.650.1166 www.woodstone-corp.com DOC NO M0324.00 REVISED APRIL 2020...

-

Page 2: Table Of Contents

Installation and Operation Manual TABLE OF CONTENTS This manual covers all configurations of the Traditional Series Oven: Gas-Fired and Wood/Gas Combination models. Make certain you read the appropriate section for your model. Highlighted blocks indicate sections relevant to your model... -

Page 3: Traditional Series Oven

TRADITIONAL SERIES OVEN Traditional Series CE Installation and Operation Manual INSTALLATION AND OPERATION MANUAL THE WOOD STONE TRADITIONAL SERIES TRANSLATION OF THE ORIGINAL INSTRUCTIONS WS-CS-RND-(15)-(RFG)-(IR)-(W)-S-CE-(NG,LP) (TS-5) WS-CS-RND-(21)-(RFG)-(IR)-(W)-S-CE-(NG,LP) (TS-6) STONE HEARTH COOKING EQUIPMENT CE MODELS GAS-FIRED & GAS/WOOD COMBINATION MODELS ADDITIONAL COPIES AVAILABLE UPON REQUEST Shown: WS-CS-RND-15-RFG-IR-S-CE M0324.00 APRIL 2020... -

Page 4: Cautions & Warnings

CAUTIONS & WARNINGS Traditional Series CE Installation and Operation Manual WOOD STONE TRADITIONAL SERIES GAS-FIRED AND GAS/WOOD COMBINATION OVEN INSTALLATION AND OPERATING INSTRUCTIONS RETAIN THIS MANUAL FOR FUTURE REFERENCE Additional copies of this manual from your local distributor. For prompt responses to service/maintenance questions, call your local distributor. -

Page 5: Cs-Rnd-15 (Ts-5) Specifications

HE INFORMATION CONTAINED IN THIS DRAWING IS THE THE INFORMATION CONTAINED IN THIS DRAWING IS THE 188,000 BTU, NG (RFG-IR) THOUT THE WRITTEN PERMISSION OF WOOD STONE IS SOLE PROPERTY OF WOOD STONE CORPORATION SOLE PROPERTY OF WOOD STONE CORPORATION... -

Page 6: Cs-Rnd-21 (Ts-6) Specifications

HE INFORMATION CONTAINED IN THIS DRAWING IS THE THE INFORMATION CONTAINED IN THIS DRAWING IS THE 188,000 BTU, NG (RFG-IR) THOUT THE WRITTEN PERMISSION OF WOOD STONE IS SOLE PROPERTY OF WOOD STONE CORPORATION SOLE PROPERTY OF WOOD STONE CORPORATION... -

Page 7: Unloading & Moving

USING A CRANE. The oven arrives with four lifting eyes attached. When craning a Wood Stone oven, use a spreader bar with a two-legged sling rigged on each end. The spreader bar should be of a sufficient length to keep the sling from contacting the oven. -

Page 8: Installation Clearances

CLEARANCES 1. The Wood Stone Mountain Series oven must have a minimum 25 mm (1") clearance to combustibles from all sides, and 152 mm (6") clearance to combustibles from the top. If building materials will contact the oven, they must be completely non- combustible. - Page 9 INSTALLATION CLEARANCES Traditional Series CE Installation and Operation Manual THE FOLLOWING CLEARANCE INFORMATION APPLIES TO ALL WOOD STONE TRADITIONAL SERIES OVENS Please see woodstone-corp.com for floor loading information. 152mm (6") 152mm (6") top clearance to combustible building materials. If enclosing the oven, any facade materials 152mm (6") to either side...

-

Page 10: Facade Details

We recommend 13mm (1/2") or smaller tiles applied over a suitable non-combustible skim coat. Smaller tiles can more easily conform to the curved shape of the oven. Because of the unique shape of the Traditional Series oven, we recommend employing a skilled tile contractor. -

Page 11: Utilities

UTILITIES Traditional Series CE Installation and Operation Manual ELECTRICAL The oven is rated at 230 VAC, 2 A, 50 Hz. The rating also appears on the data plate. It is recommended that the oven be connected to its own individual branch circuit. Electrical diagrams are located on the Terminal box and also at the end of this manual. -

Page 12: Gas Connection

Wood Stone recommends that the oven be equipped with a manual, individual shutoff valve, located between the oven and the main gas supply, and that this shutoff valve (supplied by others) be left readily accessible. Wood Stone also recommends that inspection and maintenance of the burners and gas piping connections of this appliance be performed at regularly scheduled intervals and only by professional gas appliance service agencies. - Page 13 GAS SPECIFICATIONS Traditional Series CE Installation and Operation Manual NATURAL GAS (NG) Gas Supply and Pressure TRADITIONAL SERIES MODELS EN 437 Gas Group 2ELL Inlet Pressure (mbar) 20/25 Declared Input (kW) 2ELL TS-5-RFG-CE-NG 30.8 30.8 30.8 30.8 26.3 TS-5-RFG-IR-CE-NG 55.1 55.1...

-

Page 14: Gas Specifications

GAS SPECIFICATIONS Traditional Series CE Installation and Operation Manual PROPANE (LP) Gas Supply and Pressure TRADITIONAL SERIES MODELS EN 437 Gas Group 3B/P 3B/P Inlet Pressure (mbar) 28-30/37/50* 30/37* 30/37/50* Declared Input (kW) 3B/P 3B/P TS-5-RFG-CE-LP 27.5 33.6 33.6 27.5 TS-5-RFG-IR-CE-LP 46.6... -

Page 15: Venting

The above statement taking precedence, Wood Stone Corporation recommends the following two venting options: 1. This Wood Stone Traditional Series oven can be vented as a Type A appliance (with no flue connection), designed to be installed under an exhaust hood (canopy). The hood must be connected to a grease-rated duct system. The venting system must be designed and installed in accordance with all relevant codes pertaining to grease and smoke producing commercial cooking appliances. -

Page 16: Front Panel Assembly

FRONT PANEL ASSEMBLY Traditional Series CE Installation and Operation Manual STANDARD FRONT PANEL AND TOE KICK ASSEMBLY INSTRUCTIONS Flame Height Control Knob Controller Service Panel Transformer Box Contains terminal strip for incoming power supply. NOTE: Have licensed electrician make this electrical connection. -

Page 17: Controller Functions

CONTROLLER FUNCTIONS Traditional Series CE Installation and Operation Manual CONTROLLER FUNCTIONS TYPE 2 Hearth Heat Indicator Light RFG-IR-(W) AND W-IR MODELS Dome Flame Indicates that the pilot for the Indicator Light Underfloor IR burner is lit. This Power Indicator Light... -

Page 18: Flame Height Control

FLAME HEIGHT CONTROL Traditional Series CE Installation and Operation Manual DETERMINING THE APPROPRIATE FLAME HEIGHT For each specific configuration of oven there is a system that determines what the desired flame height will be. Each flame height corresponds to a saturated floor temperature. Several factors need to be accounted for in order to determine this relationship for each oven. -

Page 19: Gas Oven Maintenance

OVEN INTERIOR Wood Stone recommends the use of long-handled brushes for sweeping up surface debris that will accumulate on the floor of the oven during use. Use a natural fiber brush—always brushing away from the radiant burner well. For deeper cleaning, use a brass bristled brush. -

Page 20: Initial Start-Up

INITIAL RFG-IR-(W) OVEN START-UP PROCEDURE Wood Stone recommends completing this start-up procedure before burning any wood. IMPORTANT: If at any time you feel that either or both of the burners are not operating properly, turn the oven off and call for service. -

Page 21: Operation

RFG-IR-(W) OPERATION Traditional Series CE Installation and Operation Manual DAILY OPERATION FOR RFG-IR-(W) MODELS IMPORTANT: If at any time you feel that the burner is not operating properly, TURN THE OVEN OFF and call for service. Before servicing, disconnect the electrical supply at the breaker and turn OFF the gas supply at the appliance’s individual gas shutoff valve. -

Page 22: Initial Start-Up

INITIAL RFG-(W) OVEN START-UP PROCEDURE Wood Stone recommends completing this start-up procedure before burning any wood. IMPORTANT: If at any time you feel that either or both of the burners are not operating properly, turn the oven OFF and call for service. -

Page 23: Operation

RFG-(W) OPERATION Traditional Series CE Installation and Operation Manual DAILY OPERATION FOR RFG-(W) MODELS IMPORTANT: If at any time you feel that the burner is not operating properly, TURN THE OVEN OFF and call for service. Before servicing, disconnect the electrical supply at the breaker and turn OFF the gas supply at the appliance’s individual gas shutoff valve. -

Page 24: Initial Start-Up

Never use any type of flammable liquid or fuel to start a fire in a Wood Stone oven. Doing so could cause a dangerous situation and/or damage to the oven ceramic. -

Page 25: Daily Operation

W-IR DAILY OPERATION Traditional Series CE Installation and Operation Manual BUILDING THE FIRE (see Wood Burning section later in this manual for additional information) Build a small kindling fire of 2.25–3 kg (5–7 lbs) of heavy, hardwood. We suggest using a fire starter (paraffin/sawdust stick) to start the fire. -

Page 26: Burning Wood Safely

Installation and Operation Manual Select Wood Stone Traditional Series models (with a "-W" in the model number) are approved to allow the burning of wood in the cooking chamber in addition to the gas burners. When burning wood, the fire should be placed to one side of the oven chamber, as close to the door opening as is possible (this is often described as the 8 o’clock or 4 o’clock position). - Page 27 OR SIMILAR LIQUIDS TO START OR FRESHEN A FIRE IN THIS OVEN. KEEP ALL SUCH LIQUIDS AWAY FROM THE OVEN WHILE IT IS IN USE. DO NOT USE PRESSED WOOD PRODUCTS IN WOOD STONE EQUIPMENT AS THEY MAY DAMAGE THE CERAMICS.

-

Page 28: Fuelwood Facts

Wet wood is the most common operational difficulty associated with wood-fired cooking equipment. Wood Stone’s optional Mini-Ligno E Wood Moisture Meter can save you from paying for water when you thought you were paying for wood (see the Tools &... -

Page 29: Operational Sequence

OPERATIONAL SEQUENCE Traditional Series CE Installation and Operation Manual RFG-(W) CE OVEN BURNER OPERATION SEQUENCE W-IR CE OVEN BURNER OPERATION SEQUENCE Power ON. Power ON. Floor temperature ICS2 Module powers Igniter Floor temperature below above Hearth Set Point and opens Pilot valve. -

Page 30: Troubleshooting Guide

TROUBLESHOOTING GUIDE Traditional Series CE Installation and Operation Manual PROBLEM CAUSE/SOLUTION Controller will not turn on 1. Incoming power to oven turned OFF. Check circuit breaker for circuit supplying the oven. Check that any wall switches external to the oven that ALL MODELS control oven power are turned on. -

Page 31: Rfg-Ir-(W)

RFG-IR-(W) ELECTRICAL DIAGRAM Traditional Series CE Installation and Operation Manual RFG-IR-(W) CE (TYPE 2 CONTROLLER) RFG-IR-(W) CE (TYPE 2 CONTROLLER) ... -

Page 32: Rfg-(W)

RFG-(W) ELECTRICAL DIAGRAMS Traditional Series CE Installation and Operation Manual RFG-(W)-CE WITH TYPE 2 CONTROLLER RFG-(W)-CE WITH TYPE 2 CONTROLLER ... -

Page 33: W-Ir

W-IR ELECTRICAL DIAGRAM Traditional Series CE Installation and Operation Manual W-IR CE (TYPE 2 CONTROLLER) ... - Page 34 Blank page M0324.00 APRIL 2020...

-

Page 35: Limited Warranty

In the event of warranty claim or otherwise, the sole obligation of Wood Stone shall be the repair and/or replacement, at the option of Wood Stone, of the appliance or component or part thereof. Such repair or replacement shall be at the expense of Wood Stone with the exception of travel over 100 miles or two hours, overtime, and holiday charges which shall be at the expense of the purchaser. - Page 36 WOOD STONE CORPORATION 1801 W. Bakerview Rd. Tel 360.650.1111 Bellingham, WA 98226 USA Fax 360.650.1166 www.woodstone-corp.com An ongoing program of product improvement may require us to change specifications without notice. M0324.00 APRIL 2020...

Need help?

Do you have a question about the TRADITIONAL Series and is the answer not in the manual?

Questions and answers