Tektronix TDS2022C Technical Reference

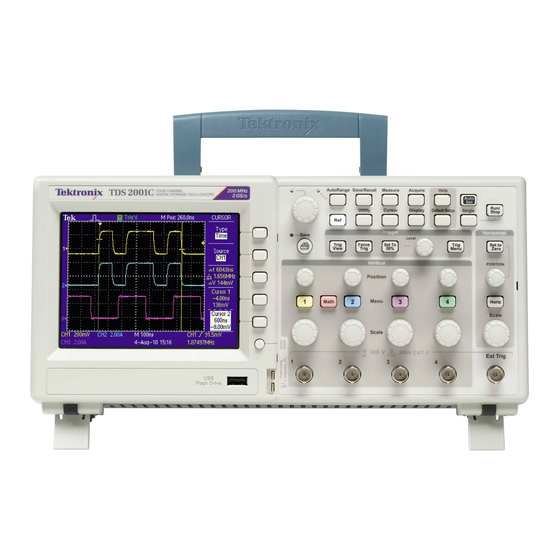

Tds2000c series digital storage oscilloscopes

Hide thumbs

Also See for TDS2022C:

- Service manual (114 pages) ,

- User manual (161 pages) ,

- Security instructions (20 pages)

Summary of Contents for Tektronix TDS2022C

- Page 1 TDS2000C Series Digital Storage Oscilloscopes Service Manual *P077044600* 077-0446-00...

- Page 3 This document applies to firmware version 1.00 and above. Warning The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to all safety summaries prior to performing service. www.tektronix.com 077-0446-00...

- Page 4 Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material.

-

Page 5: Table Of Contents

Table of Contents General Safety Summary ..................Service Safety Summary..................viii Preface ......................Manual Conventions..................Related Documentation ..................Specifications Specifications ..................... Signal Acquisition System Characteristics..............Time Base System ................... Triggering System ................... Display Specifications..................1-11 Interfaces and Output Ports Specifications.............. 1-12 Data Handling Characteristics................ - Page 6 Table of Contents Four-Channel Oscilloscopes ................Performance Verification Performance Verification ..................Required Equipment..................Test Record ....................Performance Verification Procedures ..............Self Test ....................Self Calibration..................Check DC Gain Accuracy................Check Bandwidth ..................Check Sample Rate Accuracy and Delay Time Accuracy.......... Check Edge Trigger Sensitivity ...............

- Page 7 Table of Contents Power Supply Module ................6-12 Internal Assembly..................6-13 Display Adapter Module ................6-14 Front-Panel Cable ..................6-17 Main Board Module .................. 6-18 Display Module ..................6-20 Front-Panel Module................... 6-21 Keypad ....................6-22 Troubleshooting.................... 6-23 Adjustment After Repair ................6-23 Required Tools and Equipment..............

- Page 8 Table of Contents List of Figures Figure 3-1: Module-level block diagram (2-channel) ............Figure 3-2: Module-level block diagram (4-channel) ............Figure 4-1: Example of a line graph for the Vertical Position Accuracy test ......4-13 Figure 5-1: Adjustment setups .................. Figure 6-1: Locator for trim and cabinet removal (4-channel model shown)......

- Page 9 Table of Contents List of Tables Table 1-1: Signal acquisition system characteristics ............Table 1-2: Time base system ..................Table 1-3: Triggering system..................Table 1-4: Display specifications ................1-11 Table 1-5: Interfaces and output ports specifications ............1-12 Table 1-6: Data handling characteristics ..............1-12 Table 1-7: Power distribution system ................

-

Page 10: General Safety Summary

General Safety Summary General Safety Summary Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. To avoid potential hazards, use this product only as specified. Only qualified personnel should perform service procedures. To Avoid Fire or Personal Use proper power cord. - Page 11 General Safety Summary Do not operate in wet/damp conditions. Do not operate in an explosive atmosphere. Keep product surfaces clean and dry. Provide proper ventilation. Refer to the manual’s installation instructions for details on installing the product so it has proper ventilation. Terms in This Manual These terms may appear in this manual: WARNING.

-

Page 12: Service Safety Summary

Service Safety Summary Service Safety Summary Only qualified personnel should perform service procedures. Read this Service Safety Summary and the General Safety Summary before performing any service procedures. Do Not Service Alone. Do not perform internal service or adjustments of this product unless another person capable of rendering first aid and resuscitation is present. -

Page 13: Preface

Preface This service manual provides information to verify performance of, calibrate, troubleshoot, disassemble, and replace parts on the TDS2000C Series Digital Storage Oscilloscopes. Unless noted otherwise, the term "oscilloscope" refers to all models in the TDS2000C series. Manual Conventions This manual uses certain conventions that you should become familiar with before attempting service. - Page 14 Preface TDS2000C Series Oscilloscope Service Manual...

-

Page 15: Specifications

Specifications... -

Page 17: Signal Acquisition System Characteristics

Table 1-1: Signal acquisition system characteristics Characteristic Description Number of Input Two (for the TDS2001C, TDS2002C, TDS2012C, and TDS2022C) or four (for the TDS2004C, Channels TDS2014C, and TDS2024C) nominally identical channels, sampled simultaneously. Input Coupling DC, AC, or GND Input Impedance, DC 1 MΩ... - Page 18 Specifications Table 1-1: Signal acquisition system characteristics (cont.) Characteristic Description Sensitivity Range 2 mV/div to 5 V/div in 1-2-5 sequence with the probe attenuation set to 1X. Display Gain Variable The Display Gain Variable function allows the user to vary the vertical display gain continuously over the full range.

- Page 19 1X. No probe should be installed for these measurements. typical TDS2012C, TDS2014C, TDS2022C, TDS2024C: DC to ≥ 75 MHz for 5 mV/div through 5 V/div settings with the bandwidth limit at full. Settings less than 5 mV/div are limited to 20 MHz bandwidth.

- Page 20 This is the lower frequency for Analog Bandwidth when the instrument is AC-coupled AC Coupled ≤ 10 Hz. <1 Hz when 10X, passive probes are used. Rise Time, typical Model Expected full bandwidth rise time TDS2022C and TDS2024C 2.1 ns 3.5 ns TDS2012C and TDS2014C TDS2002C and TDS2004C 5.0 ns TDS2001C 7.0 ns...

-

Page 21: Time Base System

100:1 at 60 Hz, reducing to 10:1 with 50 MHz sine wave, with equal TDS2014C Volts/Div and Coupling settings on each channel. TDS2022C TDS2024C TDS2001C 100:1 at 60 Hz, reducing to 20:1 with a sine wave with frequency equal to TDS2002C ½... - Page 22 Specifications Table 1-2: Time base system (cont.) Characteristic Description Record Length This is the total number of samples contained in a single acquired waveform record (Memory Length in IEEE 1057.2.2.1). 2,500 samples per record. Seconds/Division Range 5 ns/div to 50 s/div in 1–2.5–5 sequence Sec/Div Variable function is not available for this product.

-

Page 23: Triggering System

Trigger Types Edge, Video, Pulse Width Trigger Source Models Trigger source selections Selection TDS2001C Channel 1 TDS2002C Channel 2 TDS2012C External TDS2022C External/5 AC Line TDS2004C Channel 1 TDS2014C Channel 2 TDS2024C Channel 3 Channel 4 External External/5 AC Line External/5 selection attenuates the external signal by 5. - Page 24 TDS2012C 3 div between 10 MHz 1.5 div between 10 MHz TDS2014C and 100 MHz and 100 MHz TDS2022C 3 div between 10 MHz 1.5 div from 10 MHz to and 200 MHz TDS2024C 100 MHz 2.0 div above 100 MHz...

- Page 25 Specifications Table 1-3: Triggering system (cont.) Characteristic Description Sensitivity, Trigger Source Sensitivity Edge-Type Trigger, non-DC Coupled, Same as DC Coupled limits for frequencies 50 Hz typical and above Noise Rej Effective in Sample or Average Mode, > 10 mV/div to 5 V/div. Reduces DC Coupled trigger sensitivity by 2X.

- Page 26 Specifications Table 1-3: Triggering system (cont.) Characteristic Description Video Trigger This is the minimum peak–to–peak video signal required for stable Video-Type triggering. Sensitivity, typical Source Typical sensitivity Input Channels 2 divisions of composite video 400 mV of composite video Ext/5 2 V of composite video Pulse-Width Trigger Pulse-Width...

-

Page 27: Display Specifications

Specifications Table 1-3: Triggering system (cont.) Frequency 6 digits Counter Resolution Frequency ±51 ppm including all reference errors and ±1 count errors. Counter Accuracy, typical Frequency AC coupled. 10 Hz minimum to rated bandwidth. Counter Frequency Range, typical Frequency Pulse width or edge selected trigger source. Counter Signal Frequency counter measures selected trigger source at all times in pulse width and edge mode, including Source... -

Page 28: Interfaces And Output Ports Specifications

Description USB Device USB 2.0 Full Speed device. 12 Mb/second maximum. Supports PICTBRIDGE compatibility and provides USB-TMC communications with Tektronix extensions. Standard USB Host USB 2.0 Full Speed host. 12 Mb/sec maximum. Supports USB Mass Storage Class. Bulk Only Subclass only. -

Page 29: Mechanical Characteristics

Specifications Mechanical Characteristics Table 1-8: Mechanical characteristics Characteristic Description Weight Requirements that follow are nominal: 2.0 kg (4.4 lbs), stand alone instrument 2.2 kg (4.9 lbs), with accessories 3.6 kg (8 lbs), when packaged for domestic shipment Height Size 158 mm (6.22 in) Width 326.3 mm (12.85 in) Depth... -

Page 30: Data Logging System Characteristics

Specifications Data Logging System Characteristics NOTE. This software feature directs the oscilloscope to automatically collect data over a period of time. After you configure the trigger conditions to use, you can use the data logging menu to set up the oscilloscope so that it will save all of the triggered waveform to a USB memory device, within a time duration that you have set. - Page 31 Specifications Table 1-11: Limit testing system characteristics (cont.) Characteristic Description Vertical Limit The vertical limit in vertical divisions. 0~1000 mdiv Horizontal Limit The horizontal limit in horizontal divisions. 0~500 mdiv. Destination Ref Channel The location of the reference memory location that is used to store the limit test template. RefA, RefB, RefC, RefD.

- Page 32 Specifications 1–16 TDS2000C Series Oscilloscope Service Manual...

-

Page 33: Where To Find Operating Information

Where to Find Operating Information... - Page 35 For information on installing and operating your TDS2000C Series Digital Storage Oscilloscope, refer to the TDS2000C Series Digital Storage Oscilloscope User Manual. The user manuals are available in eleven languages and are on the Web at www.tektronix.com. TDS2000C Series Oscilloscope Service Manual 2–1...

- Page 36 Where to Find Operating Information 2–2 TDS2000C Series Oscilloscope Service Manual...

-

Page 37: Theory Of Operation

Theory of Operation... - Page 39 Theory of Operation This section covers the electrical operation of the TDS2000C series oscilloscopes to the module level by describing the basic operation of each functional circuit block. NOTE. The descriptions for the 2-channel and 4-channel models are slightly different. TDS2000C Series Oscilloscope Service Manual 3–1...

-

Page 40: System Level Block Diagrams

Theory of Operation System Level Block Diagrams Two high-level block diagrams are provided, one for 2-channel models and one for 4-channel models. (See Figure 3-1 on page 3-2.) (See Figure 3-2 on page 3-3.) Figure 3-1: Module-level block diagram (2-channel) 3–2 TDS2000C Series Oscilloscope Service Manual... -

Page 41: Figure 3-2: Module-Level Block Diagram (4-Channel)

Theory of Operation Figure 3-2: Module-level block diagram (4-channel) TDS2000C Series Oscilloscope Service Manual 3–3... -

Page 42: Main Board

Theory of Operation Main Board The Main board is also called the acquisition board. The Main board of the 4-channel oscilloscopes is essentially two 2-channel oscilloscopes tied together through a common microprocessor, and some special interconnects to support combining the display and trigger systems. The focus of the Main board discussion is the 2-channel system, with differences for the 4-channel models noted as necessary. -

Page 43: Input Signal Interface

Theory of Operation Processing and Display The processing and display system consists of the display ASIC, DRAM, and system oscillator. Digitized acquisition samples are received by the display System ASIC and stored in DRAM. Once data are received by the display ASIC, various corrections are applied, display rasterization is performed, and the waveform is placed in a display buffer. -

Page 44: Power Supply

Theory of Operation Power Supply The main power supply module for the TDS2000C series oscilloscopes is a wide input range universal supply. It can provide about 25 W of power for the oscilloscope, while allowing the input to run from about 90 V to 264 V. Input frequency ranges from 47 Hz to 440 Hz, which allows operation in virtually all countries in the world and in several off-grid environments, such as power on military aircraft. - Page 45 Performance Verification...

-

Page 47: Table 4-1: Performance Verification

Oscilloscope Calibration Option (Option 5500A-SC) 50Ω BNC Cable BNC male to BNC male, ≈ 1 m (36 in) long Tektronix part number 012-0482-XX 50Ω BNC Cable BNC male to BNC male, ≈ 25 cm (10 in) long Tektronix part number 012-0208-XX Tektronix part number 011-0049-XX 50Ω... -

Page 48: Four-Channel Oscilloscopes

Performance Verification Test Record Table 4-2: Test record Instrument Serial Number: Certificate Number: Temperature: RH %: Date of Calibration: Technician: Instrument performance test Minimum Incoming Outgoing Maximum Channel 1 DC Gain 5 mV/div 33.6 mV 36.4 mV Accuracy 200 mV/div 1.358 V 1.442 V 2 V/div... -

Page 49: Performance Verification Procedures

Performance Verification Performance Verification Procedures Before beginning these procedures, two conditions must be met: The oscilloscope must have been operating continuously for twenty minutes within the operating temperature range specified in the Environmental Performance table. (See Table 1-9.) You must perform the Self Calibration operation described below. If the ambient temperature changes by more than 5 °C, you must perform the Self Calibration operation again. - Page 50 Performance Verification 3. Connect the oscilloscope channel under test to the DC voltage source as shown in the following figure: 4. For each vertical scale (volts/division) setting in the following table, perform the following steps: a. Set the DC voltage source output level to the positive voltage listed and then record the mean measurement as V b.

-

Page 51: Check Bandwidth

70 MHz if you are checking a TDS2002C or TDS2004B 100 MHz if you are checking a TDS2012C or TDS2014C 200 MHz if you are checking a TDS2022C or TDS2024C 8. Set the oscilloscope Horizontal Scale (seconds/division) to 10 ns/div. - Page 52 Performance Verification Check Sample Rate This test checks the time base accuracy. Accuracy and Delay Time 1. Set up the oscilloscope using the following table: Accuracy Push menu button Select menu option Select setting — — Default Setup Channel 1 Probe 2.

-

Page 53: Check Edge Trigger Sensitivity

Performance Verification 10. Check that the rising edge of the marker crosses the center horizontal graticule line within ±2 divisions of the vertical center graticule line, as shown in the following figure: NOTE. One division of displacement from graticule center corresponds to a 25 ppm time base error. - Page 54 11. Push Set To 50%. Adjust Trigger Level as necessary and then check that triggering is stable. 12. For the TDS2022C and TDS2024C models, set the frequency to 200 MHz, and increase the amplitude to 1 V . Verify stable triggering.

- Page 55 Performance Verification 15. Push Set To 50%. Adjust Trigger Level as necessary and then check that triggering is stable. 16. Disconnect the test setup. 17. Repeat steps 1 through 16 for all input channels. Check External Edge This test checks the edge trigger sensitivity for the external trigger. Trigger Sensitivity 1.

-

Page 56: Check Vertical Position Accuracy

9. Push Set To 50%. Adjust Trigger Level as necessary and then check that triggering is stable. 10. For TDS2022C and TDS2024C models, set the sine wave generator output level for a channel 1 display to approximately 350 mV 11. For TDS2022C and TDS2024C models, set the sine wave generator frequency to 200 MHz. - Page 57 The PDF version of the TDS2000C service manual (which you can download from the www.tektronix.com Web site), includes an empty spreadsheet for your convenience. To access and save the test spreadsheet, see the instructions in Appendix A: Example of a Vertical Position Accuracy Test Spreadsheet on page A-1.

- Page 58 Performance Verification 5. Adjust the vertical position knob for the DC line to position the line in the center of the screen. 6. Enter the voltage on the voltmeter and on the oscilloscope into the spreadsheet in the appropriate columns, B and C. 7.

-

Page 59: Figure 4-1: Example Of A Line Graph For The Vertical Position Accuracy Test

Performance Verification Data verification. To verify data, set the spreadsheet to present a line graph of columns D, E, and F. Verify that no error values (the blue line in the center) go above the yellow line (upper line), or below the purple line (lower line). For calculations involved in this example, refer to the data in the previous table (see step 1). - Page 60 Performance Verification 4–14 TDS2000C Series Oscilloscope Service Manual...

-

Page 61: Adjustment Procedures

Adjustment Procedures... -

Page 63: Required Equipment

5500A-SC) 50 Ω BNC Cable BNC male to BNC male, ≈ 1 m (36 in) long Tektronix part number 012-0482-XX 50 Ω BNC Cable (seven) BNC male to BNC male, ≈ 25 cm (10 in) long Tektronix part number 012-0208-XX Tektronix part number 011-0049-XX 50 Ω... -

Page 64: Adjustment Procedure

Adjustment Procedures Adjustment Procedure The adjustment procedure consists of 70 steps for the 2-channel oscilloscope, and 106 steps for the 4-channel model. Each step requires an external voltage source for new calibration constants. Before performing the adjustment procedure, warm up the oscilloscope for at least ten minutes in an ambient temperature between 20 °C and 30 °C. -

Page 65: Figure 5-1: Adjustment Setups

Adjustment Procedures Figure 5-1: Adjustment setups TDS2000C Series Oscilloscope Service Manual 5–3... -

Page 66: Adjustment Procedure

Adjustment Procedures Adjustment Procedure Use this procedure to load new calibration constants. 1. Enable the Service menu. (See page 5-2, Enable the Service Menu.) 2. Push the Service option button. 3. Push the Factory Cal option button. 4. Push the Warmup Timer option button. 5. -

Page 67: Table 5-2: Adjustment Steps

Adjustment Procedures Table 5-2: Adjustment steps 2-ch model 4-ch model Input Setup diagram step number step number Signal Signal source setting Ch 1 DC voltage 1 DC Voltage 1 0.0 V through -20.0 V DC Voltage 1 Ch x DC Voltage 1 -2.0 V DC Voltage 1 -1.6 V... - Page 68 Adjustment Procedures Table 5-2: Adjustment steps (cont.) 2-ch model 4-ch model Input Setup diagram step number step number Signal Signal source setting Ch 1 Sinewave Sinewave Generator, 5 kHz, 1 V generator 50 Ω Sinewave Generator, 1 MHz, 100 mV 50 Ω...

- Page 69 Adjustment Procedures Table 5-2: Adjustment steps (cont.) 2-ch model 4-ch model Input Setup diagram step number step number Signal Signal source setting Ch 2 Sinewave Sinewave Generator, 5 kHz, 1 V generator 50 Ω Sinewave Generator, 1 MHz, 100 mV 50 Ω...

- Page 70 Adjustment Procedures Table 5-2: Adjustment steps (cont.) 2-ch model 4-ch model Input Setup diagram step number step number Signal Signal source setting Ch 3 Sinewave Sinewave Generator, 5 kHz, 1 V generator 50 Ω Sinewave Generator, 1 MHz, 100 mV 50 Ω...

- Page 71 Adjustment Procedures Table 5-2: Adjustment steps (cont.) 2-ch model 4-ch model Input Setup diagram step number step number Signal Signal source setting Ch 4 Sinewave Sinewave Generator, 5 kHz, 1 V generator 50 Ω Sinewave Generator, 1 MHz, 100 mV 50 Ω...

- Page 72 Adjustment Procedures 5–10 TDS2000C Series Oscilloscope Service Manual...

-

Page 73: Maintenance

This chapter contains the information needed to do periodic and corrective maintenance on the oscilloscope, as well as repackaging instructions to use if you need to return the oscilloscope to Tektronix for service. Preventing ESD Before servicing this product, read the Safety Summary and Introduction at the front of the manual and the electrostatic discharge (ESD) information below. -

Page 74: General Care

Use a 75% isopropyl alcohol solution as a cleaner and rinse with deionized water. Before using any other type of cleaner, consult your Tektronix Service Center or representative. Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle brush. -

Page 75: Exterior Inspection

Maintenance If the display is very dirty, moisten the wipe with distilled water or a 75% isopropyl alcohol solution and gently rub the display surface. Avoid using excess force or you may damage the plastic display surface. Exterior Inspection Inspect the outside of the oscilloscope for damage, wear, and missing part. (See Table 6-1.) Immediately repair defects that could cause personal injury or lead to further damage to the oscilloscope. -

Page 76: Cleaning Procedure, Interior

Maintenance Table 6-2: Internal inspection checklist Item Inspect for Repair action Loose, broken, or corroded solder Remove and replace damaged circuit board. Circuit boards connections. Burned circuit boards. Burned, broken, or cracked circuit-run plating. Resistors Burned, cracked, broken, blistered Remove and replace damaged circuit board. condition. - Page 77 Maintenance 3. If steps 1 and 2 do not remove all the dust or dirt, all modules in the oscilloscope except the Display Module and Front Panel Module may be spray washed using a solution of 75% isopropyl alcohol. During cleaning of the Acquisition board (Main board), make sure that no residue is left in the attenuators.

-

Page 78: Removal And Installation Procedures

Maintenance Removal and Installation Procedures WARNING. Only qualified personnel should perform service procedures. Before doing this or any other procedure in this manual, read the General Safety Summary and Service Safety Summary found at the beginning of this manual. To prevent damage to electrical components, refer Preventing ESD. -

Page 79: Figure 6-1: Locator For Trim And Cabinet Removal (4-Channel Model Shown)

Maintenance Figure 6-1: Locator for trim and cabinet removal (4-channel model shown) Figure 6-2: Locator for internal modules (4-channel model shown) TDS2000C Series Oscilloscope Service Manual 6–7... - Page 80 Maintenance Required Tools Use the following tools to remove and replace all modules in the oscilloscope: Torque-limiting screwdriver, long shank, 12 in-lb (1.3 N·m) range with Torx® T-15 tip; if you use a magnetic screwdriver with interchangeable bits, the T-15 bit must be a long bit, at least 5 cm (2 in) overall length Torque-limiting screwdriver with Torx T-8 bit 5/8 inch deep socket with wide center hole (S·K Hand Tool Corp., S-K...

- Page 81 Maintenance Flip Feet You will need a pair of needle-nose pliers to remove the flip feet. Refer to the exploded view diagram. (See page 8-10.) Removal. 1. Place the oscilloscope face down on a soft surface such as an anti-static mat. 2.

- Page 82 Maintenance Rear Case You will need a torque-limiting Torx T-15 screwdriver and pliers for this procedure. Refer to the exploded view diagram. (See page 8-10.) Removal. 1. Remove the power button. (See page 6-9, Power Button.) 2. Place the oscilloscope face down on a soft surface such as an anti-static mat. 3.

- Page 83 Maintenance Front Feet You will need a torque-limiting Torx T-15 screwdriver and pliers for this procedure. Refer to the exploded view diagram for the 2-channel models or the 4-channel models. (See page 8-4.) (See page 8-6.) Removal. 1. Remove the power button and rear case. (See page 6-10, Rear Case.) 2.

-

Page 84: Power Supply Module

Maintenance Power Supply Module Use a torque-limiting Torx T-15 screwdriver and pliers for this procedure. Refer to the exploded view diagram. (See page 8-8.) Removal. 1. Remove the power button and rear case. (See page 6-10, Rear Case.) 2. Disconnect the following wires: The ground wire on the power supply module from the chassis ground lug. -

Page 85: Internal Assembly

Maintenance Internal Assembly You will need a torque-limiting Torx T-15 screwdriver and a pair of pliers for this procedure. Refer to the exploded view diagram. (See page 8-10.) Removal. 1. Remove the front-panel knobs. (See page 6-9, Front-Panel Knobs.) 2. Remove the power button and rear case. (See page 6-10, Rear Case.) 3. -

Page 86: Display Adapter Module

Maintenance Display Adapter Module You will need a torque-limiting Torx T-15 screwdriver and pliers for this procedure. Refer to the exploded view diagram. (See page 8-8.) Removal. 1. Remove the power button and rear case. (See page 6-10, Rear Case.) 2. -

Page 87: Figure 6-4: Connecting The Display Cable

Maintenance 6. Remove the four screws that hold the Display Adapter board to the chassis and save the screws for installation of the replacement board. 7. Loosen the Display Adapter board and disconnect the display cable at J201. 8. Remove the Display Adapter board from the chassis. Installation. - Page 88 Maintenance 6. Connect the LCD data cable to the Display Adapter board. (See Figure 6-3.) 7. Twist the LCD backlight cable 5 revolutions and connect the cable to the Display Adapter board at J204. 8. Twist the Display Adapter power cable four revolutions and connect the cable to the Display Adapter board at J202.

-

Page 89: Front-Panel Cable

Maintenance Front-Panel Cable You will need a torque-limiting Torx T-15 screwdriver and pliers for this procedure. Refer to the exploded view diagram. (See page 8-8.) Removal. 1. Remove the front-panel knobs. (See page 8-4.) (See page 8-6.) 2. Remove the power button and rear case. (See page 6-10, Rear Case.) 3. -

Page 90: Main Board Module

Maintenance Main Board Module You will need a torque-limiting Torx T-15 long shank screwdriver, a torque wrench, and a 5/8 inch deep socket for this procedure. Refer to the exploded view diagram. (See page 8-8.) CAUTION. The Main board module is particularly sensitive to ESD. Read the Preventing ESD section before removing or installing the Main board. - Page 91 Maintenance 4. Connect the following cables on the Main board: The power supply cable at J101 The display cable at J201 The front-panel cable at J202 5. Assemble the oscilloscope by performing the installation procedure for each module that was removed. TDS2000C Series Oscilloscope Service Manual 6–19...

-

Page 92: Display Module

Maintenance Display Module You will need a torque-limiting Torx T-15 screwdriver, a torque-limiting Torx T-8 screwdriver, and pliers for this procedure. Refer to the exploded view diagram for the 2-channel or the 4-channel models. (See page 8-4.) (See page 8-6.) CAUTION. -

Page 93: Front-Panel Module

Maintenance Front-Panel Module You will need a torque-limiting Torx T-15 screwdriver and a flat-blade screwdriver for this procedure. Refer to the exploded view diagram for the 2-channel models or the 4-channel models. (See page 8-4.) (See page 8-6.) Removal. 1. Remove the power button and rear case. (See page 8-10.) 2. -

Page 94: Keypad

Maintenance Keypad You will need a torque-limiting Torx T-15 screwdriver for this procedure. Refer to the exploded view diagram for the 2-channel models or the 4-channel models. (See page 8-4.) (See page 8-6.) Removal. 1. Remove the power button and rear case. (See page 6-10, Rear Case.) 2. -

Page 95: Troubleshooting

USB flash drive Tektronix part number 119-7276-00, 128 MB USB type A to type B cable Tektronix part numbers: 174-4401-00, 0.91 meters (3 feet) 174-5194-00, 1.83 meters (6 feet) PC with USB host post and PC with USB communication port... -

Page 96: Figure 6-5: Oscilloscope Troubleshooting Tree

Maintenance Figure 6-5: Oscilloscope troubleshooting tree (page 1 of 4) 6–24 TDS2000C Series Oscilloscope Service Manual... -

Page 97: Figure 6-6: Oscilloscope Troubleshooting Tree

Maintenance Figure 6-6: Oscilloscope troubleshooting tree (page 2 of 4) TDS2000C Series Oscilloscope Service Manual 6–25... -

Page 98: Figure 6-7: Oscilloscope Troubleshooting Tree

Maintenance Figure 6-7: Oscilloscope troubleshooting tree (page 3 of 4) 6–26 TDS2000C Series Oscilloscope Service Manual... -

Page 99: Figure 6-8: Oscilloscope Troubleshooting Tree

Maintenance Figure 6-8: Oscilloscope troubleshooting tree (page 4 of 4) TDS2000C Series Oscilloscope Service Manual 6–27... -

Page 100: Probe Comp Output

Maintenance Probe Comp Output When the oscilloscope is on and operating properly, the Probe Comp output should generate a square wave, approximately 5 V in amplitude, at a 1 kHz frequency. Use the oscilloscope and use a 10X TPP0101 or TPP0201 probe to probe this output. -

Page 101: Troubleshooting The Power Supply

Maintenance Troubleshooting the Power To troubleshoot the power supply, follow these steps: Supply 1. Remove the rear case. (See page 6-10, Rear Case.) 2. Use the test oscilloscope to measure the voltages from the power supply module at J101 on the Main board module. The following table lists the voltages you should expect to see. -

Page 102: Troubleshooting The Display

Maintenance Troubleshooting the To troubleshoot a nonfunctional display, follow these steps: Display 1. Remove the rear case. (See page 6-10, Rear Case.) 2. Turn on the oscilloscope and verify that the display lights up. If it does not, either the display or power supply is defective. If this procedure is not conclusive, continue with Troubleshooting the Power Supply. - Page 103 Maintenance 6. If all or some of the signals are missing, turn off the oscilloscope and disconnect the display cable at J201 on the Main board. Carefully pull the cable straight up from the connector to avoid damage. 7. Turn on the oscilloscope. 8.

-

Page 104: Troubleshooting The Backlight

Maintenance Troubleshooting the To troubleshoot a nonfunctional backlight, follow these steps: Backlight 1. Remove the rear case. (See page 6-10, Rear Case.) 2. Turn on the oscilloscope. 3. Check that the power supply P2 connector generates +3.3 V and +6 V. If either reading is not correct, the power supply module is probably defective. -

Page 105: Figure 6-9: Measuring The Backlight Voltage

Maintenance 6. Check that the current output at J204 of the Display Adapter board for each wire is around 25 mA. If the reading is not correct, the Display Adapter module is probably defective. Replace it. Figure 6-9: Measuring the backlight voltage TDS2000C Series Oscilloscope Service Manual 6–33... -

Page 106: Troubleshooting The Front Panel

Maintenance Troubleshooting the Front To troubleshoot an improperly functioning front panel, follow these steps: Panel 1. To execute the internal diagnostic tests, remove all input signals from the oscilloscope, and enable the Service menu. (See page 5-2, Enable the Service Menu.) 2. -

Page 107: Table 6-10: Expected Signals At J202

Maintenance Table 6-9: Troubleshooting the front panel – Mfg. test (cont.) Menu Comments Warm-up Timer Ensures a ten-minute warm-up time for the oscilloscope before executing the calibration procedure. Stop Test Exits the front-panel test (Test FP) and the screen test (Test Screen). - Page 108 Maintenance Table 6-10: Expected signals at J202 (cont.) Signal at J202 Description 10 FPDATA_34_P Front Panel Scan Data line B No fixed pattern. Stable when triggered from FPCLR_34_P. Pattern depends on rotation of knobs being scanned. 11 FPCLR_34_P Front Panel Clock line B 405 kHz. High with 50 ns pulses going low.

-

Page 109: Troubleshooting The Main Board

Maintenance Troubleshooting the Main To troubleshoot the Main board (acquisition module), follow these steps: Board 1. Remove the rear case. (See page 6-10, Rear Case.) 2. Use the test oscilloscope to measure the voltages from the power supply module at J101 on the Main board module. The following table lists the voltages you should expect to see. -

Page 110: Table 6-12: List Of Error Codes

Table 6-12: List of error codes Error code Description Probable cause 0 DI Diagnostics internal error Contact Tektronix 1 DI ADG522 diagnostics failed Main board or power supply failure 2 DI PROM diagnostics failed Main board or power supply failure... - Page 111 Maintenance Clearing the error log. To clear the error log after fixing a problem, follow these steps: 1. Enable the Service menus. (See page 5-2, Enable the Service Menu.) 2. Push the UTILITY button and push the Service option button to display the Service menu.

-

Page 112: Repackaging Instructions

The oscilloscope should not move around inside the carton when the carton is sealed. If the oscilloscope is being shipped to a Tektronix Service Center, enclose the following information:... -

Page 113: Diagrams

Diagrams This section describes the electrical operation of the TDS2000C series oscilloscopes using the major circuit blocks or modules. The oscilloscope module interconnections are shown in the figure. (See Figure 7-1.) TDS2000C Series Oscilloscope Service Manual 7–1... -

Page 114: Figure 7-1: Tds2000C Series Block Diagram

Diagrams The shaded area in the figure represents modules and circuits used only in 4-channel oscilloscopes. Figure 7-1: TDS2000C series block diagram 7–2 TDS2000C Series Oscilloscope Service Manual... -

Page 115: Replaceable Parts

Replaceable Parts... -

Page 117: Parts Ordering Information

Level revision level number. When you order parts, Tektronix will provide you with the most current part for your product type, serial number, and modification (if applicable). At the time of your order, Tektronix will determine the part number revision level needed for your product, based on the information you provide. -

Page 118: Using The Replaceable Parts List

figure and index numbers to the exploded view illustrations that follow. Tektronix Part Number Use this part number when ordering replacement parts from Tektronix. 3 and 4 Serial Number Column three indicates the serial number at which the part was first effective. Column four indicates the serial number at which the part was discontinued. -

Page 119: Parts Lists And Exploded Views

Tektronix part no. effective discont’d Qty. Name and description 2-CHANNEL MODELS 850-0156-00 FRONT CASE ASSY; COVER, W/FEET; TDS2001C, TDS2002C, TDS2012C, TDS2022C 366-0863-00 ASSEMBLY, KNOB; 0.685 DIAMETER 366-0862-00 ASSEMBLY, KNOB; 0.470 DIAMETER 335-2308-00 MARKER, IDENTIFICATION 2CH LANGUAGE, FRENCH 335-2309-00 MARKER, IDENTIFICATION 2CH LANGUAGE, ITALIAN... -

Page 120: Figure 8-1: Exploded Diagram, 2-Channel Models

Replaceable Parts Figure 8-1: Exploded diagram, 2-channel models 8–4 TDS2000C Series Oscilloscope Service Manual... -

Page 121: Table 8-3: Replaceable Parts List, 4-Channel Models

Replaceable Parts Table 8-3: Replaceable parts list, 4-channel models Figure Serial Serial index Tektronix part no. effective discont’d Qty. Name and description 4-CHANNEL MODELS 850-0157-00 FRONT CASE ASSY; COVER, W/FEET; TDS2004C, TDS2014C, TDS2024C; COLOR 366-0863-00 ASSEMBLY, KNOB; 0.685 DIAMETER 366-0862-00 ASSEMBLY, KNOB;... -

Page 122: Figure 8-2: Exploded Diagram, 4-Channel Models

Replaceable Parts Figure 8-2: Exploded diagram, 4-channel models 8–6 TDS2000C Series Oscilloscope Service Manual... -

Page 123: Table 8-4: Replaceable Parts List, Power Supply Module, Cables, And Wires

Replaceable Parts Table 8-4: Replaceable parts list, power supply module, cables, and wires Fig. & Tektronix Serial Serial index part number number effective discont’d Name & description POWER SUPPLY, CABLES, WIRES 346-0299-00 CABLE TIE; BAND 174-5859-00 CA ASSY; DISPLAY CABLE 211-1272-00 SCREW, MACHINE;... -

Page 124: Figure 8-3: Power Supply Module, Cables, And Wires (2-Ch Model Shown, With 4-Ch Model In Circle)

Replaceable Parts Figure 8-3: Power supply module, cables, and wires (2-ch model shown, with 4-ch model in circle) 8–8 TDS2000C Series Oscilloscope Service Manual... -

Page 125: Table 8-5: Replaceable Parts List, Back Case And Trim

Replaceable Parts Table 8-5: Replaceable parts list, back case and trim Fig. & Tektronix Serial Serial index part number number effective discont’d Name & description BACK CASE, TRIM 850-0154-00 REAR CASE ASSY: COVER WITH FEET AND HANDLE 348-1703-00 FOOT, FRONT: FLIPMPC/ABS, SILVER GRAY... -

Page 126: Figure 8-4: Exploded Diagram, Back Case And Trim

Replaceable Parts Figure 8-4: Exploded diagram, back case and trim 8–10 TDS2000C Series Oscilloscope Service Manual... -

Page 127: Appendix A: Example Of A Vertical Position Accuracy Test Spreadsheet

077-0446-00, this manual) includes an empty VPA test spreadsheet for your convenience. To access and save the test spreadsheet: 1. Go to the Tektronix Web site (www.tektronix.com) and click the Manuals link (in the left column on the screen). 2. Enter 077044600 in the Search By Keyword field and then click Go. - Page 128 Appendix A: Example of a Vertical Position Accuracy Test Spreadsheet Table A-1: Vertical position accuracy test spreadsheet (cont.) ‡ ‡ ‡ 1.88 0.000 Offset in 0.005 volts ‡ ‡ ‡ 1.84 0.000 Total 0.01=I2*I4+I5 voltage offset 1.80 1.80 1.79 0.010 -0.028 0.028 0.018...

- Page 129 Appendix A: Example of a Vertical Position Accuracy Test Spreadsheet Table A-1: Vertical position accuracy test spreadsheet (cont.) 0.80 0.805 -0.005 -0.018 0.018 0.013 0.76 0.76 0.764 -0.004 -0.0176 0.0176 0.014 0.72 0.72 0.724 -0.004 -0.0172 0.0172 0.013 0.68 0.68 0.683 -0.003 -0.0168...

- Page 130 Appendix A: Example of a Vertical Position Accuracy Test Spreadsheet Table A-1: Vertical position accuracy test spreadsheet (cont.) -0.72 -0.72 -0.713 -0.007 -0.0172 0.0172 0.010 -0.76 -0.76 -0.754 -0.006 -0.0176 0.0176 0.012 -0.80 -0.8 -0.794 -0.006 -0.018 0.018 0.012 -0.84 -0.84 -0.835 -0.005...

Need help?

Do you have a question about the TDS2022C and is the answer not in the manual?

Questions and answers