Summary of Contents for Metrohm 942 Extension Module Vario ChS-PP

- Page 1 942 Extension Module Vario 942 Extension Module Vario ChS-PP Manual 8.942.8004EN / 2020-02-25...

- Page 3 Metrohm AG CH-9100 Herisau Switzerland Phone +41 71 353 85 85 Fax +41 71 353 89 01 info@metrohm.com www.metrohm.com 942 Extension Module Vario 942 Extension Module Vario ChS-PP 2.942.0300 Manual 8.942.8004EN / 2020-02-25...

- Page 4 Technical Communication Metrohm AG CH-9100 Herisau techcom@metrohm.com This documentation is protected by copyright. All rights reserved. This documentation has been prepared with great care. However, errors can never be entirely ruled out. Please send comments regarding possible errors to the address above.

-

Page 5: Table Of Contents

Mode of operation for the peristaltic pump ......20 Metrohm Suppressor Module (MSM) ....... 21 3.4.1 Inserting the rotors ..............21 3.4.2 Connecting the Metrohm Suppressor Module (MSM) ..... 23 Connecting an Extension Module ........28 4 Start-up 5 Operation and maintenance Servicing the door .............. 31 ■■■■■■■■... - Page 6 Notes for operating the Metrohm Suppressor Module (MSM) ................... 33 5.3.2 Taking care of the suppressor housing ........34 5.3.3 Servicing the Metrohm Suppressor Module (MSM) ....34 6 Troubleshooting Problems and their solutions ..........43 7 Technical specifications Reference conditions ............45 Ambient conditions ............

- Page 7 Mounting the bottle holder ............. 14 Figure 8 Peristaltic pump ................21 Figure 9 Metrohm Suppressor Module (MSM) – Connection capillaries ..24 Figure 10 Pump tubing connection – Replacing the filter ......... 33 Figure 11 Parts of the Metrohm Suppressor Module (MSM) ......35 ■■■■■■■■...

-

Page 9: Introduction

940 Professional IC Vario instrument can be expanded with up to 3 942 Extension Module Vario instruments. The 942 Extension Module Vario ChS-PP can be used in IC systems where an additional suppressor module or sample preparation module is needed. -

Page 10: Intended Use

■■■■■■■■■■■■■■■■■■■■■■ 1.2 Intended use Intended use The 942 Extension Module Vario ChS-PP expands an IC system by adding a suppressor or a sample preparation module. This instrument is suitable for processing chemicals and flammable sam- ples. Usage of the 942 Extension Module Vario therefore requires the user to have basic knowledge and experience in handling toxic and caustic substances. -

Page 11: Safety Instructions

This instrument left the factory in a flawless state in terms of technical safety. To maintain this state and ensure non-hazardous operation of the instrument, the following instructions must be observed carefully. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 12: Electrical Safety

The electrical safety when working with the instrument is ensured as part of the international standard IEC 61010. WARNING Only personnel qualified by Metrohm are authorized to carry out service work on electronic components. WARNING Never open the housing of the instrument. The instrument could be damaged by this. -

Page 13: Tubing And Capillary Connections

The correct disposal of your old instrument will help to prevent negative effects on the environment and public health. More details about the disposal of your old instrument can be obtained from your local authorities, from waste disposal companies or from your local dealer. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

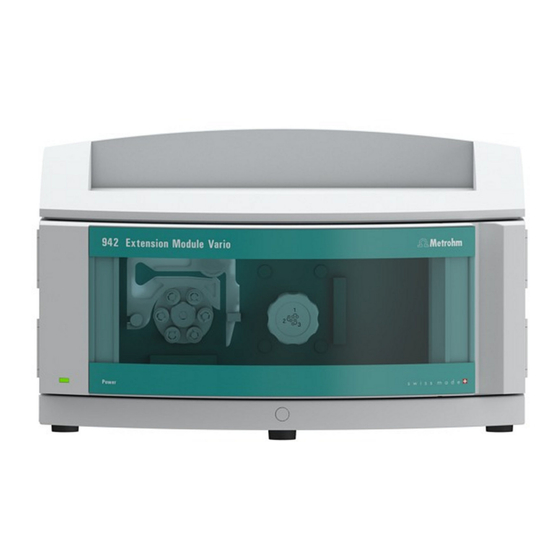

Page 14: Overview Of The Instrument

■■■■■■■■■■■■■■■■■■■■■■ 2.1 Front 2 Overview of the instrument Front Figure 1 Front Peristaltic pump Suppressor drive (see chapter 3.3.1, page 15). (see chapter 3.4, page 21). Standby indicator ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 15: Rear

Installed between the instrument and base tray (3-B). ■ Stacked next to the instrument (3-C). In this case, we recommend ■ ordering a separate base tray (6.2061.110) and a separate bottle holder (6.2061.100) for the stack. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 16: Figure 3 Proposed Setup

If this is not possible, extension modules that are farther apart have to be connected together using a longer connecting cable (6.2156.070). ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 17: Installation

The bottle holder and base tray must be removed or set up if one of the following instruments is to be mounted on or under a 940 Professional IC Vario: One or more 942 Extension Module Vario ■ Or another instrument with the same-sized footprint ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 18: Mounting Base Tray And Bottle Holder (Optional)

The capillaries are removed from the guide ducts between the instru- ■ ment and the base tray. There are no loose parts in the instrument. ■ Accessories 3 mm hex key (6.2621.100) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 19: Figure 4 Removing The Base Tray

All of the cable connections on the rear have been disconnected. ■ There are no loose parts in the instrument. ■ The instrument is lying on its side, and the bottom surface is visible. ■ Accessories 3 mm hex key (6.2621.100) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 20: Figure 5 Mounting The Base Tray

Drainage tubing is disconnected from the drainage tubing connection ■ of the bottle holder. The capillaries are removed from the guide ducts between the instru- ■ ment and the bottle holder. Accessories 3 mm hex key (6.2621.100) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 21: Figure 6 Removing The Bottle Holder

Stack other instruments in the required order. Mount the bottle holder (6.2061.100) onto the topmost instrument on the stack. Mounting the bottle holder Prerequisite The instrument is switched off. ■ Accessories 3 mm hex key (6.2621.100) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 22: Figure 7 Mounting The Bottle Holder

5 If one of the instruments in the stack is equipped with a leak sensor connection socket, connect the leak sensor (see manual of the IC instrument). 6 Restore any capillary connections that may have been removed. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 23: Peristaltic Pump

1 Select pump tubing suitable for the application (see table 1, page 15). 2 Select an adapter suitable for the pump tubing. The adapters are included with the pump tubing connection with locking nut and filter (6.2744.180). ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) - Page 24 Coupling olive/UNF 10/32 (6.2744.034) ■ Pump tubing connection with locking nut and filter (6.2744.180): ■ Includes a locknut, 3 adapters and a tubing olive with filter holder. 2 × pressure screw, short (6.2744.070) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 25 – Tighten it using the union nut. 2 Removing the tubing cartridge Press in the tubing cartridge's snap-action lever. ■ Tilt the tubing cartridge upwards. ■ Unhook the tubing cartridge from the mounting bolt. ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 26 ■ regeneration solution. Connecting capillaries for rinsing solution (as an alternative to STREAM) Accessories For this step, you need the following accessories: Aspiration capillary (6.1803.030) ■ 2 × pressure screw, short (6.2744.070) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 27 The rotational speed of the drive ■ The contact pressure of the tubing cartridge ■ NOTICE Pieces of pump tubing are consumables. The service life of the pump tubing depends on the contact pressure, among other factors. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

-

Page 28: Mode Of Operation For The Peristaltic Pump

The pump tubing is clamped between the rollers (8-5) and the tub- ing cartridge (8-2). During operation, the peristaltic pump drive rotates the roller hub (8-6), so that the rollers (8-5) advance the liquid in the pump tubing. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 29: Metrohm Suppressor Module (Msm)

Rotor A (6.2844.000), must first be fitted into the adapter (6.2842.020), which can then be inserted into the suppressor housing. A connecting piece (6.2835.010) is used for all rotors for connecting the Metrohm Suppressor Module (MSM) to the IC system. NOTICE The instruments are supplied without rotor and without adapter. - Page 30 1 is on top and the three pins of the connecting piece fit into the corresponding recesses on the suppressor drive. 4 Attaching the union nut Tighten the union nut on the thread of the suppressor drive by hand (do not use any tools). ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

-

Page 31: Connecting The Metrohm Suppressor Module (Msm)

3.4.2 Connecting the Metrohm Suppressor Module (MSM) The three entries and exits of the suppressor units, numbered 1, 2 and 3 on the connecting piece, each have two permanently installed PTFE capil- laries. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 32: Figure 9 Metrohm Suppressor Module (Msm) - Connection Capillaries

■■■■■■■■■■■■■■■■■■■■■■ 3.4 Metrohm Suppressor Module (MSM) Figure 9 Metrohm Suppressor Module (MSM) – Connection capillaries Outlet capillary for the eluent. Inlet capillary for the eluent. regenerant waste reg. Inlet capillary for the regeneration solution. Outlet capillary for the regeneration solu- tion;... - Page 33 (see manual of the conductivity detector). 3.4.2.2 Installing bottles with auxiliary solutions Accessories To connect the bottles of the auxiliary solutions, you will need the follow- ing accessories: Accessories from the accessory kit: IC Vario/Flex ChS (6.5000.030) ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 34 2 Connect the capillary labeled regenerant to the outlet of the pump tubing using a pressure screw (6.2744.070). 3 Connect the PTFE capillary from the regeneration solution bottle to the inlet of the pump tubing. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 35 ■■■■■■■■■■■■■■■■■■■■■■ 3 Installation 3.4.2.4 Connecting the rinsing solution Various possibilities exist for rinsing the Metrohm Suppressor Module: Rinsing solution via STREAM (recommended) ■ Use the eluent from the conductivity detector as rinsing solution. Rinsing solution via peristaltic pump ■ Prepare the rinsing solution in a separate bottle and convey it with the peristaltic pump.

-

Page 36: Connecting An Extension Module

Extension Module and tighten it in place. 2 Plug the other end of the connecting cable into the Extension Module connection socket on the IC instrument and tighten it in place. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) - Page 37 (6.2156.070) into the In connection socket on the second Extension Module and tighten it in place. 2 Plug the other end of the connecting cable into the Out connection socket on the first Extension Module and tighten it in place. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

-

Page 38: Start-Up

The peristaltic pump is installed and connected. ■ A rotor is correctly inserted. ■ The 942 Extension Module Vario ChS-PP is connected to the 940 Pro- ■ fessional IC Vario. You can find additional information on carrying out initial start-up in the Start-up chapter in the manual for the IC instrument and the MagIC Net online help. -

Page 39: Operation And Maintenance

The pump tubing (6.1826.xxx) is made of PVC or PP and therefore must not be used for rinsing with solutions containing organic solvents. In this case, use different pump tubing or use another pump for rinsing. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 40: Servicing The Peristaltic Pump

The filters may need to be replaced more frequently, depending on the application. Accessories For this step, you need the following accessories: 1 filter from the spare filter set (6.2821.130) ■ 2 adjustable wrenches (6.2621.000) ■ Tweezers ■ ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 41: Metrohm Suppressor Module (Msm)

Therefore, always mount the inlet and outlet capillaries according to the diagram outlined in Chapter Connecting the Metrohm Suppressor Module (MSM), page 23. The Metrohm Suppressor Module (MSM) consists of three suppressor units, which, in rotation, are (1.) used for suppression, (2.) regenerated ■■■■■■■■... -

Page 42: Taking Care Of The Suppressor Housing

If the Metrohm Suppressor Module (MSM) is in a dry state, it must be rinsed for at least five minutes before it may be switched over. -

Page 43: Figure 11 Parts Of The Metrohm Suppressor Module (Msm)

■■■■■■■■■■■■■■■■■■■■■■ 5 Operation and maintenance 5.3.3.1 Parts of the Metrohm Suppressor Module (MSM) The SPM is made up of the same parts as the Metrohm Suppressor Mod- ule (MSM). Figure 11 Parts of the Metrohm Suppressor Module (MSM) Union nut... - Page 44 Pump tubing made of PVC must not be used for solutions containing organic solvents. We recommend using the high-pressure pump for regeneration. Regenerating the anion suppressor rotor 1 Disconnecting the Metrohm Suppressor Module (MSM) from the IC system Disconnect the capillaries of the MSM labeled regenerant and ■...

- Page 45 As soon as all three suppressor units have been rinsed, disconnect ■ the capillary labeled rinsing solution from the coupling. 4 Connecting the Metrohm Suppressor Module (MSM) to the IC system Reconnect the capillaries of the MSM labeled regenerant and ■...

- Page 46 5.3.3.4 Cleaning the Metrohm Suppressor Module (MSM) In the following cases, it may be necessary to clean the Metrohm Suppres- sor Module (MSM): Increased backpressure at the MSM's connection tubing. ■ Irremediable blockage of the MSM (solutions can no longer be pum- ■...

- Page 47 Check whether water comes out at the connecting piece. ■ If one of the capillaries remains blocked, the connecting piece (see "Replacing parts of the Metrohm Suppressor Module (MSM)", page 41) must be replaced (order number 6.2835.010). 4 Cleaning the rotor Clean the sealing surface of the rotor (11-3) with ethanol using a ■...

- Page 48 5.3.3.5 Replacing parts of the Metrohm Suppressor Module (MSM) Parts of the Metrohm Suppressor Module (MSM) may need to be replaced in the following cases: Irremediable loss of suppressor capacity (reduced phosphate sensitivity ■...

- Page 49 ■■■■■■■■■■■■■■■■■■■■■■ 5 Operation and maintenance Replacing parts of the Metrohm Suppressor Module (MSM) 1 Disconnecting the Metrohm Suppressor Module (MSM) from the IC system Switch off the instrument. ■ Disconnect all capillaries of the MSM from the IC system. ■...

- Page 50 Reattach the union nut (11-1) and tighten by hand (do not use a ■ tool). 7 Connecting and conditioning the Metrohm Suppressor Mod- ule (MSM) Reconnect all capillaries of the MSM to the IC system. ■...

-

Page 51: Problems And Their Solutions

See problem "SPM – Insufficient flow of regen- eration solution or rinsing solution." MSM – Reduced capacity. Regenerate the MSM (see chapter 5.3.3.2, page 35). SPM – Reduced capacity. Regenerate the SPM (see chapter 5.3.3.2, page 35). ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) - Page 52 32). SPM – Backpressure too Clean the SPM (see chapter 5.3.3.4, page 38) high. or replace parts (see chapter 5.3.3.5, page 40). Peristaltic pump – Pump Replace the pump tubing. tubing defective. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

-

Page 53: Reference Conditions

Housing Dimensions Width 365 mm Height 131 mm Depth 380 mm Material of base Polyurethane hard foam (PUR) with flame retardation for fire class tray, housing and UL94V0, CFC-free, coated bottle holder ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) -

Page 54: Weight

Interfaces 1 15-pin D-sub plug (male) Connection to the ion chromatograph or another Extension Module. 1 15-pin D-sub plug (female) Connection to another Extension Module or an 891 Professional Ana- log Out (optional). ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300) - Page 55 The PDF file with the accessories data is created. NOTICE Once you have received your new product, we recommend download- ing the accessories list from the Internet, printing it out and keeping it together with the manual for reference purposes. ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

- Page 56 Pump tubing Peristaltic pump ....46 Install ......... 15 Reference conditions ..45 Heavy metals Service life ......31 Suppressor ......46 Contamination of suppressor Temperature ......45 ........... 35 Transport ........45 ■■■■■■■■ 942 Extension Module Vario ChS-PP (2.942.0300)

Need help?

Do you have a question about the 942 Extension Module Vario ChS-PP and is the answer not in the manual?

Questions and answers