Summary of Contents for Standard Pump SP3A20NPT

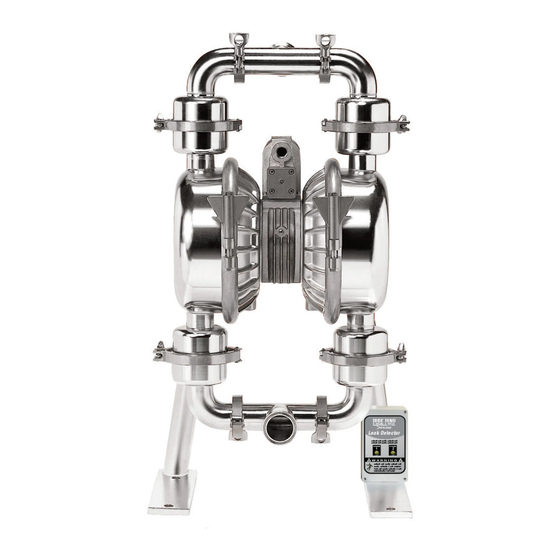

- Page 1 SP3A20NPT 2" 3-A Certified with Metallic Center Section 3-A Sanitary Pump • Stainless Steel STANDARD PUMP, INC ® 1610 Satellite Blvd, Duluth, GA 30097 • Phone: (770) 307-1003 • www.standardpump.com...

- Page 2 Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

- Page 3 Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..3 • Principle of Pump Operation • Typical Installation Guide • Troubleshooting SECTION 3: EXPLODED VIEW ......7 • Composite Drawings •...

- Page 4 Performance SP3A20NPT - 2” 3-A Sanitary Pump – Metallic Center Flow Rate Capacity Per Stroke, 0.35 Gal. (1.32 L) Adjustable to . . . . . . . 0-147 gpm (556 lpm) 10 20...

- Page 5 1/2" NPT AIR INLET 34.70 881.45 26.38 670.03 32.63 828.88 16.80 1" NPT 426.72 AIR EXHAUST 6.97 176.96 2.52 O.D. TRI- CLAMP SUCTION 12.70 FLANGE 15.41 391.36 15.88 14.00 355.60 10.00 254.00 3.00 76.20 18.57 471.76 Model SP3A20NPT • standardpump sp3a20nptsm-rev0516...

- Page 6 Pump can be submerged if the pump materials of construction are compatible with the liquid being pumped. The air exhaust must be piped above the liquid level . When the pumped product MUFFLER source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills . 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE standardpump • Model SP3A20NPT sp3a20nptsm-rev0516...

- Page 7 SAE 10 non-detergent oil for every 20 SCFM (9 .4 liters/sec .) of air the pump consumes . Consult the Performance Curve to determine air consumption . Air Line Moisture Water in the compressed air supply may cause icing or freezing of the exhaust air, causing the pump to cycle erratically or stop operating. Water in the air supply can be reduced by using a point-of-use air dryer . Air Inlet And Priming To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. Model SP3A20NPT • standardpump sp3a20nptsm-rev0516...

- Page 8 Inspect check valves and seats for wear and proper setting . Replace if necessary . Entrained air or vapor lock in chamber(s) . Purge chambers through tapped chamber vent plugs . For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 standardpump • Model SP3A20NPT sp3a20nptsm-rev0516...

- Page 9 Pump Inspection and Cleaning The SP3A20NPT sanitary pump can be cleaned using several techniques. However, it is important to follow guidelines set by the IAMFES, the USPHS, and the DIC and/or internal rules for inspection, cleaning and sanitization. If the pump is to be steam cleaned, disconnect the suction line from the pump. Connect the steam line to the pump inlet.

- Page 10 THIS IS A PROPRIETARY DOCUMENT. DO NOT REPRODUCE OR DISCLOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF WARREN RUPP INC. E4 3A DESCRIPTION DRAWING NUMBER E4SJ5F5S0-3A UPDATED TO NEW MANUAL FORMAT 6/5/12 REVISION DATE Torque to: 480 in-lbs standardpump • Model SP3A20NPT sp3a20nptsm-rev0516...

- Page 11 Water Chamber 200-246 Large Clamp Half 200-357 Bolt 200-358 Wing Nut 200-269 Manifold Tee 200-248 Manifold Elbow 200-247 Ball Cage 200-463 Manifold Elbow Clamp 200-409 Manifold Tee Clamp 200-412 Leak Detector 200-006 Leak Detector Probe 200-007 Model SP3A20NPT • standardpump sp3a20nptsm-rev0516...

- Page 12 Dir produkt voldoet aan de volgende EG-richtlijnen: Denna produkt överensstämmer med följande EU direktiv: Standard Pump, Inc., erklærer herved som fabrikant, at ovennævnte produkt er i overensstemmelse med bestemmelserne i Direkktive: Tämä tuote täyttää seuraavien EC Direktiivien vaatimukstet: Dette produkt oppfyller kravene til følgende EC Direktiver: Este produto está...

- Page 13 3-A Symbol to the models of equipment, conforming to 3-A Sanitary Standards for: Number 44-03 44-03 (Diaphragm Pumps) set forth below Clean-in-Place Models: SP3A15NPT, SP3A20NPT. VALID THROUGH: December 31, 2016 Timothy R. Rugh Executive Director 3-A Sanitary Standards, Inc.

Need help?

Do you have a question about the SP3A20NPT and is the answer not in the manual?

Questions and answers