HADEF 28/06AP-EX Installation, Operating And Maintenance Instructions

Pneumatic chain hoist

Hide thumbs

Also See for 28/06AP-EX:

Table of Contents

Advertisement

Quick Links

Installation,- Operating and

Maintenance Instructions

HADEF Pneumatic Chain Hoist

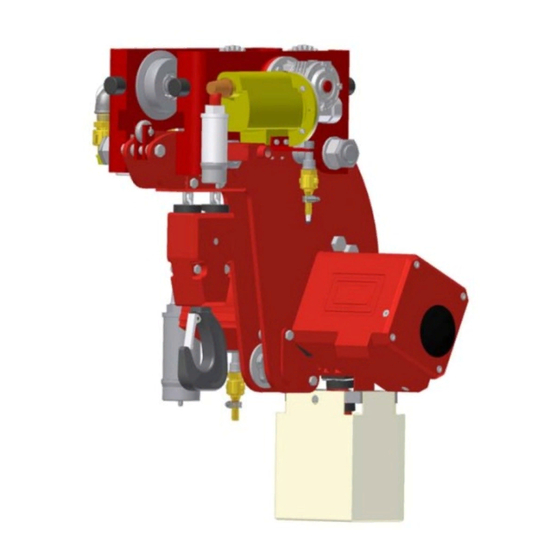

Type 28/06AP-EX

low headroom configuration

with monorail push travel trolley

with monorail hand geared trolley

with monorail pneumatic trolley

Explosion proof design

II 2G IIB c T4 or

II 2G IIB c T3 or

DANGER!

Not to be used with IIC gases and IIB gases hydrogen sulphide and ethylene oxide and

light metal and shock sensitive dusts.

It is not allowed to use the equipment in area at risk from explosion where gas AND

dust does both exist at the same time!

o

5.52.132.01.01.08

II 2D c 135°C

II 2D c 200°C

Rev.08

APR

APH

APP

Advertisement

Table of Contents

Summary of Contents for HADEF 28/06AP-EX

- Page 1 Installation,- Operating and Maintenance Instructions HADEF Pneumatic Chain Hoist Type 28/06AP-EX low headroom configuration with monorail push travel trolley with monorail hand geared trolley with monorail pneumatic trolley Explosion proof design II 2G IIB c T4 or II 2D c 135°C II 2G IIB c T3 or II 2D c 200°C...

-

Page 2: Table Of Contents

Heinrich de Fries GmbH Heinrich de Fries GmbH, Gauss Str. 20, D-40235 Düsseldorf Heinrich De Fries GmbH will be named HADEF in the following text. Original operating- and maintenance instructions in German language. Translation in other languages is made of the German original. -

Page 3: Information

Functional test .................. 21 11.1 Checks before the initial start-up................... 21 11.2 Functional test ......................... 21 Maintenance ..................21 12.1 General ..........................21 12.2 Monitoring ........................22 12.3 Replacing the load chain ....................22 12.4 Pneumatic motor ......................22 12.5 ... -

Page 4: Indications To Determine The Used Part Of The Theoretical Usage Life

“winches, lifting and pulling devices”. NOTICE! Commitment A general overhaul may only be performed by HADEF or by a specialized company, authorized by HADEF. Safety DANGER! To assess the intended use of the devices correctly, the user must carry out an Ex-zone classification. -

Page 5: Requirements For The Operating Personnel

Our delivery includes the hoist supplied beginning at its suspension and ending at the load hook and if supplied with control, the control line/hose that leads to the hoist. Further operating material, tools, load attaching devices as well as main energy supply lines must be assembled according to the valid rules and regulations. -

Page 6: Basic Safety Measures

The appropriate use of the hoists is vertical lifting and lowering of unguided loads. In combination with trolleys, loads can also be moved horizontally. DANGER! It’s only allowed to use the unit in the EX-classification which is named on the type plate; or in lower classes EX II 2G IIB c T4 or EX II 2D c 135°C EX II 2G IIB c T3 or EX II 2D c 200°C... - Page 7 Check the grease level of the bearings regularly Exchange friction surfaces in time and (an exception to this are electric units - maintenance of the brakes must only be effected by HADEF). Protect the device from impact, friction, rough handling and moisture.

-

Page 8: Explosion Protection

Special scope Use of different EX-zones is depended from the EX-classification of the unit. Find the EX-classification on its type plate. Unit classified No use in EX-classification in EX-zone 3G/D 0,20,1,21 2G/D 0,20 0,20,1,21,22 0,20,1,21,2 0,20,21,22 0,20,1,2 Explosion protection The EX classification of the unit is indicated on a separate plate, situated on the unit. - Page 9 2.6.1 EX-Category 1+21 1+21 EX- Zone 2+22 2+22 Device category Expl.-group of gases Temperature class - gases Temperature class - dust 135°C 200°C DANGER! The classification for the device can be found on the EX-type plate on the unit. The device must only be used in the classification stated or in a lower classification. 2.6.2 Surface temperature of the devices DANGER!

- Page 10 2.6.4 Explosion hazards … recognizing and preventing! 5.52.132.01.01.08...

-

Page 11: Transport And Storage

The EX-classification is mentioned on the EX-type plate on the hoist. The use of the unit is only allowed for the EX-classification mentioned on the EX-type plate or lower EX classification. Design HADEF pneumatic chain hoists, with low headroom design and pneumatic trolley Type 28/06APP, with hand-geared trolley Type 28/06APH and push travel trolley Type 28/06 APR are monorail trolleys with integrated hoisting gear. -

Page 12: Functions

Type 28/06APP - Table 2-10t Type 28/06APP - Table 2-15t Functions The lifting gear and motor-driven trolleys are moved by pressing the buttons on the control switch. The spring-operated brake which is integrated in the lifting motor prevents the load from being lowered automatically after releasing the control keys. - Page 13 Trolley g gear Combina ation of worm m gear and m motor Closed d design - vent tilation not ne ecessary. 4.4.3 Control Control s switch with e emergency st Classific cation of cont trol according g to lifting ge ear sizes Kind of co ontrol...

-

Page 14: Technical Data

Technical data Table 1 Capacity 1000 1600 2000 3200 5000 hoisting unit Number of chain falls FEM 9.511/EN 818-7 Load chain 5x15 7x21 9x27 7x21 9x27 11,3x31 load bar size 82-185 76-196 125-192 76-196 125-192 140-215 for beam flange width 186-310 197-310 193-310... -

Page 15: Adjusting The Gauge

Adjusting the gauge The trolley can be adjusted to various beam flange widths. Adjustment to the relevant beam flange width “B” depends on the type and size and is to be made as follows: There are distance tubes (5) and/or washers (6) situated on the load bars (2) of the trolley. -

Page 16: Pressure Roller

CAUTION! The distance “X” between the wheel flanges of the trolley wheels must be for trolleys up to 3,2 t: 2-3 mm (1-1,5 mm each side) bigger and for trolleys from 4 t up: 3-5 mm (1,5-2,5 mm each side) bigger than the flange width "B" of the beam Pressure roller 6.4.1 Units with a load capacity of up to 6,3 t... -

Page 17: Tools

Tools Capacity Size Tool 0,5t SW27 SW36 1,5t + 2t SW46 Load bar 2,5t + 3,2t + 4,0t SW55 5t + 6,3t SW60 7,5t + 10t SW75 12,5t SW22 Load bar 16t – 60t SW24 with fixing ring only if pneumatic Pneumatic div. -

Page 18: Operation

Indirect pneumatic control 1 Emergency stop 2 lifting 3 lowering Hoists combined with trolleys have control switches where push buttons for trolley movement are added. Special design units can be supplied upon request. Illustration 9 Push button functions Relieved push button = stand still push button pushed = respective movement Illustration 10 Red Emergency-Stop button... -

Page 19: Commissioning

DANGER! It is not allowed: pulling loose of stuck loads, dragging of loads and inclined pulling is not allowed. in explosive atmosphere, except the unit is especially modified for it and marked by an indication label In reactor containment vessels. to transport people The device is not suitable for use on stages and in studios persons must not stand under a suspended load... -

Page 20: Gear

The oiler enriches the air with oil. Setting of oil addition: approx. 2 drops of oil must be added per minute. NOTICE! HADEF does not assume any responsibility for damage caused by non-observance of the instructions. CAUTION! Should the unit be assembled at the customer, the maintenance unit is supplied without oil. -

Page 21: Safety Check

CAUTION! Do not use grease for lubrication of load chain. Without lubrication, manufacturer's warranty and/or liability will be void. NOTICE! Continuous, thorough lubrication will increase the life of the chain considerably. Safety check Before putting into service initially or when putting back into service, it must be checked whether: All fastening screws (if existent), socket pins, flap socket and safety devices are tightened and secured. -

Page 22: Monitoring

Servicing and maintenance work must only be done when the hoist is not loaded. Records must be kept of all test results and measures taken. 12.2 Monitoring The monitoring and servicing intervals stated are valid for operation under normal conditions and single-shift operation. -

Page 23: Overload Protection

Motor output brake lining thickness B min. 0,52-0,75 1,5-2,5 Illustration 14 12.5 Overload protection If the hoist does not lift the permitted load, the overload protection must be adjusted. Adjustment may only be done by a service company, authorised by the manufacturer! DANGER! The factory setting of the overload protection is secured by a seal. -

Page 24: Periodic Checks

13.2 Periodic checks Independently from the regulations of the individual countries, lifting devices must be checked at least yearly by a qualified person or licensed qualified person regarding its functional safety. 13.2.1 Components to be checked The following must be checked: Dimensions of load chain, load hooks, pawls, bolts, ratchet wheels, brake linings. -

Page 25: Checking The Load Hook

Chain dimensions Dimension Chain dimension 5x15 7x21 9x27 11,3x31 16x45 23,5x66 171,4 238,8 300,8 348,1 505,6 743,0 16,0 22,4 28,1 32,7 47,4 69,5 10,2 14,4 21,2 WARNING! When the dimensions listed in the table are reached due to wear or deformation, the chain must be replaced! DANGER! In case of corrosion and/or wear of the surface coating, the chains must be exchanged by original... -

Page 26: Inspection - Gear - Oil Level

13.5 Inspection – Gear – Oil level Check oil level all 3 month. Locking screw(C) Tool AK 4 – AK 6 AK 7 – AK 8 SW10 AK 4-8 AK9-10 Solve the locking screw (C) a bit. (do not remove) If oil drips out = level OK. -

Page 27: Hoist Gear

Clean and lubricate the bearings of hooks and pulleys with grease Slight bearings are maintenance free When bearings resp. slight bearings are worn of, change the complete pulley Recommendation Interval Load hook FUCHS Acc. to demand 12 month bearing RENOLIN PG220 14.4 Hoist gear Low maintenance. -

Page 28: Trolley

Troll Trolleys are e lifetime lubr ricated, Refil l lubricant is normally no t necessary. Lubricate ge ear rim and p pinion drive e each ¼ year r or if required d more often n, with grease Recom mendation Interval ulleys FUCHS ear rim... -

Page 29: Lubricant For Food Industry - Selection (As Option*)

14.8 Lubricant for food industry – selection (as option*) FUCHS SHELL MOBIL CASTROL KLÜBER Klübersynth Gear Geralyn SF 220 Cassida Fluid GL 220 Glygoyle 220 Optimol GT 220 UH1 6-220 Klübersynth Driving gear Geralyn SF 320 Cassida Fluid GL 220 Glygoyle 320 Optimol GT 320 UH1 6-320... -

Page 30: Remedy

Remedy Problem* Unit Cause Remedy No main power Check connection to mains supply Unit cannot be switched on Electric Hoists exchange 2 phases Phase sequence not correct (with low voltage control) (see waring note at the plug) Fuse burnt out Replace the fuse Defective switching unit in the control button switch Replace the switching unit... -

Page 31: Decommissioning

Decommissioning WARNING! It is essential that the following points are observed in order to prevent damage to the equipment or critical injury when the device is being decommissioned: It is mandatory that all steps for decommissioning the machine are carried out in the indicated sequence: First secure the working area for decommissioning, leaving plenty of space.

Need help?

Do you have a question about the 28/06AP-EX and is the answer not in the manual?

Questions and answers