Table of Contents

Advertisement

Quick Links

Installation, Operating and

Maintenance Instructions

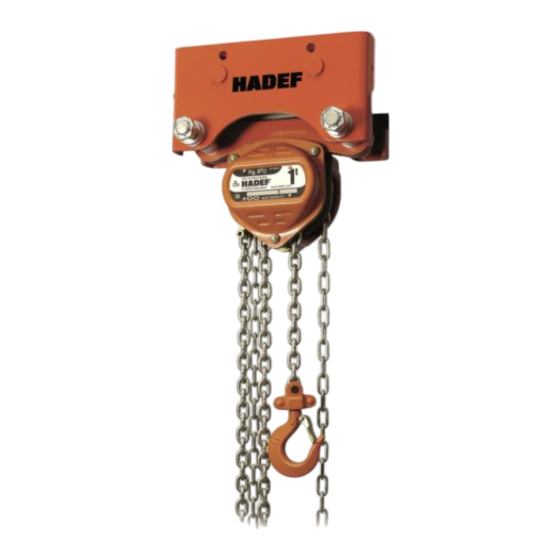

HADEF Spur Gear Hoist

Type 240/12

with monorail push travel trolley

with monorail hand geared trolley

NOTICE!

The installation or mounting instructions for incomplete machines you'll find in chapter "Installation"

o

by Heinrich de Fries GmbH

Heinrich de Fries GmbH, Gauss Str. 20, D-40235 Düsseldorf

Heinrich De Fries GmbH will be named HADEF in the following text.

Original operating- and maintenance instructions in German language.

Translation in other languages is made of the German original.

A copy may be requested in writing or is available for download on

Subject to changes.

5.52.145.00.01.05

HR

HH

www.hadef.com

Rev.05

Advertisement

Table of Contents

Summary of Contents for HADEF 240/12

- Page 1 Heinrich de Fries GmbH Heinrich de Fries GmbH, Gauss Str. 20, D-40235 Düsseldorf Heinrich De Fries GmbH will be named HADEF in the following text. Original operating- and maintenance instructions in German language. Translation in other languages is made of the German original.

-

Page 2: Table Of Contents

Table of Contents Information ..................3 Safety ....................3 Warning notice and symbols .................... 3 Duty of care of the owner ....................3 Requirements for the operating personnel ..............4 Appropriate use ......................... 4 Basic safety measures ...................... 5 Transport and Storage ............... 6 Transport .......................... -

Page 3: Information

NOTICE! Danger from electricity. Danger from explosive area. Duty of care of the owner DANGER! Failure to follow the instructions of this manual can lead to unpredictable hazards. For any resulting damage or personal injury, HADEF assumes no liability. 5.52.145.00.01.05... -

Page 4: Requirements For The Operating Personnel

The unit was designed and built following a risk analysis and careful selection of the harmonized standards that are to be complied with, as well as other technical specifications. It therefore represents state-of-the-art technology and provides the highest degree of safety. Our delivery includes the hoist supplied beginning at its suspension and ending at the load hook and if supplied with control, the control line/hose that leads to the hoist. -

Page 5: Basic Safety Measures

Device classification for Type of drive Explosive atmosphere Not explosive atmosphere )* )** according to ATEX Manually driven -20°C/+50°C -20°C/+40°C Motor driven -20°C/+40°C -20°C/+40°C ) * At an atmospheric pressure range from 0.8bar to 1.1bar and an oxygen content of approx. 21% ) ** Devices of this category have been specially modified and labeled by the manufacturer DANGER! The permissible ambient temperature must not be exceeded! -

Page 6: Transport And Storage

The safety catch of hooks must be closed. When charged, the housing may not be in contact somewhere. Stop lowering the load when the bottom block or the load is being set down or is prevented from being lowered further. -

Page 7: Design

DANGER! It is not permitted to use the unit in an area at risk from explosion! Design HADEF Spur Gear Hoists of compact design are monorail trolleys combined with manual hoists. With monorail push travel trolley or with monorail hand geared trolley Operation by hand through hand chain. -

Page 8: Technical Data

Technical data 240/12 HH Capacity 1000 1500 2000 3000 5000 10000 Number of chain falls Load chain 5 x 15 6x18 8 x 24 8 x 24 8 x 24 10 x 30 10x30 Load bar size at beam flange width... -

Page 9: Installation On The Beam

Installation on the beam 1 Tighten the hexagon nut (3) and safety nuts (4). 2 Push on the trolley at the face of the beam flange. 3 If this is not possible, the trolley can also be mounted on the beam from below. 4 Therefore, remove the hexagon nut (3) and the safety nut (4) on the side without gear. -

Page 10: Brake And Pawl

CAUTION! Run in of chain into the chain container for hoist with double lifting mechanism For a correct run in of chain into both chain containers, the lowering operation must be carried out, without load, at certain intervals, until both chain container are empty. For motorized devices with operating limit switches "lowering"... -

Page 11: Safety Check

CAUTION! Do not use grease for lubrication of load chain. Without lubrication, manufacturer's warranty and/or liability will be void. NOTICE! Continuous, thorough lubrication will increase the life of the chain considerably. Safety check Before putting into service initially or when putting back into service, it must be checked whether: ... -

Page 12: Inspection

Procedure: Only insert new chains in an unloaded state and as the chains that are currently in the device – i.e. not twisted. Remove chain from its fastening at the end and attach a chain link which is open at the side. ... -

Page 13: Checking The Load Hook

acc. DIN 685-part 5 L11 = pitch increase over 11 chain links L1 = pitch increase over 1 chain link Illustration 6 dm= detected link diameter (d1+d2)/2 Illustration 7 Chain dimensions Table 1 Dimensions Chain size 4x12 4,2x12,2 5x15 5,6x15,8 5,6x17 6x18 6,3x19,1... -

Page 14: Checking - Brake System

12.5 Checking - Brake System Ratchet wheel (A) and brake linings (B) 2x B 1000 1500-3000 5000-20000 12.6 Checking - Suspension and load hook bolt Load hook bolt Suspension bolt 1000 1500 2000 3000 5000-10000 Service 13.1 Load chain Wear at the links is mainly due to insufficient maintenance of the chain. To ensure optimal lubrication of the links, the chain must be lubricated at regular intervals, depending on usage. - Page 15 13.2 Pulleys Recommendation Interval FUCHS Pulleys Acc. to demand 12 month RENOLIN PG220 13.3 Load hook Check bearings and pulleys yearly Clean and lubricate the bearings of hooks and pulleys with grease Slight bearings are maintenance free ...

- Page 16 Lubricant for food industry – Selection (as option*) 13.8 KLÜBER SHELL MOBIL CASTROL Gearing FM Grease HD2 Mobilgrease FM 222 Klüberoil 4UH 1-1500 N Load chain Optimol Viscoleb 1500 Lubricant FM 100 Load hook; Pulleys FM Grease HD2 Mobilgrease FM 222 Gear rim;...

- Page 17 16.1 Temporary decommissioning Measures are as above. Also read the chapter “Transport and storage”. 16.2 Final decommissioning/disposal Measures are as above. After disassembly, ensure that the disposal of the equipment and any materials it contains is carried out in accordance with environmental regulations.

Need help?

Do you have a question about the 240/12 and is the answer not in the manual?

Questions and answers