Table of Contents

Advertisement

Quick Links

NOTICE: This document contains references to Varian.

Please note that Varian, Inc. is now part of Agilent

Technologies. For more information, go to

www.agilent.com/chem.

Checklist

NOTE: Do not unpack the shipping cartons.

Check off each checklist box after satisfying each requirement as described in the instructions. All requirements

must be met before requesting installation.

NOTE: If the site is not ready for installation when the Varian Representative arrives, Varian, Inc.

reserves the right to invoice for the Representative's time.

REQUIREMENTS

Installation site is in compliance with all relevant safety regulations.

User Representative will be available during the installation and certification period.

Entrance to the installation site is at least 92 cm (36 in.) wide.

Bench space is sufficient.

Bench can support system weight.

320-MS with 460-LC, at least 114 kg (250 lb)

320-MS with HTS PAL, at least 103 kg (231 lb)

Bench does not vibrate.

Exhaust system is suitable.

Temperature maintained between 16 and 30 °C, (61-86 °F).

Relative humidity maintained between 20 and 80%.

Installation site is free of excessive particulate matter.

Specified electrical supply and power outlets are installed.

Nitrogen gas (at least 99% pure), regulator, and gas lines are installed.

Air (less than 0.1 ppm hydrocarbons), regulator, and gas lines are installed.

Argon (greater than 99.0% pure), regulator, and gas lines are installed. Argon required only for

triple quadrupole instruments.

Materials and solvents of specified grade are on site.

Shipping cartons examined for damage. If there was any damage, the conditions were reported.

Requesting Installation

After preparing the site, contact the Customer Service office in your region to schedule installation.

9300025700: Rev. A

Varian 320-MS LC/MS

Quadrupole Mass Spectrometer

Pre-installation Instructions

1 of 14

Pre-installation Instructions

Advertisement

Table of Contents

Summary of Contents for Agilent Technologies Varian 320-MS

- Page 1 NOTICE: This document contains references to Varian. Please note that Varian, Inc. is now part of Agilent Varian 320-MS LC/MS Technologies. For more information, go to Quadrupole Mass Spectrometer www.agilent.com/chem. Pre-installation Instructions Checklist NOTE: Do not unpack the shipping cartons.

-

Page 2: Table Of Contents

Contents Introduction ..............2 Power Requirements ..........8 Safety ..............2 Installation Site Power .......... 10 Before the Installation ........... 3 Qualified Computer Equipment ......11 User Representative ..........3 Gas Requirements ..........11 ... -

Page 3: Before The Installation

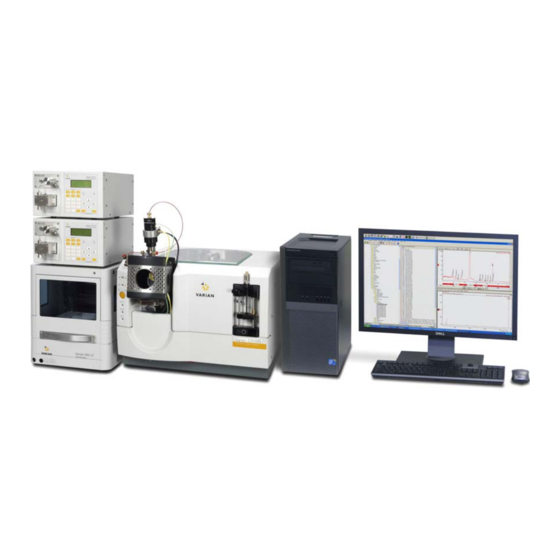

Before the Installation User Representative Schedule the installation when the User Representative will be available. One of the important duties of the Varian Representative is to familiarize the User Representative with the basic functions of the LC/MS. Check the checklist box: User Representative will be available during the installation and certification period. - Page 4 LC/MS with 212-LC and LC-460 Figure 1 shows a possible layout for the LC/MS with the 212-LC pumps and the 460-LC AutoSampler. Figure 1 Suggested Layout with 212-LC and 460-LC Table 1 and Table 2 provide information about the modules in Figure 1. Table 1 Bench Width with the 460-LC Bench Monitor and...

- Page 5 212-LC and HTS PAL Figure 2 shows a possible layout for the LC/MS with 212-LC pumps and CTC HTS PAL Autosampler. Figure 2 Suggested Layout with 212-LC and HTS PAL Table 3 and Table 4 provide information about the modules in Figure 2. Table 3 Bench Width with the HTS PAL Bench Monitor and...

-

Page 6: Vibration

Table 5 Additional Bench Space Requirements Function Space Allowance Provide space for air circulation, gas 15 to 30 cm (6 to 12 in.) behind the system. lines, and electrical connections. Dissipate room heat and allow for At least 76 cm (30 in.) above the system. routine maintenance. -

Page 7: Temperature

MS40+ Foreline Pump Table 8 MS40+ Foreline Pump Details Item Information Diameter of hole in bench, if needed 5.8 cm (2.3 in.) Width 29.7 cm (11.8 in.) Depth 41.8 cm (16.5 in.) Height 22.8 cm (9 in.) Vacuum hose length 1.8 m (6 ft) Power cord length 2.5 m (8 ft) -

Page 8: Humidity

Humidity The relative humidity of the operating environment must be between 20 and 80%, with no condensation. Operating the LC/MS at a very low humidity may result in the accumulation and discharge of static electricity, shortening the life of electronic components. Operating the system at high humidity may create condensation and result in short circuits. - Page 9 LC/MS The LC/MS requires the following. Table 9 LC/MS Circuits, Power Plug and Outlet Types Component Circuit Power Plug and Outlet Type 320-MS 1 each 220V US: 1 each NEMA 6-15P EU: 1 each CEE 7/7 plugs MS40+ Foreline 1 each 220V US: 1 each NEMA 6-15P Pump EU: 1 each CEE 7/7 plugs...

-

Page 10: Installation Site Power

Plugs Outlets Figure 3 Outlets and Plugs Installation Site Power In the United States, the power supply to the installation site must be 200-240V ac for the MS and the foreline pump and 100-120V ac for the LC, autosampler, computer, printer and other modules. -

Page 11: Qualified Computer Equipment

Qualified Computer Equipment If the Varian MS Workstation software is to be installed on a computer not purchased from Varian, the customer is responsible to ensure that the computer is adequately equipped and compatible with the operation of the data system and its communication interfaces. -

Page 12: Materials And Solvents

Materials and Solvents The Varian Representative will prepare solutions to tune and evaluate the LC/MS. Please supply the materials on Table 13 and the solvents on Table 14. Table 13 Materials Quantity (each) Item 50 mL clean and new volumetric flasks 1 L clean and new bottles for mobile phase reservoirs 1 L or larger bottle for LC/MS waste 10 mL clean and new volumetric flask... -

Page 13: When The Lc/Ms Arrives

When the LC/MS Arrives Inspecting the Shipping Cartons Do not open any shipping cartons. The Varian Representative opens them during installation. Move the shipping cartons to a warm, dry, and secure area near the installation site. After the instrument arrives, carefully inspect the exterior of the shipping cartons for evidence of any damage that could have possibly occurred during shipment. -

Page 14: Unpacking And Installing

Varian will not accept liability for damage if obviously received damaged materials were received without noting the damage on the receiving documents. Check the checklist box: Shipping cartons inspected for damage. If there was any damage, the conditions were reported. Unpacking and Installing The Varian Representative will review the Pre-installation Checklist with the customer to ensure that the site requirements were met.