Summary of Contents for Durr Dental Hygopac View

- Page 1 Hygopac View Installation and operating instructions 6024100132L02 *6024100132L02*...

- Page 3 Contents Contents Information about electrical con- nections ....Installation ..... . . Important information Remove the transport locks .

-

Page 4: Table Of Contents

Contents 15.1 Securing the sealing log ..16 Cleaning and disinfection ... 16.1 Unit surfaces ....Troubleshooting 17 Messages . - Page 5 Important information Other symbols Important information These symbols are used in the document and on or in the unit: Note, e.g. specific instructions regarding About this document efficient and cost-effective use of the unit. These installation and operating instructions rep- resent part of the unit.

- Page 6 Important information Copyright information Safety All circuits, processes, names, software pro- Dürr Dental has designed and constructed this grams and units mentioned in this document are unit so that when used properly and for the protected by copyright. intended purpose it does not pose any danger to The Installation and Operating Instructions must people or property.

- Page 7 Important information The Installation and Operating Instructions Transport ❯ must be accessible to all operators of the unit The original packaging provides optimum protec- at all times. tion for the unit during transportation. If required, original packaging for the unit can be Specialist personnel ordered from Dürr Dental.

- Page 8 15 x 30 cm, 1 x 500 pcs ..6020-063-00 delivery: Hygofol transparent sterilisation packaging Hygopac View ....6024100001 rolled foil – Hygopac View 5.0 cm x 100 m .

- Page 9 Product description Wear parts and replacement parts Information about replacement parts is available from the portal for authorised specialist dealers at: www.duerrdental.net. 6024100132L02 1906V003...

- Page 10 Product description Technical data Electrical data Voltage 230, 1~ Frequency 50 - 60 Nominal current Power output, max. Fuse 2 x T 5.0 AH / 250 V~ (IEC 60127-2) Type of protection IP 20 Protection class Degree of soiling (in accordance with EN 61010-1) General data Sealing temperature...

- Page 11 Höpfigheimer Str. 17 74321 Bietigheim-Bissingen Germany Name of product: Hygopac View We hereby declare that the above product meets all applicable requirements of the directives listed below: – Machinery directive 2006/42/EC in its current version. Name of the person with responsibility for compiling all technical documentation: F.

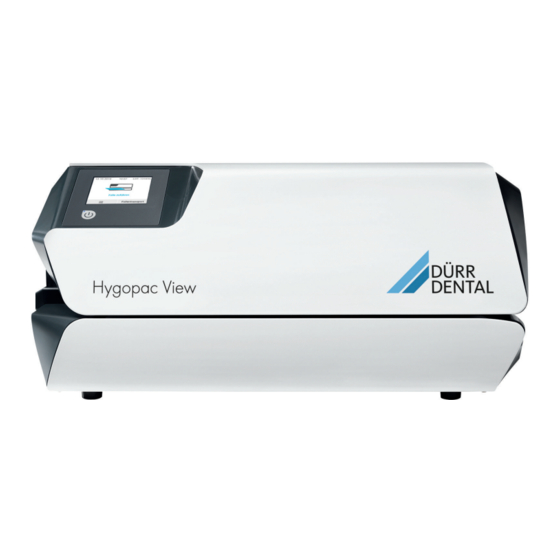

- Page 12 Product description Operation On / off switch Standby LED Touch screen Infeed Adjustable stop SD card slot Mains connection Fuse holder Network connection 10 Outlet The touch screen is used to display information, and settings can be entered here for operation of the device.

- Page 13 Product description In the area of the infeed there is a light barrier that is used to detect inserted sterilisation packaging and start the transport. Then the transport belt runs for a maximum foil width of 75 cm. If a new foil is quickly inserted afterwards but not placed against the adjustable stop, a foil can be picked up by the transport belt without the light barrier being triggered.

- Page 14 Assembly Installation Assembly Remove the transport locks Remove the transport protection. Requirements ❯ Installation/setup room The room chosen for set up must fulfil the follow- ing requirements: – Closed, dry, well-ventilated room – Should not be a room made for another pur- pose (e.

- Page 15 Assembly Plug a network cable into the network connec- Commissioning ❯ tion on the unit (optional when using Insert the SD card into the unit. ❯ e.g. Tyscor Pulse) and into the network socket. Switching on the unit: ❯ Press the On/Off switch (blue LED lights up).

- Page 16 Assembly Handover of the device Configuring the unit A factory calibration is performed on the Selecting the access level device at the factory. A printout of these The adjustment options depend on the selected test results is included in the supplied access level.

- Page 17 Assembly Adjust the time and tap Save. Tap to go Requirements: ❯ ü Access level Administrator or Service Techni- back. cian selected. Automatic adjustment If DHCP is activated then the settings are In order to use automatic time setting, applied automatically. DHCP must be activated (see "9.7 Con- Deactivate DHCP if you wish to adjust the figuring the network").

- Page 18 Assembly Touch screen calibration Press the centre of the circle and keep press- ❯ ing until the colour changes (to green). The touch screen is calibrated at the factory. However, if touch screen operation does not work it is properly to calibrate the touch screen on site.

- Page 19 Usage 10.1 Recommendations for the Usage sterile product packaging Here are various recommendations for working 10 Use of suitable sterile with sterile product packaging: – Select sufficiently large packaging. product packaging – Only fill packaging to 75% of its capacity to The following may be used: ensure that the sealing seams are tension-free.

- Page 20 Usage 11 Operation Menu items Scroll bar, active if there are more than three entries 11.1 Switching the unit on/off 1 step back Switching on the unit: ❯ Start screen Press the On/Off switch (blue LED lights up). Messages A signal sounds, the blue LED flashes and the ❯...

- Page 21 Usage Operate the touch screen by tapping it with a Label the packaging with the expiry date and ❯ ❯ fingertip or the stylus to select a menu or input required additional information (e.‑g. ster- field. iliser no., personnel, program etc.) 11.4 Start the transport belt manu- ally...

- Page 22 Usage 12 Monitoring the unit with 13 Adjustment of the VistaSoft Monitor adjustable stop If the device is connected to the network then it The adjustable stop allows the distance between can be monitored with the VistaSoft Monitor soft- the sealing seam and the edges to be adjusted ware.

- Page 23 Usage 14 Validation of the sealing If the outcome of the operational qualifica- ❯ tion is not satisfactory, tap No in the Seam process sealing test OK? screen. The following appears on the screen: Please 14.1 Validation steps adjust temperature The validation of the sealing process consists of Tap OK.

-

Page 24: Securing The Sealing Log

Usage The sealed and empty sterilisation packages of 15 Document the sealing pro- ❯ the same type should be added to different cess sterilisation batches of the defined sterilisation program (the batch documentation for the ster- The batch documentation is required as proof of ilisation processes forms part of the validation). -

Page 25: Cleaning And Disinfection

Usage 16 Cleaning and disinfection Disinfect the surfaces using a disinfection wipe. ❯ Alternatively, use disinfectant on a soft, lint-free cloth. Disconnect all power from the unit. When cleaning and disinfecting the unit and its accessories, observe country-specific directives, standards and specifications for medical prod- ucts as well as the specific specifications for dental practices and clinics. -

Page 26: Troubleshooting

Troubleshooting Troubleshooting 17 Messages 17.1 "Caution" messages After acknowledgement the unit will continue to work, but only with limited functions. Message: Caution No SD card present. Insert the SD card and restart the device. SD card write error. Restart the device. Pressing force too high. -

Page 27: Tips For Operators And Service Technicians

Troubleshooting 18 Tips for operators and service technicians Any repairs exceeding routine maintenance may only be carried out by qualified personnel or our service. Prior to working on the unit or in case of danger, disconnect it from the mains. 18.1 Displaying the sealing parameters Tap Sealing Parameters >... - Page 28 Troubleshooting Error Possible cause Remedy Light barrier triggered for too Light barrier was triggered for Acknowledge the message. In ❯ too long. The unit can process the event of a persistent fault, long. foils up to a total width of 75 cm. contact a Service Technician.

- Page 29 Troubleshooting Error Possible cause Remedy Sealing temperature too low Temporary fault on the tempera- Please repeat the sealing pro- ❯ ture control cess; if the sealing tempera- Please repeat the sealing pro- cess. ture continues to be too low then the temperature control is defective.

- Page 30 Troubleshooting Error Possible cause Remedy Power supply unit defective. The voltage of the power supply Inform your Service Techni- ❯ unit is possibly too low. cian. Temperature sensor defective. Possibly due to a short circuit or Inform your Service Techni- ❯...

-

Page 31: Appendix

Appendix Appendix 19 Menu structure Level 1 Level 2 Level 3 Level 4 Access levels Operator Administrator Service Technician Sealing parameters + / - Temperature Slow Speed Medium Fast Temperature Live display Speed Pressing force System settings German (DE) Language English (EN) Automatic Enabled... - Page 32 Appendix Level 1 Level 2 Level 3 Level 4 Device data REF: Device information Firmware: Lib: PCB SN: Device usage data LOT: Operating hours: Path counter: see "17.1 "Caution" Alarm history messages" Visible from access level Operator or higher Visible from access level Administrator or higher Visible from access level Service Technician or higher 6024100132L02 1906V003...

-

Page 33: Sealing Log

After the sealing process, the relevant sealing data is stored in a text file. The file can be saved to the SD card in the unit or to a connected PC via a documentation program. The individual fields are separated by a semicolon. Explanation Hygopac View; item description 6024100001; order number xxxxx; serial number yyyyy ; firmware version Time;... - Page 36 Hersteller/Manufacturer: DÜRR DENTAL SE Höpfigheimer Str. 17 74321 Bietigheim-Bissingen Germany Fon: +49 7142 705-0 www.duerrdental.com info@duerrdental.com...

Need help?

Do you have a question about the Hygopac View and is the answer not in the manual?

Questions and answers