Advertisement

Quick Links

Advertisement

Summary of Contents for Flomec QS100-10

- Page 1 QS100-10 In-line Irrigation Ultrasonic Flowmeter 3/2021 920901-03 Rev C...

- Page 2 Please save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Getting Started………………………………………………………. 4 General Safety Instructions……………………………………….. 5 Electrical / Mechanical Specifications……………………………6 Installation……………………………………………………………. 8 Operation……………………………………………………………. 12 Troubleshooting…………………………………………………… 13 Service & Warranty ……………………..………………………… 15... -

Page 4: Getting Started

#18 AWG wire cable (Direct Burial). Controller manufacturer may recommend thicker gauge wire for longer distances. UNPACKING Contents: • QS100-10 In-line Irrigation Ultrasonic Flowmeter • Owner’s Manual Inspect After unpacking the unit, inspect carefully for any damage that may have occurred during transit. -

Page 5: General Safety Instructions

GENERAL SAFETY INSTRUCTIONS IMPORTANT: It is your responsibility Ensure that all equipment operators have access to adequate instructions concerning safe operating and maintenance procedures. This product is not approved for use with CAUTION petroleum products (diesel fuel, unleaded gasoline, jet fuel, kerosene, etc.), aromatic hydrocarbons or other incompatible chemicals. -

Page 6: Electrical / Mechanical Specifications

SPECIFICATIONS QS100-10 MECHANICAL Housing SCH 80 PVC (Polyvinyl chloride) Material Wetted Materials PVC (Polyvinyl chloride) Coverplate PC/ABS Material (Polycarbonate/Acrylonitrile Butadiene Styrene) Type Ultrasonic Flowmeter Unit of Controller Dependent Measure 0.22-33 GPM Flow Rate 0.83-124.92 L/min 0.1-15 ft/sec Accuracy +/- 2% of Reading 0.04 GPM... - Page 7 (6.6 cm) Figure 1 K-Factor Information FLOMEC ultrasonic meters use K-factor values for greater accuracy during calibration. These values are derived by calibrating the meters using NIST traceable instrumentation. The K-factor value for this meter is listed below. IMPORTANT: The K-factor provided is for reference. Accuracy can be affected by plumbing configuration, fluid condition, adjoining pipe schedule, and entrapped air.

-

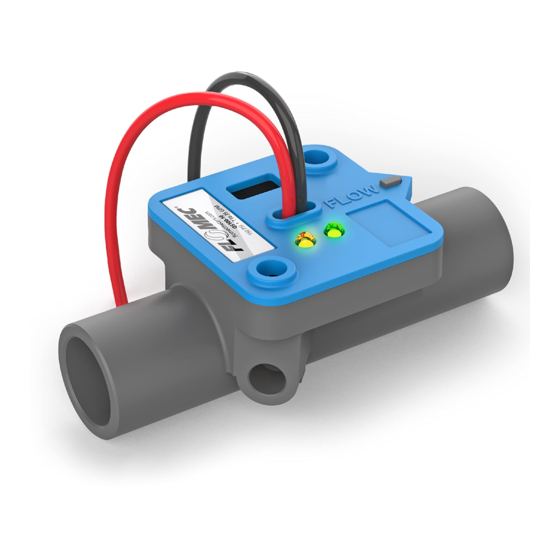

Page 8: Installation

INSTALLATION Meter Components and Features Below is a QS100-10 meter with labeled components. Familiarize yourself with the meter before installation. Figure 2 Preferred Installation Layout Provide a straight pipe run of at least 10 times the pipe's diameter (Ø) upstream (inlet end) of the meter, and at least 5 times the pipe's diameter (Ø) downstream (outlet end) of the meter. - Page 9 INSTALLATION (CONTINUED) Connecting Components NOTE: Keep the meter bore clean and free of dirt and debris during installation. 1. Remove all I.D and O.D edge burrs on the pipe ends. (see Figure 4) 2. Clean and apply primer to the pipe ends, fittings and meter. (see Figure 5) Note: The joint cementing sequence in 5 and 6 below is for general reference.

- Page 10 INSTALLATION (CONTINUED) For Below Ground Installation Install a valve box around the meter. Valve box extensions may be needed depending on depth. (See Figure 7) Note: A minimum of 10 in. thick layer of gravel should be installed immediately below the meter and valve box.

- Page 11 INSTALLATION (CONTINUED) Reference Figures 8a thru 8e on previous page 8a. Strip insulation 3/4 in. (19 mm). 8b. With wire ends even, insert wires into the connector and tighten until secure. 8c. Insert the connector all the way into the grease filled tube until the connector rests on the bottom of the tube.

-

Page 12: Operation

LEDs Functionality There are two LEDs on the QS100-10 meter. The GREEN LED is used to indicate basic power and functionality of the meter. The AMBER LED is used to indicate that there is a flow of water through the QS100-10 meter. -

Page 13: Troubleshooting

TROUBLESHOOTING 1. The LEDs are the primary indicators of meter performance. Refer to the Operations Section for LED indicating functionality. 2. Entrained air is air bubbles suspended in the water flow. Entrained air creates errors in accuracy of ultrasonic technology meters. Recommend a maximum of 10% entrained air in the water flow. - Page 14 NOTES: ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________ ___________________________________________...

-

Page 15: Service & Warranty

REPAIR The QS100-10 meter electronics casing is permanently sealed. All internal cavities and their electronic components are potted with cured electronic resin. There are no serviceable parts in the QS100-10 meter. SERVICE & WARRANTY FLOMEC® TWO-YEAR LIMITED WARRANTY Great Plains Industries, Inc. 5252 E. 36... - Page 16 GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER. The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for which it was designed.

Need help?

Do you have a question about the QS100-10 and is the answer not in the manual?

Questions and answers