Table of Contents

Advertisement

®

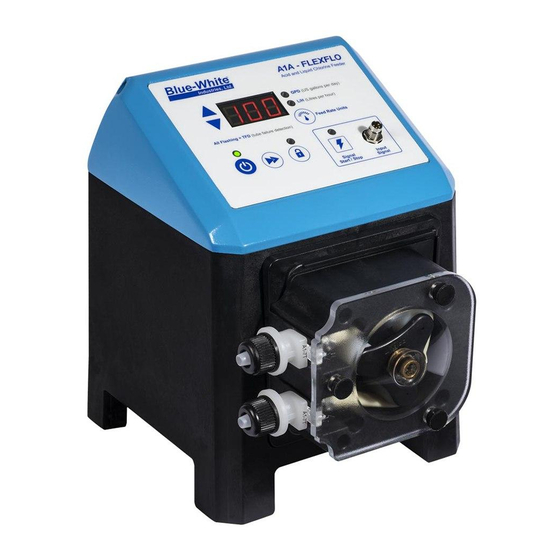

Peristaltic Metering Pump

SERIES A1A

NEMA 4X

Operating Manual

Exclusive:

TF D

system

Tube Failure Detection

Patented

Protected by Patents: 8,418,364; 8,215,931;

7,001,153; 7,284,964; 4,496,295

and other patents pending

5300 Business Drive, Huntington Beach, CA 92649, USA

Phone: 714-893-8529

FAX: 714-894-9492

E mail: sales@blue-white.com | techsupport@blue-white.com

URL: www.Blue-White.com

Advertisement

Table of Contents

Summary of Contents for Blue-White industries FLEXFLO A1A Series

- Page 1 ® Peristaltic Metering Pump SERIES A1A NEMA 4X Operating Manual Exclusive: TF D system Tube Failure Detection Patented Protected by Patents: 8,418,364; 8,215,931; 7,001,153; 7,284,964; 4,496,295 and other patents pending 5300 Business Drive, Huntington Beach, CA 92649, USA Phone: 714-893-8529 FAX: 714-894-9492 E mail: sales@blue-white.com | techsupport@blue-white.com URL: www.Blue-White.com...

-

Page 2: Table Of Contents

® Page 2 FlexFlo A1A TABLE OF CONTENTS INTRODUCTION ........Available Models . - Page 3 ® Page 3 FlexFlo A1A READ THE INSTRUCTION MANUAL PRIOR TO INSTALLATION AND USE.

-

Page 4: Introduction

NOTE: The pump was pressure-tested at the factory with clean water before it was shipped, so there may be trace amounts of clean water in the pre-installed tube assembly. This is part of Blue-White Industries, Ltd.'s stringent quality assurance process. -

Page 5: Engineering Specifications

® Page 5 FlexFlo A1A ENGINEERING SPECIFICATIONS Maximum Working Pressure (Excluding pump tubes) 40 PSI (2.76 bar) Maximum Suction Lift 30 ft. of water at sea level (14.7 atm psi) Ambient Operating Temperature 14 F to 125 F (-10 C to 52 C) Ambient Storage Temperature -40 F to 158 F (-40 C to 70 C) 115V60Hz 1 PH (0.6A max.) -

Page 6: Construction Materials

® FlexFlo A1A Page 6 CONSTRUCTION MATERIALS Wetted Components Pump Tube Assembly ® Tubing Flex-A-Prene Adapter Fittings PVDF Injection / Back-Flow Check Valve Body & Insert Polypropylene (optional PVDF) Check Ball Ceramic Spring Hastelloy C-276 Ball Seat O-Ring TFE/P Static Seal O-Ring Ancillary Items Provided Suction Tubing 3/8”... -

Page 7: Features

® Page 7 FlexFlo A1A Features > Designed with non-clogging valves. Self-priming (even against maximum line pressure), which means no required bypass valves, and it cannot > vapor lock or lose prime. Output rates from .01 to 100 GPD (.01 to 15.8 LPH). >... - Page 8 ® Page 8 FlexFlo A1A ENCLOSURE RATING NEMA 4X Constructed for either indoor or outdoor use to provide a degree of protection to personnel against incidental contact with enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water;...

-

Page 9: Installation

® Page 9 FlexFlo A1A INSTALLATION CAUTION The pump should be serviced by qualified persons only. If equipment is used in a manner not specified in this manual, the protection provided by the equipment may be impaired. CAUTION Risk of chemical overdose. Be certain pump does not overdose chemical during backwash and periods of no flow in circulation system. -

Page 10: Wall Mounting

® Page 10 FlexFlo A1A Wall Mounting Using the provided #10 self-tapping screws, mount the bracket to a secure wall that is located where it can be easily serviced. 4.50 in. [11.43 cm] #10 Self-Tap (2 X) Wall Mount Bracket (Side View) Mounted Pump (Front View) Lower the pump so that the tab on the wall mount is inserted into the slot located on the back of the pump. -

Page 11: Installing Injection Fitting And Strainer

® Page 11 FlexFlo A1A Installing Injection Fitting and Strainer CAUTION Proper eye and skin protection must be worn when installing and servicing pump. Assemble the injection fitting and strainer per the figures below. NOTE: Install upward for best results. NOTE: The injection nose may be trimmed (removed) when injecting into a small pipe. -

Page 12: Power Connections

® Page 12 FlexFlo A1A POWER CONNECTIONS WARNING Risk of electric shock – cord connected models are supplied with a grounding conductor and grounding-type attachment plug. To reduce risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle. WARNING Electrical connections and grounding (earthing) must conform to local wiring codes. -

Page 13: Touchpad Layout

® FlexFlo A1A Page 13 TOUCHPAD LAYOUT A1A - FLEXFLO Acid and Liquid Chlorine Feeder (US gallons per day) (Litres per hour) Feed Rate Units All Flashing = TFD All Flashing = TFD All Flashing = TFD (tube failure detection) (tube failure detection) (tube failure detection) Signal... -

Page 14: Io Connection

® FlexFlo A1A Page 14 IO Connection WARNING Risk of electric shock - All wiring must be insulated and rated 300V minimum. 4-Pin M8 Connector Function Specifications Relay 48 VDC @ 80 mA MAX. Relay 48 VDC @ 80 mA MAX. Remote Start/Stop N.O. -

Page 15: Operation Mode

® FlexFlo A1A Page 15 Operation Mode Start & Stop Key LED Signal Key LED P3-P4 Status Stop Green Stop Green Green Close Green Green Open Stop Green Close Stop Green Open How to Change the Signal Key LED Color To change the Signal Key LED color, press and hold the Signal Key button for 5 seconds. -

Page 16: Output Adjustment

® FlexFlo A1A Page 16 OUTPUT ADJUSTMENT Speed of pumping mechanism is adjustable from 0.01 GPD to 100 GPD (0.01 LPH to 15.8 LPH). A1A - FLEXFLO Acid and Liquid Chlorine Feeder (US gallons per day) (Litres per hour) Feed Rate Units All Flashing = TFD All Flashing = TFD All Flashing = TFD... -

Page 17: Tube Failure Detection (Tfd)

® FlexFlo A1A Page 17 TUBE FAILURE DETECTION (TFD) The pump is equipped with a Tube Failure Detection (TFD) system, which is Tubing failure designed to stop the pump and provide an output alarm in the event the pump tube should rupture, and a chemical enters the pump head. The pump will detect a chemical with a conductivity reading greater than 500 microsiemens. -

Page 18: Pump Maintenance

® FlexFlo A1A Page 18 10.0 PUMP MAINTENANCE CAUTION Always wear protective clothing, face shield, safety glasses and gloves when working on or near your metering pump. Additional precautions should be taken depending on solution being pumped. Refer to MSDS precautions from your solution supplier. 10.1 Routine Inspection and Maintenance The pump requires minimal maintenance. -

Page 19: Tube Replacement

® FlexFlo A1A Page 19 11.0 TUBE REPLACEMENT CAUTION Prior to service, pump clean water through the pump and suction / discharge line to remove any chemical. CAUTION Always wear protective clothing, face shield, safety glasses and gloves when working on or near your metering pump. - Page 20 ® FlexFlo A1A Page 20 4. Press the Start & Stop key to start the pump and set the pump to 6 GPD (1 LPH). 5. With the pump running, pull the inlet (suction) fitting out of the pump head. Guide the tube counterclockwise away from the rollers.

-

Page 21: Tube Installation

® FlexFlo A1A Page 21 11.3 Tube Installation NOTE: Thoroughly clean the pump head and rotor. The rotor can be removed by pulling it straight out. After cleaning, push the rotor back on the shaft. 1. Press Start & Stop key to start the pump. 2. - Page 22 ® FlexFlo A1A Page 22 4. Pull the outlet fitting out of the pump head. 5. Place the clear cover onto the pump head. Secure the cover with the provided three thumb screws. The pump is now ready for operation.

-

Page 23: Pump Head Replacement Parts List

® FlexFlo A1A Page 23 12.0 PUMP HEAD REPLACEMENT PARTS LIST Item Description Part Quantity Spacer, back 90011-014 Roller assembly complete (rotor) 71000-350 Tube assembly, 3/8” OD tube compression, A1-7T ® Flex-A-Prene Pump head cover, polycarbonate 90002-185 Thumb screw with 9/64” key drive, 90011-160 maximum torque 6-8 in. -

Page 24: 13.0 Troubleshooting

Check power supply output voltage Under Voltage Check power supply output voltage Check ambient conditions, restart pump once cooled Temperature exceeds 75°C at control to ambient temperature Contact Blue-White Industries (714) 893-8529 Inverter Error techsupport@blue-white.com Contact Blue-White Industries (714) 893-8529 No Motor Connection techsupport@blue-white.com... - Page 25 ® FlexFlo A1A Page 25 THIS PAGE IS LEFT INTENTIONALLY BLANK.

-

Page 26: Warranty

The warranty status is determined by the pump's serial label and the sales invoice or receipt. The serial label must be on the pump and be legible. The warranty status of the pump will be verified by Blue-White Industries, Ltd. or a factory authorized service center. - Page 27 ® FlexFlo A1A Page 27 Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of the WEEE Directive must not dispose of end of life EEE as unsorted municipal waste, but use the collection framework available to them for the return, recycle, recovery of WEEE and minimize any potential effects of EEE on the environment and human health due to the presence of hazardous substances.

-

Page 28: Appendix A: Acronyms

® FlexFlo A1A Page 28 APPENDIX A: ACRONYMS °C Celsius WEEE Waste Electrical and Electronic Equipment °F Fahrenheit Alternating current Unit of pressure Clean-in-place Centimeters Cash on Delivery Depth Direct current Electrical and electronic equipment Ethylene propylene Electrical Testing Labs/Intertek European Union Food and Drug Administration Fluoroelastomer... -

Page 29: Appendix B: Model Number Matrix

® FlexFlo A1A Page 29 ® FLEXFLO Peristaltic Metering Pump Engineering and Technical Data Model Number Matrix ® FlexFlo Model Number ® FlexFlo Peristaltic Metering Pump Power Cord (Operating voltage requirement 96VAC to 264VAC) 115V 50/60Hz, power cord NEMA 5/15 plug (US) 230V 50/60Hz, power cord NEMA 6/15 plug (US) 220V 50/60Hz, power cord CEE 7/V11 plug (EU) 240V 50/60Hz, power cord AS 3112 plug (Australia/New Zealand) - Page 30 ® FlexFlo A1A Page 30 THIS PAGE IS LEFT INTENTIONALLY BLANK.

- Page 31 ® FlexFlo A1A Page 31 THIS PAGE IS LEFT INTENTIONALLY BLANK.

- Page 32 Blue-White Industries, Ltd. 5300 Business Drive, Huntington Beach, CA 92649, USA Phone: 714-893-8529 FAX: 714-894-9492 E mail: sales@blue-white.com or techsupport@blue-white.com URL: www.Blue-White.com P.N. 80000-605 Rev. 9 20200916...

Need help?

Do you have a question about the FLEXFLO A1A Series and is the answer not in the manual?

Questions and answers