Table of Contents

Advertisement

IP2163EN • 2020-11-26

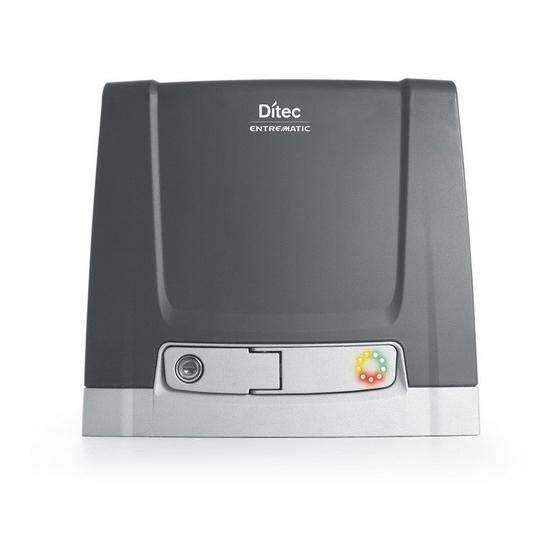

Ditec CS12M

Control panel installation manual for

Ditec NEOS+ automations

(Translation of the original instructions)

Antenna

-

24V output

+

Safety stop

-

24V output

+

Closing safety device

Flashing light

Step-by-step

Partial opening

Automatic external

closing

Opening

Closure

Stop

Automation status

lamp

Lighting kit

www.ditecautomations.com

ZENRS

ZENPRS

RDX

UP

AUX

DOWN

ENTER

ESC

24V

MOTOR

USB

JR1

C

O

M

DIA

LSW

BAT

blue

black

NES100LED

NES100FCM

SBU

Selection of automation

type

(FACTORY SET)

+

Power supply

-

Release

microswitch

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for DITEC CS12M

- Page 1 IP2163EN • 2020-11-26 Ditec CS12M Control panel installation manual for Ditec NEOS+ automations (Translation of the original instructions) Antenna ZENRS ZENPRS 24V output Safety stop NES100LED 24V output Closing safety device DOWN NES100FCM Flashing light ENTER Step-by-step Selection of automation...

-

Page 2: Table Of Contents

Contents Subject Page General safety precautions EC Declaration of Conformity Technical specifications Commands 4.1 Inserting plug-in card (AUX) 4.2 Self-controlled safety edge Outputs and accessories Selections Adjustments 7.1 Switching on and off 7.2 Key combinations 7.3 Main menu 7.4 Second level menu - AT (Automatic Configurations) 7.5 Second level menu - BC (Basic Configurations) 7.6 Second level menu - BA (Basic Adjustment) 7.7 Second level menu - RO (Radio Operations) -

Page 3: General Safety Precautions

1. General safety precautions Failure to observe the information given in this manual may lead to personal injury or damage to the equipment. Keep these instructions for future reference This installation manual is intended for qualified personnel only. Installation, electrical connections and adjustments must be performed in accordance with Good Working Methods and in compliance with the present standards. -

Page 4: Ec Declaration Of Conformity

2. EC Declaration of Conformity The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44 Land- skrona, Sweden, declares that the Ditec CS12M type control panel complies with the condi- tions of the following EC directives: 2014/30/EU (EMCD) -

Page 5: Commands

4. Commands Command Function Description 2 NO AUTOMATIC Permanent closing of the contact enables automatic CLOSING closing if → 3 NO OPENING Closing of the contact activates an opening operation. 4 NO CLOSING Closing of the contact activates a closing operation. 5 NO STEP-BY-STEP When selecting... -

Page 6: Inserting Plug-In Card (Aux)

4.1 Inserting plug-in card (AUX) To access the plug-in card (AUX), cut the control panel cover as shown in the figure. DOWN ENTER 4.2 SOFA1-SOFA2 or GOPAVRS self-controlled safety edge Command Function Description SAFETY TEST Place the SOFA1-SOFA2 or GOPAVRS device into the SOFA1-SOFA2 special housing for AUX plug-in cards. - Page 7 Examples of installation of self-controlled safety edge SOFA15 SOFA20 SOFA25 SOFA15 SOFA20 SOFA25 OPENING GOPAVT SOFA15 SOFA15 SOFA20 SOFA20 SOFA25 SOFA25 IN1 IN2 +BC OPENING...

-

Page 8: Outputs And Accessories

5. Outputs and accessories Value Output Description Accessories Power supply to accessories. External accessories power supply output. NOTE: the maximum absorption of 0.3A corresponds to the 24V 0.3A sum of all terminals 1. The gate open indicator light (1-13) is not calculated in the 0.3A indicated above, the maximum value considered is 3W. - Page 9 Value Output Description Accessories The control panel has a housing for plug-in control and safe- SOFA1-SOFA2 ty cards. GOPAV The action of the control card can be selected by selecting LAN4S → LAB9 If slot-in radio boards are used, remove the RDX module. The BIXLR12 display will show BIXLR22...

-

Page 10: Selections

NOTE: the operating temperature of the rechargeable batteries is from +5°C to +40°C. For advanced control of battery-powered operation, refer to the menu LSW - Magnetic limit switch kit (optional on Ditec NES300 and NES400). NES100FCM 6. Selections Jumper Description Display mode selection. -

Page 11: Adjustments

Adjustments NOTE: pressure on the keys can be quick (less than 2 s) or prolonged (longer than 2 s). Unless specified otherwise, quick pressure is intended. To confirm the setting of a parameter, prolonged pressure is necessary. Switching the display on and off The procedure to switch on the display is as follows: •... -

Page 12: Key Combinations

Key combinations • Simultaneous pressing of the keys ↑and ENTER performs an opening com- mand. • Simultaneous pressing of the keys ↓and ENTER performs a closing command. • Simultaneous pressing of the keys ↑ and ↓ performs a POWER RESET com- mand. -

Page 13: Main Menu

Main menu • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm After confirming the selection, you access the second level menu. Display Description AT - Automatic Configurations. The menu allows you to manage the automatic configurations of the control panel. -

Page 14: Second Level Menu At (Automatic Configurations)

Second level menu AT (Automatic Configurations) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description RT - Opening to right. LF - Opening to left. H0 - Predefined setting, residential use 0. This selection loads predefined values for certain standard parameters: AC - enabling of automatic closing : 1-2... - Page 15 Display Description AA - Activating advanced parameters menu. → 2” After activation you can scroll through the third level menus. The third level menus are activated for 30 min. Depending on the type of automation and control panel, some menus may not be avail- able.

-

Page 16: Second Level Menu - Bc (Basic Configurations)

Second level menu - BC (Basic Configurations) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description AC - Enabling of automatic closing. ON - Enabled 1-2 - Dependent on input 1-2 SS - Selection of automation status at start. - Page 17 7.5.1 Additional BC level parameters that can be configured (available with → enabled) Display Description OL - Automation open indicator light mode ON - Steady on OF - Flashing C5 - Step-by-step/opening command operation. 1-5 - Step-by-step 1-3 - Opening RM - Radio receiver operation.

-

Page 18: Second Level Menu - Ba (Basic Adjustment)

Second level menu - BA (Basic Adjustment) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description MT - Display of type of automation. N3 - Motor with 300kg capacity N4 - Motor with 400kg capacity N6 - Motor with 600kg capacity N1 - Motor with 1000kg capacity NOTE: this parameter is DISPLAY only. - Page 19 Display Description R2 - Adjustment of thrust on obstacles and current during opening [%] The control panel is equipped with a safety device that stops movement if an obstacle is detected during an opening operation with disengagement of 10cm. 00 - Minimum thrust 99 - Maximum thrust R1 - Adjustment of thrust on obstacles and current during closing [%]...

- Page 20 7.6.1 Additional BA level parameters that can be configured (available with → enabled) Display Description DT - Adjustment of obstacle recognition time. [s/100] 10 - Minimum 60 - Maximum NOTE: the parameter is adjusted in hundredths of a second. MP - Start at maximum power ON - During start-up it increases the thrust on obsta- cles to maximum.

- Page 21 Display Description PC - Adjustment of approach speed during closing. [cm/s] Indicates the speed from the end of the deceleration ramp to the end of the stroke. 02 - Minimum 10 - Maximum NOTE: gradually increase the approach speed if there is a series of quick vibrations (chattering) in heavy gates installed with a slight incline.

-

Page 22: Second Level Menu - Ro (Radio Operations)

Second level menu - RO (Radio Operations) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description SR - Remote control storage. You can directly access the Remote control storage menu even with the dis- play turned off, but only with the Display visualisation mode option set to 00 or 03: - for transmitting a remote control not present in the memory;... - Page 23 Display Description RK - Menu navigation using remote control keyboard. ON - Enabled OF - Disabled We recommend using a NES100TXT (433,92MHz) or NES200TXT (868,35MHz) remote control. With the display turned off, quickly type in the se- 3 3 3 3 2 2 4 4 1 1 quence of keys from the stored re- mote control you want to use.

- Page 24 7.7.1 Additional RO level parameters that can be configured (available with → enabled) Display Description C1, C2, C3, C4 - Selection of CH1, CH2, CH3, CH4 func- tion of stored remote control. NO - No setting selected 1-3 - Opening command 1-4 - Closing command 1-5 - Step-by-step command P3 - Partial opening command...

-

Page 25: Second Level Menu - Sf (Special Functions)

Second level menu - SF (Special Functions) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description CU - Displaying the control panel firmware version. (example) Release 1.1 [esempio] → → →... - Page 26 7.8.1 Additional SF level parameters that can be configured (available with → enabled) Display Description SP - Setting the password. → → → → → 2” [esempio] (example) NOTE: this can only be selected when the password is not set. Setting the password prevents unauthorised personnel from accessing se- lections and adjustments.

-

Page 27: Second Level Menu - Cc (Cycles Counter)

Second level menu - CC (Cycles Counter) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description CV - Display of total operations counter. 182 manovre [esempio] operations (example) → → →... - Page 28 7.9.1 Additional CC level parameters that can be configured (available with → enabled) Display Description CA - Setting the maintenance alarm (factory setting - alarm disabled: 0.0 00. 00). You can set the required number of operations (regarding the partial opera- tions counter) for signalling the maintenance alarm.

-

Page 29: Second Level Menu - Em (Energy Management)

7.10 Second level menu - EM (Energy Management) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description PV - Solar panel power supply (panels not supplied) ON - Enabled OF - Disabled ES - Accessory power supply disconnection with automation stopped or in stand-by “Energy Saving”... - Page 30 7.10.1 Additional EM level parameters that can be configured (available with → enabled) Display Description LL - Voltage threshold for indicating that batteries are almost flat (V) 17 - Minimum 24 - Maximum NOTE: it is set with an interval of sensitivity of 0.5 V shown when the decimal point on the right lights up.

-

Page 31: Second Level Menu - Ap (Advanced Parameters)

7.11 Second level menu - AP (Advanced Parameters) • using keys ↑ and ↓ select the desired function • press the ENTER key to confirm Display Description FA - Selection of opening limit switch mode. NO - None SX - Stop limit switch (after activation the door wing stops its movement) PX -... - Page 32 Display Description DS - Setting of display visualisation mode. 00 - No display 01 - Commands and safety devices with radio test (see paragraph 8.2). Display of count down to automatic closing. 02 - Automation status (see paragraph 8.1) 03 - Commands and safety devices (see paragraph 8.2) NOTE: setting displays the receipt of a radio trans-...

- Page 33 7.11.1 Additional AP level parameters that can be configured (available with → enabled) Display Description ED - Enabling of diagnostics Enables periodic saving of data via serial for diagnos- tic use. NO - Disabled 01 - Checking virtual encoder (DO NOT USE) 02 - Alarm log US - Type of C-NO contact use OF - Contact always open...

- Page 34 Display Description PA - Automation parallel (see examples of applica- tions) Sets the type of automation parallel 01 - Simultaneous automations 02 - Interlocked one-way or two-way transit automa- tions without presence detection 03 - Interlocked one-way transit automations with pres- ence detection G1 - Setting the G1 input mode NO - Absent...

- Page 35 Display Description OT - Selection of type of obstacle. 00 - Overcurrent or door stopped 01 - Overcurrent 02 - Door stopped CR - Correction to calculated speed. [mm/s] DO NOT USE (diagnostic purposes only) R9 - Enabling automatic closing after command 1-9 (STOP) from terminal board.

- Page 36 Display Description WC - Setting of pre-flashing time on closing. [s] Adjustment of the lead time for the switch-on of the flashing light, in relation to the start of the closing op- eration from a voluntary command. 00 - Minimum 05 - Maximum TS - Setting of renewal of automatic closing time after safety device release.

-

Page 37: Display Visualisation Mode

8. Display visualisation mode WARNING: depending on the type of automation and control panel, some menus may not be available. Display of automation status The automation status display mode is only visible with Display visualisation mode set to 02. → →... - Page 38 Display Description → Automation closed. Automation closed. Release door open. Automation open. Automation open. Release door open. Automation stopped in intermediate position. Automation stopped in intermediate position. Release door open. Automation closing. Automation that slows down during closing. Automation opening. Automation that slows down during opening.

-

Page 39: Display Of Safety Devices And Commands

Display of safety devices and commands The safety and command display mode is only visible with Display visualisation mode set at 01 or 03. → → → → Display Description 1-2 - Automatic closing command. 1-3 - Opening command. 1-4 - Closing command. 1-5 - Step-by-step command. - Page 40 EX - Rolling-code radio reception out of sequence EP - Radio reception not complying with the parameter configuration → CX - Receipt of command from AUX card. F1 - Closing limit switch F2 - Opening limit switch O1 - Detection of an obstacle during closing O2 - Detection of an obstacle during opening OO - Reaching of obstacle detection limit during opening OC - Reaching of obstacle detection limit during closing...

- Page 41 JR1 - Variation of the JR1 jumper status. G1 - General Purpose 1 PC - Recognition of connected HOST (Personal Computer). UB - Recognition of connected USB memory stick UD - Disconnection of cable and USB memory stick ES - Switch to Energy Saving mode. AO - Interlocked automation opening control request.

-

Page 42: Display Of Alarms And Faults

Display of alarms and faults Alarms and faults can be displayed with any display selection. The signalling of alarm messages takes priority over all other displays. Type of Display Description Operation alarm M0 - Selected motor not suitable. Set correct motor wiring. M3 - Automation blocked (open/ Check the mechanical parts closed) - Page 43 Type of Display Description Operation alarm R3 - Storage module not detected Insert a working storage module or (with RDX inserted). remove RDX. R5 - Storage module not working (re- Replace the storage module. gardless of RDX) A0 - Failure of test of safety sensor Check that device SOFA1-A2/GOPAV on contact 6.

- Page 44 Type of Display Description Operation alarm IA - Internal parameter error Reset. (EEPROM) If the problem persists, replace the control panel. IB - Internal parameter error (RAM) Reset. If the problem persists, replace the control panel. IC - Operation time out error (>5 min Manually check that the door wing or >7 min in acquisition mode) moves freely.

-

Page 45: Start-Up

2- Adjust the opening and closing stop limit switches, if any. NOTE: The limit switches must remain pressed until the operation is completed and placed as shown in the Ditec NEOS installation manual. 3- Set the desired opening direction from the menu. -

Page 46: Troubleshooting

10. Troubleshooting Problem Possible cause Signal Operation Alarm The automation does not No power. Check power supply cable. open or close. Short-circuited accessories Disconnect accessories from terminals 0-1 (a voltage of 24V= must be present) and reconnect them one at a time. Contact Technical Service Blown line fuse. - Page 47 Problem Possible cause Signal Operation Alarm The external safety devices Incorrect connections Check that is dis- are not activated. tween the photocells and the played control panel. Connect NC safety contacts together in series and remove any jumpers on the control panel terminal board.

- Page 48 11. Examples of sliding gate applications When the CS12M control panel is used for sliding automation applications, the following connections can be made: - set the correct opening direction: x2 s x2 s Example 1 - Door wing stops against mechanical end stops (standard setting)

-

Page 49: Examples Of Application

Stop Automation status The MASTER automation could be the one you lamp decide to open partially (1-20 connected). CS12M Master 1. Disconnect connectors 1-G1-G3 from the control panels. 2. Set the following parameters on both auto- 24V output mations via the display:... -

Page 50: Examples Of Applications For Parallel Automations

Commands 1-5, 1-4 and 1-20 can be used in Automation status lamp special cases, for example, to allow very long vehicles to pass through. CS12M Command 1-9 can interrupt the interlock ZENRS sequence, i.e., cancel the command given ZENPRS to automation B. -

Page 51: Examples Of Application For Automations With Two-Way Interlocking Device With- Out Presence Detection

Stop Automation status tions (e.g. magnetic loop). lamp Once the delay time set with CS12M Master > has elapsed, the SLAVE au- tomation will open and will close after the time set with > Commands 1-5, 1-4 and 1-20 can... -

Page 52: Examples Of Application For Automations With Two-Way Interlocking Device With Presence Detection

3. Reconnect connectors 1-G1-G3. 4. Set > > on the MASTER automation. 5. Enable automatic closing on the MASTER automation with > > and on the SLAVE automation with > > 6. Set the desired automatic closing time ( > ) on both automations.

Need help?

Do you have a question about the CS12M and is the answer not in the manual?

Questions and answers