Table of Contents

Advertisement

Quick Links

Gas Analysis

Sample gas probes

GAS 222.20 Denox

Installation and Operation Instructions

Original instructions

BE460035

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

04/2021

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: analyse@buehler-technologies.com

Internet: www.buehler-technologies.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Buhler GAS 222.20 Denox

- Page 1 Gas Analysis Sample gas probes GAS 222.20 Denox Installation and Operation Instructions Original instructions BE460035 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen 04/2021 Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 E-Mail: analyse@buehler-technologies.com...

- Page 2 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 Internet: www.buehler-technologies.com E-Mail: analyse@buehler-technologies.com Read this instruction carefully prior to installation and/or use. Pay at- tention particularly to all advises and safety instructions to prevent in- juries.

-

Page 3: Table Of Contents

GAS 222.20 Denox Contents Introduction............................................. 2 Intended Use......................................... 2 Type plate .......................................... 2 Contents.......................................... 2 Ordering Instructions...................................... 3 Product description ...................................... 3 Safety instructions......................................... 4 Important advice ......................................... 4 General hazard warnings .................................... 5 Transport and storage ........................................ 6 4 Installation and connection ...................................... 7 Installation site requirements.................................. -

Page 4: Introduction

When connecting, please note the specific values of the device, and the correct version when ordering spare parts. 1.2 Type plate Example: Manufacturer including address Model designation Sample Gas Probe GAS 222.20 Denox ID no., Item no. 2017 02230017 462225012001 Electrical supply 230V 50 Hz Read manual! 1.3 Contents... -

Page 5: Ordering Instructions

GAS 222.20 Denox 1.4 Ordering Instructions The item number is a code for the configuration of your unit. Please use the following model code: 4622250 X X X X X 0 0 Product Characteristics Flange DIN DN65 PN6 ASME DN3"-150... -

Page 6: Safety Instructions

GAS 222.20 Denox 2 Safety instructions 2.1 Important advice Operation of the device is only valid if: – the product is used under the conditions described in the installation- and operation instruction, the intended application according to the type plate and the intended use. In case of unauthorized modifications done by the user Bühler Technolo- gies GmbH can not be held responsible for any damage, –... -

Page 7: General Hazard Warnings

GAS 222.20 Denox 2.2 General hazard warnings The equipment must be installed by a professional familiar with the safety requirements and risks. Be sure to observe the safety regulations and generally applicable rules of technology relevant for the installation site. Prevent malfunctions and avoid personal injuries and property damage. -

Page 8: Transport And Storage

GAS 222.20 Denox 3 Transport and storage The device should be only transported in the original case or in appropriate packing. CAUTION Transport Transport the product in a way which is not damaging to health. Where necessary, use auxiliary means for transport and assembly. -

Page 9: Installation And Connection

GAS 222.20 Denox 4 Installation and connection 4.1 Installation site requirements Sample gas probes are intended for flange mounting. – Installation site and installation position are determined based on requirements specific to the application. – If necessary, the connection piece should be slightly tilted toward the centre of the channel. -

Page 10: Connecting The Gas Line

GAS 222.20 Denox 4.5 Connecting the gas line This table provides an overview of the sample gas probe connections: Connecting flange DN65 PN6 oder ASME DN3"-150 Sample gas input: G3/4 Sample gas outlet: GL14 (6 mm) 1) Test gas connection (option): Pipe Ø6 mm or 1/4”... -

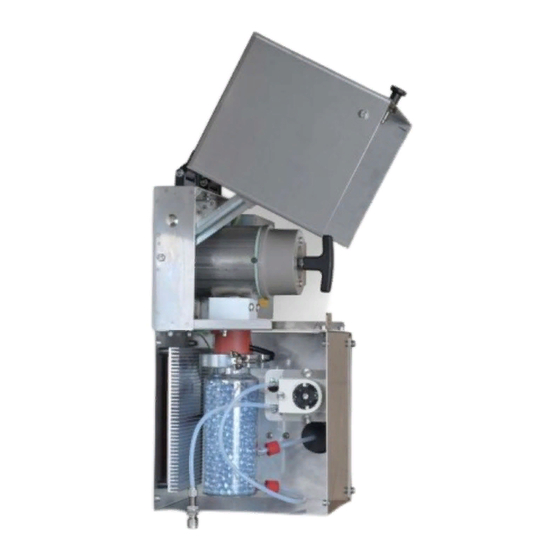

Page 11: The Glass Pearl Receptacle

GAS 222.20 Denox 4.6 The glass pearl receptacle The glass pearl receptacle must be filled with glass pearls before use. Follow the steps under Replacing the glass pearl receptacle [> page 16]. The condensate output is located at the lower position of the glass pearl receptacle. It features a factory installed peristaltic pump for removing condensate. - Page 12 GAS 222.20 Denox The device must be incorporated into the protective conductor system of the operator. The following separation facilities are to be provided for the current and voltage supply of the components: RCD, main switch and circuit breaker or fuses The following conditions must be met for use: –...

-

Page 13: Operation And Controls

GAS 222.20 Denox 5 Operation and controls NOTICE The device must not be operated beyond its specifications. 5.1 Basic function of the probe controller 5.1.1 Controller function After switching on the combination the probe is heated up. The display with the current temperature will light up on the regu- lator. -

Page 14: Menu Navigation Overview

GAS 222.20 Denox 5.2.1 Menu navigation overview Temperature and status display ____ Display The probe temperature is indicated in 0.5°C increments. Press the Enter key to access the main menu. Current temperature The temperature can be displayed in Celsius or Fahrenheit. -

Page 15: Detailed Description Of The Operational Principle

GAS 222.20 Denox 5.2.2 Detailed description of the operational principle The detailed description will guide you through the menu step by step. Connect the unit to the power supply and wait for the startup procedure to complete. At first the software version im- plemented on the unit will be displayed for a brief period. -

Page 16: Submenu Probe Regulator [Display: Prob]

GAS 222.20 Denox 5.3.2 Submenu probe regulator [Display: Prob] Controller -> Nominal temperature (Temperature) This item allows setting of the nominal temperature of the device. The value can be set within a range from 50 °C (122 °F) to 280 °C (536 °F). -

Page 17: Maintenance

GAS 222.20 Denox 6 Maintenance During maintenance, remember: – The equipment must be maintained by a professional familiar with the safety requirements and risks. – Only perform maintenance work described in these operating and installation instructions. – When performing maintenance of any type, observe the respective safety and operation regulations. -

Page 18: Replacing The Downstream Filter

GAS 222.20 Denox 6.1.1 Replacing the downstream filter – Unlock and lift up the weather hood. – Turn the handle at the back end of the probe by 90° (handle must then be horizontal), pushing in slightly, and remove. – Remove the dirty filter element and check the sealing surfaces. -

Page 19: Service And Repair

GAS 222.20 Denox 7 Service and repair This chapter contains information on troubleshooting and correction should an error occur during operation. Repairs to the unit must be performed by Bühler authorised personnel. Please contact our Service Department with any questions: Tel.: +49-(0)2102-498955 or your agent... -

Page 20: Spare Parts And Accessories

GAS 222.20 Denox 7.2 Spare parts and accessories Please also specify the model and serial number when ordering parts. Upgrade and expansion parts can be found in our catalog. Available spare parts: Item no. Description 46 222 024 O-ring kit for filter element and probe, material: Perfluorelastomer 46 222 026P Filter element ceramic 3 µm perfluor... -

Page 21: Disposal

GAS 222.20 Denox 8 Disposal Dispose of parts so as not to endanger the health or environment. Follow the laws in the country of use for disposing of elec- tronic components and devices during disposal. BE460035 ◦ 04/2021 Bühler Technologies GmbH... -

Page 22: Appendices

GAS 222.20 Denox 9 Appendices 9.1 DeNOx technical Data Gas Probe Technical Data Operating temperature: max. 280 °C Operating pressure: 90 kPa…100 kPa Controller temperature range: +50 °C to +280 °C Ambient temperature: +5 °C to +50 °C* without anti-freeze heater -20 °C to +50 °C* with optional anti-freeze heater... -

Page 23: Denox Wiring Diagram

GAS 222.20 Denox 9.3 DeNOx Wiring diagram Mains factory wired connection by customer Fig. 1: DeNOx wiring diagram BE460035 ◦ 04/2021 Bühler Technologies GmbH... -

Page 24: Attached Documents

GAS 222.20 Denox 10 Attached documents – Drawings: 46/135-Z01-02-1, 46/135-Z01-01-1 – Declaration of Conformity KX460023 – RMA – Decontamination Statement Bühler Technologies GmbH BE460035 ◦ 04/2021... - Page 28 RMA-Formular und Erklärung über Dekontaminierung RMA-Form and explanation for decontamination RMA-Nr./ RMA-No. Die RMA-Nummer bekommen Sie von Ihrem Ansprechpartner im Vertrieb oder Service./ You may obtain the RMA number from your sales or service representative. Zu diesem Rücksendeschein gehört eine Dekontaminierungserklärung. Die gesetzlichen Vorschriften schreiben vor, dass Sie uns diese Dekontaminierungserklärung ausgefüllt und unterschrieben zurücksenden müssen.

- Page 29 Dekontaminierungserklärung DE000011 Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen 01/2019 Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20 E-Mail: service@buehler-technologies.com Internet: www.buehler-technologies.com...

Need help?

Do you have a question about the GAS 222.20 Denox and is the answer not in the manual?

Questions and answers