Table of Contents

Advertisement

Quick Links

4

18/02/19

3

18/04/16

2

31/07/12

1

25/06/10

0

05/05/99

Rev.

Date

HLAS – Single acting hydraulic linear actuator

Use and maintenance manual

SINGLE ACTING SPRING-

RETURN HYDRAULIC

LINEAR ACTUATOR

Use and maintenance manual

Updated data-plate

Updated applicable

regulation (chapter 1.1.1)

General update

General update

Document release

Description

© Copyright by BIFFI Italia. All right reserved.

Contents may change without notice

HLAS

MAN 620

Sassi

Ermanni

Ermanni

Ermanni

Lazzarini

Prepared

Orefici

Vigliano

Orefici

Vigliano

Stoto

Vigliano

Stoto

Vigliano

Aliani

Ziveri

Checked

Approved

Pag. 1

Advertisement

Table of Contents

Summary of Contents for BIFFI HLAS

- Page 1 HLAS – Single acting hydraulic linear actuator Use and maintenance manual HLAS SINGLE ACTING SPRING- RETURN HYDRAULIC LINEAR ACTUATOR MAN 620 Use and maintenance manual Sassi Orefici Vigliano 18/02/19 Updated data-plate Updated applicable Ermanni Orefici Vigliano 18/04/16 regulation (chapter 1.1.1)

-

Page 2: Table Of Contents

HLAS – Single acting hydraulic linear actuator Use and maintenance manual TABLE OF CONTENTS 1 General warnings ..............4 1.1 Generalities ................. 4 1.1.1 Applicable regulation ............... 4 1.1.2 Terms and conditions .............. 4 1.2 Identification plate ............... 5 1.3 introducing the actuator ............... 5 1.4 data sheet ................... - Page 3 The information contained is of exclusive reserved ownership of BIFFI Italia S.r.l and may be modified without prior notice. All rights reserved. © Copyright by BIFFI Italia. All right reserved.

-

Page 4: General Warnings

2014/34/EU: Directive and safety instructions for use in hazardous area 1.1.2 Terms and conditions Biffi Italia srl guarantees that all the items produced are free of defects in workmanship and manufacturing materials and meet relevant current specifications, provided they are installed, used and serviced according to the instructions contained in the present manual. -

Page 5: Identification Plate

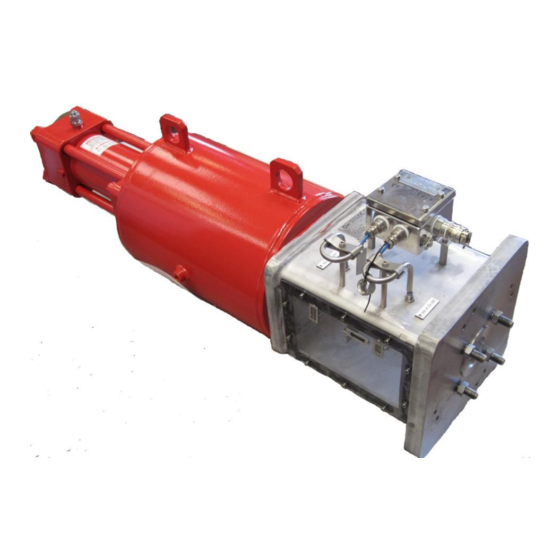

(Figure1). Figure 1 – Data plate INTRODUCING THE ACTUATOR HLAS single acting hydraulic linear actuators, are suitable for the operation of linear valves ( wedge gate valves, through conduit gate valves) for ON-OFF and modulating heavy-duty service. The actuator is made up of an hydraulic cylinder, a spring cartridge and a mounting pedestal complete with a joint for the coupling to the valve stem of actuator output stem. - Page 6 The actuator pedestal has a flange with threaded holes to fix the actuator to the valve. BIFFI can supply different types of control system following Customer’s requirements. The expected lifetime of actuator is approximately 25 years .

-

Page 7: Data Sheet

The actuator should be handled with appropriate lifting means. The weight of the actuator is reported on the delivery bill. Picture 1 – Lifting points for HLAS actuators © Copyright by BIFFI Italia. All right reserved. Pag. 7 Contents may change without notice... - Page 8 HLAS – Single acting hydraulic linear actuator Use and maintenance manual 1 = Lifting points ( obligatory ) Picture 2 - Positioning by chains 2 = don’t lay the actuator on tie-rods of 1 = point of support - 3 = don’t lay the actuator on accessories ( manual cylinder hand-pump, hydraulic control system etc.

-

Page 9: Storage

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 2.3 STORAGE If the actuator needs storage, before installation follow these steps: Place it on a wood surface in order not to deteriorate the area of ❑ valve coupling. - Page 10 HLAS – Single acting hydraulic linear actuator Use and maintenance manual Check that the assembly position, as shown on the documentation, complies with system’s geometry. Check the consistency of the parts of actuator-valve coupling. A) TO ASSEMBLE THE ACTUATOR ONTO THE VALVE BY BRACKET...

- Page 11 HLAS – Single acting hydraulic linear actuator Use and maintenance manual 3) . Screw the actuator coupling joint onto the valve by rotating the actuator, or screw down the valve stem stroke-ring with Red Loctite 542 and fix the half-bearings. When the threaded holes of the actuator flange are in correspondence with the holes on the valve flange screw the proper stud bolts.

- Page 12 HLAS – Single acting hydraulic linear actuator Use and maintenance manual 3) -Disassemble the two halves of actuator pedestal shell joint (item 8) by unscrewing the retaining screws (item 4 ),therefore disassemble the valve stem joint (item 7). 4) -Lift the actuator by utilizing the proper lifting eyelets, and unscrew the nuts and the stud bolts from the actuator pedestal.

-

Page 13: Hydraulic Connections

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 2.5 HYDRAULIC CONNECTIONS Check that the values of hydraulic supply available are compatible with those reported on the identification plate of the actuator. The connections should be made by qualified staff. -

Page 14: Commissioning

HLAS – Single acting hydraulic linear actuator Use and maintenance manual COMMISSIONING Installation, commissioning and maintenance and repair works should be made by qualified staff. Upon actuator commissioning please carry out the following checks: Check that paint is not be damaged during transport, if necessary ❑... -

Page 15: Operation And Use

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 3 Operation and use OPERATION DESCRIPTION The supply fluid pressurizes the hydraulic-cylinder chamber relevant to the operation to carry out (opening or closing) (see following pages). This pressure starts the linear motion of the piston and the consequent motion of the valve stem that is coupled. -

Page 16: Residual Risks

The HLAS actuators can have an emergency manual override in addition to the local and/or remote control system which controls the oil supplied by a power pack for the “normal” actuator operation. The emergency manual override mounted on the actuator, consists of an hydraulic manual override and a hydraulic manual selector to choose the actuator “Normal operation”, with oil supply from a power... - Page 17 HLAS – Single acting hydraulic linear actuator Use and maintenance manual © Copyright by BIFFI Italia. All right reserved. Pag. 17 Contents may change without notice...

-

Page 18: Calibration Of The Linear Stroke

HLAS – Single acting hydraulic linear actuator Use and maintenance manual CALIBRATION OF THE ANGULAR STROKE It is important that the mechanical stops of the actuator (and not those of the valve) stop the linear stroke at both extreme valve position (fully open and fully closed), except when this is required by the valve operation). - Page 19 HLAS – Single acting hydraulic linear actuator Use and maintenance manual HYDRAULIC WRENCH WRENCH WRENCH CYLINDER SIZE (mm) (mm) (mm) Figure 6 – Mechanical stop of the cylinder For high pressure cylinder models, the mechanical stop is internal (without protection cover) proceed at the same way : (1) remove the plug and (2) operate the adjusting screw ©...

-

Page 20: Calibration Of Microswitches (If Foreseen)

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 3.5 CALIBRATION OF MICROSWITCHES (BIFFI LIMIT SWITCH BOX ONLY) Operate only the micro-switch corresponding to the direction of operation being carried out, as clearly reported on the micro-switch. If different micro-switches assembly or limit switch box is supplied, please refer to the specific documentation. - Page 21 HLAS – Single acting hydraulic linear actuator Use and maintenance manual If the index (Picture 9), does not signal the proper position of the valve but is turned by 90°: Remove the roll pin placed on the position indicator (index).

-

Page 22: Calibration Of The Operation Time

For actuator models with control system it’s possible regulate the speed of actuator operations. The calibration of the operation time is made by Biffi Italia S.r.L according to customer requirements and to technical data-sheet included in technical documentation. If necessary it’s possible to modify or reset the operating time through... -

Page 23: Operational Tests And Inspections

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 4 Operational tests and inspections Important: To ensure the guaranteed SIL grade, according to IEC 61508, the functionality of actuator must be checked with regular intervals of time, as described in the Safety Manual ©... -

Page 24: Maintenance

Installation, commissioning and maintenance and repair works should be carried out by qualified staff. PERIODIC MAINTENANCE HLAS actuators are designed to operate long-term in heavy-duty operating conditions, without maintenance needs. Periodicity regularity... -

Page 25: Check And Restore Oil Level In The Manual Hand-Pump

HLAS – Single acting hydraulic linear actuator Use and maintenance manual solvent and blow through with oil. If the filter is made of cellulose, it must be replaced when clogged. Picture 11 – Level measuring stick 5.1.1 Check and restore oil level in the hydraulic manual handpump ( refer to chapt. - Page 26 The cleanliness level for actuator without control-system is NAS 8 minimum. For actuator with control system the cleanliness level is that required by singles components, in any case Biffi Italia S.r.L respect the customer requirements to scope of supply, for applicable cleanliness level, refer to document:...

-

Page 27: Extraordinary Maintenance

Anyway contact BIFFI ITALIA customer care. 5.2.1 Lubrication of mechanism For normal duty the HLAS actuator is lubricated "for life". In case of high load and high and high frequency of operation it may be necessary to periodically restore the lubrication: it is advisable to apply a generous coating of grease on the contact surfaces of moving parts. - Page 28 HLAS – Single acting hydraulic linear actuator Use and maintenance manual AGIP MU/EP/2 AEROSHELL GREASE equivalent To be used in standard temperature To be used in low temperature conditions (-30°C/+85°C) conditions (-60°C/+65°C) NLGI consistency: 2 Worked penetration: 280 dmm Colour: Buff ASTM Dropping Point: 185°C...

- Page 29 HLAS – Single acting hydraulic linear actuator Use and maintenance manual 2) Measure the distance of the stop screw (10) with reference to the end flange surface (12), so as to be able to easily restore the setting of the actuator mechanical stop, once the maintenance procedures have been completed.

- Page 30 HLAS – Single acting hydraulic linear actuator Use and maintenance manual 1) Remove the existing Teflon seal ring (8) with its O-ring from their groove. 2) Clean the groove carefully and lubricate it with a protective oil or grease film.

- Page 31 HLAS – Single acting hydraulic linear actuator Use and maintenance manual SINGLE ACTING-SPRING RETURN HYDRAULIC LINEAR ACTUATOR - SECTIONAL DRAWING © Copyright by BIFFI Italia. All right reserved. Pag. 31 Contents may change without notice...

-

Page 32: Dismantling And Demolition

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 5.3 DISMANTLING AND DEMOLITION Before starting the disassembly a large area should be created around the actuator so to allow any kind of movement without problems of further risks created by work-site. -

Page 33: Troubleshooting

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 6 Troubleshooting FAILURE OR BREAKDOWN RESEARCH Event Possible cause Remedy Actuator does not work Lack of hydraulic Open line stop valve supply Blocked valve Repair or replace Wrong position of the... -

Page 34: Layouts

Use and maintenance manual 7 Layouts SPARE PARTS ORDER For spare parts order to the relevant BIFFI office please make reference to BIFFI order confirmation concerning all the supply, and serial number of the actuator (Sect. 1.2) for any specific spare part for a specific actuator model. -

Page 35: Parts-List For Maintenance And Replacing Procedure

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 7.2 PARTS-LIST FOR MAINTENANCE AND REPLACING PROCEDURE Table 1: Pedestal with coupling joint © Copyright by BIFFI Italia. All right reserved. Pag. 35 Contents may change without notice... - Page 36 HLAS – Single acting hydraulic linear actuator Use and maintenance manual Table 2: Spring cartridge © Copyright by BIFFI Italia. All right reserved. Pag. 36 Contents may change without notice...

- Page 37 HLAS – Single acting hydraulic linear actuator Use and maintenance manual Table 3: hydraulic cylinder © Copyright by BIFFI Italia. All right reserved. Pag. 37 Contents may change without notice...

- Page 38 HLAS – Single acting hydraulic linear actuator Use and maintenance manual Table 4: Hydraulic control unit MHP © Copyright by BIFFI Italia. All right reserved. Pag. 38 Contents may change without notice...

- Page 39 HLAS – Single acting hydraulic linear actuator Use and maintenance manual © Copyright by BIFFI Italia. All right reserved. Pag. 39 Contents may change without notice...

- Page 40 HLAS – Single acting hydraulic linear actuator Use and maintenance manual © Copyright by BIFFI Italia. All right reserved. Pag. 40 Contents may change without notice...

-

Page 41: Date Report For Maintenance Operations

HLAS – Single acting hydraulic linear actuator Use and maintenance manual 8 Date report for maintenance operations Last maintenance operation date : ( in factory, on delivery ): ….. ……… exec. by : ………… ……… exec. by : ………… ……… exec. by : …………...

Need help?

Do you have a question about the HLAS and is the answer not in the manual?

Questions and answers