Table of Contents

Advertisement

Quick Links

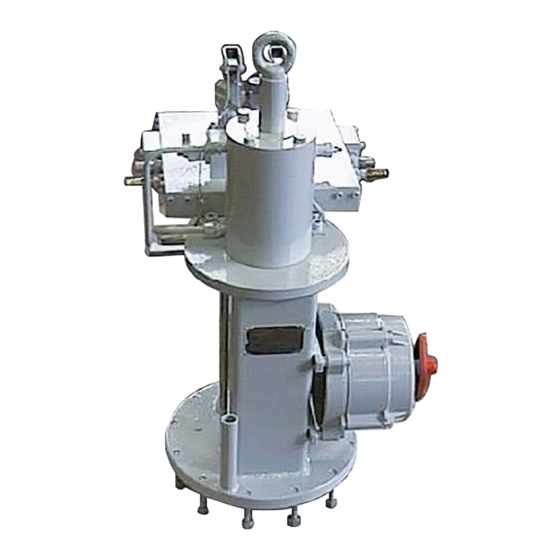

Biffi HLRA

Hydraulic Double-Acting Linear Actuator

Copyright © Biffi. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.biffi.it or from your nearest Biffi

Center: Biffi Italia s.r.l. - Strada Biffi 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – biffi_italia@biffi.it

Installation, Operation and Maintenance Manual

MAN 627 Rev. 0

September 2023

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for BIFFI HLRA

- Page 1 Hydraulic Double-Acting Linear Actuator Copyright © Biffi. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.biffi.it or from your nearest Biffi Center: Biffi Italia s.r.l. - Strada Biffi 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – biffi_italia@biffi.it...

- Page 2 Installation, Operation and Maintenance Manual Notes MAN 627 Rev. 0 September 2023 This page intentionally left blank.

-

Page 3: Table Of Contents

Installation, Operation and Maintenance Manual Table of Contents MAN 627 Rev. 0 September 2023 Table of Contents Section 1: General Warnings Generalities ......................1 1.1.1 Electrostatic Charge ...................1 1.1.2 Noise Emission ....................1 Identification Plate ....................1 Description of the Actuator ..................2 Section 2: Installation Checks upon Actuator Receipt ................3 Actuator Handling ....................3 Storage ........................4... - Page 4 Installation, Operation and Maintenance Manual Notes MAN 627 Rev. 0 September 2023 This page intentionally left blank.

-

Page 5: Section 1: General Warnings

1.1.2 Noise Emission The verification of the noise of the actuated valve is at valve maker care. Biffi points out that the actuator's noise can be considered negligible since it is an equipment for regular on-off or intermittent use. -

Page 6: Description Of The Actuator

Description of the Actuator The line of Double-Acting Hydraulic Linear Actuators, has been designed and produced by Biffi mainly to satisfy specific needs present on plants. For the above reason, the Biffi production of the above linear actuators, even based on a fixed criteria of design, is normally done job by job to adapt the actuator to the different parameters and thrust/stroke of valves. -

Page 7: Section 2: Installation

Installation, Operation and Maintenance Manual Section 2: Installation MAN 627 Rev. 0 September 2023 Section 2: Installation Checks upon Actuator Receipt Checks to be carried out on receiving the actuator: If the actuator arrived already assembled onto the valve, the settings of the mechanical stops and of the microswitches (if existing) has already been made by the person who assembled the actuator onto the valve. -

Page 8: Storage

Section 2: Installation Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Storage The actuators leave the factory in excellent working conditions and with an excellent finish (these conditions are guaranteed by an individual inspection certificate); in order to maintain these characteristics until the actuator is installed on the plant, it is necessary to observe a few rules and take appropriate measures during the storage period. -

Page 9: Hydraulic Connections

Installation, Operation and Maintenance Manual Section 2: Installation MAN 627 Rev. 0 September 2023 Table 1. Thread Size Recommended Tightening Torque (Nm) 1100 1400 1700 Hydraulic Connections WARNING Check that the values of hydraulic supply available are compatible with those reported on the identification plate of the actuator. -

Page 10: Electrical Connections (If Any)

Section 2: Installation Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Electrical Connections (if Any) WARNING Use components appropriate as for type, material and dimensions. The connections should be made by qualified staff. Before carrying out any operation, cut line power off. Safety provisions as per CEI 64-8 regulation should be complied with (same as IEC 60364). -

Page 11: Section 3: Operation And Use

Installation, Operation and Maintenance Manual Section 3: Operation and Use MAN 627 Rev. 0 September 2023 Section 3: Operation and Use Setting of the Linear Stroke The setting of the open valve position is performed by adjusting the travel stop screw that is screwed into the end flange of the hydraulic cylinder. -

Page 12: Preparation For Start-Up

Section 3: Operation and Use Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Preparation for Start-Up Refer to Section 2. Start-Up and Commissioning WARNING Installation, commissioning and maintenance and repair works should be made by qualified staff. Upon actuator commissioning, please carry out the following checks: •... -

Page 13: Operation Description

Installation, Operation and Maintenance Manual Section 3: Operation and Use MAN 627 Rev. 0 September 2023 Operation Description The supply fluid pressurizes the hydraulic cylinder chamber relevant to the operation to carry out (opening or closing) (see following pages). This pressure starts the linear motion of the piston and the consequent motion of the valve stem that is coupled. -

Page 14: Section 4: Operational Tests And Inspections

Section 4: Operational Tests and Inspections Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Section 4: Operational Tests and Inspections NOTICE To ensure the guaranteed SIL grade, according to IEC 61508, the functionality of actuator must be checked with regular intervals of time, as described in the Safety Manual. -

Page 15: Section 5: Maintenance

Anyway every 2 years of operation, the following is recommended: HLRA actuators have been designed to work for long periods in the severest conditions with no need for maintenance. Check if the actuator operates the valve correctly and with the required operating times. -

Page 16: Special Maintenance

Section 5: Maintenance Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Special Maintenance If there are leaks in the hydraulic cylinder or a malfunction in the mechanical components, or in case of scheduled preventive maintenance, the actuator must be disassembled and seals must be replaced with reference to the attached sectional drawing and adopting the following procedures. - Page 17 Installation, Operation and Maintenance Manual Section 5: Maintenance MAN 627 Rev. 0 September 2023 To replace the piston rod seal rings (3) proceed as follows: Remove the existing Teflon seal ring (3) with its O-ring from their groove. Clean the groove carefully and lubricate it with a protective oil or grease film. Assemble the new O-ring into its groove and lubricate it with a protective oil or grease film.

-

Page 18: Reassembly

Section 5: Maintenance Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 5.2.3 Reassembly Assemble the head flange (1), on pedestal (15). Lubricate the piston rod (19) surface, with a protective oil or grease film and introduce it into the head flange hole, taking care not to damage the piston seal ring (3). - Page 19 Installation, Operation and Maintenance Manual Section 5: Maintenance MAN 627 Rev. 0 September 2023 Figure 4. HLRA Double-Acting Hydraulic Linear Actuator Maintenance...

- Page 20 Section 5: Maintenance Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Table 3. Parts List Item Description Material Cylinder lower flange Carbon steel ASTM A 283 Gr. D Scraper ring * Teflon + nitrile rubber Piston rod seal ring * Teflon + nitrile rubber Back-up ring * Nitrile rubber...

-

Page 21: Extraordinary Maintenance

For this operation, it is necessary to disassemble the closing plates (if present) from pedestal with coupling joint. The following grease is used by Biffi for standard working temperature and suggested for re-lubrication: Table 4. -

Page 22: Dismantling And Demolition

Section 5: Maintenance Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Dismantling and Demolition Before starting the disassembly, a large area should be created around the actuator so as to allow any kind of movement without problems of further risks created by work site. -

Page 23: Section 6: Troubleshooting

Repair or replace Wrong position of the distributor of the hydraulic Restore correct position Actuator does not work manual override Call Biffi Italia s.r.l. Failure of the control system Customer Service Clean or replace Clogged filter the cartridge Restore the correct... -

Page 24: Section 7: Layouts

Section 7: Layouts Spare Parts Order For spare parts order to the relevant Biffi office, please make reference to Biffi order confirmation concerning all the supply and serial number of the actuator (Section 1.2) for any specific spare part for a specific actuator model. -

Page 25: Parts List For Maintenance And Replacing Procedure

Installation, Operation and Maintenance Manual Section 7: Layouts MAN 627 Rev. 0 September 2023 Parts List for Maintenance and Replacing Procedure Figure 5. HLRA Double-Acting Hydraulic Linear Actuator Layouts... - Page 26 Section 7: Layouts Installation, Operation and Maintenance Manual September 2023 MAN 627 Rev. 0 Table 6. Parts List Item Description Material Cylinder lower flange Carbon steel ASTM A 283 Gr. D Scraper ring * Teflon + nitrile rubber Piston rod seal ring * Teflon + nitrile rubber Back-up ring * Nitrile rubber...

-

Page 27: Section 8: Date Report For Maintenance Operations

Installation, Operation and Maintenance Manual Section 8: Date Report Maintenance Operations MAN 627 Rev. 0 September 2023 Section 8: Date Report for Maintenance Operations Last maintenance operation date: (in factory, on delivery ): ……… exec. by : ………… ……… exec. by : ………… ………... - Page 28 Biffi Italia s.r.l. FCIM-20058-EN © 2023 Biffi. All rights reserved. Strada Biffi 165 29017 Fiorenzuola d’Arda The contents of this publication are presented for information purposes (PC) only, and while every effort has been made to ensure their accuracy, they...

Need help?

Do you have a question about the HLRA and is the answer not in the manual?

Questions and answers