Table of Contents

Advertisement

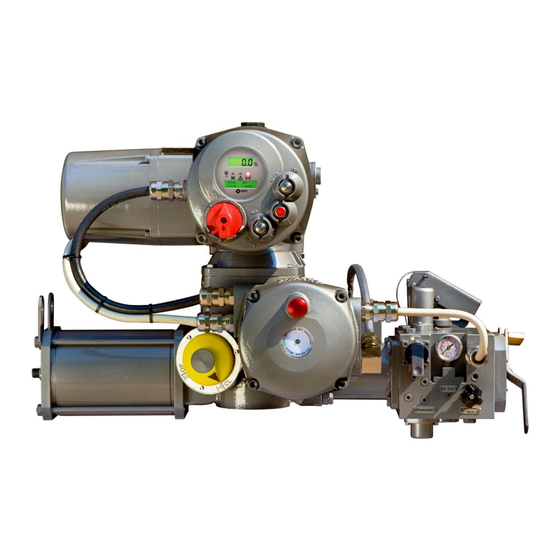

Biffi Fail SaFe electric actuatorS, model eFS2000v4

InstructIon and operatIng Manual

iNDEX

1. General safety instructions........................... 1

2. machine description ...................................... 3

3. Storage and pre-installation ........................ 4

5. adjustment of angular stroke ...................... 6

6. installation ..................................................... 7

7. eFS operation ................................................ 9

8. actuator operation ...................................... 13

9. optional modules ........................................ 16

10. local controls .............................................. 20

11. Set-up menu ................................................ 26

12. view menu ................................................... 27

13. Set-up routines ............................................ 31

14. view routines ............................................... 47

15. local indicator setting ................................ 57

speed setting ............................................... 58

17. maintenance and trouble-shooting ............ 61

18. exploded view and parts list ....................... 67

19. lubrication ................................................... 70

20. operational tests and inspections.............. 70

21. disassembling and demolition ................... 70

1 GENEral safEty iNstructioNs

1.1 Manufacturer

the manufacturer with respect to the

machinery directive 2006/42/ec is Biffi italia,

as specified on the machinery label.

1.2 Device intended use

the devices to which this instruction and

operating manual applies are the eFS2000v4

Fail Safe electric actuators, which are designed

to operate any kind of quarter-turn industrial

valves for use in emergency Shut down (eSd)

applications in heavy industrial, chemical,

petrochemical, food, water and power

generating plants.

www.biffi.it

Biffi italia will not be liable for any possible

damage or physical injury resulting from use

in other than the designated application or

by lack of care during installation, operation,

adjustment and maintenance of the machinery.

Such risks lie entirely with the user.

depending on the specific working conditions,

additional precautions may be required.

the eFS2000v4 is produced by Biffi italia and

identified on the proper label by the product

designation: eFS xxx/yyyy-zz

WarNiNG!

It is assumed that the installation, configuration,

commissioning, maintenance and repair works

are carried out by qualified personnel and

checked by responsible specialists.

iMportaNt

This manual gives basic information for

EFS2000v4 configuration; more detailed

information for configuration and control of the

electric actuator part ICON2000 are included

on the VCIOM-01232 which form part of the

mandatory instructions documentation.

the eFS2000v4 is designed in accordance

with the applicable international rules and

specifications but in any case the following

regulation must be observed:

• the general installation and safety

regulations.

• the plant specific regulations and

requirements.

• the proper use of personal protective devices

(glasses, clothing, gloves).

• the proper use of tools, lifting and transport

equipment.

1.3 terms and conditions

the manufacturer guarantees each single

product to be free from defects and to

conform with current goods specifications and

regulations as applicable. the warranty period

is 12 months from the date of installation by

the first user or 18 months from the date of

shipment to the first user, whichever occurs

first. No warranty is given for products, which

have been subject to damages or corrosion due

to the improper storage, improper installation,

copyright © Biffi. all rights reserved.

misuse, or which have been modified or

repaired by unauthorized personnel.

repair work due to improper use will be

charged at standard rates.

1.4 Manufacturer's liability

the manufacturer declines all liability in the

event of:

• use of the device in contravention of local

safety at work legislation.

• incorrect installation, disregard or incorrect

application of the instructions provided on the

product nameplate and in this instruction and

operating manual.

• modification of the product without the

manufacturer's authorization.

• Work done on the product by unqualified or

unsuitable personnel.

reference code: maN_681

VcioM-02511-EN 17/12

Advertisement

Table of Contents

Summary of Contents for BIFFI EFS2000v4

-

Page 1: Table Of Contents

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual Biffi italia will not be liable for any possible misuse, or which have been modified or damage or physical injury resulting from use repaired by unauthorized personnel. repair work due to improper use will be... - Page 2 WarNiNG! preventing the risk of explosion in the presence In case the EFS2000v4 is to be installed in a of gas or ignitable dusts. eFS 2000v4 have iP66/68 degree of protection hazardous area, as defined by the applicable rules, it is mandatory to check if the nameplates according to eN/iec 60529.

- Page 3 (electric Fail Safe) is an electric Note: in order to avoid misunderstanding, in quarter turn spring return actuator which has • a local control and configuration panel, which is used to configure the parameters and to the purpose to move the valve in a "fail safe"...

-

Page 4: Storage And Pre-Installation

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual input shaft of the epicyclical gearing reduction • check that the model, the serial number is connected the multi-turn actuator output of the actuator and the performance data shaft; output shaft of the epicyclical gearing... - Page 5 4.1 actuator supplied with insert already is possible. machined • assemble the insert into the eFS2000v4 as to assemble the actuator onto the valve shown in the following pictures (the engraving proceed as follows: realized on the insert has to correspond to •...

-

Page 6: Adjustment Of Angular Stroke

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 5 aDjustMENt of aNGular strokE • tighten the lock nut. • if the actuator angular stroke is stopped it is important that the mechanical stops of the beyond the end position (fully open or closed),... -

Page 7: Installation

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 6 iNstallatioN For electrical connections use components (cable glands, cables, hoses, conduits) which 6.1 Working condition meet the requirements and the applicable the standard eFS2000v4 are suitable for the... - Page 8 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 6.4.1 Entries on the manually operated electrical Procedure to be followed: switch enclosure • do not damage the explosion-proof mating surfaces on the housing and on the electrical enclosure covers.

-

Page 9: Efs Operation

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 7 Efs opEratioN do not operate the actuator without first checking that the configuration is according 7.1 operating the Efs 2000v4 for the first time to the required application by using the “vieW Before connecting electrical power to the and Set-uP”... - Page 10 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 7.2 EsD clutch status the condition eFS action in progress can be a red/green led on the clutch enclosure configured to switch-over the monitor relay indicates the status of the eSd electrical clutch...

- Page 11 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual Hand pump 7.5 Manual override operation the following parameters are available in the vieW and SetuP menu, actuator SetuP, the auto/maNual selector allows selecting between maNual and auto mode.

- Page 12 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 7.6.1 Command to initiate PST cycle 7.6.4 PST curves and PST baseline during the PSt cycle the time corresponding to the PSt cycle is initiated only if the actuator is in the correct end of travel (fully open with any 1% of valve position variation is memorized.

-

Page 13: Actuator Operation

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 7.8 Efs local report 8 actuator opEratioN By the vieW and SetuP menu of the local 8.1 actuator local controls operator interface, the status of the eFS module can be viewed (see chapter ‘local For eFS "standard"... - Page 14 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 8.3 locking the 3-position selector two wires (see the remote connections diagram shown). the 3-position selector can be locked in any of its three positions by means of a padlock.

- Page 15 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual pst (iNt/EXt powered) 8.4.2 Output contacts the PSt/eFS input is opto-coupled. the circuits Standard version: associated to the input can be supplied by the • monitor relay: on the terminal board, a single...

-

Page 16: Optional Modules

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 9 optioNal MoDulEs 9.2 aiN/aout card the behavior in case of loss of main voltage With the above card the icoN2000 is provided is different if the power supply of the 4-20 ma... - Page 17 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 9.2.2 The 4-20 mA analog input the “vieW and Set-uP” features can configure the 4-20 ma analog input is the position different options which are described in chapter request r% signal and is used by the icoN2000 ‘Set-up routines’, paragraph ‘Positioner’.

- Page 18 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 9.4 Base card of Efs 2000v4 the following figures show the ‘base card’ of cards of eFS 2000 and its different option cards. Base card of the eFS 2000v4...

- Page 19 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual the type of card depends on the fieldbus available in the plant. top view of base card equipped with Fieldbus interface Bluetooth™ card potentiometer /4-20 ma position card Potentiometer /4-20 ma card: with this card properly set trough the vieW and Set-uP menu,...

-

Page 20: Local Controls

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 10 local coNtrols local controls: oPeN/YeS, cloSe/No, and - time - Fdi report* StoP push buttons. - date - Base report 10.1 Description of the local operator the StoP push button resets any existing... - Page 21 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 10.3 Description of variables and reports ☐ torque: output torque in % of the nominal torque stated in the NamePlate menu ☐ motor speed: rPm of electrical motor ☐ main voltage: voltage (v) and frequency (Hz) of mains ☐...

- Page 22 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual local remote = oPeN/YeS push button = cloSe/No push button = StoP push button alphanumeric display Press only oPeN, cloSe YeS and StoP and StoP controls simultaneously to enter...

-

Page 23: Setup Menu

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 10.4 configuration options 10.4.1 Actuator set-up this menu includes the routines that allow the eFS2000 actuator can be totally configured from the local interface by means of a series... - Page 24 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 10.4.4 Maintenance if the option ‘Selector in oFF: disabled’ is this menu includes all diagnostic and historic configured, move the selector to oFF and then data which can help the operator in case of...

- Page 25 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 10.4.6 Entering the set-up mode all settings are automatically saved to a non-volatile memory and retained also if the to change the existing configuration or to set the stroke limits, it is necessary to enter the electrical power is removed from the actuator.

- Page 26 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual From eXit ? Yes Stop display to view menu local remote Press No until the desired language appears and then press YeS 3-position selector to setup menu From eXit ?

-

Page 27: View Menu

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual Set password Stroke limits tagname routine From enter password routine routine routine routine routine routine xxxxxxx xxxxxxx xxxxxxx Set eSd miscella- Flange type reference neous routine routine 12 ViEW MENu the below figure shows the procedure to move in the view routine . - Page 28 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual to exit? alarm log Serial Stroke limit tagname From language number routine routine routine routine selection routine routine routine routine xxxxxxx xxxxxxx xxxxxxx xxxxxxx revision miscellaneous Flange type data logger...

-

Page 29: Set-Up Routines

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13 sEt-up routiNEs close limit by torque move the local selector to local. the local 13.1 actuator set-up controls can be used. 13.1.1 Set stroke limits Press the cloSe control. the actuator moves... - Page 30 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13.1.2 Torque set-up • Period: time interval between PSt, in days from 1 to 1000, in PSt auto mode. the output torque limits to close or to open may be configured between 40% and 100% •...

- Page 31 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual pst set-up By selecting the option ‘off’, the remote controls are disabled. • Press YeS if the parameter ‘PSt mode’ is correct, press No to scroll through the list of configuration should be done during actuator set-up.

- Page 32 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual control mode the monitor relay is normally energized and Press YeS if the display shows the correct will be de-energized on: control mode or press No to scroll through the •...

- Page 33 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual the contacts may be configured to make or • configuration error • local/off selected break on condition. • HW error configuration procedure • local stop pressed • move the local selector to oFF and then •...

- Page 34 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13.1.7 Positioner the following examples will clarify the above the positioning function is only available in option: example a): modulating eFS2000v4 actuators and allows with input signal = 4 ma, the to position the valve according to a ‘position...

- Page 35 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual Position request % Position request % configured values: configured values: % min = 0% % min = 25% % max = 100% % max = 75% Polarity: 4 ma = cl...

- Page 36 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual configuration procedure configuration procedure • Press YeS if the configured value of the • move the local selector to oFF and then delaY is correct (from 0 to 255 sec), or press •...

- Page 37 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual configuration procedure 13.1.10 Interlock • Press YeS if the position value where pulsing • move the local selector to oFF and then the interlock inputs can be used to inhibit the control stops is correct, press No to scroll actuator movement in open or close direction.

- Page 38 In the EFS it through the list of available routines and then must be always configured ‘CCW’. It is necessary press YeS to select miscellaneous. to call the Biffi service to modify the above parameter if factory setting routine is used.

- Page 39 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual actuator direction: closing actuator direction: opening closing torque % of nominal opening torque % of nominal Breakout limit Breakout limit ending limit ending limit running limit running limit Position %...

- Page 40 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual configuration procedure 13.1.13.5 Valve jammed (time) • move the local selector to oFF and then the valve jammed time is used to monitor the following situations: simultaneously press oPeN and StoP within 20 sec (see chapter ‘local controls, entering...

- Page 41 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13.3.1 Set password 13.3.3 Set torque reference the set torque profile reference routine the actuator is supplied with a default password (‘0 0 0 0’). according the above allows to transfer the last torque profile to the reference profile registers.

- Page 42 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13.3.5 Clear recent data log When the message displayed is ‘Set-uP the clear recent data log routine allows to mode oK?’ press YeS. Press No to scroll clear the counters of the recent operation log.

- Page 43 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual configuration procedure 13.3.9 PST commands(normal or baseline) the PSt cmd routine allows performing the • move the local selector to oFF and then simultaneously press oPeN and StoP within PSt cycle by the local operator interface of the actuator.

- Page 44 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13.3.11 Example of set-up routine: Torque set-up remote local 3-position selector display Yes Stop to set-up menu Select language to exit from vieW menu, press YeS or No simultaneously...

-

Page 45: View Routines

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 14 ViEW routiNEs 14.1 actuator set-up the above menu allows viewing the present actuator configuration. No change can be made to the present data. the following data can be viewed:... - Page 46 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual View procedure • Press YeS to answer the prompt ‘alarm log view?’. • move the local selector to oFF and then simultaneously press oPeN and StoP within • Press YeS to scroll through the list of alarms (‘alarms view?’).

- Page 47 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual the following data may be viewed: closing torque opening torque Breakout % Breakout % Breakout reference % Breakout reference % Peak run % Peak run % Peak run reference %...

- Page 48 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 1.1.1.1 reference latest torque curve View procedure the data are grouped into 2 families: general • move the local selector to oFF and then and recent data. the general data log collects simultaneously press oPeN and StoP within data from ‘test date’...

- Page 49 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual View procedure • opening time: this information is only • move the local selector to oFF and then available in the general data log. it is updated at the end of every full valve stroke of the simultaneously press oPeN and StoP within 20 sec (see chapter ‘local controls, entering...

- Page 50 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual View procedure • t-recorder mode: the icoN2000 measures • move the local selector to oFF and then and memorizes the following 3 data: simultaneously press oPeN and StoP within •...

- Page 51 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual torque limit in oP reached curve selector: -torque -motor temperature -main voltage the figure below shows a graph with sampling up to 5.000 cycles of full memory overwriting • Press YeS to view the mode, the SamPliNG are allowed, then the logger stops.

- Page 52 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 14.4.7 Example of view routine: Torque set-up local remote 3-position selector display Yes Stop to set-up menu Select language to exit from vieW menu, press YeS and No simultaneously or...

- Page 53 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 14.4.8 PST Graph the PSt curves cannot be viewed on the local operator interface of the eFS2000. they can only be viewed by a Pc or Pda connected by a Bluetooth interface and equipped with the a-manager ®...

- Page 54 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 14.4.9 ESD Graph the eSd curves cannot be viewed on the local operator interface of the eFS2000. they can only be viewed by a Pc or Pda connected by a Bluetooth interface and equipped with the a-manager ®...

-

Page 55: Local Indicator Setting

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 15 local iNDicator sEttiNG move the eFS2000v4 to the fully closed position 1. remove the black plug 2. unscrew the central screw 3. remove the indicator 4. unloose the counter nut 5. -

Page 56: Manual Operation And Failsafe Speed Setting

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 16 MaNual opEratioN aND failsafE spEED sEttiNG 16.1 hydraulic control group diagram automatic oPeratioN electric actuator electric supply drain/charge exhaust connection plug (plugged) maNual oPeratioN electric actuator electric supply... - Page 57 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual remove the cover adjust the fail safe speed iMportaNt 16.2 control group functions the eFS2000v4 is equipped with a hydraulic The failsafe time should not exceed the electric control group with two base functions: stroke time.

- Page 58 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual Hand pump High pressure manometer WarNiNG! • check that the needle valve (352) is Needle valve (352) For safety reasons it is required that at the end completely closed.

-

Page 59: Maintenance And Trouble-Shooting

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 17 MaiNtENaNcE aND trouBlE shootiNG 17.1 routine maintenance it is mandatory to check the actuator, with a WarNiNG! maximum interval of one year, as follows: The EFS2000v4 contains parts with springs, •... - Page 60 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 17.3 repairs original spare parts must be required to the When needed, repair must only be carried out manufacturer: to ensure that right spare is with manufacturer’s original spare parts.

- Page 61 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 17.5 trouble-shooting 17.5.4 The actuator does not work from remote if the actuator does not work before trouble- controls Power card shooting make sure that: - check that manual override selector is in •...

- Page 62 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 17.5.7 Excessive torque for valve operation 17.5.10 Diagnostic messages - clean, lubricate and check the valve stem. the alarm and warning lists contain the - valve packing too tight: loosen the gland bolt alarms and warnings momentarily present.

- Page 63 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 17.5.11 Alarm table available controls Display message condition for alarm action local remote alarm reset High torque in measured torque greater than the operate the actuator in opening only open...

- Page 64 Number indicates the module that is not working. the problem may be due to a malfunction of the module, to an incorrect wiring between modules, or to an incorrect configuration of the icoN2000. Please contact Biffi after sales service to solve the problem. the following hardware alarms can be detected: •...

-

Page 65: Exploded View And Parts List

Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 18 EXploDED ViEW aND parts list parts list item Quantity Description Material icon2000 electric actuator Spring cartridge electric actuator failsafe Spring to close hydraulic actuator Hydraulic control group ITEM Q.ty... - Page 66 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual parts list item Qnt Description Material item Qnt Description Material item Qnt Description Material insert carbon steel rock alloy steel Screw Stainless steel Screw Stainless steel Bush Steel-PtFe- Seal ring...

- Page 67 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual parts list ITEM Q.ty DESCRIPTION MATERIAL item Quantity Description Material Circlip Stainless steel circlip Stainless steel Q-Ring NBR Rubber o-ring NBr rubber NBR Rubber Q-Ring o-ring NBr rubber Aluminium...

- Page 68 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual parts list item Quantity Description Material Head spring flange carbon steel ITEM Q.ty DESCRIPTION MATERIAL Washer Head spring ange Carbon steel tie rod alloy steel Washer ------ Tie rod...

- Page 69 Biffi Fail SaFe electric actuatorS, model eFS2000v4 InstructIon and operatIng Manual 13-14 29-30 11-12 26-27 9-10 22-23 14-16 38-39 45-46 49-50 42-43 41-14 9-10 58-59 parts list item Qnt Description Material item Qnt Description Material item Qnt Description Material By pass flange...

-

Page 70: Lubrication

For standard applications please refer to paragraph 17.1. Biffi reserves the the right to change product designs and specifications without notice. Biffi italia s.r.l. località caselle San Pietro, 420, 29017 Fiorenzuola d’arda (Pc) italY Ph: +39 (0)523 944 411 e-mail: biffi_italia@biffi.it www.biffi.it...

Need help?

Do you have a question about the EFS2000v4 and is the answer not in the manual?

Questions and answers