Table of Contents

Summary of Contents for Amazone Cenius 4002-2T Super

- Page 1 Operating Manual Cenius 4002-2T Super / Special Mulch cultivator Read and observe this operating manual before using MG4717 the machine for the first time! BAG0100.2 04.13 Keep it in a safe place for Printed in Germany future use!

- Page 2 Reading the instruction manual and to adhere to it should not appear to be inconvenient and superfluous as it is not enough to hear from others and to realise that a machine is good, to buy it and to believe that now everything would work by itself.

- Page 3 + 49 (0) 5405 501-234 E-mail: amazone@amazone.de Spare part orders Spare parts lists are freely accessible in the spare parts portal at www.amazone.de. Please send orders to your AMAZONE dealer. Formalities of the operating manual Document number: MG4717 Compilation date: 04.13 ...

- Page 4 Send us your suggestions by fax. AMAZONEN-WERKE H. DREYER GmbH & Co. KG Postfach 51 D-49202 Hasbergen Phone: + 49 (0) 5405 50 1-0 Fax: + 49 (0) 5405 501-234 E-mail: amazone@amazone.de Cenius 4002-2T BAG0100.2 04.13...

-

Page 5: Table Of Contents

Table of Contents User information ..................8 Purpose of the document......................8 Locations in the operating manual...................8 Diagrams used .........................8 General safety instructions.................9 Obligations and liability ......................9 Representation of safety symbols..................11 Organisational measures .......................12 Safety and protection equipment ...................12 Informal safety measures.......................12 User training...........................13 Safety measures in normal operation ..................14 Dangers from residual energy....................14... - Page 6 Table of Contents Running gear......................... 51 Tensioned crosspiece ......................51 5.10 Stand ............................. 52 5.11 Feeler wheels (Option)......................52 5.12 Rear harrow (option) ......................53 5.13 GreenDrill catch crop sowing unit ..................54 5.14 Safety chain for implements without brake system............... 54 Commissioning ..................

- Page 7 Table of Contents 12.14 Hydraulic system (workshop work) ..................85 12.14.1 Labelling hydraulic hose lines ....................86 12.14.2 Maintenance intervals ......................86 12.14.3 Inspection criteria for hydraulic hose lines................86 12.14.4 Installation and removal of hydraulic hose lines ..............87 12.15 Lower link pins ........................87 Hydraulic circuit diagram................88 13.1 chassis / folding ........................88...

-

Page 8: User Information

User information User information The "User information" section supplies information on using the op- erating manual. Purpose of the document This operating manual Describes the operation and maintenance of the machine. Provides important information on safe and efficient handling of the machine. -

Page 9: General Safety Instructions

General safety instructions General safety instructions This section contains important information on safe operation of the machine. Obligations and liability Comply with the instructions in the operating manual Knowledge of the basic safety information and safety regulations is a basic requirement for safe handling and fault-free machine operation. Obligations of the operator The operator is obliged only to let those people work with/on the ma- chine who... - Page 10 General safety instructions Risks in handling the machine The machine has been constructed to the state-of-the art and the recognised rules of safety. However, there may be risks and restric- tions which occur when operating the machine For the health and safety of the user or third persons, ...

-

Page 11: Representation Of Safety Symbols

General safety instructions Representation of safety symbols Safety instructions are indicated by the triangular safety symbol and the highlighted signal word. The signal word (DANGER, WARNING, CAUTION) describes the gravity of the risk and has the following sig- nificance: DANGER Indicates an immediate high risk, which will result in death or serious physical injury (loss of body parts or long term damage) if not avoided. -

Page 12: Organisational Measures

General safety instructions Organisational measures The operator must provide the necessary personal protective equip- ment, such as: Protective goggles, Safety shoes, Protective overall, Skin protection cream, etc.. The instruction manual Must always be kept at the place at which the machine is operated. -

Page 13: User Training

General safety instructions User training Only trained and instructed persons should be allowed to work with/on the machine. The responsibilities of the operating and maintenance personnel must be clearly defined. People being trained may only work with/on the machine under the supervision of an experienced person. -

Page 14: Safety Measures In Normal Operation

General safety instructions Safety measures in normal operation Only operate the machine if all the safety and protection equipment is fully functional. Check the machine at least once a day for visible damage and check the function of the safety and protection equipment. Dangers from residual energy Note that there may be residual mechanical, hydraulic, pneumatic and electrical/electronic energy at the machine. -

Page 15: Spare And Wear Parts And Aids

Immediately replace any machine parts which are not in a perfect state. Use only genuine AMAZONE spare and wear parts or parts approved by AMAZONEN-WERKEN to ensure that the operating permit retains its validity in accordance with national and international regulations. If... -

Page 16: Warning Pictograms And Other Signs On The Machine

General safety instructions 2.13 Warning pictograms and other signs on the machine 2.13.1 Positioning of warning pictograms and other labels The following diagrams show the arrangement of the warning picto- grams on the machine. Fig. 1 Fig. 2 Cenius 4002-2T BAG0100.2 04.13... - Page 17 General safety instructions Fig. 3 Fig. 4 Always keep all the warning pictograms of the machine clean and in a legible state. Replace illegible warning pictograms. You can obtain the warning pictograms from your dealer using the order number (e.g. MD 078). Cenius 4002-2T BAG0100.2 04.13...

- Page 18 General safety instructions Warning pictograms - structure Warning pictograms indicate danger areas on the machine and warn of residual dangers. Permanent or unexpected dangers exist in these areas. A warning pictogram consists of two fields: Field 1 is a pictogram describing the danger, surrounded by triangular safety symbol.

- Page 19 General safety instructions Order number and explanation Warning pictograms MD 078 Risk of crushing of fingers/hand by accessi- ble, moving parts of the machine! This danger can cause extremely serious injuries resulting in the loss of limbs. Never reach into the danger area when the trac- tor engine is running with the PTO shaft or hy- draulic/electrical system connected.

- Page 20 General safety instructions MD 082 Danger of falling from treads and platforms when riding on the machine. This danger causes serious or potentially fatal injuries anywhere on the body. It is forbidden to ride on the machine and/or climb the machine while it is running. This also applies to machines with treads or platforms.

- Page 21 General safety instructions MD 096 Risk of hydraulic fluid escaping under pres- sure from leaking hydraulic lines! This can inflict serious injuries with potentially fatal consequences if hydraulic fluid escaping at high pressure passes through the skin and into the body. ...

- Page 22 General safety instructions MD 115 The maximum operating pressure of the hydrau- lic system is 200 bar. MD 154 Danger of cutting or penetration for other road users caused by transport with un- guarded, sharp harrow tines of the seed har- row! This danger can cause extremely serious and potentially fatal injuries.

-

Page 23: Dangers Of Not Observing Safety Instructions

General safety instructions 2.14 Dangers of not observing safety instructions Nonobservance of the safety information Can pose both a danger to people and also to the environment and machine. Can lead to the loss of all warranty claims. Seen individually, non-compliance with the safety information could pose the following risks: ... -

Page 24: Safety Information For Users

General safety instructions 2.16 Safety information for users WARNING Before starting up the machine and the tractor, always check their traffic and operational safety. 2.16.1 General safety and accident prevention information Beside these instructions, comply with the general valid national safety and accident prevention regulations. - Page 25 General safety instructions Be particularly careful when coupling the machine to the tractor or uncoupling it from the tractor! There are contusion and cutting points in the area of the coupling point between the tractor and the machine. Standing between tractor and implement when the three point hydraulic is actuated is prohibited.

- Page 26 General safety instructions Machine transportation When using public highways, national road traffic regulations must be observed. Before moving off, check: the correct connection of the supply lines the lighting system for damage, function and cleanliness the brake and hydraulic system for visible damage ...

-

Page 27: Hydraulic System

Replace the hydraulic hose line if it is damaged or worn. Only use AMAZONE original hydraulic hose lines. The hydraulic hose lines should not be used for longer than six years, including any storage time of maximum two years. Even... -

Page 28: Electrical System

General safety instructions 2.16.3 Electrical system When working on the electrical system, always disconnect the battery (negative terminal). Only use the prescribed fuses. If fuses are used that are too highly rated, the electrical system will be destroyed – danger of fire! ... -

Page 29: Cleaning, Maintenance And Repairs

Spare parts must meet at least the specified technical require- ments of AMAZONEN-WERKE! This is ensured through the use of AMAZONE original spare parts! Cenius 4002-2T BAG0100.2 04.13... -

Page 30: Loading And Unloading

Loading and unloading Loading and unloading WARNING Risk of crushing due to accidental falling of a machine attached to a load carrier during loading and unloading! Use only slings (ropes, belts, chains, etc.) with a minimum ten- sile strength greater than the total weight of the machine (see Technical data). -

Page 31: Product Description

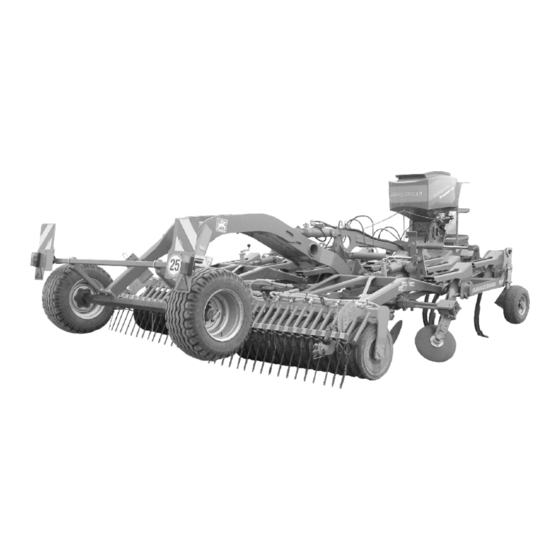

Product description Product description This section: Provides a comprehensive overview of the machine structure. Provides the names of the individual modules and controls. Read this section when actually at the machine. This helps you to understand the machine better. Overview of subassemblies Fig. -

Page 32: Safety And Protection Equipment

Product description Safety and protection equipment Fig. 7 Protective cover on both sides for the front and rear tine for road transport. (1) Tine covered. (2) Protective cover in parking position. Fig. 8 Automatic locking mechanism secures against the machine folding out uninten- tionally. -

Page 33: Transportation Equipment

Product description Transportation equipment Fig. 10 (1) Rear lights, brake lights and turn indicators, red rear reflectors (2) Warning signs (3) Red reflectors Fig. 11 (1) Front boundary lights (2) Front warning signs Two side reflectors each, left and right side (not illustrated). ... -

Page 34: Intended Use

Compliance with all the instructions in this operating manual. Execution of inspection and maintenance work. Exclusive use of AMAZONE original spare parts. Other uses to those specified above are forbidden and shall be con- sidered as improper. For any damage resulting from improper use: ... -

Page 35: Danger Area And Danger Points

Product description Danger area and danger points The danger area is the area around the machine in which people can be caught: By work movements made by the machine and its tools By materials or foreign objects ejected by the machine ... -

Page 36: Rating Plate And Ce Marking

Product description Rating plate and CE marking The type plate and CE signare located on the frame. The rating plate shows the following information: Vehicle- / machine ID no.: Type Basic weight kg Permissible support load kg ... -

Page 37: Technical Data

Product description Technical data Cenius Super / Special 4002-2T 4000 Working width [mm] 3000 Transport width [mm] 7700 Transport length [mm] 3250 Transport height [mm] Permissible max. transport [km/h] speed Tine spacing [mm] Number of tines Number of tine rows Maximum working depth [mm] Overload protection of the... - Page 38 Product description Weight (net weight) Super Special Cenius 4002-2T Basic machine 3530 3010 [kg] 6000 Permissible total weight [kg] 2700 Permissible drawbar load [kg] 3300 Permissible axle load [kg] Equipment Concave discs [kg] Spring tines [kg] Tandem roller [kg] Wedge ring roller [kg] Tooth packer roller [kg]...

-

Page 39: Necessary Tractor Equipment

Product description Necessary tractor equipment For the machine to be operated as intended, the tractor must fulfil the following requirements: Tractor engine power from 120 kW (160 hp) Electrical system Battery voltage: 12 V (volts) Lighting socket: 7-pin Hydraulics Maximum operating pressure: ... -

Page 40: Structure And Function

Structure and function Structure and function The following section provides information on the machine structure and the functions of the individual components. Fig. 13 The Cenius Mulch cultivator is suitable for Stubble processing Non-tilling topsoil processing Seed bed preparation It consists of ... -

Page 41: Tines

Structure and function Tines Cenius Super: Tines with overload protection by two tension springs. The overload protection, which consists of two tension springs, allows the tines to give way if an overload situation occurs. Fig. 14 Cenius Special: Tines with over- load protection by shear bolt. -

Page 42: Coulter

Structure and function Coulter The tines can be fitted with various coulters: Stubble coulter: used to mix in volunteer grain and straw when processing flat stubble. Helix coulter: used for average soil depths; good mixing in of organic matter. ... -

Page 43: Coulter Arrangement

Structure and function Coulter arrangement Fig. 17 The coulter arrangement recommended by the factory is illustrated. However, an individual arrangement is also possible. Cenius 4002-2T BAG0100.2 04.13... -

Page 44: Levelling Unit

Structure and function Levelling unit The following components act as levelling ele- ments: A concave disc arrangement or A spring tine arrangement. Concave discs The discs mix, crumble and level out the earth. The bearings of the concave discs consist of a two rows of angular-contact ball bearings with slip ring seal and oil filling and are maintenance- free. -

Page 45: Boundary Discs Discs / Tines

Structure and function Boundary discs discs / tines Extendable boundary discs (Fig. 22) / tines (Fig. 22) prepare an even field with no lateral banks. When transporting the machine, completely slide in both boundary discs / boundary tines, fix with bolts and secure with linch pins. -

Page 46: Rollers

Structure and function Rollers The rollers serve for back-packing and for guid- ing the depth of the coulters. Tooth packer roller Fig. 24 Tandem roller The tandem roller consists of the front spiral tube roller, the rear rod roller. Fig. - Page 47 Structure and function Cutting ring roller The cutting ring roller is equipped with an adjust- able knife holder. Raising the knife holder with increased organic matter content reduces the risk of blocking. Fig. 28 Fig. 29 (1) Knife holder raised (2) Knife holder lowered (3) Adjustment screw with lock nut ...

- Page 48 Structure and function Border blade for knife ring rollers (optional) Border blade for an improved work pattern in the border and intermediate areas. Installation 1. Open linch pin and remove outer blade. 2. Insert border blade. 3. Attach border blade with outer blade and secure using the linch pin.

-

Page 49: Hydraulic Connections

Structure and function Hydraulic connections WARNING Danger of infection from escaping hydraulic fluid at high pres- sure! When coupling and uncoupling the hydraulic hose lines, ensure that the hydraulic system is depressurised on both the machine and trac- tor sides. If you are injured by hydraulic fluid, contact a doctor immediately. -

Page 50: Disconnecting Hydraulic Hoses

Structure and function Observe the maximum admissible working pressure of 200 bar. Check the compatibility of the hydraulic fluids before connecting the machine to the hydraulic system of your tractor. Do not mix mineral oils with bio-oils.. ... -

Page 51: Running Gear

Structure and function Running gear chassis raised, implement in working position. Fig. 32 chassis lowered in transport position. Fig. 33 Tensioned crosspiece Fig. 34 The category III tensioned crosspiece is used to couple the machine to the tractor. Cenius 4002-2T BAG0100.2 04.13... -

Page 52: Stand

Structure and function WARNING Risk of accidents if the connection between machine and tractor separates! Always use ball sleeves with sockets and integral linch pins. 5.10 Stand Fig. 35/… (1) Handle (2) Pin During operation or transport: Jack fixed in raised position with pin and secured with linch pin. -

Page 53: Rear Harrow (Option)

Structure and function 5.12 Rear harrow (option) The rear harrow is used to crumble and level the soil. The working intensity can be adjusted by in- serted the pins into different holes. After adjustment, secure the pins with linch pins. Fig. -

Page 54: Greendrill Catch Crop Sowing Unit

Structure and function 5.13 GreenDrill catch crop sowing unit The GreenDrill catch crop sowing unit enables the sowing of fine seeds and catch crops during soil cultivation. (1) GreenDrill (2) Foldable ascent (3) Locking pin for securing the foldable ascent See also the GreenDrill operating manual Fig. -

Page 55: Commissioning

Commissioning Commissioning This section contains information on operating your machine for the first time. on checking how you may connect the machine to your tractor. Before operating the machine for the first time the operator must have read and understood the operating manual. ... -

Page 56: Checking The Suitability Of The Tractor

Commissioning Checking the suitability of the tractor WARNING Danger of breaking during operation, insufficient stability and insufficient tractor steering and braking power in the event of improper use of the tractor! Check the suitability of your tractor before you attach or hook up the machine. - Page 57 Commissioning 6.1.1.1 Data required for the calculation Fig. 40 [kg] Empty tractor weight See tractor operating manual or vehicle [kg] Front axle load of the empty tractor documentation [kg] Rear axle load of the empty tractor [kg] Front weight (if available) See front weight in technical data, or weigh [kg] Maximum drawbar load...

- Page 58 Commissioning 6.1.1.2 Calculation of the required minimum front ballast G of the tractor to ensure safe V min steering Enter the numeric value for the calculated minimum ballast G V min required on the front side of the tractor, in the table (section 6.1.1.7). 6.1.1.3 Calculation of the actual tractor front axle load T V act...

- Page 59 Commissioning 6.1.1.7 Table Actual value according to Approved value ac- Double approved calculation cording to tractor load capacity (two instruction manual tyres) Minimum ballast front/rear Total weight Front axle load Rear axle load You can find the approved values for the total tractor weight, axle loads and load capacities in the tractor registration papers.

-

Page 60: Requirements For Tractor Operation With Attached Machines

Commissioning 6.1.2 Requirements for tractor operation with attached machines WARNING Risk of breakage during operation of components through unap- proved combinations of connecting equipment! Ensure: that the connection fittings on the tractor possess sufficient permissible support capability for the drawbar load actually present. -

Page 61: Securing The Tractor/Machine Against Unintentional Start-Up And Rolling

Commissioning Securing the tractor/machine against unintentional start-up and rolling WARNING Risk of crushing, shearing, cutting, catching, drawing in and knocks during all work on the machine By driven work elements. By unintentional movement of work elements or uninten- tional actuation of hydraulic functions when the tractor en- gine is running. -

Page 62: Coupling And Uncoupling The Machine

Coupling and uncoupling the machine Coupling and uncoupling the machine When coupling and uncoupling machines, follow the instructions giv- en in the section "Safety instructions for the operator" page 24. WARNING Risk of crushing, catching, drawing in and/or knocks due to un- intentional starting and rolling of the tractor when coupling or uncoupling the PTO shaft and supply lines. -

Page 63: Coupling The Machine

Coupling and uncoupling the machine Coupling the machine WARNING Risk of crushing and contusions between the tractor and the machine when coupling the machine! Instruct people to leave the danger area between the tractor and the machine before you approach the machine. Any helpers may only act as guides standing next to the tractor and the machine, and may only move between the vehicles when both are at a standstill. - Page 64 Coupling and uncoupling the machine 1. Secure the ball sleeves over the lower link pins in the pivot points of the three-point attachment frame. 2. Secure each of the pins with lynch pins to ensure that they do not accidentally come loose. 3.

-

Page 65: Uncoupling The Machine

Coupling and uncoupling the machine Uncoupling the machine DANGER Danger of injury from coulters breaking and coulter pieces being ejected! Do not rest the implement on the tines! Park the folded implement with running gear and jack on a level park- ing surface with solid ground. -

Page 66: Adjustments

Adjustments Adjustments WARNING Risk of contusions, cutting, catching, drawing in and knocks through unintentional falling of the machine raised using the trac- tor's three-point hydraulic system. unintentional falling of raised, unsecured machine parts. unintentional start-up and rolling of the tractor-machine combination. -

Page 67: Hydraulic Depth Adjustment

Adjustments (1) Spindle (2) Tools for setting the spindle length (in parking position). (3) Lock nut The working depth of the tines is set by adjusting the spindle length using the tool. 1. Slacken lock nut. 2. Set the spindle length. ... -

Page 68: Working Depth Of The Levelling Unit

Adjustments Working depth of the levelling unit The working depth of the levelling unit can be adapted to the working depth of the tines at the cranks. 1. Remove the linch pin (Fig. 43/1). 2. Adjust the working depth at the crank. 3. -

Page 69: Setting The Feeler Wheels

Adjustments Setting the feeler wheels Adjust the feeler wheels height using the group of holes so that they run with a 1-3 cm gap above the ground. 1. Take the eccentric lever out of park posi- tion. 2. Completely insert the pivot pins of the ec- centric lever into a suitable hole in the hole group and release the safety pins. -

Page 70: Transportation

Transportation Transportation DANGER During transportation, follow the instructions given in the section "Safety instructions for the operator", page 27. Before moving off, check: that the supply lines are connected correctly. the lighting system for damage, proper operation and cleanness, ... -

Page 71: Changing From Working To Transport Position

Transportation WARNING Danger of breaking during operation, insufficient stability and insufficient tractor steering and braking power on improper use of the tractor! These risks pose serious injuries or death. Observe the permissible axle and drawbar loads of the tractor. WARNING Risk of falling from the machine if riding against regulations! It is forbidden to ride on the machine and/or climb the running ma- chine. -

Page 72: Use Of The Machine

Use of the machine Use of the machine DANGER! Observe the chapter "Safety instructions for the user", page 24, when using the machine. Observe the warning signs on the machine. The warning signs provide you with important hints for the safe opera- tion of the machine. -

Page 73: Faults

Faults Faults Fault Correction Discs / tine rows clog with crop material. Raise the machine and lower again. Build up of soil in front of the roller. Raise the machine and lower again. Reduce working depth. Clogging of the packer roller. Adjust the strippers. -

Page 74: Cleaning, Maintenance And Repairs

Cleaning, maintenance and repairs Cleaning, maintenance and repairs WARNING Risk of contusions, cutting, catching, drawing in and knocks through unintentional falling of the machine raised using the trac- tor's three-point hydraulic system. unintentional falling of raised, unsecured machine parts. ... -

Page 75: Cleaning

Cleaning, maintenance and repairs 12.1 Cleaning Pay particular attention to the brake, air and hydraulic hoses! Never treat brake, air and hydraulic hoses with petrol, benzene, petroleum or mineral oils. After cleaning, grease the machine, in particular after cleaning with a high pressure cleaner/steam jet or liposoluble agents. - Page 76 Cleaning, maintenance and repairs Lubricants For lubrication work, use a lithium saponified multipurpose grease with EP additives: Company Lubricant name Normal operating condi- Extreme operating con- tions ditions ARAL Aralub HL 2 Aralub HLP 2 FINA Marson L2 Marson EPL-2 ESSO Beacon 2 Beacon EP 2...

- Page 77 Cleaning, maintenance and repairs Fig. 49 Fig. 50 Cenius 4002-2T BAG0100.2 04.13...

-

Page 78: Maintenance Plan - Overview

Cleaning, maintenance and repairs 12.3 Maintenance plan - overview Carry out maintenance work when the first interval is reached. The times, running hours or maintenance intervals of any third party documentation shall have priority. After the first working run Component Servicing work Workshop work... -

Page 79: Installing And Removing The Tines

Cleaning, maintenance and repairs 12.4 Installing and removing the tines CAUTION The tines and coulter of the Cenius can be replaced when on the field. For this purpose, slightly raise the machine in order to minimise the risk of injuries by the machine lowering unintentionally. 12.5 Changing the coulters CAUTION... -

Page 80: Installing And Removing The Disc Segments (Workshop Work)

Cleaning, maintenance and repairs Order the disassembly device via customer services / dealer: Order number 78800341 (for Cenius and Centaur, hydrau- lic) Order number 78800576 (for Cenius, mechanical) When changing the springs, change the spring bolts as well. ... -

Page 81: Replacing Discs (Workshop Work)

Cleaning, maintenance and repairs 12.8 Replacing discs (workshop work) Minimum disc diameter: 360 mm. The discs are replaced the machine lifted, headland setting discs raised, the machine secured against unintentional lowering Fig. 54 12.9 Tine connection Inspect the bolts of the tine connection for tight- ness. -

Page 82: Disc Carrier Connection

Cleaning, maintenance and repairs 12.11 Disc carrier connection Inspect the bolts of the tine connection for tight- ness. Required tightening torque: 210 Nm Fig. 57 12.12 Hydraulic cylinder for folding Check that the cylinder eye is firmly attached to the hydraulic cylinder. If it is loose, secure the piston rod with high-strength bolt locking compound and tighten the lock nut to 300 Nm. -

Page 83: Tyres/Wheels

Cleaning, maintenance and repairs 12.13 Tyres/wheels Check chassis wheels regularly for damage and firm seating on the wheel rim. Required tyre pressure. chassis wheels: 3,0 bar Feeler wheels: 6,5 bar Required tightening torque for wheel nuts or bolts: 325 Nm ... -

Page 84: Mounting Tyres (Workshop Work)

Cleaning, maintenance and repairs Check tyre pressures regularly when the tyres are cold, i.e. be- fore starting a run. The difference in pressure between the tyres on one axle must be no greater than 0.1 bar. Tyre pressure can be raised by up to 1 bar after a fast run or in warm weather. -

Page 85: Hydraulic System (Workshop Work)

Replace the hydraulic hose line if it is damaged or worn. Only use AMAZONE original hydraulic hose lines. The hydraulic hose lines should not be used for longer than six years, including any storage time of maximum two years. Even... -

Page 86: 12.14.1 Labelling Hydraulic Hose Lines

Cleaning, maintenance and repairs 12.14.1 Labelling hydraulic hose lines The assembly labelling provides the follow- ing information: Fig. 58/... (1) Manufacturer's marking on the hydraulic hose line (A1HF) (2) Date of manufacture of hydraulic hose line (04/02 = year/month = February 2004) (3) Maximum approved operating pressure (210 BAR). -

Page 87: 12.14.4 Installation And Removal Of Hydraulic Hose Lines

12.14.4 Installation and removal of hydraulic hose lines When installing and removing hydraulic hose lines, always observe the following information: Only use AMAZONE original hydraulic hose lines. Ensure cleanliness. You must always install the hydraulic lines so that, in all states of operation: ... -

Page 88: Hydraulic Circuit Diagram

Hydraulic circuit diagram Hydraulic circuit diagram 13.1 chassis / folding Fig. 59 Cenius 4002-2T BAG0100.2 04.13... -

Page 89: Depth Adjustment

Hydraulic circuit diagram 13.2 depth adjustment Fig. 60 Cenius 4002-2T BAG0100.2 04.13... -

Page 90: Screw Tightening Torques

Hydraulic circuit diagram 13.3 Screw tightening torques 10.9 12.9 M 8x1 M 10 16 (17) M 10x1 M 12 18 (19) M 12x1,5 M 14 M 14x1,5 M 16 M 16x1,5 M 18 M 18x1,5 M 20 M 20x1,5 M 22 M 22x1,5 1050 M 24... - Page 91 Notes Cenius 4002-2T BAG0100.2 04.13...

- Page 92 Postfach 51 Phone: +49 5405 501-0 D-49202 Hasbergen-Gaste Fax: +49 5405 501-234 Germany e-mail: amazone@amazone.de http:// www.amazone.de Plants: D-27794 Hude D-04249 Leipzig, Germany F-57602 Forbach, France, Branches in England and France Manufacturers of mineral fertiliser spreaders, field sprayers, sowing machines, soil cultivation ma-...

Need help?

Do you have a question about the Cenius 4002-2T Super and is the answer not in the manual?

Questions and answers