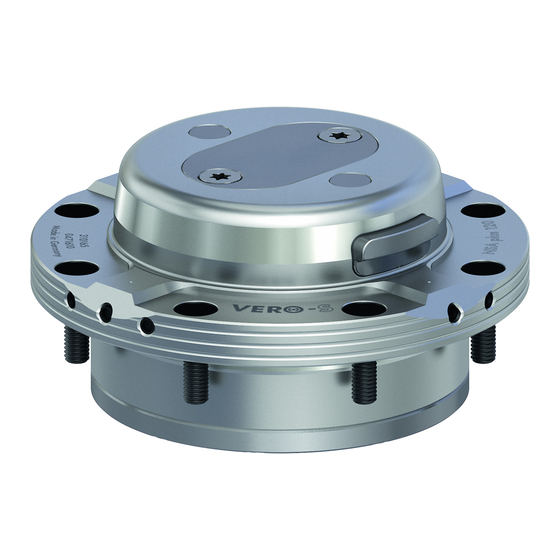

SCHUNK VERO-S NSA plus 120 Assembly And Operating Manual

Quick-change pallet system

Hide thumbs

Also See for VERO-S NSA plus 120:

- Assembly and operating manual (40 pages) ,

- Assembly and operating manual (36 pages)

Summary of Contents for SCHUNK VERO-S NSA plus 120

- Page 1 Translation of the assembly and operating manual VERO-S Quick-Change Pallet System NSA plus 120 - 160 Assembly and operating manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual remains the copyrighted property of SCHUNK GmbH & Co. KG. It is solely supplied to our customers and operators of our products and forms part of the product. This documentation may not be duplicated or made accessible to third parties, in particu- lar competitive companies, without our prior permission.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 About this manual ....................4 1.1 Presentation of Warning Labels ................4 1.2 Applicable documents ....................5 2 Basic safety notes ..................... 6 2.1 Intended use ......................6 2.2 Not intended use ...................... 6 2.3 Notes on particular risks ................... -

Page 4: About This Manual

About this manual About this manual This manual contains important information for a safe and appro- priate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and under- stood this operating manual. -

Page 5: Applicable Documents

About this manual Applicable documents • General terms of business * • Catalog data sheet of the purchased product * The documents marked with an asterisk (*) can be downloaded on our homepage www.schunk.com. 02.00|NSA plus 120 - 160|en... -

Page 6: Basic Safety Notes

• It is used as a pressing tool, a chuck, a load-handling device or as lifting equipment. • It is used for turning applications without consulting SCHUNK. • It is used in working environments that are not permissible. • People work on machines or technical equipment that do not comply with the EC Machinery Directive 2006/42/EC, disregarding the applicable safety regulations. -

Page 7: Notes On Particular Risks

Basic safety notes Notes on particular risks This product may pose a danger to persons and property if, for example: • It is not used as intended; • It is not installed or maintained properly; • The safety and installation instructions, local applicable safety and accident prevention regulations or the EC Machinery Di- rective are not observed. - Page 8 Basic safety notes WARNING Risk of injury to persons due to falling down of the fixture, pallet or workpiece by erroneous or negligent loosening of the clamping rings. • During operation, incorrect or incautious loosening of the clamping ring must be prevented by suitable measures (disconnection of power supply after locking, use of safety valves or safety switches).

-

Page 9: Product Safety

Basic safety notes CAUTION Risk of slipping or falling if the chuck's operational environment is not clean (e.g. contaminated with cooling lubricants or oil). • Ensure that the working environment is clean before starting assembly and installation work. • Wear suitable safety boots. •... -

Page 10: Holding Force And Screw Strength

2.4.2 Constructional changes, attachments, or modifications Additional threads, bore holes or attachments which are not supplied as accessories by SCHUNK may affect safety. They may only be applied after obtaining the prior consent of SCHUNK. Personnel qualification The assembly and disassembly, commissioning, operation and maintenance of the system may be performed only by trained specialist personnel. -

Page 11: Organizational Measures

Only allow specialists to remedy malfunctions. Spare parts Only use original SCHUNK spare parts. Environmental regulations The applicable environmental regulations must be observed for all maintenance and repair work. -

Page 12: Warranty

Warranty / Scope of delivery Warranty If the product is used as intended, the warranty is valid for 24 months from the ex-works delivery date under the following conditions: • Observe the applicable documents ( 1.2, Page 5) • Observe the ambient conditions and operating conditions •... -

Page 13: Technical Data

Technical data Technical data NSA plus Id.-No. 0471610 0471710 Retenion force 50 kN 75 kN Pull-down force without turbo 3 kN 5 kN Pull-down force with turbo 9 kN 15 kN Lifting force 100 kg 200 kg Lifting height 0.5 mm 0.5 mm Operating pressure 6 bar... -

Page 14: Assembly

Assembly Assembly Actions before starting assembly Lift the quick-change pallet system carefully (e.g. using suitable lifting equipment) out of the packaging. CAUTION Risk of injury due to sharp edges and rough or slippery surfaces • Wear personal protective equipment, particularly protective gloves. -

Page 15: General Assembly Notes

Assembly General assembly notes If you wish to install the unit yourself, please request our drawing. If several clamping units are to be mounted in serial connection, please make sure that the evenness and deviation in height of the supporting surfaces from module to module keeps within 0.01 mm (relating to a depth gauge of 200 mm). -

Page 16: Fastening And Connection

Assembly Fastening and connection If you wish to install the unit yourself, please request our drawing. 6.2.1 NSA plus 120 NSA plus 120 - Fastening and connections 02.00|NSA plus 120 - 160|en... - Page 17 Assembly The NSA plus 160 is fastened in the installation area with 8 screws Positioning of the module is done via the centering dieameter of the installation area:Ø 90 H6. All base sided air connections for “module opened” and the turbo function are closed with M5 x 4 set-screws at the delivery.

-

Page 18: Nsa Plus 160

Assembly 6.2.2 NSA plus 160 NSA plus 160 - Fastening and connections 02.00|NSA plus 120 - 160|en... - Page 19 Assembly The NSA plus 160 is fastened in the installation area with 8 screws Positioning of the module is done via the centering diameter of the installation area: Ø 128 H6. All base sided air connections for “module opened” and the turbo function are closed with M6 x 5 set-screws at the delivery.

-

Page 20: Clamping Rings Sra, Srb, Src

Notes on clamping rings and fastening screws Screws of strength class 12.9 must be used for fastening the clamping rings. Only original SCHUNK clamping rings may be used. If the clamping rings are to be used in customer-owned devices, the customer must provide sufficiently dimensioned threaded holes or a sufficiently thick mounting material. - Page 21 Assembly Installation recommendations for clamping rings Tolerances and assembly conditions Type Id.-No. SRA 120 RF 0471650 > 8 > 13 M8 > 9 > 12 M6 12 Ø 118 H6 Ø 100±0.2 Ø 35 SRB 120 RF 0471651 > 8 > 13 M8 >...

- Page 22 Assembly Application / Disposition of different clamping ring types (Application example: pallet with 6 clamping areas) 02.00|NSA plus 120 - 160|en...

-

Page 23: Operation

Operation Operation WARNING Risk of injury due to losing pallets or workpieces in the case of incorrect actuation caused by incorrect operation.Risk of injury due to compressed air hoses coming loose when connected improperly. • Disconnect the energy supply after locking. •... -

Page 24: Function

Function Function NOTICE In order to achieve the maximum lifting force, the clamping system should be actuated with an operating pressure of 6 bar. A lower operating pressure avoids proper decoupling of the clamping system Clamping function Unlocking 1 To unlock the clamping system, compressed air has to be supplied (operating pressure 6 bar). -

Page 25: Lifting Function

Function 7 The clamping slides move outside and lock the clamping ring at the pallet self-locking as well as form-fit. Therefore pressure actuation of the clamping module during machining is not necessary. Centering of the clamping rings is done at the conical surface of the clamping module. -

Page 26: Dynamic Pressure Monitoring At The Clamping Slides

Function prevail at the supporting surface. Moreover, the bore holes of the air control are used as blow-out function for cleaning the plane surfaces (see chapter "Clamping function" - Locking ( 8.1, Page 24)). When using this control and cleaning function, it must be ensured that the clamping ring is in the right position orientation. -

Page 27: Pneumatic Circuit Diagram

Function function is not mandatory for the basic operation of the clamping module. For slide monitoring for "module opened", the clamping modules of a clamping station (connected in parallel up to a certain number) can be queried via a pressure switch. For slide monitoring for "module clamped", the clamping slides must be queried individually via their own pressure switch. - Page 28 Function The following points have to be observed when the NSE plus quick-change pallet systems are controlled: Turbo-Function: • The operating pressure for the Turbo-Function should not exceed 6 bar. Clamping slide monitoring: • The max. pressure of the slide monitoring amounts to 2 bar. •...

-

Page 29: Maintenance And Care

Risk of injury and risk of damage to the clamping module when opening the housing cover. If the clamping module has to be disassembled, ship the module to SCHUNK for repair. The covers of the clamping modules are spring-packaged may be removed only by trained personnel. -

Page 30: Trouble Shooting

Faulty air connections Check air supply Pressure drops below minimum Check operating pressure (min. 5 bar) Component is broken, e.g. through Replace module or send it to SCHUNK for overloading repair Tensile load to the clamping pin is too Reduce load... -

Page 31: Seal Kit And Part Lists

Seal kit and part lists Seal kit and part lists 11.1 Seal kit lists NSA plus 120 (ID no. 0471612) Item Designation Quantity Bearing shell Quad ring Quad ring O-ring O-ring O-ring O-ring O-ring O-ring O-ring NSA plus 160 (ID no. 0471712) Item Designation Quantity... -

Page 32: Part Lists

Seal kit and part lists 11.2 Part Lists NSA plus 120 Item Designation Quantity Body Clamping slide Piston Cover Bearing shell Lifting pin Cover plate Countersunk screw Steel ball Countersunk screw Compression spring Quad ring Quad ring O-ring O-ring O-ring O-ring O-ring O-ring... - Page 33 Seal kit and part lists NSA plus 160 Item Designation Quantity Body Clamping slide Piston Cover Bearing shell Lifting pin Cover plate Countersunk screw Steel ball Countersunk screw Compression spring Quad ring Quad ring O-ring O-ring O-ring O-ring O-ring O-ring Set-screw O-ring Screw...

-

Page 34: Assembly Drawing

Assembly drawing Assembly drawing 02.00|NSA plus 120 - 160|en... -

Page 35: Translation Of The Original Declaration Of Incorporation

Translation of the original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Distributor Lothringer Str. 23 D-88512 Mengen... -

Page 36: Annex To Declaration Of Incorporation

Annex to Declaration of Incorporation Annex to Declaration of Incorporation according 2006/42/EG, Annex II, No. 1 B 1.Description of the essential health and safety requirements pursuant to 2006/42/EC, Annex I that are applicable and that have been fulfilled with: Product designation VERO-S quick-change pallet system Type designation NSA plus 120;... - Page 37 Annex to Declaration of Incorporation Risks due to other hazards 1.5.1 Electricity supply 1.5.2 Static electricity 1.5.3 Energy supply other than electricity 1.5.4 Errors of fitting 1.5.5 Extreme temperatures 1.45.6 Fire 1.5.7 Explosion 1.5.8 Noise 1.5.9 Vibrations 1.5.10 Radiation 1.5.11 External radiation 1.5.12 Laser radiation...

Need help?

Do you have a question about the VERO-S NSA plus 120 and is the answer not in the manual?

Questions and answers