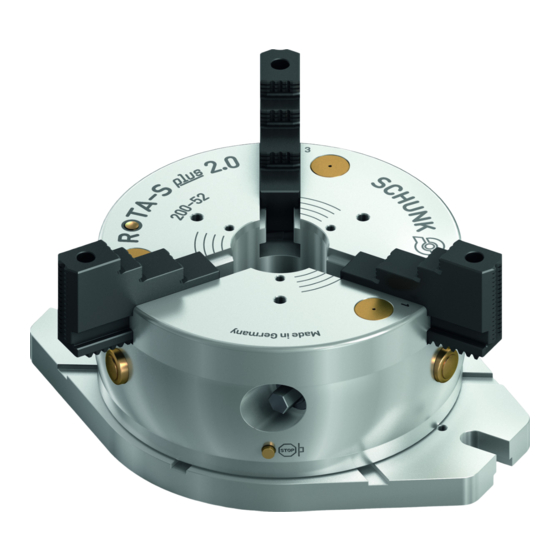

SCHUNK ROTA-S plus 2.0 Assembly And Operating Manual

Manual chuck

Hide thumbs

Also See for ROTA-S plus 2.0:

- Assembly and operating manual (41 pages) ,

- Assembly and operating manual (44 pages)

Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK ROTA-S plus 2.0

- Page 1 Translation of the original manual Manual chuck ROTA-S plus 2.0 Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 About this manual ....................5 1.1 Presentation of Warning Labels ................5 1.2 Applicable documents ....................6 2 Basic safety instructions ................... 7 2.1 Intended use ......................7 2.2 Not intended use ...................... 7 2.3 Notes on particular risks ................... - Page 4 Table of Contents 9 Maintenance ......................34 9.1 Disassembling and assembling the chuck .............. 34 9.2 Jaw change ......................36 9.3 At least once a month .................... 36 9.4 In the case of decreasing clamping force or after approx. 200 operating hours .. 37 9.5 Maintenance intervals ....................

-

Page 5: About This Manual

About this manual About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

• Catalog data sheet of the purchased product * • Calculation of the jaw centrifugal forces, "Technology" chapter in the lathe chuck catalog * The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com 05.00|0889002_ROTA-S plus 2.0 |en... -

Page 7: Basic Safety Instructions

Only original SCHUNK spare parts may be used. Intended use The product is suitable for clamping workpieces on milling or lathe machines and other suitable tooling machines. -

Page 8: Notes On Particular Risks

Basic safety instructions Notes on particular risks This product may pose a danger to persons and property if, for example: • It is not used as intended; • It is not installed or maintained properly; • The safety and installation instructions, local applicable safety and accident prevention regulations or the EC Machinery Directive are not observed. - Page 9 Basic safety instructions WARNING Risk of injury due to dropping the chuck during transport, installation or removal. • Take special care in the danger zone when transporting, installing or removing the chuck. • Note the relevant load securing regulations for working safely with cranes, ground conveyors, lifting gear and load-handling equipment.

-

Page 10: Notes On Safe Operation

Basic safety instructions CAUTION Danger of damage due to incorrectly selected clamping position of the clamping jaws to the workpiece. An incorrectly selected clamping position of the clamping jaws to the workpiece can result in damage to the base and top jaws. •... - Page 11 (clamping force, coefficient of friction, wear characteristics). (For product information about LINOMAX plus, see the "Accessories" chapter of the SCHUNK lathe chuck catalog or contact SCHUNK.) • Use a suitable high-pressure grease gun to ensure that you reach all the greasing areas.

- Page 12 Basic safety instructions • We recommend checking the clamping force using a clamping force tester before starting a new production run and between maintenance intervals. *Optimum safety can only be guaranteed through regular checks*. • The clamping force should always be measured with the chuck in the same condition as it is used in for the current clamping application.

- Page 13 • If the chuck is involved in a collision, it must be subjected to a crack test before using it again. Damaged parts must be replaced with original SCHUNK spare parts. • Renew the chuck jaw mounting bolts if there are signs of wear or damage.

-

Page 14: Constructional Changes

• Structural changes should only be made with the written approval of SCHUNK. Personnel qualification Assembly and disassembly, commissioning, operation and repair of the chuck may be performed only by qualified specialists who have been instructed with respect to safety. -

Page 15: Personal Protective Equipment

Basic safety instructions Spare parts Only ever use original SCHUNK spare parts. Environmental regulations Comply with the applicable legal norms when disposing of waste. Personal protective equipment Use of personal protective equipment Personal protective equipment serves to protect staff against danger which may interfere with their health or safety at work. -

Page 16: Warranty

Scope of delivery Warranty The warranty period is 60 months after delivery date from factory or 50 000 cycles*, if it is used as intended, under the following conditions: • Observe the applicable documents, (1.2, Page 6) • Observe the ambient conditions and operating conditions. •... -

Page 17: Technical Data

28.8 54.2 18.2 30.4 60.5 Centrifugal force of the For the ROTA-S plus 2.0 chuck, it is necessary to specifically base jaw determine this data. with fine serration Examples of calculation can be found in the "Special chuck [kgm] jaws/technology" chapter in our current chuck jaw catalog. -

Page 18: Clamping Force / Speed Diagrams

The chuck is in perfect condition and lubricated with SCHUNK LINOMAX plus special grease. If one or more of these prerequisites is modified, the graphs will no longer be valid. - Page 19 Technical data Clamping force RPM diagram ROTA-S plus 2.0 160-42 - 3 jaws Clamping force RPM diagram, ROTA-S plus 2.0 200-62 - 3 jaws Clamping force RPM diagram ROTA-S plus 2.0 250-52 - 3 jaws 05.00|0889002_ROTA-S plus 2.0 |en...

- Page 20 Technical data Clamping force RPM diagram, ROTA-S plus 2.0 315-92 - 3 jaws Clamping force RPM diagram ROTA-S plus 2.0 160-42 - 2 jaws Clamping force RPM diagram, ROTA-S plus 2.0 200-62 - 2 jaws 05.00|0889002_ROTA-S plus 2.0 |en...

- Page 21 Technical data Clamping force RPM diagram ROTA-S plus 2.0 250-52 - 2 jaws Clamping force RPM diagram, ROTA-S plus 2.0 315-92 - 2 jaws 05.00|0889002_ROTA-S plus 2.0 |en...

-

Page 22: Calculations For Clamping Force And Speed

Technical data Calculations for clamping force and speed Missing information or specifications can be requested from the manufacturer. Legend Total centrifugal force [N] Centrifugal torque of top jaws [Kgm] Effective clamping force [N] Centrifugal torque of base jaws [Kgm] Minimum required clamping force Speed [rpm] spmin Initial clamping force [N]... - Page 23 Technical data DANGER Risk to life and limb of the operating personnel and significant property damage when the RPM limit is exceeded! With gripping from the outside inwards, and with increasing RPM, the effective clamping force is reduced by the magnitude of the increasing centrifugal force (the forces are opposed).

-

Page 24: Calculation Example: Required Initial Clamping Force Fsp0 For A Given Rpm N

Technical data NOTICE This calculated force must not be larger than the maximum clamping force ΣS engraved on the chuck. See also "Chuck data" table (6.1, Page 17) From the above formula it is evident that the sum of the effective clamping force F and the total centrifugal force F is multiplied by... - Page 25 Technical data • max. speed of rotation n = 3200 ("Chuck data" table) • RPM n = 1200 (application-specific) • Mass of one (!) top jaw m = 5.33 kg (application- specific) • Center of gravity radius of top jaw r = 0.107 m (application- specific) •...

-

Page 26: Calculation Of The Permissible Rpm Nzul In Case Of A Given Initial Clamping Force Fsp0

Technical data 6.3.3 Calculation of the permissible rpm nzul in case of a given initial clamping force Fsp0 The following formula can be used to calculate the permissible RPM for a given initial clamping force during shutdown: NOTICE The calculated permissible RPM may not exceed the maximum RPM inscribed on the chuck for safety reasons! Example of calculation: Permissible RPM for a given effective clamping force... -

Page 27: Attachment Of The Manual Chuck

Attachment of the manual chuck Attachment of the manual chuck The item numbers specified for the corresponding individual components relate to chapter drawings.( 12, Page 40) Handling prior to attachment Before mounting on the lathe, remove the base jaws from the chuck, then re-install the base jaws and turn the spindle several times as far as it will go to the right and left. -

Page 28: Mounting Of The Manual Chuck

Attachment of the manual chuck ROTA-S plus 2.0 chucks are delivered with different short taper mountings. For the type C bayonet mounting, for the type S Camlock mounting and with the intermediate flange for type A short taper. (Our technical sales would be glad to answer any questions you may have.) -

Page 29: Function

Function Function The item numbers specified for the corresponding individual components relate to chapter drawings.(12, Page 40) Handling and jaw change NOTE: For rotating lathe chucks, the centrifugal forces applied can cause the indicator pin to emerge from the chuck body. When the lathe chuck comes to a stop, the indicator pin must be reinserted. - Page 30 Function NOTICE Actuating the chuck if a jaw is not engaged will damage the chuck! Manually move the jaw back and forth without actuating the pressure bolt. This ensures that the jaw is engaged. The pressure bolt has to be in the initial position. For all the wedge bar teeth (items 5 and 6) to be supportive, the base jaws in the guides must always be inserted at least up to the marking line on the chuck body (item 1) (see Fig.

-

Page 31: Important Notes

Function If you turn the spindle to the right, the indicator pin (item 17) will protrude from the chuck body (item 1) (gold-colored pin) shortly before the stop. WARNING If the indicator pin protrudes, the entire serration of the wedge bars (items 5 and 6) no longer engages into the base jaws. -

Page 32: Control Of The Chuck

The chuck may have become twisted. Control of true-running (For delivery of a ROTA-S plus 2.0 with hard jaws STF/SHF grounded on the chuck) For control of true-running and face play hardened and ground inspection arbors or inspection disks are clamped (see illustration "Control of true-running"). - Page 33 Function Chuck size 160-42 200-52 250-62 315-92 Jaw type STF-160 STF-200 STF-250 STF-315 SHF-160 SHF-200 SHF-250 SHF-315 Md [Nm] L [mm] d (STF) [mm] Ø 34 Ø 41 Ø 41 Ø 55 d (SHF) [mm] Ø 34 Ø 41 Ø 41 Ø...

-

Page 34: Maintenance

For this reason, it is recommended to regularly clean the chuck and lubricate it using SCHUNK LINOMAX plus special grease. CAUTION Allergic reactions due to grease in contact with skin! Wear gloves. - Page 35 The chuck is now completely disassembled. Clean all parts carefully with degreasing agent and check for wear and damage. Replace damaged parts with original SCHUNK spare parts only! Before installation, lubricate all individual components with LINOMAX plus grease. 05.00|0889002_ROTA-S plus 2.0 |en...

-

Page 36: Jaw Change

Lubricate the chuck at the two lubrication nipples (item 37) on the circumference of the chuck body (item 1) using a manual press. Use SCHUNK LINOMAX plus special grease as lubricant. The chuck must be in fully the open position (jaw change position) so that all the important areas are covered with grease by the lubrication system. -

Page 37: In The Case Of Decreasing Clamping Force Or After Approx. 200 Operating Hours

In this case disassemble the chuck, carefully clean all parts with degreasing agent and check for wear and damage. Replace damaged parts with original SCHUNK spare parts only! Before installation, lubricate all individual components with SCHUNK LINOMAX plus special grease. -

Page 38: Disposal

• Dispose of the chuck's metal parts as scrap metal. Alternatively, you can return the chuck to SCHUNK for proper disposal. 05.00|0889002_ROTA-S plus 2.0 |en... -

Page 39: Spare Parts

Spare parts Spare parts When ordering spare parts, it is imperative to specify the type, size and above all the manufacturing no of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws and wiper bars plus parts coming into contact with the workpiece are not covered by the warranty. -

Page 40: Assembly Drawing

Assembly drawing Assembly drawing 05.00|0889002_ROTA-S plus 2.0 |en...

Need help?

Do you have a question about the ROTA-S plus 2.0 and is the answer not in the manual?

Questions and answers