Graco A Series Important Safety Instructions Manual

Mix manifold kit

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Table of Contents

Advertisement

Quick Links

Instructions-Parts

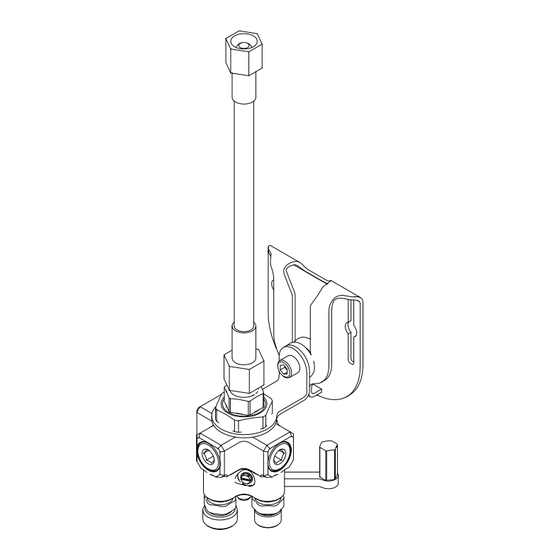

Mix Manifold Kit

For at-the-gun mixing of 2 component materials when used with a ProMix™ PD2K Proportioner.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual

and in your PD2K proportioner manual. Save these

instructions.

See page 2 for model part numbers,

maximum fluid working pressure, and

approvals.

PROVEN QUALITY. LEADING TECHNOLOGY.

3A2801A

EN

Advertisement

Table of Contents

Summary of Contents for Graco A Series

- Page 1 Instructions-Parts 3A2801A Mix Manifold Kit For at-the-gun mixing of 2 component materials when used with a ProMix™ PD2K Proportioner. For professional use only. Important Safety Instructions Read all warnings and instructions in this manual and in your PD2K proportioner manual. Save these instructions.

- Page 2 Models Part No. Series Description Maximum Fluid Working Pressure 24R991 Low Pressure Mix Manifold 300 psi (2.1 MPa, 21 bar) 24R992 High Pressure Mix Manifold 1500 psi (10.5 MPa, 105 bar) 24T273 High Pressure Mix Manifold, for 1500 psi (10.5 MPa, 105 bar) acid-catalyzed materials 3A2801A...

-

Page 3: Fire And Explosion Hazard

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. -

Page 4: Personal Protective Equipment

Warnings WARNING TOXIC FLUID OR FUMES Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed. • Read MSDSs to know the specific hazards of the fluids you are using. •... -

Page 5: Installation

Installation Installation Operation 1. Connect the component A supply to the A side 1. Check that all hose connections are tight before fitting (19a) of the mix manifold. each use. 2. Connect the component B supply to the B side 2. - Page 6 Repair Repair Disassembly 1. Flush the mix manifold before servicing. See the PD2K operation manual. 2. Relieve the pressure as described in the PD2K operation manual. Disconnect the hoses, taking note of which port (A or B) they are connected to. 3.

- Page 7 Repair Reassembly bottoms on the shoulder. Loosely screw the outlet fitting (11) into the body (1). NOTE: Lubricate all o-rings when reassembling. 5. Apply thread adhesive to the check valves (19, 20). Be sure to install the A and B check Plug Seals Repair Kit 420011 is available.

- Page 8 Parts Parts Mix Manifold Kit Parts Part No. 24R991 Low Pressure Mix Manifold Kit Part No. 24R992 High Pressure Mix Manifold Kit Part No. 24T273 High Pressure Mix Manifold Kit, for acid catalyzed materials Ref. Part Description 16W557 BRACKET, belt 16W558 BRACKET, gun/belt 16W559 RETAINER, bracket 16W560 NUT, retaining...

- Page 9 Parts Mix Manifold Parts Part No. 16W556 Mix Manifold (used on 24R991 and 24R992 Kits) Part No. 16W616 Mix Manifold (used on 24T273 Kit for acid-catalyzed materials) Ref. Part Description — — — 8†‡ BEARING, guide; acetal 9†‡ 111457 O-RING; PTFE —...

- Page 10 Accessories Accessories Part No. Description 24N641 1/8 in. (3 mm) ID Fluid Whip Hose; nylon; 6 ft (1.8 m); for high and low pressure applications. 3200 psi (22 MPa, 220 bar) Maximum Fluid Working Pressure. 24N305 1/4 in. (6 mm) ID Fluid Whip Hose; nylon; 6 ft (1.8 m); for low pressure applications only. 225 psi (1.6 MPa, 16 bar) Maximum Fluid Working Pressure.

-

Page 11: Technical Data

Technical Data Technical Data Mix Manifold U.S. Metric Maximum fluid working pressure: 24R991 Low Pressure 300 psi 2.1 MPa, 21 bar Mix Manifold 24R992 High Pressure 1500 psi 10.5 MPa, 105 bar Mix Manifold 24T273 High Pressure 1500 psi 10.5 MPa, 105 bar Mix Manifold, for acid-catalyzed materials Mixing ratio range:... -

Page 12: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers