Graco A Series Instructions-Parts List Manual

Paint spray gun

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Advertisement

Quick Links

Instructions – Parts List

STAINLESS STEEL, AIR–OPERATED

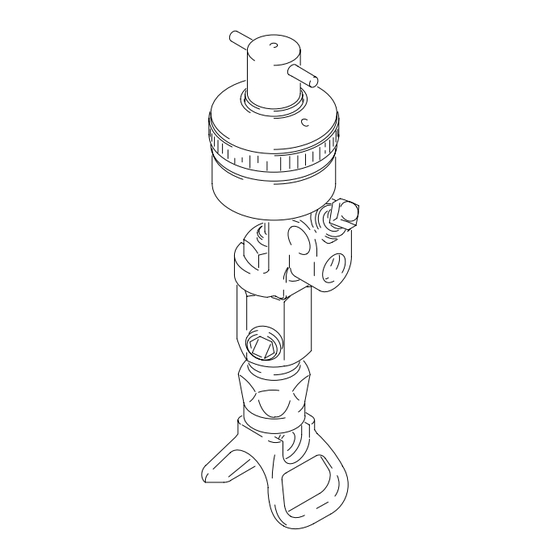

Paint Spray Gun

3000 psi (21 MPa, 210 bar) Maximum Working Pressure

Model 238377, Series A

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1996, Graco Inc. is registered to I.S. EN ISO 9001

Parts

308613D

05952A

Advertisement

Summary of Contents for Graco A Series

- Page 1 3000 psi (21 MPa, 210 bar) Maximum Working Pressure Model 238377, Series A Important Safety Instructions Read all warnings and instructions in this manual. Save these instructions. 05952A GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 Copyright 1996, Graco Inc. is registered to I.S. EN ISO 9001...

- Page 2 ........Graco Warranty .......

- Page 3 WARNING INJECTION HAZARD Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin is a serious injury.

- Page 4 D Do not use hoses to pull equipment. D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F). D Do not lift pressurized equipment.

- Page 5 Procedure on page 7. Start the pump and flush the system with a compatible solvent as explained in the Accessories are available from Graco. Be sure all instructions for your pump. Check the system under accessories are properly sized to withstand the pres- pressure for leaks;...

- Page 6 Operation Adjustments Pressure Relief Procedure Before each day’s operation, lubricate with a spray of WARNING oil inside the protection tube (13) to prevent fluid buildup on these parts. Any buildup could damage the FLUID INJECTION HAZARD valve packings (16, 17 or 18). To reduce the risk of serious bodily in- jury, including fluid injection,splashing in Set the actuating air to at least 50 psi (3.5 bar) and...

- Page 7 Maintenance Clean Dispensing Valve and System Daily To remove a hardened particle from the orifice, blow CAUTION air through the orifice from the front. Be sure that the solvent you use is compatible with Oil Dispensing Valve Daily the fluid being dispensed, to avoid clogging the valve’s fluid passages.

- Page 8 Troubleshooting NOTE: Check all possible solutions before disassembling the pump. Problem Cause Solution Uneven spray pattern Fluid pressure too low Increase pressure to pump, or ad- just fluid pressure regulator Spray gun will not stop spraying Fluid pressure too high Reduce pressure to pump, or ad- just fluid pressure regulator Fluid needle binding...

- Page 9 Notes 308613...

- Page 10 Parts Model 238377 Includes items 1–22 05953A 308613...

- Page 11 Parts Ref. Ref. Part No. Description Qty. Part No. Description Qty. 243161 GUARD, RAC 191195* TUBE, protection 206987* SEAT, valve 191174 NUT, packing 101748 PLUG, pipe; 3/8 npt 102300 NUT, 9/16–18 nf 166470 HOUSING, valve 166255* GLAND, packing 166847 HOUSING, valve 166258* PACKING, valve 101554...

- Page 12 Notes 308613...

- Page 13 Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers