Grundfos SRG 60 Hz Installation And Operating Instructions Manual

Hide thumbs

Also See for SRG 60 Hz:

- Installation and operating instructions manual (100 pages) ,

- Instructions manual (200 pages) ,

- Installation and operating instructions manual (428 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Grundfos SRG 60 Hz

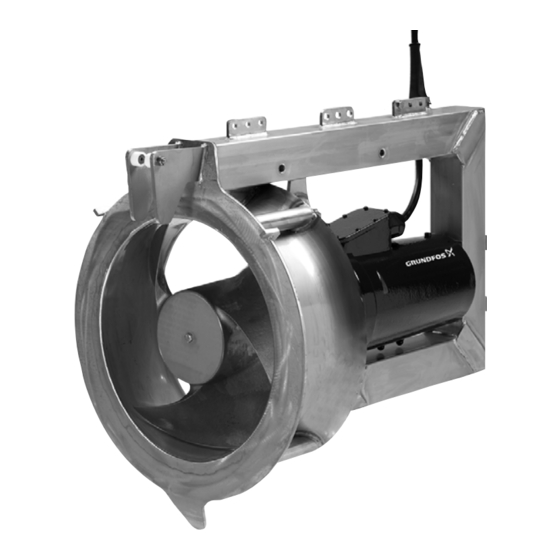

- Page 1 GRUNDFOS INSTRUCTIONS 60 Hz, North America Installation and operating instructions...

-

Page 2: Table Of Contents

English (US) Installation and operating instructions Original installation and operating instructions 1. Limited warranty These installation and operating instructions describe Grundfos New equipment manufactured by seller or service supplied by SRG 60 Hz recirculation pumps. seller is warranted to be free from defects in material and... -

Page 3: General Information

3. Safety instructions This booklet includes instructions for installing, starting-up and DANGER servicing Grundfos 60 Hz recirculation pumps, type SRG, designed for transfer of liquids of low to medium viscosity ( ≤ 500 Electric shock cSt (mPas)) from one tank to another. -

Page 4: Receiving The Product

If the pump or any accessories have been damaged during Pressurized system transportation, contact your local Grundfos company before Minor or moderate personal injury continuing to install the equipment. Do not dismantle a damaged... -

Page 5: Installing The Product

5. Installing the product During installation, the pump must only be lifted when using the suspension point. The lifting equipment supplied with the pump as well as the wire used for lifting and lowering the pump into the tank must not be used as universal lifting equipment. -

Page 6: Torques

5.2 Torques 3. SRG.xx.32.xx: Weld the guide claws to the connection flange. See fig. 4. All nuts and bolt s used for the installation must be made of stainless steel. Use grease (Alu-paste) together with a spring washer or lock nut; otherwise, use Loctite or a similar product for lubrication and locking. - Page 7 10. Place the column profile on the profile section on the 16. Fix the power supply cable to the lifting wire by means of a connection flange and mount the top end with the epoxy cable clamp approx. 2.6 ft (0.8 m) above the pump. This will insulator and the turnable metal part on the already installed prevent the cable from falling down and becoming entangled top fixation bracket.

-

Page 8: Electrical Connection

5.4 Electrical connection 20. Mount the cable sock (18) to the top fixation bracket using the shackle, and pull the motor cable through it to the desired The electrical connections must be carried out by a qualified position. See fig. 9. The power supply cable should be slightly electrician in accordance with local regulations. - Page 9 5.4.2 Wiring diagrams For voltage and starting method 1H, wire the motor using the delta connection. For voltage and starting method 0H, wire the motor using the star connection.method. Connection methods are shown in fig. 10. See also section 7.2.2 Nameplate, fig.

-

Page 10: Electrical Protection

5.5 Electrical protection 5.4.5 Requirements • Peak voltage and dU/dt must be in accordance with the table 5.5.1 Motor protection below. The values stated are maximum values supplied to the The pumps are provided with the following type of motor motor terminals. -

Page 11: Protection Against Electro-Chemical Corrosion

Maximum load: 250 V, 5 A. limiting unit (polarization cell or anti-parallel diode) or an isolation When the Grundfos leakage relay is connected, a current of up to transformer. 10 mA will flow through the leak sensor (terminals 5 and 7 in fig. -

Page 12: Starting-Up The Product

Impeller Hydraulic inlet 7.1 Applications Grundfos SRG recirculation pumps are used for the pumping of return sludge in sewage treatment plants and for other pump Fig. 14 Oil check and oil filling applications involving a high flow rate and low head. The pumps are designed for continuous operation (S1). -

Page 13: Identification

7.2 Identification 7.2.1 Type key Example 524. Type range SRG: Submersible recirculation pump with gearbox Motor output power, P2 Code from type designation / 10 [hp] 11: 1.1 hp Impeller diameter [in] 12: 12 inches Impeller speed [RPM] 524: 524 RPM Impeller blade pitch [°] 08: 8 °... -

Page 14: Servicing The Product

Liquid temperature range toxic, the pump will be classified as contaminated. Production site If you request Grundfos to service the product, contact Grundfos with details about the pumped liquid before returning the product. Enclosure class according to IEC Otherwise Grundfos can refuse to accept the product for service. -

Page 15: Service Chart

(otherwise cooling is affected). maintenance-free. They must be motor The motor housing may only be replaced if they get noisy. dismantled by Grundfos. Check the power supply cable twice a year for surface damage, Power supply strain, kinks, etc. cable If damaged, the cable must be replaced by Grundfos. -

Page 16: Oil

8.3 Oil 8.4 Changing the oil Place the pump in a horizontal position on supports and place a 8.3.1 Oil quality pan underneath to collect the oil. Gear oil designation according to ISO VG 68. CAUTION 8.3.2 Oil quantity Pressurised system Gearbox Type Minor or moderate personal injury... -

Page 17: Fault Finding The Product

The impeller cannot rotate freely. Clean the impeller and check manually that it can rotate freely. e) The stator windings are faulty. Contact Grundfos. The motor has cut out because of Wait until the motor has cooled and attempt to restart overheating. -

Page 18: Technical Data

10.1 General technical data environmentally sound way: 1. Use the public or private waste collection service. Voltage tolerance +/- 10 % of nameplate value 2. If this is not possible, contact the nearest Grundfos company Enclosure class IP68 or service workshop. Insulation class... - Page 19 Appendix 1. Dimensions and weights 1.1 SRG Pump 1.2 60 Hz Weight Pump type [hp (kW)] [in (mm)] [in (mm)] [in (mm)] [in (mm)] [in (mm]) [in (mm)] [in (mm)] [in (mm)] [lb. (kg)] SRG.11.12.524. 1.1 (0.8) SRG.15.12.628. 1.5 (1.1) 33.4 23.7 29.0...

- Page 21 Canada México Grundfos Water Utility Inc. GRUNDFOS Canada GRUNDFOS México 3905 Enterprise Court 2941 Brighton Road Boulevard TLC No. 15 P.O. Box 6620 Oakville, Ontario L6H 6C9 Canada Parque Industrial Stiva Aeropuerto Aurora, IL 60598-0620 Phone: +1-905 829 9533 C.P. 66600 Apodaca, N.L. México...

- Page 22 99135311 0519 ECM: 1248714 www.grundfos.com www.grundfos.us...

Need help?

Do you have a question about the SRG 60 Hz and is the answer not in the manual?

Questions and answers