Summary of Contents for Grundfos SRP Series

- Page 1 GRUNDFOS INSTRUCTIONS 60 Hz, North America Installation and operating instructions...

- Page 3 English (US) Installation and operating instructions............4 Español (MX) Instrucciones de instalación y funcionamiento .

- Page 4 Products which are sold but not manufactured by Grundfos are subject to the warranty provided by the manufacturer of said products and not by Grundfos' warranty. Grundfos will not be liable for damage or wear to products caused by abnormal operating conditions, accident, abuse, misuse, unauthorized alteration or repair, or if the product was not installed in accordance with Grundfos' printed installation and operating instructions.

-

Page 5: Table Of Contents

CONTENTS 1. Symbols used in this document Page Warning Symbols used in this document If these safety instructions are not observed, Product introduction it may result in personal injury. Applications Technical data Warning Identification If these instructions are not observed, it may lead Type key Nameplate to electric shock with consequent risk of serious... -

Page 6: Product Introduction

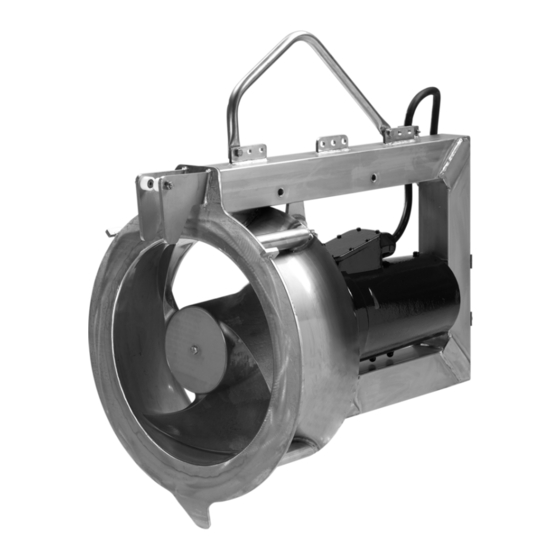

2.1 Applications [-]: First generation A: Second generation Grundfos SRP recirculation pumps are used for the pumping of B: Third generation return sludge in sewage treatment plants and for other pump applications involving a high flow rate and low head. The pumps are designed for continuous operation fully submerged (S1 operation). -

Page 7: Nameplate

Maximum installation depth If the pump or any accessories have been damaged during Service factor transportation, contact your local Grundfos company before The additional nameplate supplied with the pump should be fixed continuing to install the equipment. Do not dismantle a damaged in a visible position at the installation site. -

Page 8: Installation

6. Installation During installation, the pump must only be lifted when using the suspension point. The lifting equipment supplied with the pump as well as the cable used for lifting and lowering the pump into the tank must not be used as universal lifting equipment. -

Page 9: Torque Values

6.2 Torque values 3. SRP.xx.32.xx: Weld the guide claws to the connection flange. See fig. 7. All nuts and screws used for the installation must be made of stainless steel. Use grease (Alu-paste) together with a spring washer or lock nut; otherwise, use Loctite or a similar product for lubrication and locking. - Page 10 14.Mount the lifting cable (pos. 15, fig. 4) on the pump rack using Consider and follow the separate installation and Note Note the shackle. See fig. 9. operating instructions for cranes. 18.Lift the complete pump (pump rack with motor) using the crane and slide it over the guide rail.

-

Page 11: Electrical Connection

7. Electrical connection 7.1 Motor protection The pumps are provided with the following type of motor The electrical connections must be carried out by a qualified elec- protection: trician in accordance with local regulations. Standard SRP pumps incorporate three bimetallic thermal All national and local regulations relating to safety and accident switches (PTO = Protection Thermique á... -

Page 12: Gearbox Protection

If the monitoring function is required, the leak sensor must be connected to a Grundfos relay, type ALR 20. If the gearbox/shaft seal housing is not monitored for the ingress of water, it is Netz Rel. -

Page 13: Wiring Diagrams

7.5 Wiring diagrams 7.7 Protection from electro-chemical corrosion Two different metals or alloys cause electro-chemical corrosion if they are connected by an electrolyte. This applies if more than one pump is installed in the same tank. We recommend the following additional protection: •... -

Page 14: Start-Up

If Grundfos is requested to service the pump, Grundfos must be contacted with details about the pumped liquid, etc. before the pump is returned for service. Otherwise Grundfos can refuse to accept the pump for service. -

Page 15: Service Chart

The motor housing may only be replaced if they get noisy. not required. dismantled by authorized Grundfos personnel. The power cable must be checked twice a year for surface damage, Power cable strain, kinks, etc. If damaged, the cable must be replaced. -

Page 16: Oil Change

9.3 Oil 9.4 Oil change Place the pump in a horizontal position on supports and place a 9.3.1 Oil quality pan underneath to collect the oil. Gear oil designation for SRP pumps according to DIN 51502: ISO VG 68. Warning For unobstructed operation Shell Omala oil is recommended. -

Page 17: Fault Finding

Propeller cannot rotate freely. Clean the propeller and check manually that it can rotate freely. e) Stator windings are faulty. Contact Grundfos. Motor has cut out because of overheating. Wait until the motor has cooled and attempt to restart the pump. -

Page 18: Technical Data

This product or parts of it must be disposed of in an environmentally sound way: 1. Use the public or private waste collection service. 2. If this is not possible, contact the nearest Grundfos company or service workshop. Subject to alterations. - Page 19 Appendix 1. Dimensions and weight Pump Weight Pump type [hp] [lb (kg)] (mm)] (mm)] (mm)] (mm)] (mm)] (mm)] (mm)] (mm)] SRP.11.12.524. 242.5 (110) SRP.15.12.628. 242.5 (110) SRP.19.12.720. 242.5 (110) SRP.26.12.805. 242.5 (110) 33-3/8 23-5/8 22-1/2 2-9/16 17-1/2 8-5/8 9/16 SRP.30.12.883. 242.5 (110) (848) (602)

- Page 20 Canada México GRUNDFOS Pumps Corporation GRUNDFOS Canada Inc. Bombas GRUNDFOS de México S.A. de C.V. 17100 West 118th Terrace 2941 Brighton Road Boulevard TLC No. 15 Olathe, Kansas 66061 Oakville, Ontario Parque Industrial Stiva Phone: +1-913-227-3400 L6H 6C9 Aeropuerto Telefax: +1-913-227-3500 Phone: +1-905 829 9533 Apodaca, N.L.C.P.

- Page 21 Thinking ahead makes it possible Innovation is the essence 97761676 0611 The name Grundfos, the Grundfos logo, and the payoff Be–Think–Innovate are registrated trademarks ECM: 1065734 owned by Grundfos Management A/S or Grundfos A/S, Denmark. All rights reserved worldwide. www.grundfos.com...

Need help?

Do you have a question about the SRP Series and is the answer not in the manual?

Questions and answers